设计简介

摘 要

长期以来,食品加工一直以手工加工操作为主。在现代社会的今天,时间和效率就是生命,就是金钱。应用食品加工机械不仅能减轻人们的劳动强度,节约宝贵的时间,还可以保证食品质量,减少原料的浪费,又能增加产量,提高劳动生产率,降低食品成本。而由食品加工机械组成的连续化、自动化的大型生产线,又为食品加工社会化创造了有利条件,减少了人身与食品物料的直接和病菌传播机会。通过高压高温消毒及灭菌处理等操作,还可有效地防止污染食品。近年来,随着东亚、东南亚经济的崛起,人众多的中国已出现了粮食的富余。米制品的开发利用也逐渐受到重视,米制品的生产已有一些初步理论研究。而在米粉加工中它不同于面粉加工不同,在面粉加工中,如面条生产中面条的抗拉强度主要是靠面粉蛋白质形成的面筋来支撑,而大米蛋白是不会形成面筋,必须依靠大米淀粉的糊化、回生来完成。而米粉的糊化问题又是米制品加工的关键。总结各方面的要求,设计了专门为米粉充分糊化的米粉复蒸柜。复蒸柜是利用高温加热米粉,提高米粉α度。降低米粉吐浆率且使米粉,有滑油润感。复蒸柜设计的原理就是根据淀粉糊化原理。 在设计的过程中应该使柜内淀粉尽量糊化,而尽量避免淀粉的回生。因此如何掌握温度、时间、水分,根据糊化与回生理论,人为地控制大米淀粉的α化、防止米粉β化,对提高米粉的质量,是至关重要的。关键词:米粉复蒸柜 糊化 淀粉α化

The rice noodle duplicate steams the cabinet the system design

Abstract: Since long ago, food processing continuously by manual processing operation primarily.In modern society's today, the time and the efficiency are lives, is the money.Can reduce people's labor intensity not only using the food processing machinery, saves the precious time, but also may guarantee food quality, reduces raw material the waste, also can the gain in yield, enhances the labor productivity, reduces food cost.But is composed continuous, the automated large-scale production line by the food processing machinery, also has created the advantage for the food processing socialization, reduced the person and food material direct and the germ dissemination opportunity.Through high-pressured operations and so on high temperature disinfection and antiseptic processing, but also may effectively antipollution food.In recent years, along with East Asian, Southeast Asia economy rising, human's multitudinous China appeared the grain extra.The rice product development use also gradually receives takes, the rice product production had some preliminary fundamental research.But it is different in the rice noodle processing with the bread flour processing is different, in the bread flour processing, like in the noodles production the noodles tensile strength mainly is depends on the gluten which the bread flour protein forms to support, but the rice protein cannot form the gluten, must depend upon the rice starch the dextrinize, revives completes.But the rice noodle dextrinize question also is the rice product processing key. summarizes various aspects request, designed duplicate has specially steamed the cabinet for the rice noodle full dextrinize rice noodle.Duplicate steams the cabinet uses the high temperature heating rice noodle, enhances the rice noodle alpha.Reduces the rice noodle to spit the thick liquid rate also causes the rice noodle, has the slippery glossy feeling.Duplicate steams the principle which the cabinet designs acts according to the starch pasting principle. Should cause in the cabinet in the design process the starch as far as possible dextrinize, but avoids the starch as far as possible reviving.How therefore grasps the temperature, the time, the moisture content, with revives the theory according to the dextrinize, artificial controls the rice starch alpha, prevented the rice noodle beta, to enhances the rice noodle the quality, is very important.Key words: The rice noodle duplicate steams the cabinet Dextrinize Starch alph

