设计简介

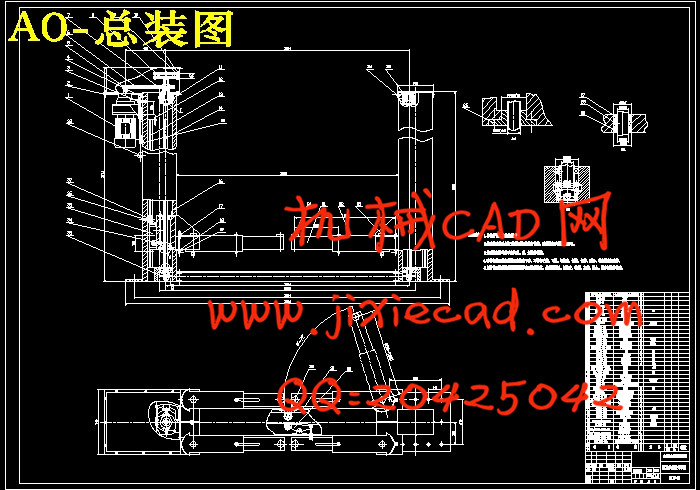

摘要:机械螺旋驱动双柱举升机是众多举升机的一种,它主要用于对汽车的维修。当前举升机的产品种类比较多:按提升动力来分有液压和机械两种形式;按结构类型来分有有单柱式、双柱式、四柱式和剪式。然而各种类型的举升机都有自己的优缺点,本课题就是将举升机进行优化,设计出经济型、适用型更好的举升机。

首先,对市面上常用的一些举升机进行分析,结合它们的优缺点,我设计选用机械传动作为举升机的动力传动。传动路线为:电动机——皮带传动——主螺旋副传动——链传动——副螺旋副传动形式。经过几个月的努力:

1)完成了对电动机的选择,选用一般用途(IP44)系列三相异步电动机,根据整机结构布置,采用卧式封闭结构

2)完成了对立柱与托臂的计算和校核

3)设计出了传动系统即螺旋传动

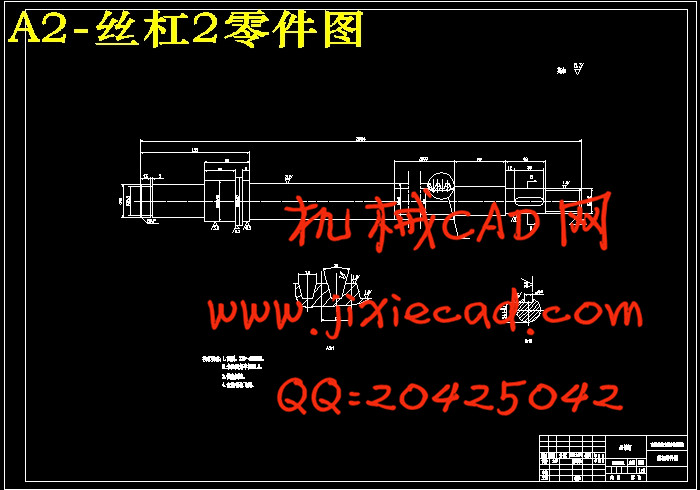

4)确定了丝杠的直径与螺母的高度以及对螺杆与螺母的计算

5)完成了丝杠螺母结构的安全性设计

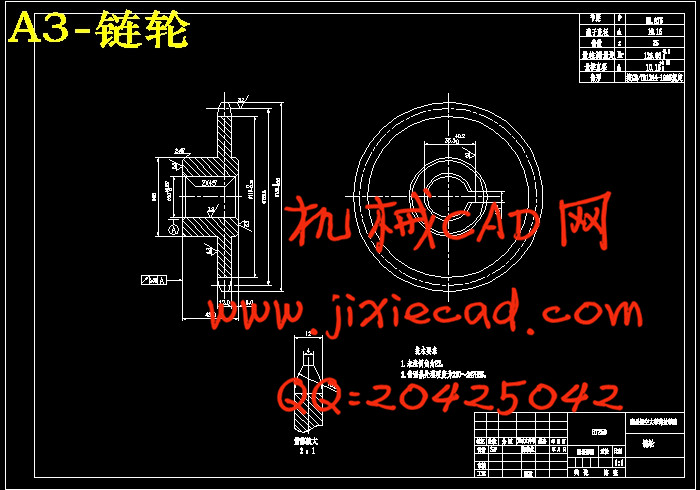

6)确定了链条的型号16A,可选用的节距P=25.4

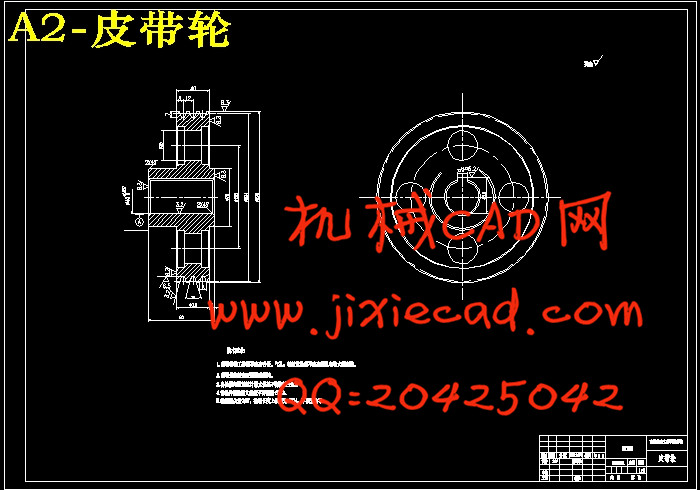

7)完成了对V带的选择

关键词:滑动螺旋副 丝杠 链条 V带

Abstract: mechanical screw driven double column lifter is a large lifting machine, which is mainly used for car repair. The current lift more products: according to enhance power to mechanical and hydraulic two forms; according to the types of structures have a single column, double column, type and shear type. However, various types of lifting machine has its own advantages and disadvantages, is the topic of lifting machine optimization design, economical, suitable and better lifting machine.

