设计简介

近年来,由于机械设备行业,汽车工业等行业的迅速发展,推动了弹簧工业的产品设计制造工艺生产设备以及弹簧的材料等的发展。由于行业的需要,对于弹簧的检测以及分选设备的设计开发,是弹簧工业发展的必然趋势。弹簧分选机是安装在弹簧加工过程中的检测工艺工段线上。对此,本文是针对碟形弹簧分选机的设计,涉及到机械、电气等方面的技术,是一个典型的机电一体化系统设计,主要是碟形弹簧分选机的机构设计。结合目前所掌握的各项技术,旨在开发一套具有较高自动化水平,安全可靠,性价比高的数控自动碟形弹簧分选机。弹簧检测是其生产过程必不可少的工序,而测力是检测的主要内容之一。弹簧力参数直接影响弹簧的性能和工作状态。尤其是高精度弹簧以及需配对或者配套使用的弹簧,要求严格按力参数分选包装。

结合碟形弹簧的特点,本文旨在设计一种自动化数控机构,能够在生产碟形弹簧时,根据其弹性系数的不同,按照不同指标测试弹力,筛选出不同弹性系数的碟形弹簧,并且流入不同的落料箱,以达到碟形弹簧分选的目的。要求设计的试验机能按照试验标准要求进行连续运行,运动动力源采用电动机,其筛选的范围是根据碟形弹簧直径而定为50mm-100mm。

关键词 碟形弹簧 测力 分选 弹性系数 电动机

Abstract

In recent years, the rapid development of machinery industry, automobile industry and other industries, and promote the development of the product design and manufacturing process equipment and industrial spring material such as spring. Due to the need of the industry, for the spring testing and sorting equipment design and development, industrial development is the inevitable trend of spring. Spring sorter is installed in the spring of the detection processing section processes the line. In this regard, the design is a disc spring sorting machine design, which involves mechanical, electrical and other aspects of technology, is a typical mechatronic system design, primarily sorter disc spring mechanism design. Combined with the currently available technology, to develop a set of high level of automation, safe, reliable, cost-effective disc spring CNC automatic sorting machine. Spring testing is an essential step of its production process. One of the main load is detected. The spring force of the spring parameters directly affect the performance and operation. Especially in high-precision springs and spring required matching or supporting the use of force by demanding parameters sorting packaging.

Combining the characteristics of the disc spring, in the production of this paper is to design the disc spring, according to the different modulus of elasticity, elasticity test according to the different indicators screened different modulus of elasticity of the spring disc, and into a different tank falls to coned disc spring reaches the sorting purposes. Experimental design performance requirements in accordance with the design requirements of the standard test for continuous operation, the motive power source is an electric motor which is based on the range of screening the diameter of the disc spring is 50mm-100mm.

