设计简介

火腿肠肠衣自动压缩设备总体设计

摘 要

本次毕业设计主要是针对目前肉类食品加工包装生产线进行技术改进,提高生产线的自动化,降低工人的劳动强度,降低厂家成本,为厂商在食品领域的价格战中争取优势,提高产品的市场竞争力。众所公认,在商业竞争中,物美与价廉始终必须兼顾。若能切实做到这一点,就不难占领市场,立于不败之地。出路之一在于切实实现合理包装与简化包装的辩证统一。根据国内外工作者在食品包装类机械设备领域的研究成果,借鉴他们的成功经验,运用于设计之中。目前国内大多采用片状PVC肠衣,生产线需要多名工人辅助操作。生产成本较高。而直筒状PVC肠衣能够进一步实现自动化,提高生产效率。以下就是在设计过程中参考到的文献,这些文献给与本文很大的参考价值,本文主要查阅有关机械设计和包装设备的文献期刊。

关键词:包装机械 传动装置 食品加工机械

Abstract

The graduation project mainly is for technology to improve the current meat food processing packaging production line, improve the production line automation to reduce labor intensity, reduce factory costs for manufacturers in the food price war, fighting for advantage, improve product market competitionforce. It is recognized that in the commercial competition, must always take into account the poor quality and low cost. If we can effectively do this, it is not difficult to capture the market and become invincible. One way is the dialectical unity of the practical realization of a reasonable packaging and simplified packaging. According to the research of domestic and foreign workers in the field of food packaging machinery and equipment, learn from their successful experiences, and applied to the design. At present, most of the sheet PVC casings, production line requires a number of workers assisted operating. Higher production costs. Straight shape of the PVC casings to further automate and improve production efficiency.The following is the reference to the literature in the design process, these documents give a great reference value of this paper In this paper, access to literature journals on mechanical design and packaging equipment.

Key words:Packaging Machinery,Gearing,Food processing machinery

目 录

1 绪论.....................................................................................................................................1

2 机械系统方案的简述.........................................................................................................2

2.1 运动方案选择............................................................................................................2

2.2 电动机类型和结构形式............................................................................................3

2.3 选择电动机容量........................................................................................................4

2.4 电动机的外形............................................................................................................4

2.5 总传动比的确定及各级传动比的分配....................................................................5

2.5.1 理论总传动比 ...........................................................................................5

...........................................................................................5

2.5.2 各级传动比的分配.......................................................................................5

2.6 各轴转速,转矩与输入功率....................................................................................6

2.6.1 各轴理论转速...............................................................................................6

2.6.2 各轴的输入功率...........................................................................................6

2.6.3 各轴的理论转矩...........................................................................................6

2.6.4 各轴运动和动力参数汇总表.......................................................................7

3 传动设计.............................................................................................................................7

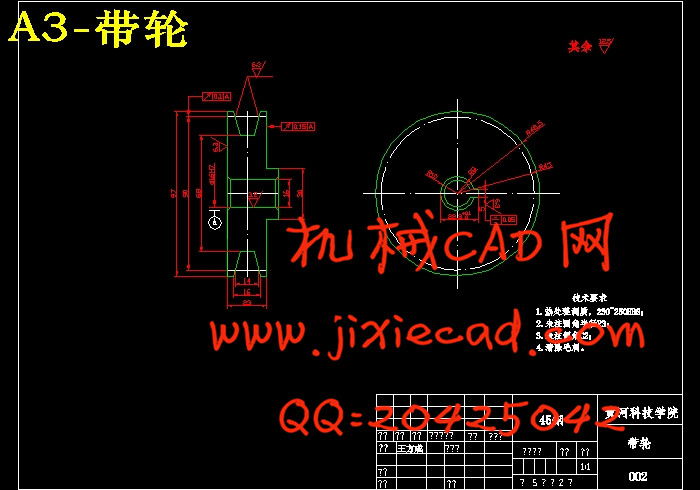

3.1 V带传动设计………....................………………………………………………....7

3.1.1 原始资料.......................................................................................................7

3.1.2 设计计算.......................................................................................................7

3.1.3 带传动主要参数汇总表..............................................................................12

3.1.4 带轮材料及结构..........................................................................................12

3.2 链轮传动设计...........................................................................................................13

3.2.1 原始资料.......................................................................................................13

3.2.2 选择链轮齿数...............................................................................................13

3.2.3 确定计算功率...............................................................................................13

3.2.4 选择链条型号和节距...................................................................................14

3.2.5 计算链条型号和中心距...............................................................................15

3.2.6 计算链速 ,确定润滑方式........................................................................16

,确定润滑方式........................................................................16

3.2.7 计算压轴力...................................................................................................17

3.2.8 链轮结构设计与计算...................................................................................17

