设计简介

摘 要

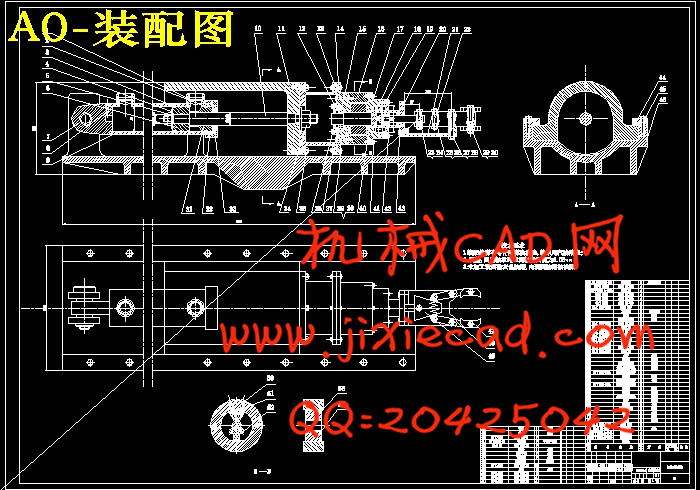

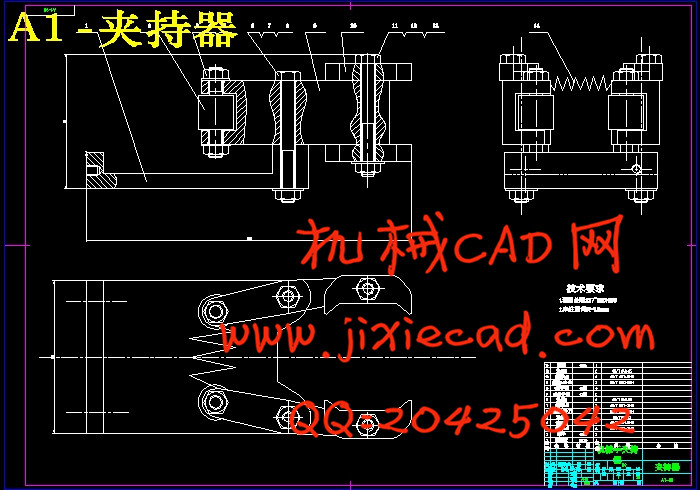

这次设计我选的题目是机械手夹持器设计,本课题是针对流水线自动化生产而设计的机械夹持器。本课题包括机械夹持器总体设计、计算;液压传动系统的设计与计算、部件和零件设计。机械手与机器人的联系非常密切,机械手的应用和发展,大大促进了智能机器人的研制。同时,机械手是一门应用很广的学科,它几乎在各个部门和学科都有应用,尤其在机械工业和铁路工业中。

我所设计的夹持器基本要求如下:

(1)应具有适当的夹紧力和驱动力;

(2)手指应具有一定的开闭范围;

(3)应保证工件在手指内的夹持精度;

(4)要求结构紧凑,重量轻,效率高;

(5)应考虑通用性和特殊要求。

设计参数及要求如下:

(1)采用手指式夹持器,执行动作为抓紧—放松;

(2)所要抓紧的工件直径为80mm 放松时的两抓的最大距离为110-120mm/s , 1s抓紧,夹持速度20mm/s;

(3)工件的材质为5kg,材质为45#钢;

(4)夹持器有足够的夹持力;

(5)夹持器靠法兰联接在手臂上。由液压缸提供动力

关键词:机械手,夹持器,手指,液压缸。

abstract

In the graduation design, The topic I choose is manipulator grippers design, this topic is designed for automatic production line of mechanical grippers. The topics include mechanical grippers overall design and calculation; Hydraulic transmission system design and calculation, components and parts design. Contact with the robot manipulator, very close to the development and application of the manipulator, greatly promote the development of intelligent robots. Meanwhile, manipulator is an application is very wide subject, it almost in all departments and disciplines have applications, especially in the machinery industry and railway industry.

I designed by grippers basic requirement as follows:

(1) should have appropriate clamping force and driving force;

(2) finger should have certain open and close range;

(3) should guarantee the clamping workpiece precision in the finger;

(4) require compact structure, light weight, high efficiency;

(5) should consider the versatility and special requests.

