设计简介

摘 要

机械手是工业机器人系统中传统的任务执行机构,是机器人的关键部件之一。机械手的机械结构采用滚珠丝杆、滑杆、等机械器件组成;电气方面有交流电机、变频器、传感器、等电子器件组成。该装置涵盖了可编程控制技术,位置控制技术、检测技术等,是机电一体化的典型代表仪器之一。本文介绍的机械手是由PLC输出三路脉冲,分别驱动横轴、竖轴变频器,控制机械手横轴和竖轴的精确定位,微动开关将位置信号传给PLC主机;位置信号由接近开关反馈给PLC主机,通过交流电机的正反转来控制机械手手爪的张合,从而实现机械手精确运动的功能。本课题拟开发的物料搬运机械手可在空间抓放物体,动作灵活多样,可代替人工在高温和危险的作业区进行作业,并可根据工件的变化及运动流程的要求随时更改相关参数。本文在纵观了近年来机械手发展状况的基础上,结合机械手方面的设计,对机械手技术进行了系统的分析,提出了用驱动和PLC控制的设计方案。采用整体化的设计思想,充分考虑了软、硬件各自的特点并进行互补优化。对机械手的整体结构、执行结构、驱动系统和控制系统进行了分析和设计。在其驱动系统中采用驱动,控制系统中选择PLC的控制单元来完成系统功能的初始化、机械手的移动、故障报警等功能。最后提出了一种简单、易于实现、理论意义明确的控制策略。

通过以上部分的工作,得出了经济型、实用型、高可靠型机械手的设计方案,对其他经济型PLC控制系统的设计也有一定的借鉴价值。

关键词: 机械手,交流电机,可编程控制器(PLC),自动化控制,。

Abstract

Manipulator industrial robot systems traditional mandate, Robot is one of the key components. Manipulator using the mechanical structure of screw-ball, slider, and other mechanical devices composition; Electric have AC motor, inverter, sensor, and other electronic device components. The device covers a programmable control technology, position control technology, detection technology, Mechatronics is a typical representative of one of the machines. This paper presents a manipulator by three PLC output pulse, driving horizontal, the vertical axis transducer, control manipulator axis horizontal and vertical positioning precision, micro-switches position signal transmission will host PLC; location close to the switching signal from the feedback from the mainframe to the PLC, through the exchange of Motor reversion to control the manipulator gripper Zhang, thus achieving accurate manipulator movement functions. The topics to be developed by the Manipulator grasping be up in space objects, movements flexible, diverse, can replace the artificial heat and dangerous operation conducted operations, According to the workpiece can change the campaign process and the requirements of any changes to the relevant parameters.In this paper, by reviewing the developmental status of the manipulator in recent years, combining the design of manipulator and systematic analyzing technology of the manipulator, We proposed the design scheme that the manipulator was driven by the pneumatic and the system was controlled by PLC. Integrative idea was adopted in this design to fully consider the characteristics of the software and hardware and complementary optimization. We analyzed and designed the overall structure, the implementation of structural, driving system and control system of the manipulator. We used pneumatic-driven in the driving system, PLC control unit in the control system to complete initialization of the system, manipulator's moving, failure alarm and so on. Finally we put forward a control strategy which is simple, easy to realize, and clear theoretical significance.

Through the work above, a practical, economical, high-reliability sorting material manipulator was designed, which also had certain reference value for the other types of economical PLC control system design.

Key words: manipulator ;AC motor ; programmable logic controller (PLC); automatic control;sorting material

