设计简介

摘要

回转窑是建材、冶金、化工等行业生产流程中的核心设备,一次停窑将引起整个生产流程的中断,造成重大经济损失。托轮作为回转窑的支承装置保证其安全、高效、健康地运行很重要。

本文概述了回转窑的应用发展和基本结构。计算了回转窑的各档支撑力并对托轮进行受力分析。针对回转窑轴线调整使用的千斤顶,重点设计了液压回路并且对液压缸进行设计计算。最后对托轮表面维护中采用的动态车削的可行性进行了分析。

关键词 回转窑;托轮;维护;液压千斤顶;动态车削

Abstract

Rotary kiln is a key equipment in the metallurgy, chemistry and architectural material .Once stop will bring interruption to the whole Production line, and make a great Productivity losses. so safety,efficiency and Healthiness operation is the key Point to advance benefit of the enterprise.

This paper outlines the development ,application and basic structure of the rotary kiln. Rotary kiln's various grade of support strength calculation and the stress analysis to the under roller have been carried out in the paper. The paper also shows a hydraulic circuit design of the jack ,which is in the use of Kiln axis adjustment ,and the calculation to hydraulic cylinders. The feasibility analysis of dynamic turning used in the maintenance of supporting wheel surface is at the end of this paper.

Keywords Rotary kiln Jockey pulley Maintenance Hydraulic jack Turning dynamic

回转窑是建材、冶金、化工等行业生产流程中的核心设备,一次停窑将引起整个生产流程的中断,造成重大经济损失。托轮作为回转窑的支承装置保证其安全、高效、健康地运行很重要。

本文概述了回转窑的应用发展和基本结构。计算了回转窑的各档支撑力并对托轮进行受力分析。针对回转窑轴线调整使用的千斤顶,重点设计了液压回路并且对液压缸进行设计计算。最后对托轮表面维护中采用的动态车削的可行性进行了分析。

关键词 回转窑;托轮;维护;液压千斤顶;动态车削

Abstract

Rotary kiln is a key equipment in the metallurgy, chemistry and architectural material .Once stop will bring interruption to the whole Production line, and make a great Productivity losses. so safety,efficiency and Healthiness operation is the key Point to advance benefit of the enterprise.

This paper outlines the development ,application and basic structure of the rotary kiln. Rotary kiln's various grade of support strength calculation and the stress analysis to the under roller have been carried out in the paper. The paper also shows a hydraulic circuit design of the jack ,which is in the use of Kiln axis adjustment ,and the calculation to hydraulic cylinders. The feasibility analysis of dynamic turning used in the maintenance of supporting wheel surface is at the end of this paper.

