设计简介

摘 要

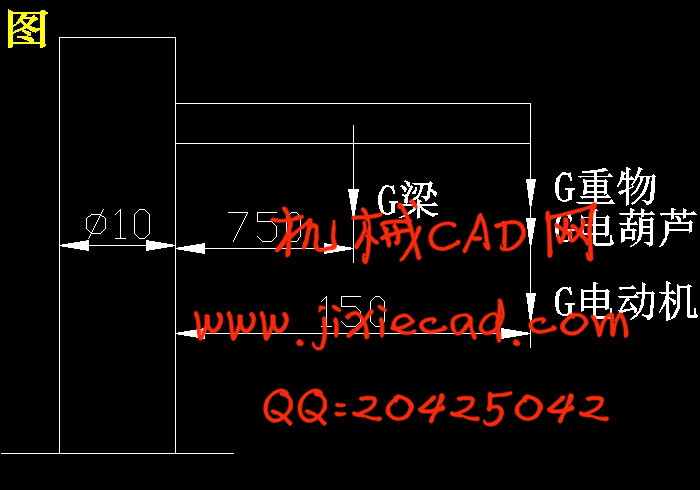

定柱式悬臂起重机是由固定立柱,旋转悬臂,旋转支撑装置,环链电动葫芦和电气控制系统组成。立柱采用无缝钢管制作,下端依靠法兰及地脚螺栓固定在基地上,上端安装有旋转支承装置。环链电动葫芦用来升降载荷并沿悬臂移动达到变幅的目的。定住式悬臂起重机立柱不动只起支承作用。由于工业生产规模不断扩大,生产效率日益提高,以及产品生产过程中物料装卸搬运费用所占比例逐渐增加,促使大型或高速起重机的需求量不断增长,起重量越来越大,工作速度越来越高,并对能耗和可靠性提出更高的要求。起重机已成为自动化生产流程中的重要环节。起重机不但要容易操作,容易维护,而且安全性要好,可靠性要高,要求具有优异的耐久性、无故障性、维修性和使用经济性。

有相当批量的起重机是在通用的场合使用,工作并不很繁重。这类起重机批量大、用途广,考虑综合效益,要求起重机尽量降低外形高度,简化结构,减小自重和轮压,也可命名整个建筑物高度下降,建筑结构轻型化,降低造价。因此电动葫芦桥式起重机和梁式起重机会有更快的发展,并将大部分取代中小吨位的一般用途桥式起重机。

起重机的更新和发展,在很大程度上取决于电气传动与控制的改进。将机械技术和电子技术相结合,将先进的计算机技术、微电子技术、电力电子技术、光缆技术、液压技术、模糊控制技术应用到机械的驱动和控制系统,实现起重机的自动化和智能化。结构方面采用薄壁型材和异形钢、减少结构的拼接焊缝,提高抗疲劳性能。采用各种合金钢新材料,提高承载能力,改善受力条件,减轻自重和增加外形美观。

关键词:定柱式;悬臂;起重机。

Abstract

As industrial production increased scale, increasing production efficiency and production process of loading and unloading of materials handling gradually increase the proportion of the cost, to large crane or the demand for high-speed growth, since more and more weight, increasing the pace of work And higher energy consumption and reliability requirements. Crane has become automated production processes in an important link. Crane should not only easy-to-use, easy to maintain and better security, higher reliability, requires excellent durability, trouble-free, maintenance and use of economy.

A considerable bulk of the crane is in common use of the occasion, the work is not very heavy. Large quantities of such cranes, wide use, consider the benefits, minimize the appearance requirements crane height, to simplify the structure, reducing the forces round pressure, may also rename the entire building height decline in light of the building structure, reducing construction costs. Therefore electric hoist girder bridge crane and a crane will be faster development, and will replace the majority of small and medium tonnage of general-purpose bridge crane.

Crane updates and development, to a large extent depend on the electric transmission and control improvements. Machinery and electronic technology to technology, advanced computer technology, microelectronic technology, power electronics technology, fiber optic cable technology, hydraulic technology, fuzzy control technology applications to drive the machinery and control systems, and crane automation and Intellectualized . The structure of a deformed steel and thin-walled profile, reduce the structure of the seam stitching and enhance anti-fatigue properties. Using all kinds of steel materials, enhance capacity and improve conditions for the force, to reduce forces and increase the aesthetic appearance.

KeyWords:The column; cantilever; Crane。