设计简介

10×10旋转溜管式生面团自动排放机

摘要:馒头是人们的主食之一,然而中国馒头生产的最大特点却是家庭作坊。馒头生产机械还是停留在手工操作的阶段。这已不再适应现今日趋加快的生活节奏。为解决馒头大规模工业生产的薄弱环节上的问题,采用嵌入式系统开发经验,设计了旋转溜管式馒头坯自动排放机,并进行了智能化改造。本文介绍了此设备的工作原理和主要技术参数。其原理是:将成型好的面团通过远红外传感器1落入旋转溜管,则传感器发信号给控制器,控制器发控制信号使步进电机旋转一定角度,向下一孔落料。面团通过旋转溜管并沿着分配上指定的导向溜管落入托盘,按直线排列成行。当排完第一行后,下一排的第一个面团通过传感器时,控制器附加发出一个控制信号使离合器吸合,而让送进机构带着托盘向前运行,当走一列距时,光电传感器2发信号使离合器段开,此时开始排放下一排。希望此次设计能提供一个食品机械自动化改造的成功实例。

关键词:自动排放,自动控制,旋转溜管,面团,排放

Automatic Discharge of 10 × 10 Rotary Slip Tube Raw Dough

Abstract

The bread is one of the staple food of the people, however, the most prominent feature of Chinese steamed bread production is the family workshops. Bread production machinery remain in the stage of manual operations. This is no longer adapted to today's increasingly accelerated pace of life。To solve the problem on the weak link of the large-scale industrial production of bread, embedded systems development experience, design a rotating slip tube bread blanks automatically discharge machine, and intelligent transformation. This article describes the working principle of this device and main technical parameters. The principle is: forming a good dough by far-infrared sensors fall into the rotary slide tube, the sensor signal to the controller, the controller control signals for the stepper motor to rotate a certain angle, down a hole blanking. Dough slide by rotating the tube along the orientation specified in the distribution of slip tube to fall into the tray, arranged in rows by a straight line.

When drained, the first line of the next row of the first dough through the sensor, additional controller to send a control signal so that the clutch pull, and sent to institutions run forward with the tray, walk a distance, the photoelectric sensorsignal clutch segment open, then discharged the next row. Hope that this design can provide successful examples of a food machinery automation transformation.

Keywords: auto emissions, automatic control, rotating slide tube, dough, emissions