Keywords Rotary kiln Jockey pulley Maintenance Hydraulic jack Turning dynamic

目 录

1绪论 1

1.1回转窑应用与发展概述 1

1.1.1回转窑应用概述 1

1.1.2回转窑发展概述 1

1.2回转窑的基本结构 2

1.3论文主要工作及研究思路 4

2回转窑各档支撑力的计算 6

2.1回转窑筒体总体结构参数的确定 6

2.2 筒体载荷计算及载荷图 7

2.2.1筒体载荷计算 7

2.2.2原始载荷图及简化 8

2.3用三弯矩方程法计算支座反力 10

2.3.1计算的有关概念 10

2.3.2支座反力的计算 11

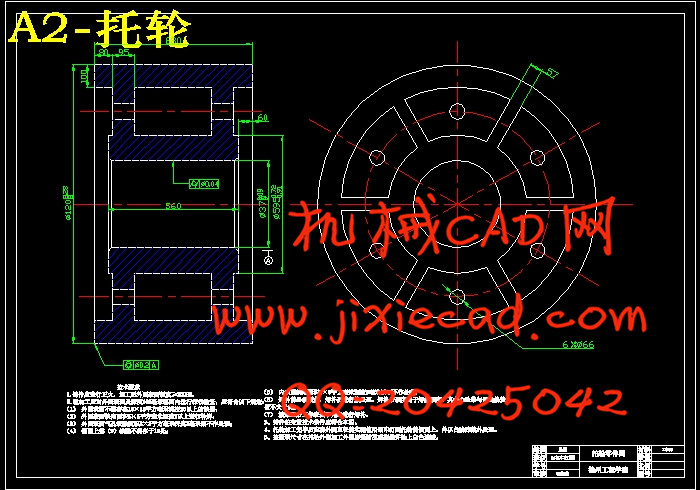

3滚圈的设计与计算 16

3.1滚圈的截面型式 16

3.2滚圈与托轮材料 16

3.3滚圈的接触应力及截面尺寸计算 16

4托轮的受力分析及尺寸计算 20

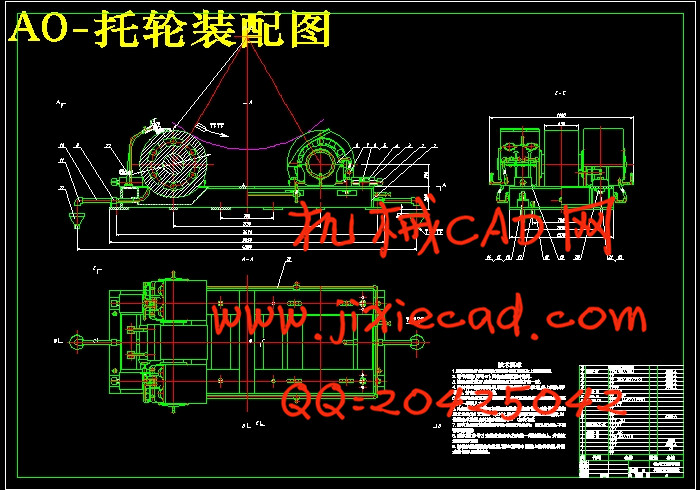

4.1托轮装置的结构及分类 20

4.2托轮的受力分析 20

4.3托轮的基本尺寸计算 21

4.4滑动轴承 22

5回转窑的轴线调整 25

5.1托轮调整对轴线的影响量 25

5.2托轮的调整方法 25

5.3托轮调整的注意事项 26

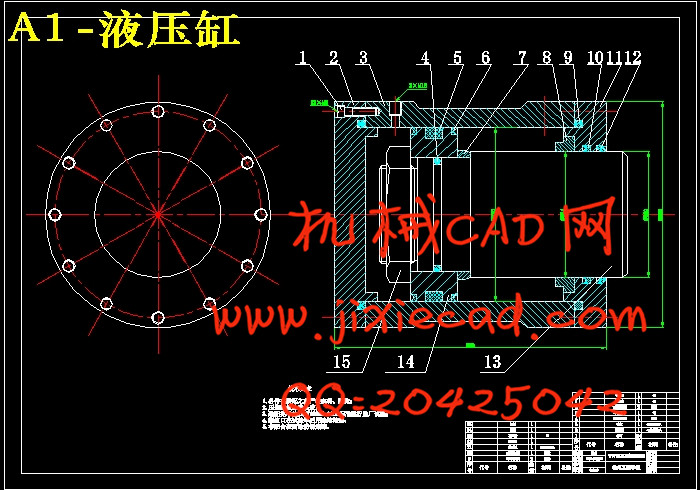

6千斤顶液压系统的设计计算 28

6.1液压系统原理图的拟定 28

6.2液压系统的计算 29

6.2.1液压缸的设计计算 30

6.2.2液压泵及电机的选择 32

6.3液压系统的发热温升 33

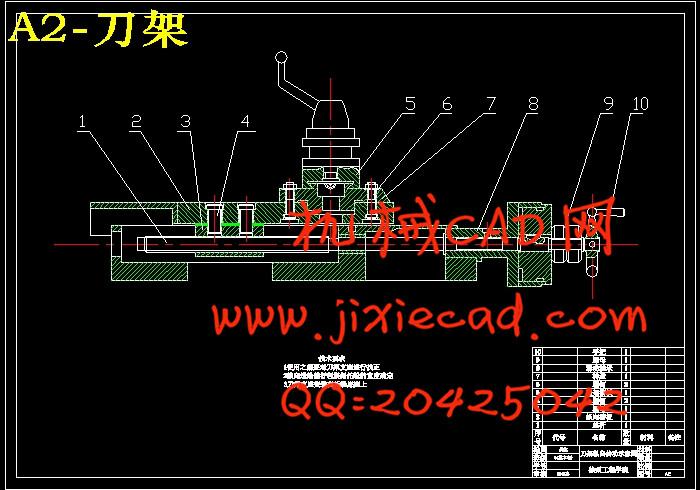

7支承托轮的动态维修 35

7.1托轮的表面缺陷 35

7.2车削的驱动力矩阻力矩计算 35

7.3现场动态车削托轮的特殊性 37

7.4专用机床的设计安装 37

结论 40

致谢 41

参考文献 42