目 录

目 录 3摘 要 5

Abstract 6

第一章 前言 7

1.1 研究的目的及意义 7

1.2 机械手在国内外现状和发展趋势 8

1.3 主要研究的内容 8

1.4 解决的关键问题 9

第二章 可编程控制PLC 9

2.1 PLC 简介 9

2.2 PLC的基本组成及各部分作用 11

2.2.1中央处理单元(CPU) 11

2.2.2存储器 12

2.2.3 I/0单元 12

2.2.4电源部分 13

2.2.5扩展接口 13

2.2.6通信接口 13

2.2.7编程器 13

第三章 驱动系统的分析与选择 20

3.1 驱动系统的分析与选择 20

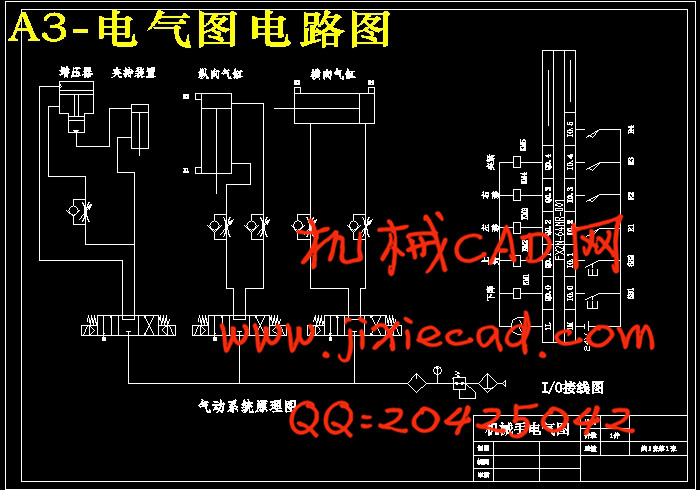

3.2 机械手驱动系统的控制设计 21

3.3 元件选取及工作原理 22

3.3.1 气源装置 22

3.3.2 执行元件 23

3.3.3 控制元件 24

3.3.4 辅助元件 25

3.3.5 真空发生器 26

3.3.6 吸盘 26

3.4 回路的工作原理 26

第四章 控制系统的分析设计 30

4.1 控制系统的组成结构 30

4.2 控制系统的性能要求 30

4.3 传感器的选择 31