目录

1、绪论 1

1.1课题背景及目的 1

1.3自动排放机工艺及设备的设计要求 2

1.4自动排放机的设计要求 3

1.5方案论证 3

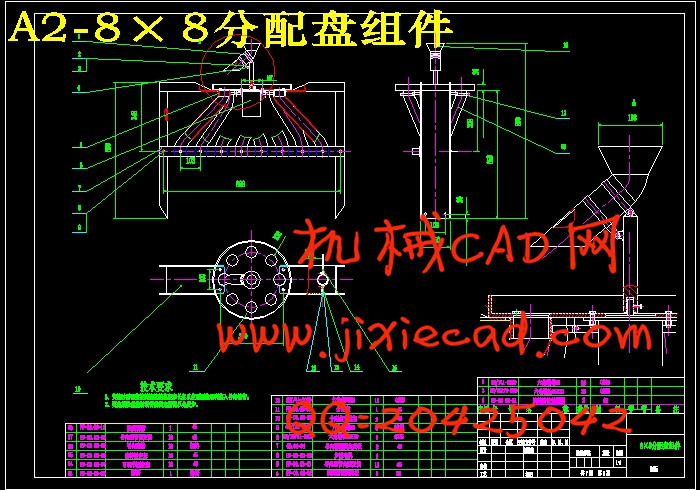

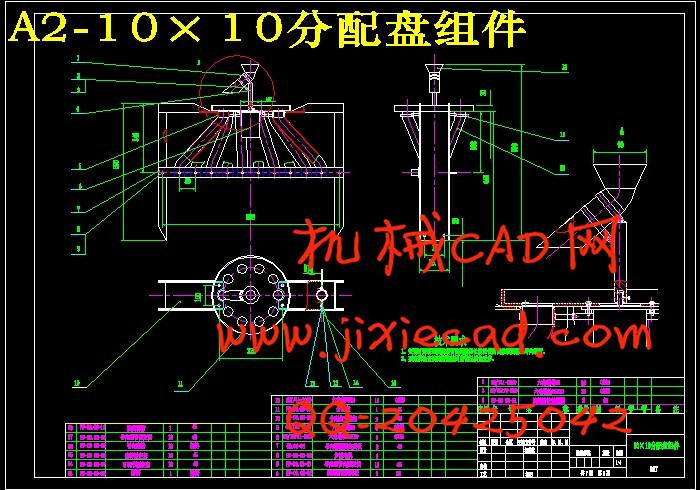

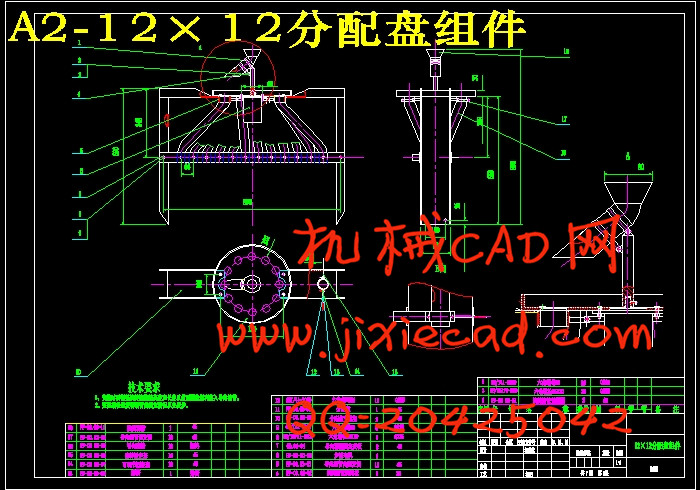

2、旋转溜管式生面团自动排放机设计 5

2.1旋转溜管式生面团自动排放机基本形式 5

2.2设计参数分析 8

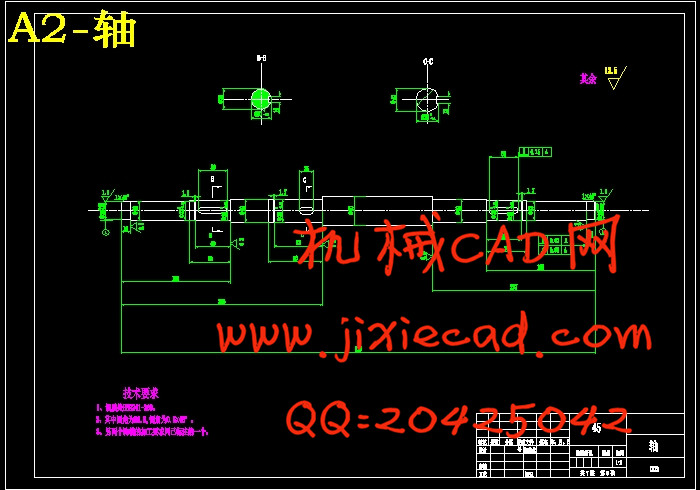

3、机械结构的设计与计算 11

3.1旋转溜管的设计 11

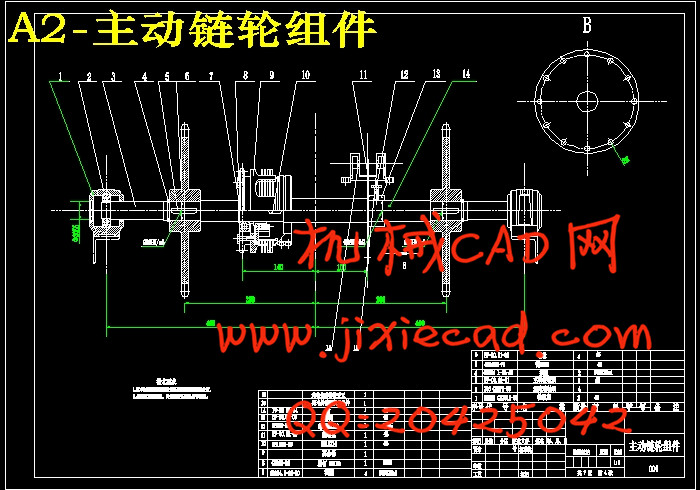

3.2送进机构的设计 11

3.2.1链条的型号及尺寸 11

3.2.2链条附件尺寸K1 12

3.3送进机构链的计算 13

3.3.1链轮转速的分析 13

3.3.2计算功率选取电机 13

3.3.3链轮齿形 14

3.3.4离合器的选取 15

4、传动机构的设计计算 17

4.1链传动特点 17

4.2传动机构计算 17

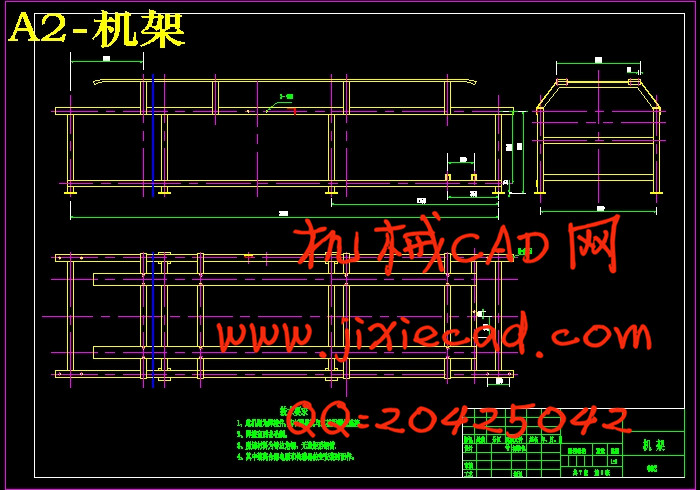

4.3机架的设计 20

5、轻型输送机的设计 22

结论 23

致谢 24

参考文献 25

摘要:馒头是人们的主食之一,然而中国馒头生产的最大特点却是家庭作坊。馒头生产机械还是停留在手工操作的阶段。这已不再适应现今日趋加快的生活节奏。为解决馒头大规模工业生产的薄弱环节上的问题,采用嵌入式系统开发经验,设计了旋转溜管式馒头坯自动排放机,并进行了智能化改造。本文介绍了此设备的工作原理和主要技术参数。其原理是:将成型好的面团通过远红外传感器1落入旋转溜管,则传感器发信号给控制器,控制器发控制信号使步进电机旋转一定角度,向下一孔落料。面团通过旋转溜管并沿着分配上指定的导向溜管落入托盘,按直线排列成行。当排完第一行后,下一排的第一个面团通过传感器时,控制器附加发出一个控制信号使离合器吸合,而让送进机构带着托盘向前运行,当走一列距时,光电传感器2发信号使离合器段开,此时开始排放下一排。希望此次设计能提供一个食品机械自动化改造的成功实例。

关键词:自动排放,自动控制,旋转溜管,面团,排放

Automatic Discharge of 10 × 10 Rotary Slip Tube Raw Dough

Abstract

The bread is one of the staple food of the people, however, the most prominent feature of Chinese steamed bread production is the family workshops. Bread production machinery remain in the stage of manual operations. This is no longer adapted to today's increasingly accelerated pace of life。