设计简介

摘要

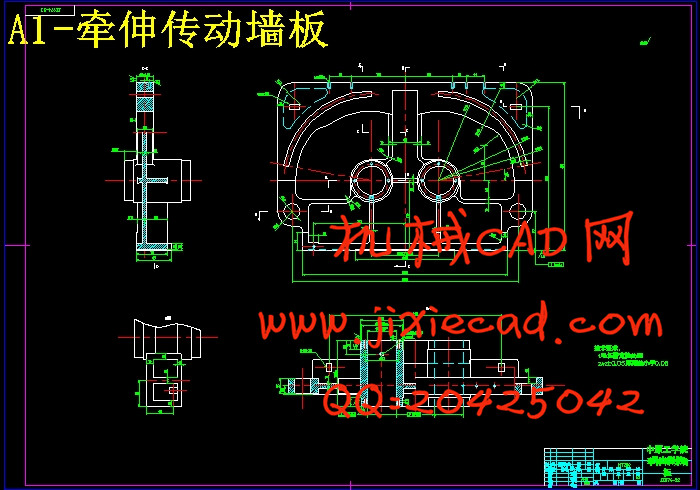

牵伸传动装置是细纱机的一个重要机构装置,牵伸传动机构主要由牵伸传动墙板及其上摇臂、轴和齿轮等构成。牵伸传动墙板是整个牵伸传动轮系的主要支撑体,牵伸传动轴装在头墙板和牵伸传动墙板上,两墙板的加工面互相平行。牵伸传动墙板的结构较复杂,尺寸大,加工困难,课题针对这一问题,为牵伸传动墙板设计了合理的加工工艺规程及相应工序的工装设备,使该零件的加工工作简单化,提高了工人的劳动效率,降低了生产成本。作为工装设计的主要任务之一,夹具设计在零件的工装设计中占有相当重要的地位,本课题主要是分析牵伸传动墙板的工艺,制定了合理的加工工艺路线,确定各个工步机加工时的切削用量,估算出基本切削时间,并根据加工工艺选择恰当的定位基准和夹紧方式,针对几个加工相对困难的工序设计了专用夹具。关键词:牵伸传动墙板,工艺,工装,夹具

Abstract

Drafting transmission device is an important institution spinning device, drafting transmission mechanism mainly by drafting transmission wallboard and rocker, axis and the gear, etc. Drafting transmission wallboard is whole drafting transmission gear train's main support body, draft in the head wallboard and shaft outfit, drafting transmission wallboard wall face each other two parallel processing.The structure of drafting transmission wallboard is relatively complex, size, processing difficulties, subject to solve this problem, designed for drafting transmission wallboard rational processing procedure and the corresponding process of tooling equipment, make this parts processing work simplification, raise workers' labor efficiency, reduce the production cost.As one of the main tasks of equipment design, clamp design in parts of the tooling design occupies an important position, this topic is mainly analysis the process of drafting transmission wallboard, formulate the reasonable processing technology route, determine various work when cutting dosages of step machining, estimate the basic cutting time, and according to the processing technology of the locating datum and choosing appropriate clamping way, according to several processing relatively difficult process design a special jig.

