设计简介

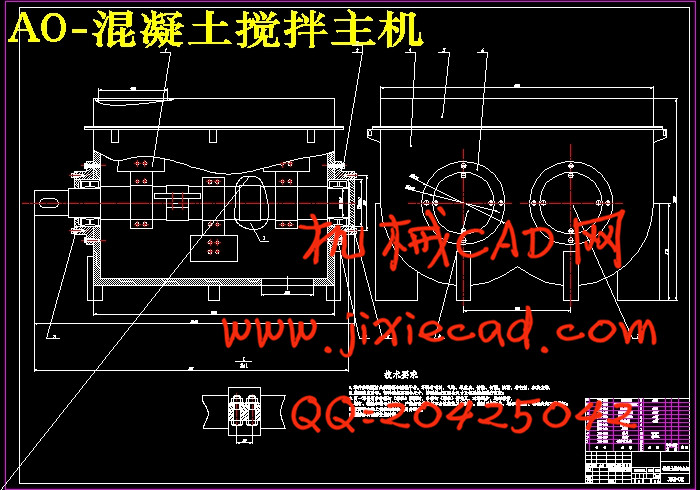

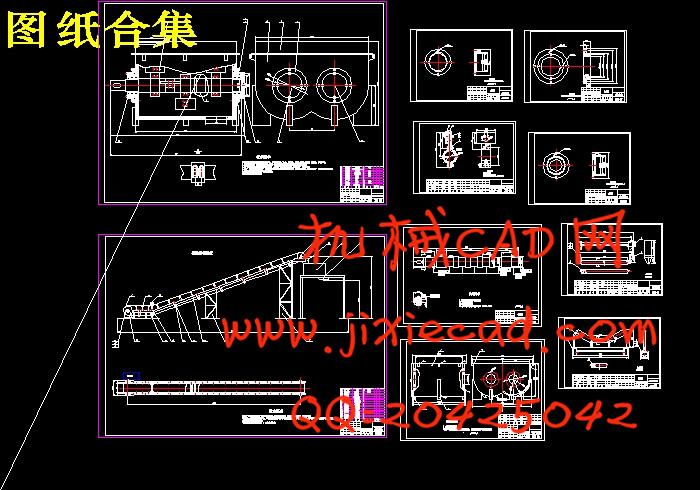

摘 要:混凝土搅拌站主要由称量系统、输送系统、搅拌系统、贮存系统和控制系统组成,本次设计目标是设计出一种双缸双轴式搅拌机和一个相匹配的输送机。通过对生产率的要求来设计输送系统,再通过计算出来的相关数据确定搅拌系统的数据从而进行设计。通过查阅资料,在设计过程中有详细的计算设计,让搅拌站各个系统统一协调。

关键词:混凝土搅拌站;双缸双轴搅拌机;带式输送机

Abstract: Concrete mixing plant consists of weighing system, conveyor system, mixing system, storage system and a control system. The design is to be aimed at creating two-cylinder two axle mixer and matching belt conveyor. The conveyor system design is based on the requirement of productivity, and the mixing system is based on data which is calculated from relevant statistics got from the former steps. By consulting sources, the whole design derives from sophisticated calculation to make sure that systems in the mixing plant are working in coordination.

Key words: Concrete mixing plant; Double-horizontal-shaft concrete mixer; Belt conveyor

