设计简介

肠衣自动压缩设备结构设计

摘 要

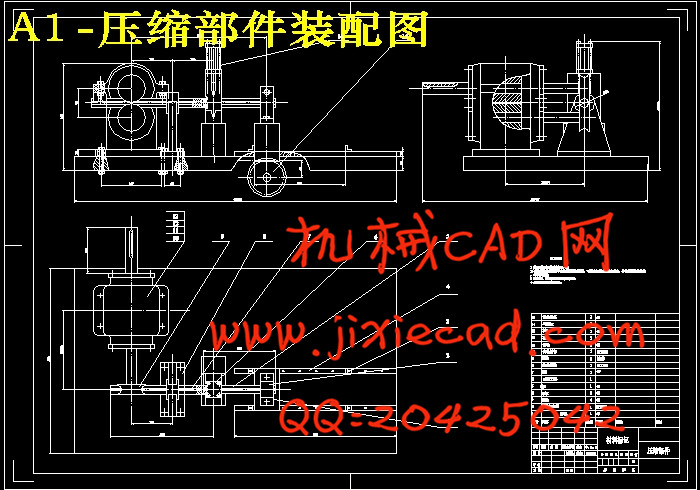

肠衣自动压缩设备是将圆筒状PVDC膜压缩,代替目前火腿肠片状外包装膜,简化生产工艺,降低工人的劳动强度,提高生产效率,增强市场竞争力。本文侧重其传动系统的设计,理论上能够实现肠衣的自动压缩,现实中还需进行必要的改进。

首先,本文介绍了PVDC膜在肉制品包装产业的发展及应用。由此映射出肠衣自动压缩设备的前景。

其次,本文将介绍肠衣自动压缩设备的电机选择,为了提高生产效率,选择的电机能够实现同时带动四台压缩设备。

再次,本文将重点设计和计算传动设备,通过带轮机构,齿轮机构,链轮机构以实现压缩设备所需要的进给速度。

最后,本文简要叙述了压缩系统部件的尺寸确定,及其理想状态的运动状态。最后的控制系统由于时间关系,已经简化。

关键词:PVDC膜,压缩设备,传动系统,控制系统

摘 要

肠衣自动压缩设备是将圆筒状PVDC膜压缩,代替目前火腿肠片状外包装膜,简化生产工艺,降低工人的劳动强度,提高生产效率,增强市场竞争力。本文侧重其传动系统的设计,理论上能够实现肠衣的自动压缩,现实中还需进行必要的改进。

首先,本文介绍了PVDC膜在肉制品包装产业的发展及应用。由此映射出肠衣自动压缩设备的前景。

其次,本文将介绍肠衣自动压缩设备的电机选择,为了提高生产效率,选择的电机能够实现同时带动四台压缩设备。

再次,本文将重点设计和计算传动设备,通过带轮机构,齿轮机构,链轮机构以实现压缩设备所需要的进给速度。

最后,本文简要叙述了压缩系统部件的尺寸确定,及其理想状态的运动状态。最后的控制系统由于时间关系,已经简化。

关键词:PVDC膜,压缩设备,传动系统,控制系统

Casing automatic compression equipment structure design

Author :Tian Chunwei

Tutor : Li Ansheng

Abstract

Casing automatic compression device is cylindrical PVDC film compression, instead of now the current packaging film ham sheet, simplifying the production process, reduce labor intensity, improve production efficiency and enhance market competitiveness.This article focuses on the design of its transmission sy

Author :Tian Chunwei

Tutor : Li Ansheng

Abstract

Casing automatic compression device is cylindrical PVDC film compression, instead of now the current packaging film ham sheet, simplifying the production process, reduce labor intensity, improve production efficiency and enhance market competitiveness.This article focuses on the design of its transmission sy

stem, in theory, enables the automatic compression casings, in reality, need to make the necessary improvements.

First, the article describes the PVDC film in the meat packing industry and application. Thus mapping out the prospect of casing automatic compression equipment.

Secondly, we will introduce the motor casing automatic compression equipment selection, in order to improve production efficiency, choice of motor to drive four simultaneous compression equipment.

Again, this article will focus on good design and calculation of transmission equipment, through the pulley body, gear, sprocket body in order to achieve compression equipment required feed rate.