4.3.1 位置检测装置 31

4.3.2 滑觉传感器 31

4.3.3 视觉传感器 32

4.4 控制系统PLC的选型及控制原理 33

4.4.1 PLC控制系统设计的基本原则 33

4.4.2 PLC种类及型号选择 38

4.4.3 I/O点数分配 38

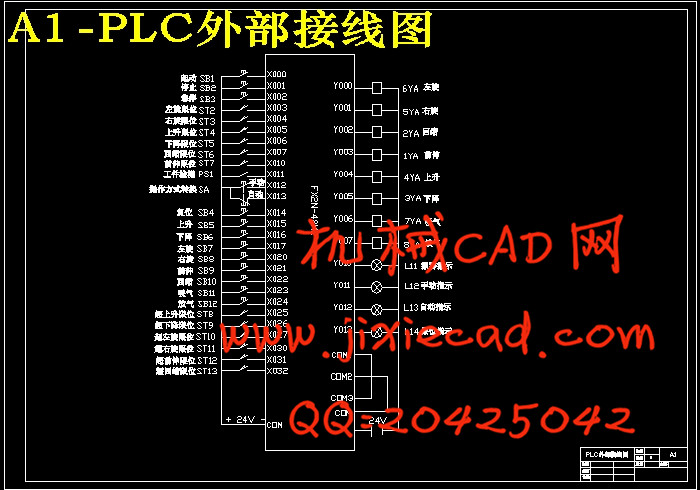

4.4.4 PLC外部接线图 39

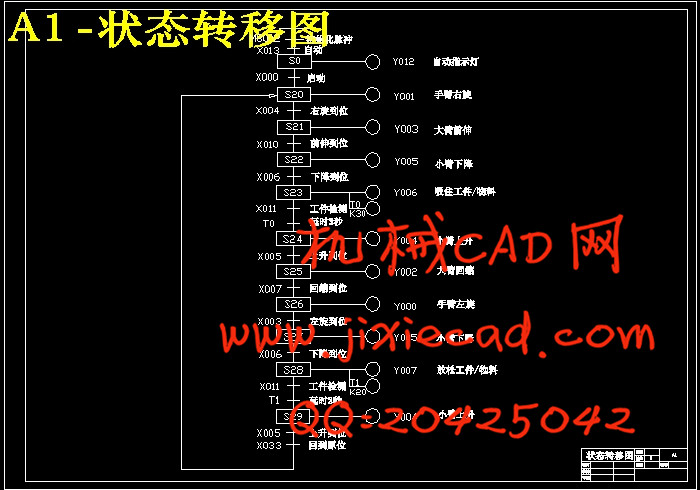

4.4.5 机械手控制原理 40

4.5 PLC程序设计 42

4.5.1 总体程序框图 42

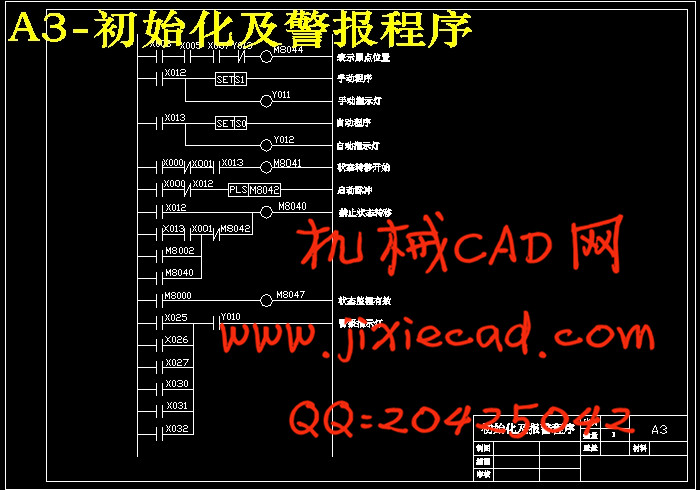

4.5.2 初始化及报警程序 44

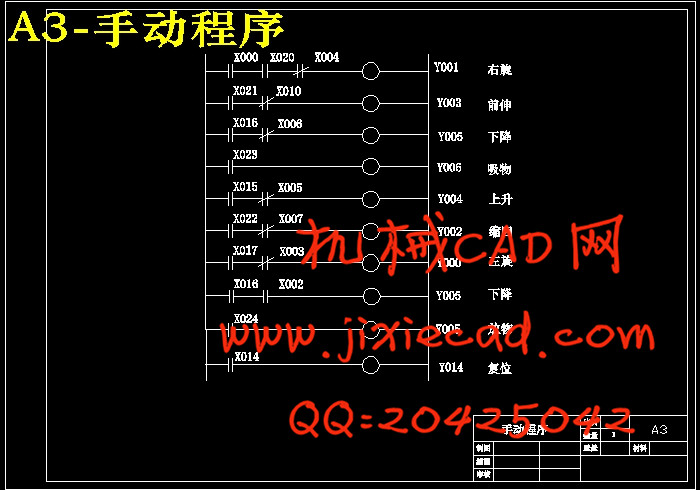

4.5.3 手动控制程序 45

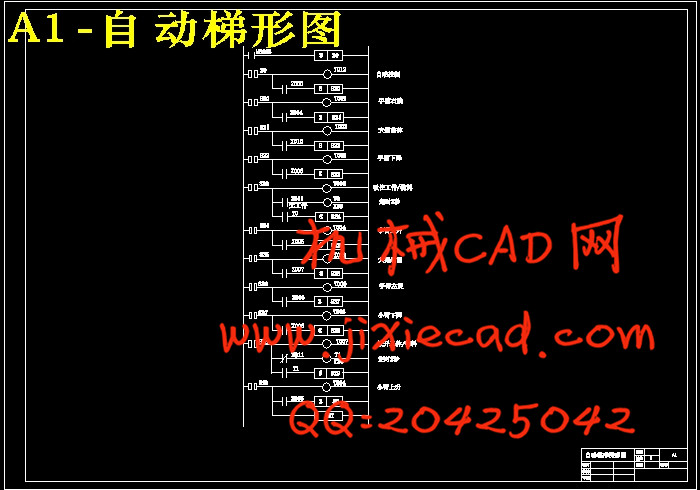

4.5.4 自动控制程序 47

第五章 总结与展望 50

参考文献 51

致 谢 52

附 录 53

附录1 程序流程图 53

附录2 顺序功能图 56

附录3 梯形图 57

附录4 指令表 59