Key words: Drafting transmission wallboard process tooling equipmnent fixture

目录

前言 1

1机床夹具概述 2

1.1夹具的现状及生产对其提出的新要求 2

1.2现代夹具的发展方向 2

1.3机床夹具及其功用 3

1.4机床夹具在机械加工中的作用 4

1.5机床夹具的组成和分类 5

1.6机床夹具的设计特点 7

1.7机床夹具的设计要求 8

2零件的分析 9

2.1零件的作用 9

2.2零件的工艺分析 9

3工艺规程设计 11

3.1确定毛坯的制造形式 11

3.2基准的选择 11

3.3制定工艺路线 11

3.4机械加工余量、工序尺寸及毛坯尺寸的确定 12

3.5确定切削用量及基本工时 12

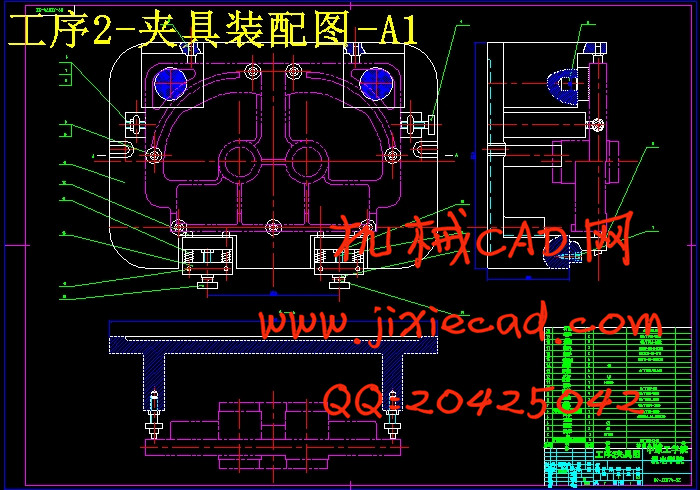

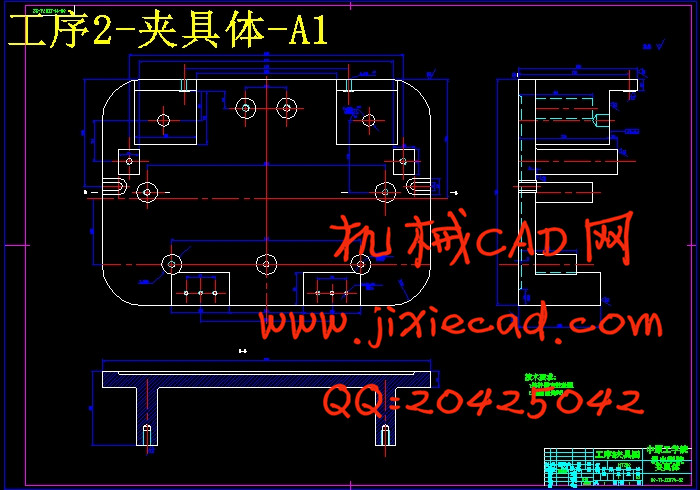

4夹具设计 27

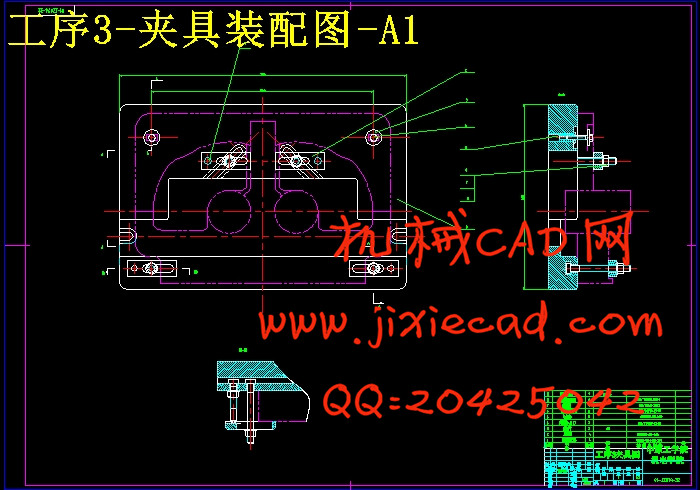

4.1问题的提出 27