Finally, a brief description of the size of compression system components to determine its ideal state of motion. Finally, the control system of time, has been simplified.

Key words: PVDC film, Compression equipment, Transmission, Control System

目 录

1 绪论.....................................................................................................................................1

2 机械系统方案的简述.........................................................................................................2

2.1 运动方案选择............................................................................................................2

2.2 电动机类型和结构形式............................................................................................3

2.3 选择电动机容量........................................................................................................3

2.4 电动机的外形............................................................................................................4

2.5 总传动比的确定及各级传动比的分配....................................................................5

2.5.1 理论总传动比

2.5.2 各级传动比的分配.......................................................................................5

2.6 各轴转速,转矩与输入功率....................................................................................6

2.6.1 各轴理论转速...............................................................................................6

2.6.2 各轴的输入功率...........................................................................................6

2.6.3 各轴的理论转矩...........................................................................................6

2.6.4 各轴运动和动力参数汇总表.......................................................................7

3 传动设计.............................................................................................................................8

3.1 V带传动设计………....................………………………………………………....8

3.1.1 原始数据.......................................................................................................8

3.1.2 设计计算.......................................................................................................8

3.1.3 带传动主要参数汇总表..............................................................................12

3.1.4 带轮材料及结构..........................................................................................12

3.2 链轮传动设计...........................................................................................................14

3.2.1 原始数据.......................................................................................................14

3.2.2 选择链轮齿数...............................................................................................14

3.2.3 确定计算功率...............................................................................................14

3.2.4 选择链条型号和节距...................................................................................15

3.2.5 计算链条型号和中心距...............................................................................16

3.2.6 计算链速

3.2.7 计算压轴力...................................................................................................17

3.2.8 链轮结构设计与计算...................................................................................18

3.2.9 链轮材料.......................................................................................................18

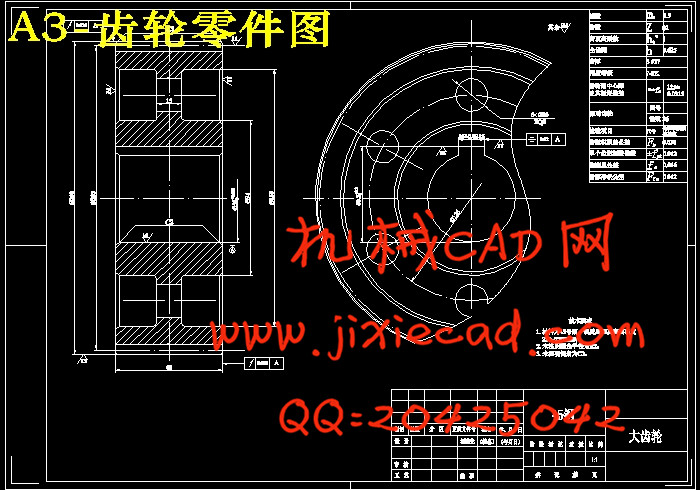

3.3 齿轮传动设计...........................................................................................................19

3.3.1 原始数据......................................................................................................19

3.3.2 选定齿轮类型、精度等级、材料及齿数..................................................20

3.3.3 按齿面接触强度设计..................................................................................21

3.3.4 按齿根弯曲强度设计..................................................................................26

3.3.5 几何尺寸计算..............................................................................................29

3.3.6 齿轮结构......................................................................................................30

3.4 减速器箱体及其附件...............................................................................................30

3.4.1 箱体结构形式及材料..................................................................................30

3.4.2 箱体主要结构尺寸表..................................................................................31

3.5 轴的设计...................................................................................................................31

3.5.1 按扭转强度条件计算.................................................................................31

3.5.2 初步确定轴的最小直径.............................................................................32

3.5.3 确定轴的尺寸.............................................................................................32

4 压缩滚轮部件的设计........................................................................................................36

4.1 压缩滚轮部件总体设计.........................................................................................36

4.2 滚轮结构设计及尺寸计算.....................................................................................37

4.3 压缩轴的设计.........................................................................................................38

4.4 轴支撑座.................................................................................................................38

4.5 轴Ⅱ固定支座.........................................................................................................39

4.6 剪切刀具设计.........................................................................................................40

4.7 直线滚动导轨设计.................................................................................................41

结论..........................................................................................................................................42

致谢..........................................................................................................................................43参考文献................................................................................................................