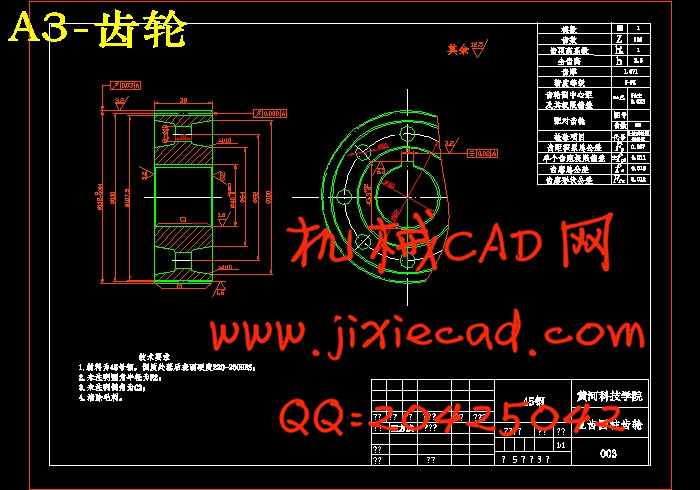

3.3 齿轮传动设计...........................................................................................................18

3.3.1 原始资料......................................................................................................18

3.3.2 选定齿轮类型、精度等级、材料及齿数..................................................18

3.3.3 按齿面接触强度设计..................................................................................20

3.3.4 按齿根弯曲强度设计..................................................................................25

3.3.5 几何尺寸计算..............................................................................................28

3.3.6 齿轮结构......................................................................................................30

3.4 减速器箱体及其附件...............................................................................................29

3.4.1 箱体结构形式及材料..................................................................................29

3.4.2 箱体主要结构尺寸表..................................................................................30

3.5 高速轴的设计...........................................................................................................30

3.5.1 按扭转强度条件计算.................................................................................30

3.5.2 设计轴的直径及绘制草图……………………………………………….31

3.5.3 键连接…………………………………………………………………….33

3.5.4 轴的受力分析…………………………………………………………….33

3.5.5 校核轴的强度…………………………………………………………….34

3.5.6 校核键连接的强度……………………………………………………….35

3.5.7 校核轴承寿命…………………………………………………………….35

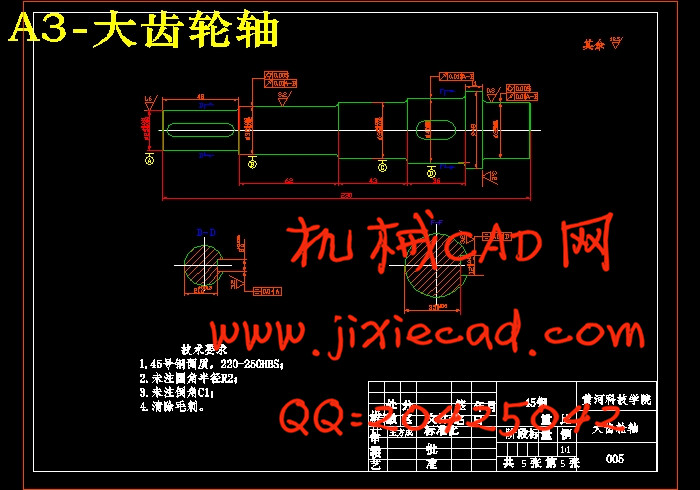

3.6 低速轴的设计…………………………………………………………………….36

3.6.1 初步确定轴的最小直径…………………………………………………36

3.6.2 设计轴的直径及绘制草图………………………………………………36

3.6.3 键连接…………………………………………………………………….38

3.6.4 轴的受力分析…………………………………………………………….38

3.6.5 校核轴的强度…………………………………………………………….39

3.6.6 校核键连接的强度………………………………………………………40

3.6.7 校核轴的寿命…………………………………………………………….40

4 压缩滚轮部件的设计........................................................................................................42

4.1 压缩滚轮部件总体设计.........................................................................................43

4.2 滚轮结构设计及尺寸计算.....................................................................................43

4.3 压缩轴的设计.........................................................................................................44

4.4 轴支撑座.................................................................................................................44

4.5 轴Ⅱ固定支座.........................................................................................................45

4.6 剪切刀具设计.........................................................................................................46

4.7 直线滚动导轨设计.................................................................................................47

5 打码机..................................................................................................................... ....... ..48

5.1打码机的选择...................................................................................................... .... . 48

6.物料放置设计....................................................................................................................49

结论..........................................................................................................................................50

致谢..........................................................................................................................................51

参考文献..................................................................................................................................52

摘 要

本次毕业设计主要是针对目前肉类食品加工包装生产线进行技术改进,提高生产线的自动化,降低工人的劳动强度,降低厂家成本,为厂商在食品领域的价格战中争取优势,提高产品的市场竞争力。众所公认,在商业竞争中,物美与价廉始终必须兼顾。若能切实做到这一点,就不难占领市场,立于不败之地。出路之一在于切实实现合理包装与简化包装的辩证统一。根据国内外工作者在食品包装类机械设备领域的研究成果,借鉴他们的成功经验,运用于设计之中。目前国内大多采用片状PVC肠衣,生产线需要多名工人辅助操作。生产成本较高。而直筒状PVC肠衣能够进一步实现自动化,提高生产效率。以下就是在设计过程中参考到的文献,这些文献给与本文很大的参考价值,本文主要查阅有关机械设计和包装设备的文献期刊。