目录

摘 要 2The rice noodle duplicate steams the cabinet the system design 3

目录 4

一、前言 5

二、复蒸柜原理 6

1.1淀粉的糊化 6

1.2、淀粉的回生 8

1.3、米粉糊化与回生在复蒸柜生产中的指导作用 9

三、复蒸柜技术参数尺寸的确定 10

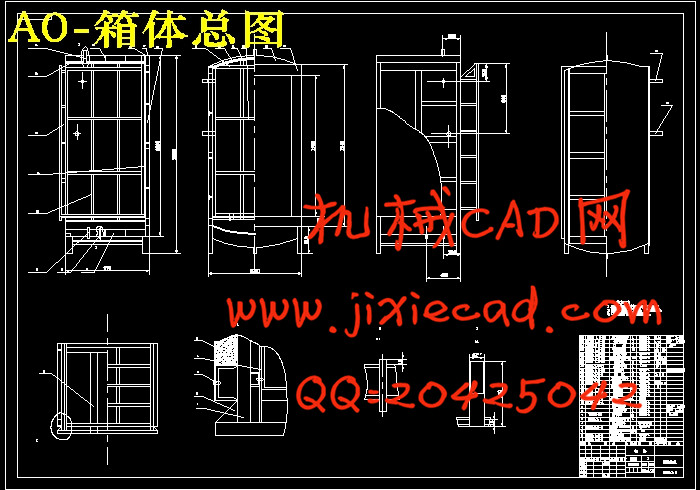

四、复蒸柜箱体机构设计 12

1﹑复蒸柜结构的设计 12

2、 箱架焊合件 13

3﹑进排气方案的确认 14

4﹑箱体上下结构的确定 15

5、箱架的总成 16

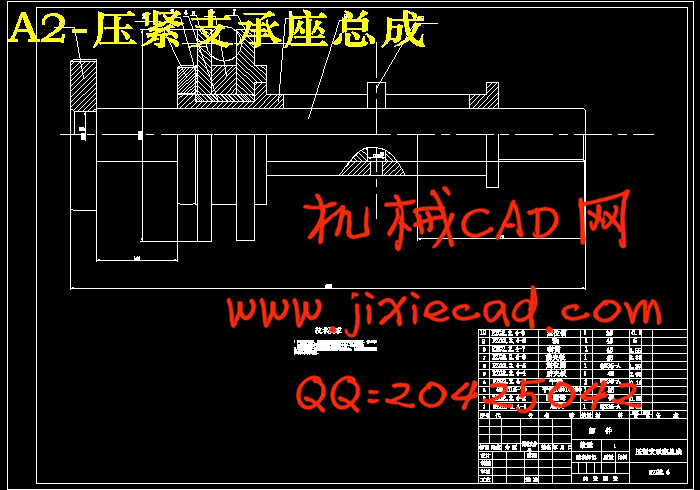

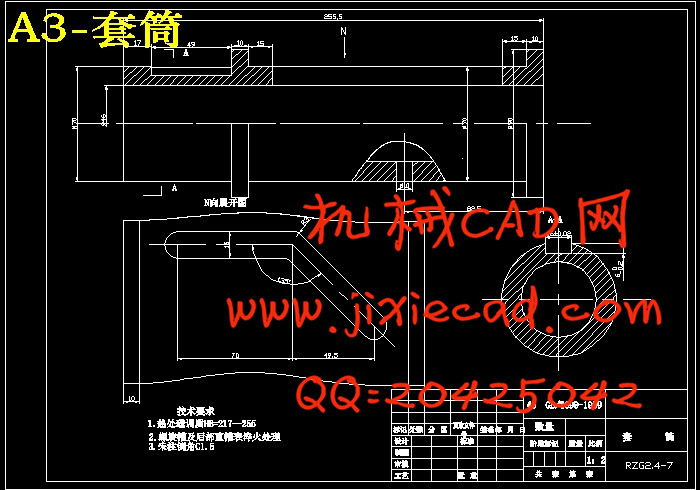

五、 压紧机构 17

5.1 压紧机构的选择 17

5.2 作用点的确定 17

5.3 压紧机构结构的结构原理 19

5.4 压紧机构结构的确定 12

六、参考文献 23