First of all, on the market used some of the lifting machine to carry on the analysis, combined with their advantages and disadvantages, I design and selection of mechanical drive for lifting machine power transmission. Transmission route: motor belt transmission -- -- -- the main screw drive chain drive -- Vice screw drive form. After several months of effort:

1) To complete the motor selection, selection of general purpose ( IP44) series of three-phase asynchronous motor, according to the overall structural arrangement, using horizontal sealing structure

2) Completed to leg and arm calculation and checking

3) Design of transmission system of spiral transmission

4) Determine the screw diameter and height on the nut and screw and nut calculation

5) Completed the lead screw nut structure safety design

6) Determine the chain model 16A, the optional pitch P=25.4

7) To complete the V band selection

Key words: sliding screw screw chain belt of V

目 录

1、 绪 论

1.1 研究背景 1

1.2 国内外研究现状 1

1.3 设计主要内容及步骤 2

1.4 设计的目的和意义 2

2、 总体结构设计

2.1 尺寸和结构 3

2.2 传动路线的设计 4

2.3 同步装置的选择 4

2.4 电机的选择 5

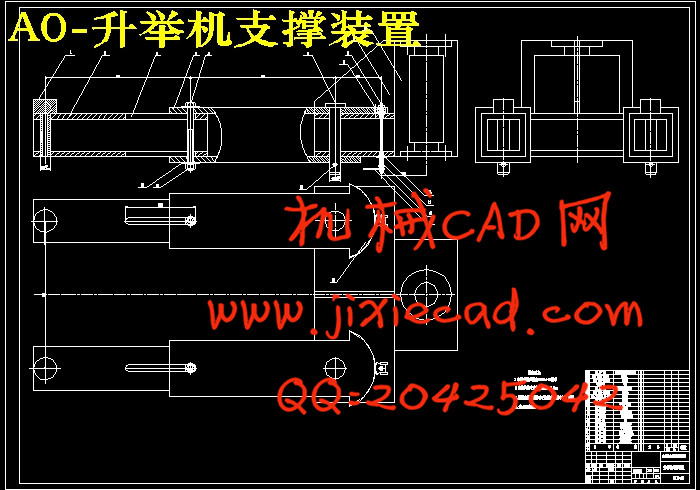

3、 立柱与托臂的设计

3.1 立柱的校核计算 7

3.2 托臂的校核 10

3.3 联接件的计算与校核 13

4、 传动系统的设计

4.1 螺旋传动的设计 16

4.2 链传动的选择 23

4.3 带传动的选择 29

5、 结论与建议

5.1 结论 33

5.2 建议 33

参考文献 34

致 谢 35

首先,对市面上常用的一些举升机进行分析,结合它们的优缺点,我设计选用机械传动作为举升机的动力传动。传动路线为:电动机——皮带传动——主螺旋副传动——链传动——副螺旋副传动形式。经过几个月的努力:

1)完成了对电动机的选择,选用一般用途(IP44)系列三相异步电动机,根据整机结构布置,采用卧式封闭结构

2)完成了对立柱与托臂的计算和校核

3)设计出了传动系统即螺旋传动

4)确定了丝杠的直径与螺母的高度以及对螺杆与螺母的计算

5)完成了丝杠螺母结构的安全性设计

6)确定了链条的型号16A,可选用的节距P=25.4

7)完成了对V带的选择

关键词:滑动螺旋副 丝杠 链条 V带

Abstract: mechanical screw driven double column lifter is a large lifting machine, which is mainly used for car repair. The current lift more products: according to enhance power to mechanical and hydraulic two forms; according to the types of structures have a single column, double column, type and shear type. However, various types of lifting machine has its own advantages and disadvantages, is the topic of lifting machine optimization design, economical, suitable and better lifting machine.

First of all, on the market used some of the lifting machine to carry on the analysis, combined with their advantages and disadvantages, I design and selection of mechanical drive for lifting machine power transmission. Transmission route: motor belt transmission -- -- -- the main screw drive chain drive -- Vice screw drive form. After several months of effort:

1) To complete the motor selection, selection of general purpose ( IP44) series of three-phase asynchronous motor, according to the overall structural arrangement, using horizontal sealing structure

2) Completed to leg and arm calculation and checking

3) Design of transmission system of spiral transmission

4) Determine the screw diameter and height on the nut and screw and nut calculation

5) Completed the lead screw nut structure safety design

6) Determine the chain model 16A, the optional pitch P=25.4

7) To complete the V band selection

Key words: sliding screw screw chain belt of V

目 录

1、 绪 论

1.1 研究背景 1

1.2 国内外研究现状 1

1.3 设计主要内容及步骤 2

1.4 设计的目的和意义 2

2、 总体结构设计

2.1 尺寸和结构 3

2.2 传动路线的设计 4

2.3 同步装置的选择 4

2.4 电机的选择 5

3、 立柱与托臂的设计

3.1 立柱的校核计算 7

3.2 托臂的校核 10

3.3 联接件的计算与校核 13

4、 传动系统的设计

4.1 螺旋传动的设计 16

4.2 链传动的选择 23

4.3 带传动的选择 29

5、 结论与建议

5.1 结论 33

5.2 建议 33

参考文献 34

致 谢 35