关键词:包装机械 传动装置 食品加工机械

Abstract

The graduation project mainly is for technology to improve the current meat food processing packaging production line, improve the production line automation to reduce labor intensity, reduce factory costs for manufacturers in the food price war, fighting for advantage, improve product market competitionforce. It is recognized that in the commercial competition, must always take into account the poor quality and low cost. If we can effectively do this, it is not difficult to capture the market and become invincible. One way is the dialectical unity of the practical realization of a reasonable packaging and simplified packaging. According to the research of domestic and foreign workers in the field of food packaging machinery and equipment, learn from their successful experiences, and applied to the design. At present, most of the sheet PVC casings, production line requires a number of workers assisted operating. Higher production costs. Straight shape of the PVC casings to further automate and improve production efficiency.The following is the reference to the literature in the design process, these documents give a great reference value of this paper In this paper, access to literature journals on mechanical design and packaging equipment.

Key words:Packaging Machinery,Gearing,Food processing machinery

目 录

1 绪论.....................................................................................................................................1

2 机械系统方案的简述.........................................................................................................2

2.1 运动方案选择............................................................................................................2

2.2 电动机类型和结构形式............................................................................................3

2.3 选择电动机容量........................................................................................................4

2.4 电动机的外形............................................................................................................4

2.5 总传动比的确定及各级传动比的分配....................................................................5

2.5.1 理论总传动比

2.5.2 各级传动比的分配.......................................................................................5

2.6 各轴转速,转矩与输入功率....................................................................................6

2.6.1 各轴理论转速...............................................................................................6

2.6.2 各轴的输入功率...........................................................................................6

2.6.3 各轴的理论转矩...........................................................................................6

2.6.4 各轴运动和动力参数汇总表.......................................................................7

3 传动设计.............................................................................................................................7

3.1 V带传动设计………....................………………………………………………....7

3.1.1 原始资料.......................................................................................................7

3.1.2 设计计算.......................................................................................................7

3.1.3 带传动主要参数汇总表..............................................................................12

3.1.4 带轮材料及结构..........................................................................................12

3.2 链轮传动设计...........................................................................................................13

3.2.1 原始资料.......................................................................................................13

3.2.2 选择链轮齿数...............................................................................................13

3.2.3 确定计算功率...............................................................................................13

3.2.4 选择链条型号和节距...................................................................................14

3.2.5 计算链条型号和中心距...............................................................................15

3.2.6 计算链速

3.2.7 计算压轴力...................................................................................................17

3.2.8 链轮结构设计与计算...................................................................................17

3.3 齿轮传动设计...........................................................................................................18

3.3.1 原始资料......................................................................................................18

3.3.2 选定齿轮类型、精度等级、材料及齿数..................................................18

3.3.3 按齿面接触强度设计..................................................................................20

3.3.4 按齿根弯曲强度设计..................................................................................25

3.3.5 几何尺寸计算..............................................................................................28

3.3.6 齿轮结构......................................................................................................30

3.4 减速器箱体及其附件...............................................................................................29

3.4.1 箱体结构形式及材料..................................................................................29

3.4.2 箱体主要结构尺寸表..................................................................................30

3.5 高速轴的设计...........................................................................................................30

3.5.1 按扭转强度条件计算.................................................................................30

3.5.2 设计轴的直径及绘制草图……………………………………………….31

3.5.3 键连接…………………………………………………………………….33

3.5.4 轴的受力分析…………………………………………………………….33

3.5.5 校核轴的强度…………………………………………………………….34

3.5.6 校核键连接的强度……………………………………………………….35

3.5.7 校核轴承寿命…………………………………………………………….35

3.6 低速轴的设计…………………………………………………………………….36

3.6.1 初步确定轴的最小直径…………………………………………………36

3.6.2 设计轴的直径及绘制草图………………………………………………36

3.6.3 键连接…………………………………………………………………….38

3.6.4 轴的受力分析…………………………………………………………….38

3.6.5 校核轴的强度…………………………………………………………….39

3.6.6 校核键连接的强度………………………………………………………40

3.6.7 校核轴的寿命…………………………………………………………….40

4 压缩滚轮部件的设计........................................................................................................42

4.1 压缩滚轮部件总体设计.........................................................................................43

4.2 滚轮结构设计及尺寸计算.....................................................................................43

4.3 压缩轴的设计.........................................................................................................44

4.4 轴支撑座.................................................................................................................44

4.5 轴Ⅱ固定支座.........................................................................................................45

4.6 剪切刀具设计.........................................................................................................46

4.7 直线滚动导轨设计.................................................................................................47

5 打码机..................................................................................................................... ....... ..48

5.1打码机的选择...................................................................................................... .... . 48

6.物料放置设计....................................................................................................................49

结论..........................................................................................................................................50

致谢..........................................................................................................................................51

参考文献..................................................................................................................................52