To solve the problem on the weak link of the large-scale industrial production of bread, embedded systems development experience, design a rotating slip tube bread blanks automatically discharge machine, and intelligent transformation. This article describes the working principle of this device and main technical parameters. The principle is: forming a good dough by far-infrared sensors fall into the rotary slide tube, the sensor signal to the controller, the controller control signals for the stepper motor to rotate a certain angle, down a hole blanking. Dough slide by rotating the tube along the orientation specified in the distribution of slip tube to fall into the tray, arranged in rows by a straight line.

When drained, the first line of the next row of the first dough through the sensor, additional controller to send a control signal so that the clutch pull, and sent to institutions run forward with the tray, walk a distance, the photoelectric sensorsignal clutch segment open, then discharged the next row. Hope that this design can provide successful examples of a food machinery automation transformation.

Keywords: auto emissions, automatic control, rotating slide tube, dough, emissions

目录

1、绪论 1

1.1课题背景及目的 1

1.3自动排放机工艺及设备的设计要求 2

1.4自动排放机的设计要求 3

1.5方案论证 3

2、旋转溜管式生面团自动排放机设计 5

2.1旋转溜管式生面团自动排放机基本形式 5

2.2设计参数分析 8

3、机械结构的设计与计算 11

3.1旋转溜管的设计 11

3.2送进机构的设计 11

3.2.1链条的型号及尺寸 11

3.2.2链条附件尺寸K1 12

3.3送进机构链的计算 13

3.3.1链轮转速的分析 13

3.3.2计算功率选取电机 13

3.3.3链轮齿形 14

3.3.4离合器的选取 15

4、传动机构的设计计算 17

4.1链传动特点 17

4.2传动机构计算 17

4.3机架的设计 20

5、轻型输送机的设计 22

结论 23

致谢 24

参考文献 25