Keywords Disc spring force Dorting Dhe elastic coefficient The electric motor

目 录

1 绪论 3

1.1 课题研究的目的及意义 3

1.2 工作原理 3

1.3 国外分选机研究现状 4

1.4 国内分选机研究现状 4

2 方案的选择与设计 6

2.1 本课题的设计任务 6

2.2 设计思想和思路 6

2.3 上料机构的设计 6

2.4 定位方案选择 7

2.5 测力机构的选择 10

2.6 分选机构方案的选择 10

3 总体的机构设计 12

3.1 碟形弹簧分选机总体要求 12

3.1.1 工作环境 12

3.1.2 主要性能要求 12

3.1.3 工件要求 12

3.2 碟形弹簧测力分选机机构组成 12

4 零件的结构设计 14

4.1 托盘设计 14

4.2 轴的设计 15

4.3 键的选择 16

4.3.1 大键的选择 16

4.3.2 小键的选择 17

4.4 齿轮的设计 17

4.4.1 大齿轮的设计 17

4.4.2 小齿轮的设计 18

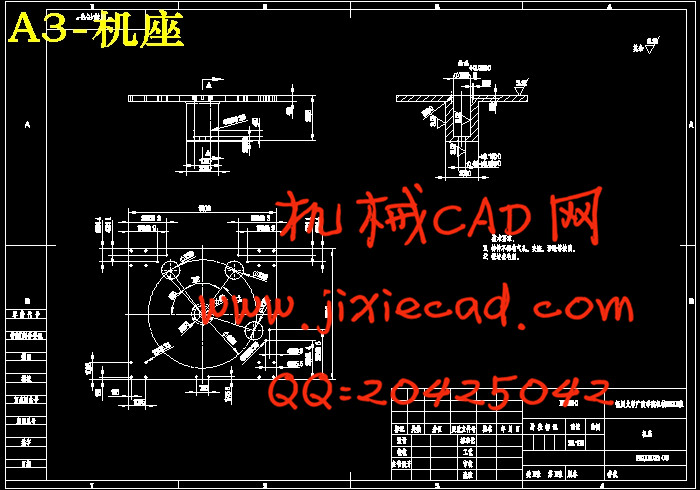

4.5 机座的设计 19

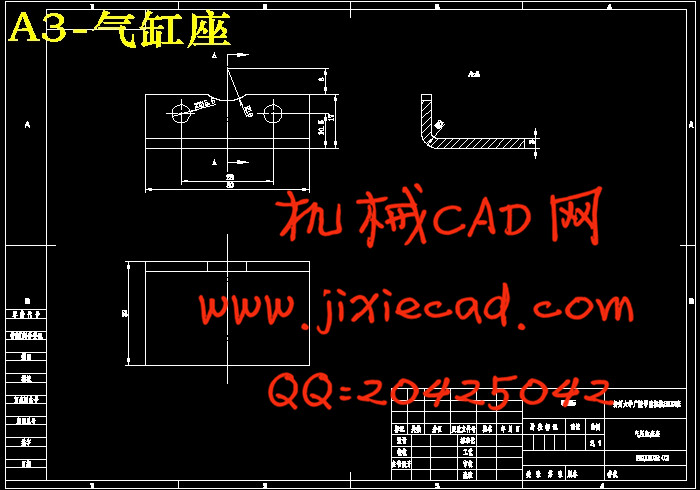

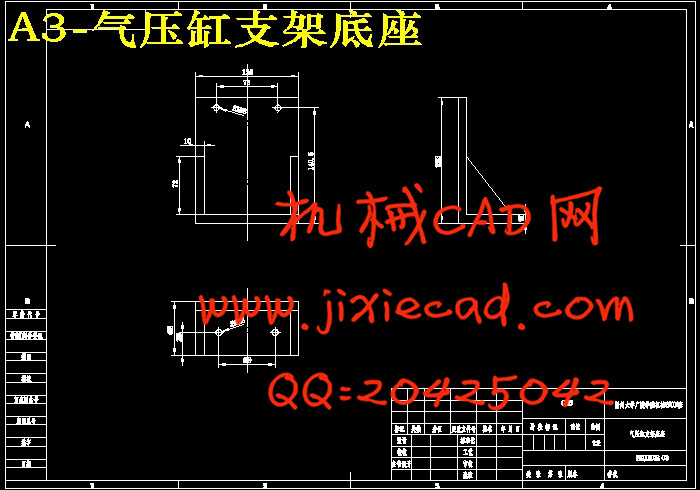

4.6 气压缸的选择 20

4.7 轴承的选择 20

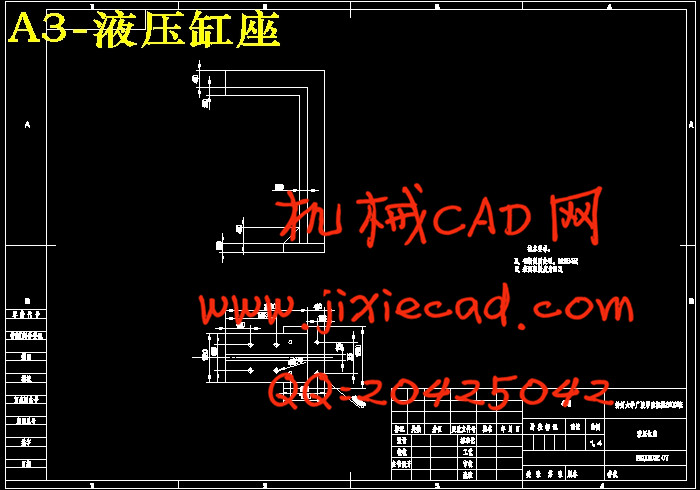

4.8 液压缸的选择 23

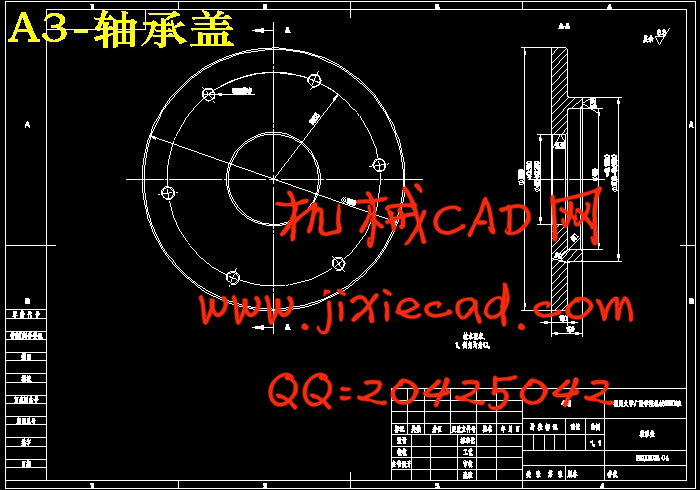

4.9 轴承盖的选择 23

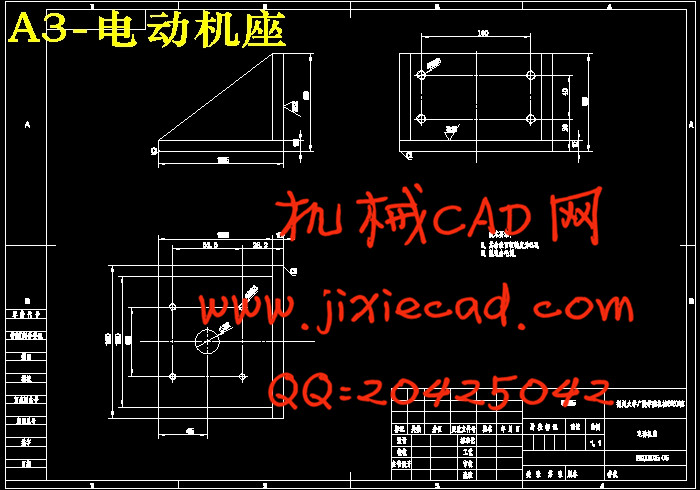

4.10 电动机的选择 24

5 强度校核 26

5.1液压缸的强度校核 26

5.2 托盘的强度校核 29

结 论 34

致 谢 35

参考文献 36

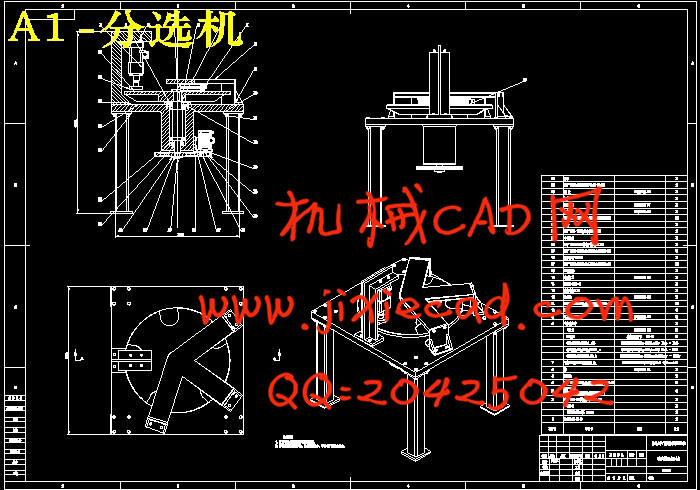

附件:碟形弹簧测力分选机结构设计装配图及零件图 37

结合碟形弹簧的特点,本文旨在设计一种自动化数控机构,能够在生产碟形弹簧时,根据其弹性系数的不同,按照不同指标测试弹力,筛选出不同弹性系数的碟形弹簧,并且流入不同的落料箱,以达到碟形弹簧分选的目的。要求设计的试验机能按照试验标准要求进行连续运行,运动动力源采用电动机,其筛选的范围是根据碟形弹簧直径而定为50mm-100mm。

关键词 碟形弹簧 测力 分选 弹性系数 电动机

Abstract