目 录

摘要……………………………………………………………………………………1

关键词…………………………………………………………………………………1

1前言………………………………………………………………………………1

1.1发展历史及其国内外发展状况……………………………………………………1

1.2发展趋势及其研究意义……………………………………………………………2

2混凝土搅拌站整体结构分析……………………………………………………3

3混凝土搅拌站输送系统设计…………………………………………………5

3.1方案选择与比较……………………………………………………………………5

3.2带式输送机工作原理及结构组成…………………………………………………5

3.3带式输送机的设计及计算…………………………………………………………5

3.3.1输送能力计算……………………………………………………………………5

3.3.2输送带的选用及其张力的计算…………………………………………………6

3.4输送部分主要部件的选用与计算…………………………………………………9

3.4.1驱动装置及减速器的选取………………………………………………………9

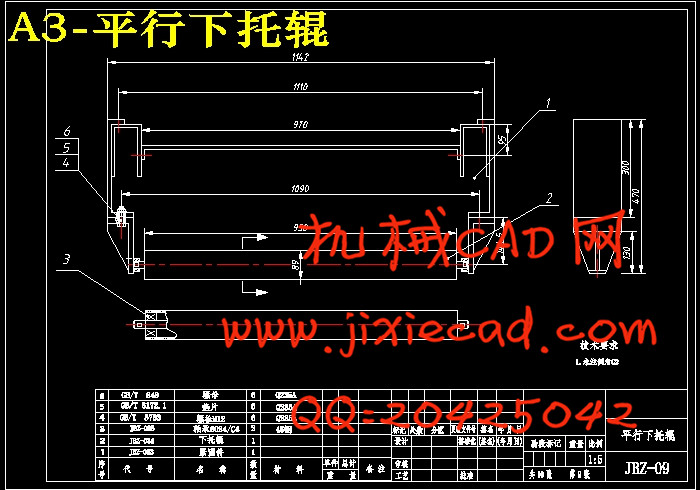

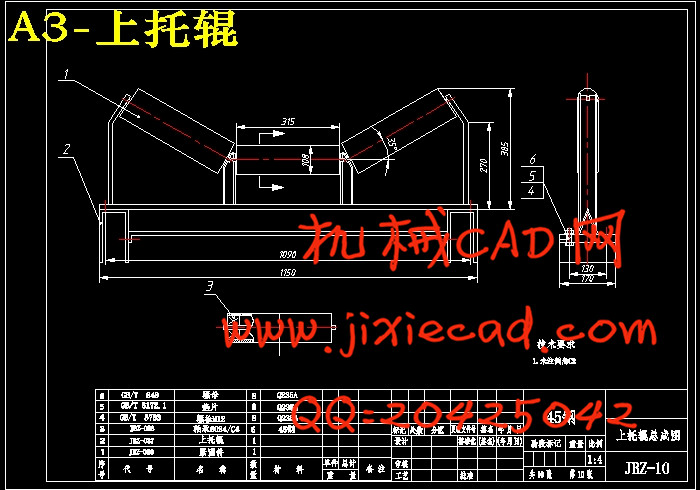

3.4.2托辊选择与计算…………………………………………………………………9

3.4.3滚筒选择与计算……………………………………………………………… 11

3.4.4拉紧装置……………………………………………………………………… 11

3.4.5清扫装置……………………………………………………………………… 12

3.4.6制动装置……………………………………………………………………… 12

4混凝土搅拌站搅拌系统设计……………………………………………………… 12

4.1搅拌机主要技术参数确定……………………………………………………… 13

4.1.1拌缸横截面流量……………………………………………………………… 13

4.1.2搅拌缸的有效容积…………………………………………………………… 13

4.1.3桨叶线速度…………………………………………………………………… 14

4.2搅拌机主要组成结构设计……………………………………………………… 15

4.2.1搅拌叶片几何尺寸计算……………………………………………………… 15

4.2.2拌缸几何尺寸计算…………………………………………………………… 16

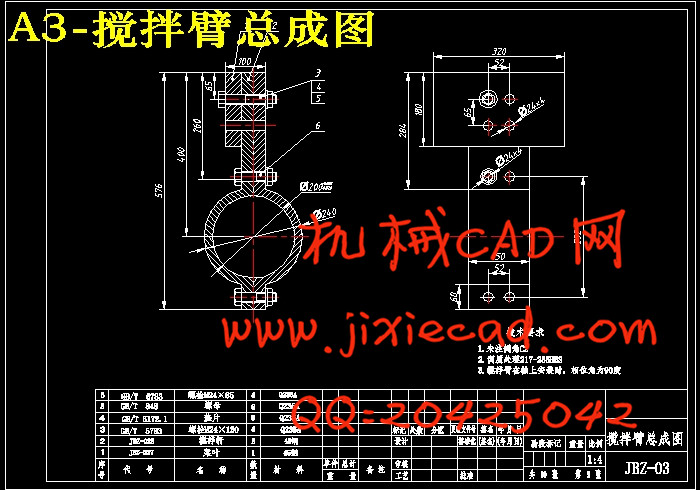

4.2.3搅拌臂在搅拌主轴上的布置与连接………………………………………… 16

4.2.4搅拌臂的设计………………………………………………………………… 16

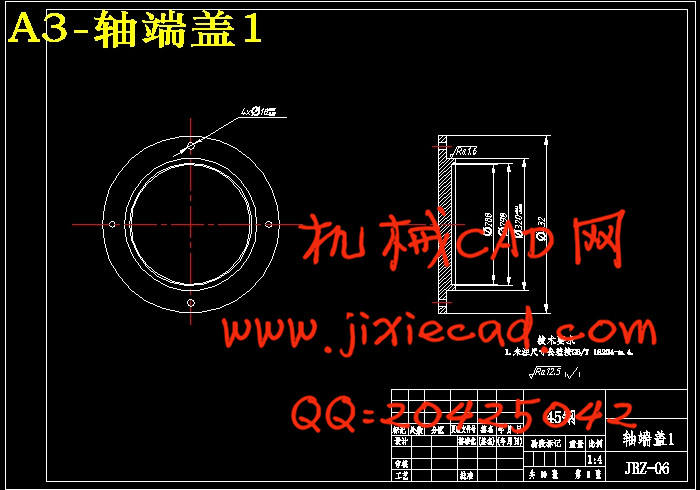

4.2.5搅拌轴的设计………………………………………………………………… 17

4.3搅拌机驱动部分选择…………………………………………………………… 21

4.3.1驱动电机选型………………………………………………………………… 21

4.3.2减速器选型…………………………………………………………………… 21

4.3.3联轴器选择…………………………………………………………………… 21

4.4搅拌系统密封件和润滑的设计与选择………………………………………… 21

5结论………………………………………………………………………………22

参考文献 ………………………………………………………………………22

致谢………………………………………………………………………………23

关键词:混凝土搅拌站;双缸双轴搅拌机;带式输送机

