设计简介

啤酒贴标机

摘 要

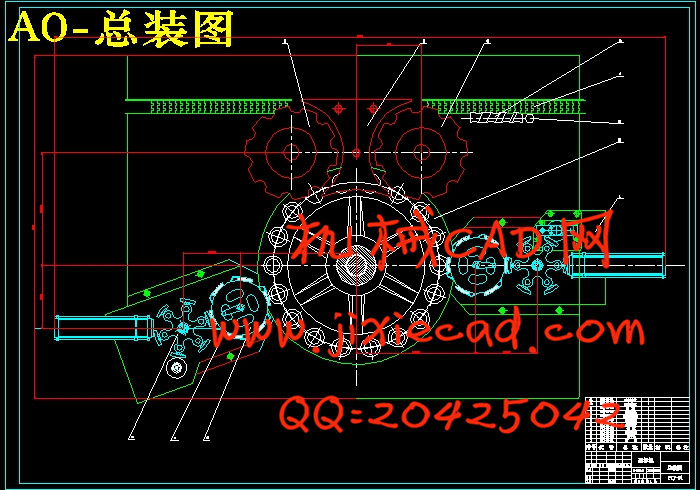

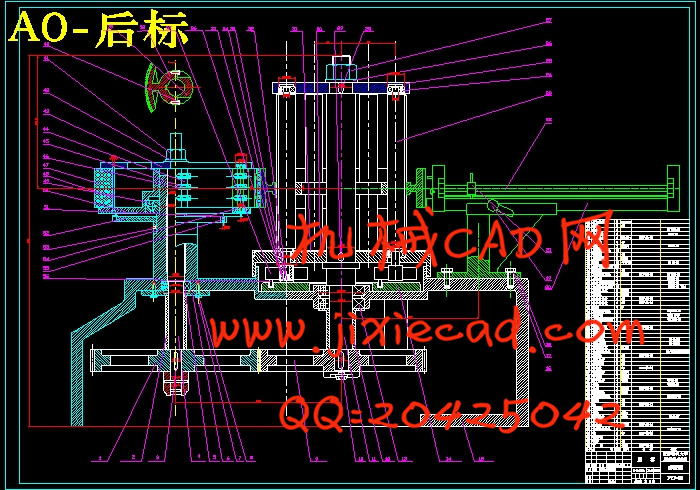

本设计主要介绍了一种包装机械,贴标机的工作原理及(后标部分)主要零部件的设计过程,对其传动系统进行设计比校核,且对本次设计有重大影响(凸轮)分瓶供送螺杆进行了详细的计算设计。本次设计主要用于贴圆柱身瓶的纸质标签。

本机主要有托瓶台、进瓶星轮、前后标签盒,其中包括前后取标装置、松标装置、胶滚、刮胶板等部件。

本机的特点是能够完成自动贴标、抚平等工作,生产效率高。主要技术特点:输瓶带与本机同步驱动全自动工作进度控制,胶水薄膜厚度有可调机构控制,无瓶——无胶——无标签电子测距装置。

关键词:自动,贴标

Beer labeler

ABSTRACT

This design has chiefly been introduced one kind of packing machinery ,and the work principle of mark machine reaches (back marks part)chiefly design process of parts,design the school and examine to his transmission system ,and to this have great to influence branch bottle supplies the stud sending has been in progress detail the calculation design .the major paper nature that is used to paste the cylinder body bottle of this design.

This machine chiefly holds in the palm bottle platform and advances a bottle star wheel and from beginning to end label box is taken the mark device around among them including and send mark device and glue rolls and scrapes the parts such as offset plate etc .The characteristic of this machine is accomplish pasting voluntarily marking and comforts equal work ,and production efficiency is high .

The major technology characteristic :Losing the bottle belt control with the full automatic working rate of progress of synchronical drive of this machine ,and that mucilage film thickness has can transfer the organization to control,and does not have bottle-nothing glue-nothing label electronics distance measuring equipment.