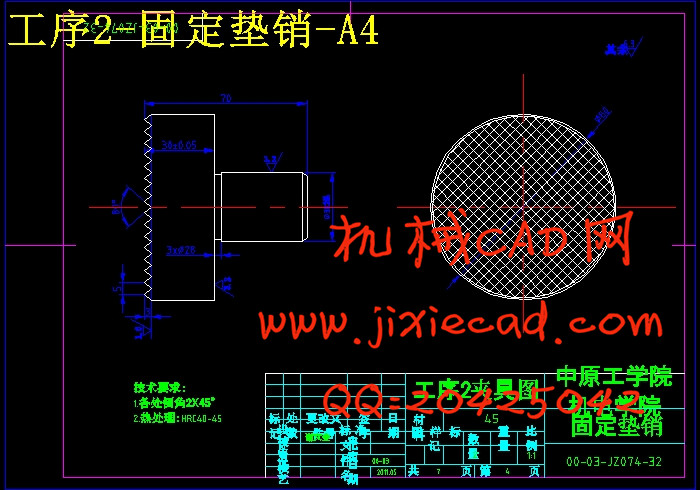

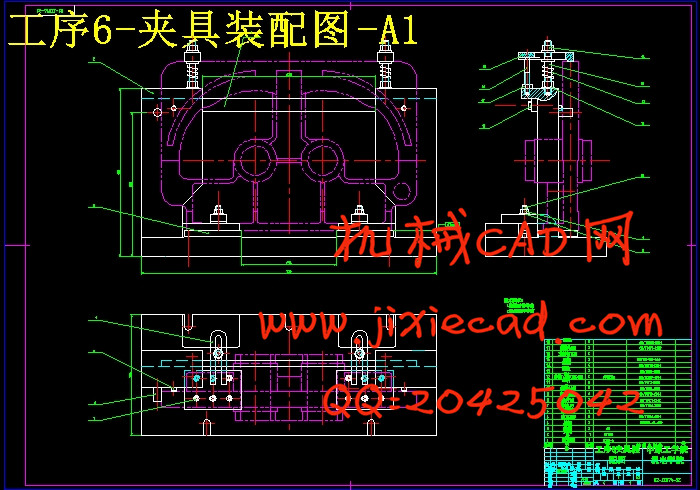

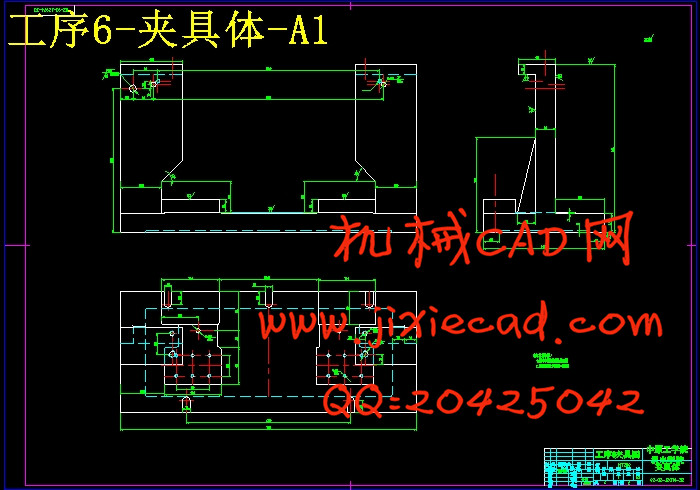

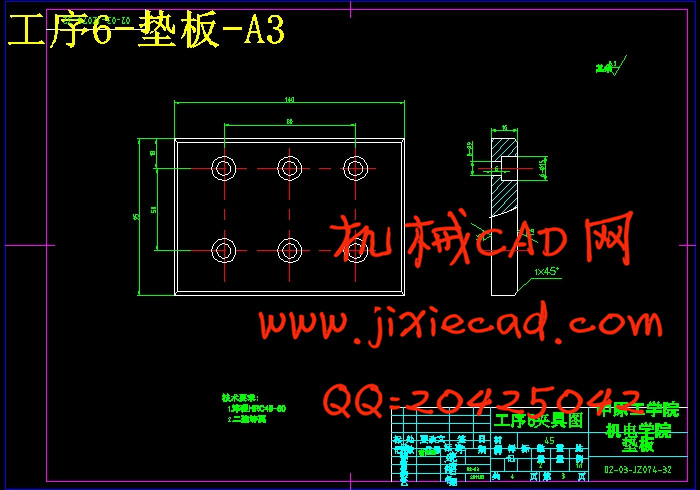

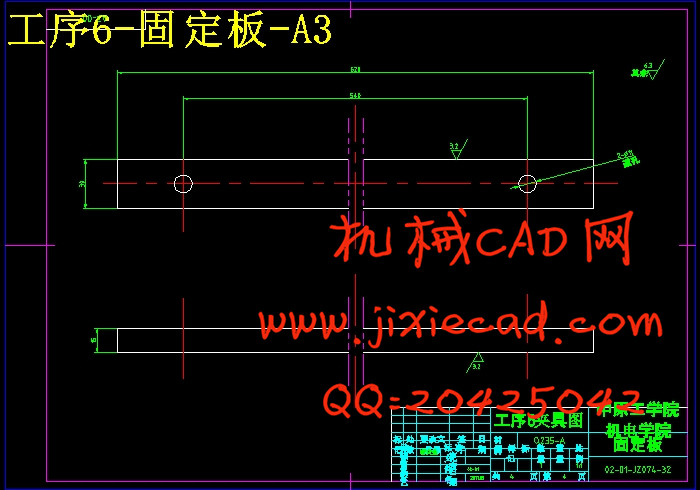

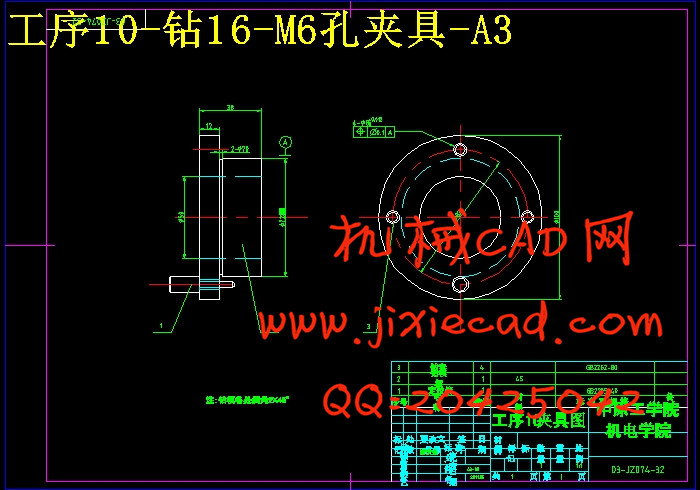

4.2夹具设计 27