Design parameters and requirement as follows:

(1) with finger type grippers, execute the movements for grasp - relax;

(2) the diameter workpiece must promptly 80mm relax a maximum distance of two catch for 110-120mm/s, 1s grasps, gripping speed 20mm/s;

(3) the workpiece material for 5kg, material for 45 # steel;

(4) grippers have enough clamping force;

(5) grippers connected in the arm by flange. Powered by hydraulic cylinder

Key words: manipulator, grippers, finger, hydraulic cylinder.

目录

第一章 前言 3

1.1机械手的概述 3

1.2 机械手在生产中的应用 4

1.3机械手的应用意义 6

第二章 手部设计. 7

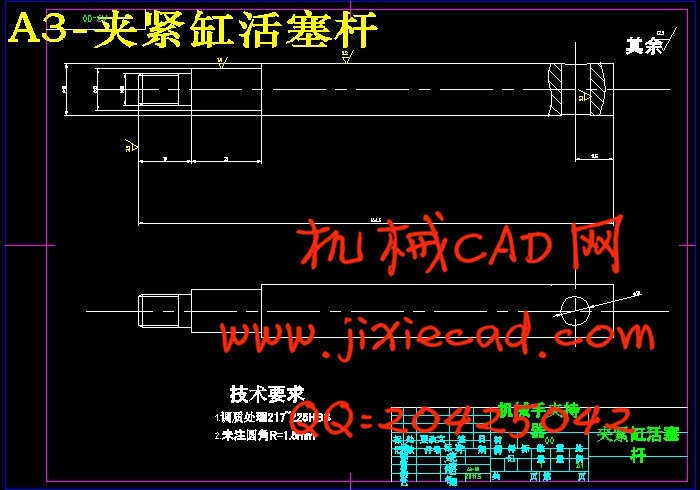

2.1夹紧力计算 7

2.2驱动力力计算 8

2.3液压缸驱动力计算 8

2.4楔块等尺寸的确定 9

2.5斜楔的传动效率 10

2.6斜楔驱动行程与手指开闭范围 10

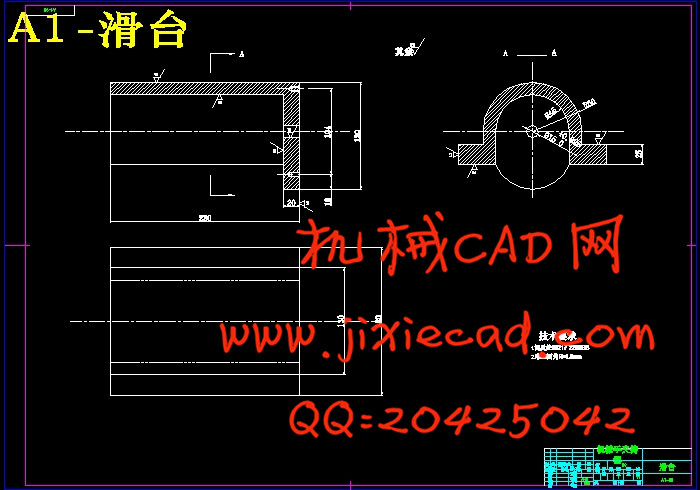

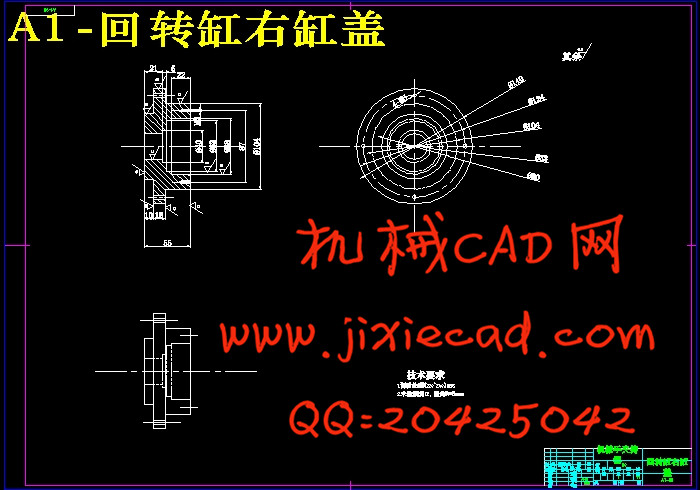

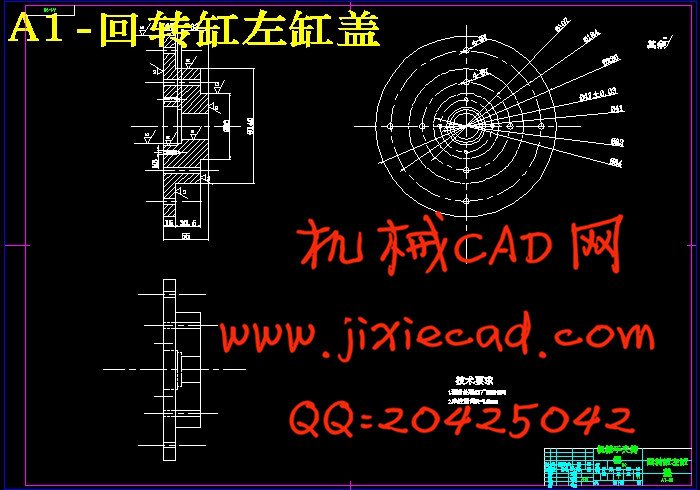

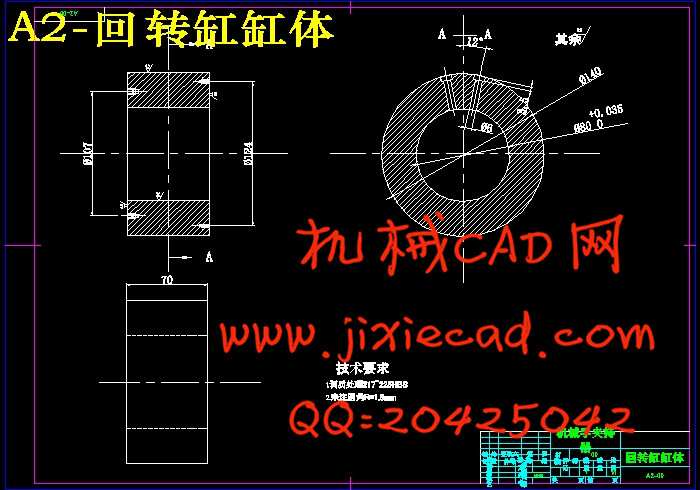

第三章 腕部设计 13

3.1腕部回转力矩的计算 13

3.2回转液压缸所驱动力矩计算 14

3.3回转缸内径D计算 16

3.4腕部轴承选择 17

3.5材料及连接件,密封件选择 17

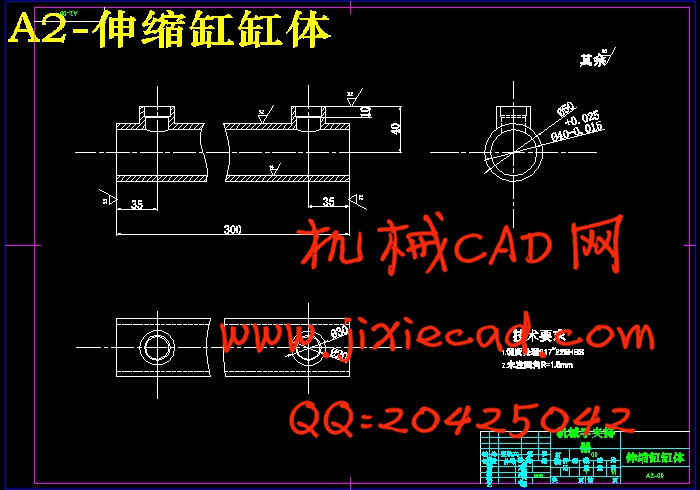

第四章 伸缩臂设计 18

4.1方案设计 18

4.2伸缩臂机构结构设计 18

4.2.1伸缩臂液压缸参数计算 18

4.3.2导向杆机构设计 23

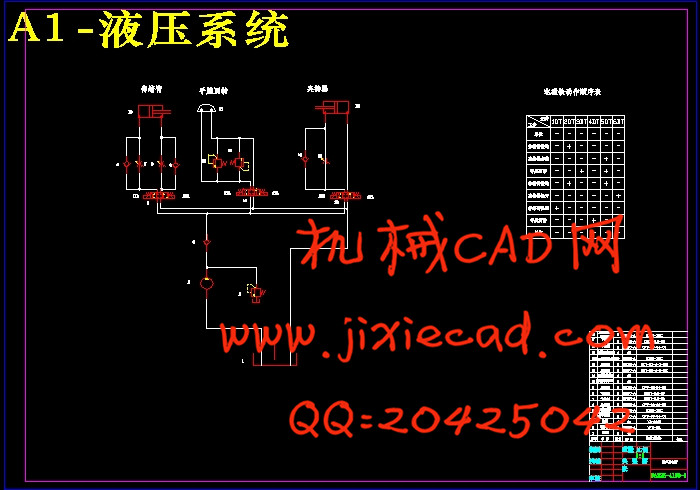

第五章 驱动系统 26

5.1驱动系统设计方案 26

5.3液压系统图 27

第六章 设计总结 30

参考文献 31