Abstract: Concrete mixing plant consists of weighing system, conveyor system, mixing system, storage system and a control system. The design is to be aimed at creating two-cylinder two axle mixer and matching belt conveyor. The conveyor system design is based on the requirement of productivity, and the mixing system is based on data which is calculated from relevant statistics got from the former steps. By consulting sources, the whole design derives from sophisticated calculation to make sure that systems in the mixing plant are working in coordination.

Key words: Concrete mixing plant; Double-horizontal-shaft concrete mixer; Belt conveyor

目 录

摘要……………………………………………………………………………………1

关键词…………………………………………………………………………………1

1前言………………………………………………………………………………1

1.1发展历史及其国内外发展状况……………………………………………………1

1.2发展趋势及其研究意义……………………………………………………………2

2混凝土搅拌站整体结构分析……………………………………………………3

3混凝土搅拌站输送系统设计…………………………………………………5

3.1方案选择与比较……………………………………………………………………5

3.2带式输送机工作原理及结构组成…………………………………………………5

3.3带式输送机的设计及计算…………………………………………………………5

3.3.1输送能力计算……………………………………………………………………5

3.3.2输送带的选用及其张力的计算…………………………………………………6

3.4输送部分主要部件的选用与计算…………………………………………………9

3.4.1驱动装置及减速器的选取………………………………………………………9

3.4.2托辊选择与计算…………………………………………………………………9

3.4.3滚筒选择与计算……………………………………………………………… 11

3.4.4拉紧装置……………………………………………………………………… 11

3.4.5清扫装置……………………………………………………………………… 12

3.4.6制动装置……………………………………………………………………… 12

4混凝土搅拌站搅拌系统设计……………………………………………………… 12

4.1搅拌机主要技术参数确定……………………………………………………… 13

4.1.1拌缸横截面流量……………………………………………………………… 13

4.1.2搅拌缸的有效容积…………………………………………………………… 13

4.1.3桨叶线速度…………………………………………………………………… 14

4.2搅拌机主要组成结构设计……………………………………………………… 15

4.2.1搅拌叶片几何尺寸计算……………………………………………………… 15

4.2.2拌缸几何尺寸计算…………………………………………………………… 16

4.2.3搅拌臂在搅拌主轴上的布置与连接………………………………………… 16

4.2.4搅拌臂的设计………………………………………………………………… 16

4.2.5搅拌轴的设计………………………………………………………………… 17

4.3搅拌机驱动部分选择…………………………………………………………… 21

4.3.1驱动电机选型………………………………………………………………… 21

4.3.2减速器选型…………………………………………………………………… 21

4.3.3联轴器选择…………………………………………………………………… 21

4.4搅拌系统密封件和润滑的设计与选择………………………………………… 21

5结论………………………………………………………………………………22

参考文献 ………………………………………………………………………22

致谢………………………………………………………………………………23