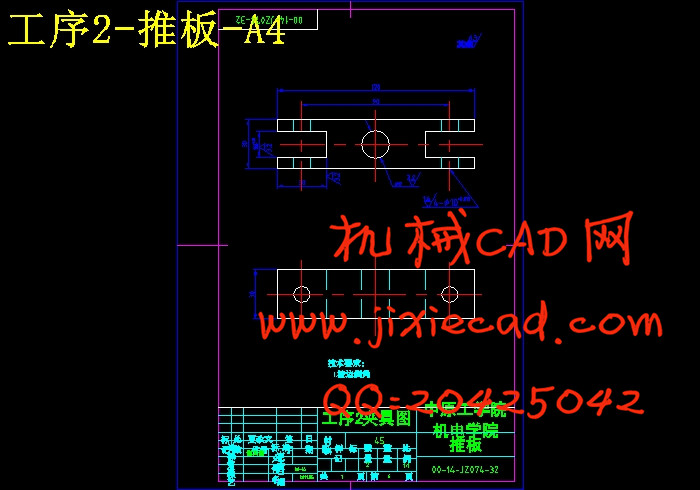

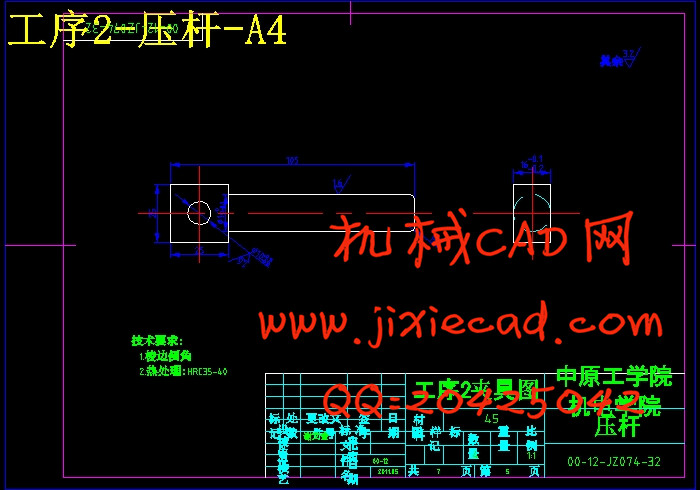

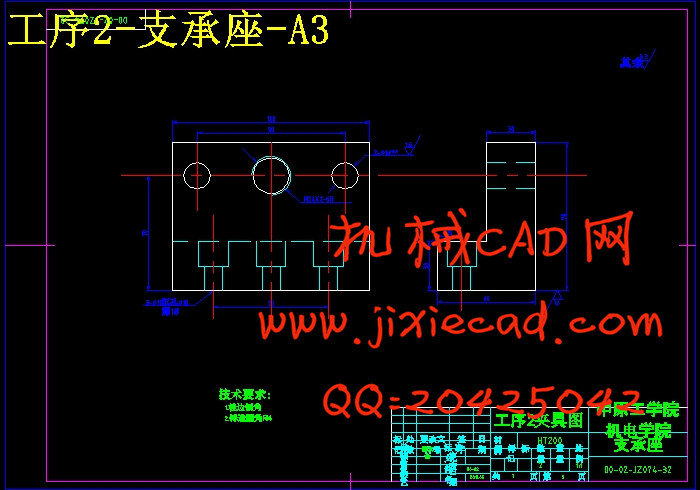

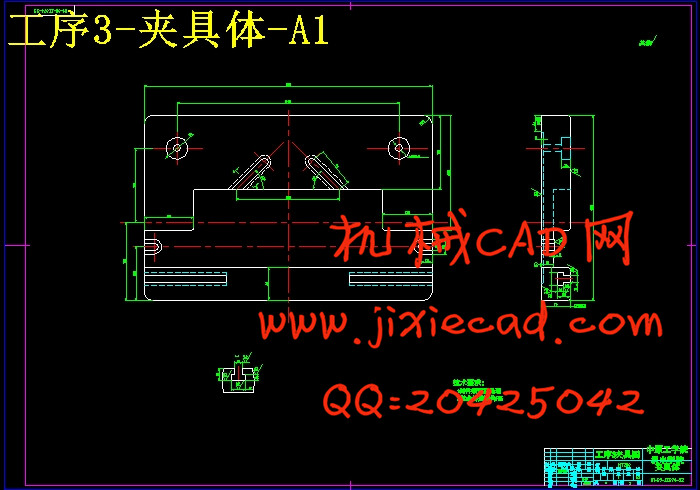

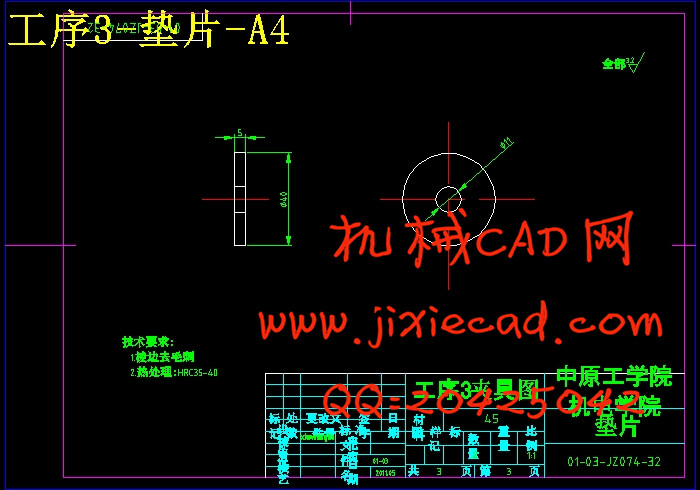

4.3夹具设计及操作的简要说明 29

5结论 30

致 谢 31

参考文献 32

附表:零件加工工艺卡 33