In recent years, the rapid development of machinery industry, automobile industry and other industries, and promote the development of the product design and manufacturing process equipment and industrial spring material such as spring. Due to the need of the industry, for the spring testing and sorting equipment design and development, industrial development is the inevitable trend of spring. Spring sorter is installed in the spring of the detection processing section processes the line. In this regard, the design is a disc spring sorting machine design, which involves mechanical, electrical and other aspects of technology, is a typical mechatronic system design, primarily sorter disc spring mechanism design. Combined with the currently available technology, to develop a set of high level of automation, safe, reliable, cost-effective disc spring CNC automatic sorting machine. Spring testing is an essential step of its production process. One of the main load is detected. The spring force of the spring parameters directly affect the performance and operation. Especially in high-precision springs and spring required matching or supporting the use of force by demanding parameters sorting packaging.

Combining the characteristics of the disc spring, in the production of this paper is to design the disc spring, according to the different modulus of elasticity, elasticity test according to the different indicators screened different modulus of elasticity of the spring disc, and into a different tank falls to coned disc spring reaches the sorting purposes. Experimental design performance requirements in accordance with the design requirements of the standard test for continuous operation, the motive power source is an electric motor which is based on the range of screening the diameter of the disc spring is 50mm-100mm.

Keywords Disc spring force Dorting Dhe elastic coefficient The electric motor

目 录

1 绪论 3

1.1 课题研究的目的及意义 3

1.2 工作原理 3

1.3 国外分选机研究现状 4

1.4 国内分选机研究现状 4

2 方案的选择与设计 6

2.1 本课题的设计任务 6

2.2 设计思想和思路 6

2.3 上料机构的设计 6

2.4 定位方案选择 7

2.5 测力机构的选择 10

2.6 分选机构方案的选择 10

3 总体的机构设计 12

3.1 碟形弹簧分选机总体要求 12

3.1.1 工作环境 12

3.1.2 主要性能要求 12

3.1.3 工件要求 12

3.2 碟形弹簧测力分选机机构组成 12

4 零件的结构设计 14

4.1 托盘设计 14

4.2 轴的设计 15

4.3 键的选择 16

4.3.1 大键的选择 16

4.3.2 小键的选择 17

4.4 齿轮的设计 17

4.4.1 大齿轮的设计 17

4.4.2 小齿轮的设计 18

4.5 机座的设计 19

4.6 气压缸的选择 20

4.7 轴承的选择 20

4.8 液压缸的选择 23

4.9 轴承盖的选择 23

4.10 电动机的选择 24

5 强度校核 26

5.1液压缸的强度校核 26

5.2 托盘的强度校核 29

结 论 34

致 谢 35

参考文献 36

附件:碟形弹簧测力分选机结构设计装配图及零件图 37