这次设计我选的题目是机械手夹持器设计,本课题是针对流水线自动化生产而设计的机械夹持器。本课题包括机械夹持器总体设计、计算;液压传动系统的设计与计算、部件和零件设计。机械手与机器人的联系非常密切,机械手的应用和发展,大大促进了智能机器人的研制。同时,机械手是一门应用很广的学科,它几乎在各个部门和学科都有应用,尤其在机械工业和铁路工业中。

我所设计的夹持器基本要求如下:

(1)应具有适当的夹紧力和驱动力;

(2)手指应具有一定的开闭范围;

(3)应保证工件在手指内的夹持精度;

(4)要求结构紧凑,重量轻,效率高;

(5)应考虑通用性和特殊要求。

设计参数及要求如下:

(1)采用手指式夹持器,执行动作为抓紧—放松;

(2)所要抓紧的工件直径为80mm 放松时的两抓的最大距离为110-120mm/s , 1s抓紧,夹持速度20mm/s;

(3)工件的材质为5kg,材质为45#钢;

(4)夹持器有足够的夹持力;

(5)夹持器靠法兰联接在手臂上。由液压缸提供动力

关键词:机械手,夹持器,手指,液压缸。

abstract

In the graduation design, The topic I choose is manipulator grippers design, this topic is designed for automatic production line of mechanical grippers. The topics include mechanical grippers overall design and calculation; Hydraulic transmission system design and calculation, components and parts design. Contact with the robot manipulator, very close to the development and application of the manipulator, greatly promote the development of intelligent robots. Meanwhile, manipulator is an application is very wide subject, it almost in all departments and disciplines have applications, especially in the machinery industry and railway industry.

I designed by grippers basic requirement as follows:

(1) should have appropriate clamping force and driving force;

(2) finger should have certain open and close range;

(3) should guarantee the clamping workpiece precision in the finger;

(4) require compact structure, light weight, high efficiency;

(5) should consider the versatility and special requests.

Design parameters and requirement as follows:

(1) with finger type grippers, execute the movements for grasp - relax;

(2) the diameter workpiece must promptly 80mm relax a maximum distance of two catch for 110-120mm/s, 1s grasps, gripping speed 20mm/s;

(3) the workpiece material for 5kg, material for 45 # steel;

(4) grippers have enough clamping force;

(5) grippers connected in the arm by flange. Powered by hydraulic cylinder

Key words: manipulator, grippers, finger, hydraulic cylinder.

目录

第一章 前言 3

1.1机械手的概述 3

1.2 机械手在生产中的应用 4

1.3机械手的应用意义 6

第二章 手部设计. 7

2.1夹紧力计算 7

2.2驱动力力计算 8

2.3液压缸驱动力计算 8

2.4楔块等尺寸的确定 9

2.5斜楔的传动效率 10

2.6斜楔驱动行程与手指开闭范围 10

第三章 腕部设计 13

3.1腕部回转力矩的计算 13

3.2回转液压缸所驱动力矩计算 14

3.3回转缸内径D计算 16

3.4腕部轴承选择 17

3.5材料及连接件,密封件选择 17

第四章 伸缩臂设计 18

4.1方案设计 18

4.2伸缩臂机构结构设计 18

4.2.1伸缩臂液压缸参数计算 18

4.3.2导向杆机构设计 23

第五章 驱动系统 26

5.1驱动系统设计方案 26

5.3液压系统图 27

第六章 设计总结 30

参考文献 31