KEY WORDS: Automation, Being pasted marks

目 录

摘要 ……………………………………………………………………..…………....I

ABSTRACT ………………………………………………………………………….II

1 绪论………………………………………………………………………………...1

1.1贴标机简介……………………………………………………………….....1

1.2贴标机的发展现状…………………………………………………….....…2

2 典型贴标机械…………………………………………………………………...…4

2.1直线式贴标机…………………………………………..…………………...4

2.2回转式贴标机………………………………………..……………………...5

3 贴标机的主要装置………………...……………………………………………... 6

3.1 标签供送装置….………………………………………..……………...…..6

3.2 标签传送装置……………………………………………………………....6

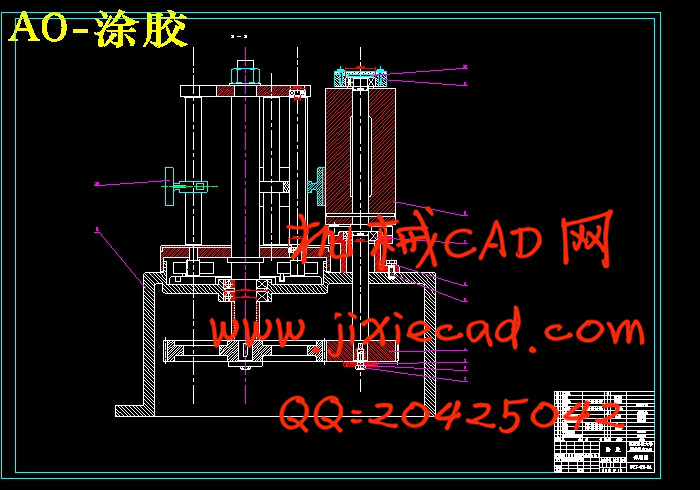

3.3 涂胶装置………………………………………………………………...….7

3.4 贴标整理装置………………………………………………………..……..7

3.5 检测连锁控制装置………………………………………………………....7

3.6 装置的总体设计……………………………………………………..……..7

4 贴标机的设计计算……………………..………………………………………...10

4.1任务分析…………………………………………………………….….….10

4.2 回转式贴标机的工作原理………………………………………….….…11

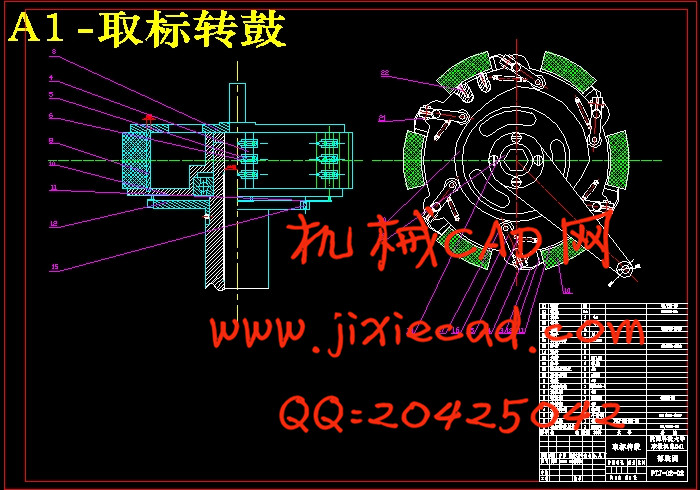

4.3取标机构的工作原理………………………………………………….......11

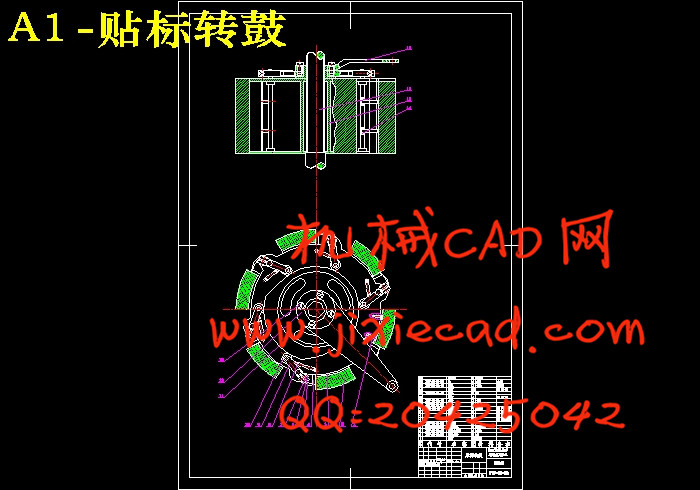

4.4 贴标机构的工作运动计算……………………………………………..…12

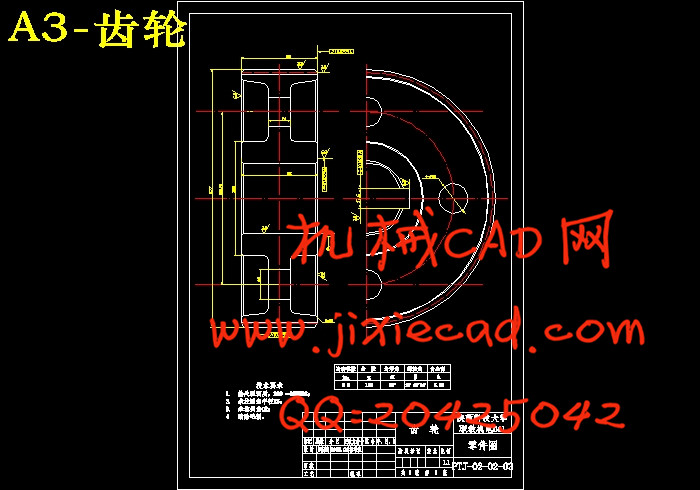

5 主要零部件设计计算………………………………………………………….....14

5.1 基本尺寸计算………………………………………………………...…...14

5.2 部分机构设计………………………………………………...…………...14

6 设计说明……………………………….…………………………………………22

6.1 夹标装置………………………………………………………………......22

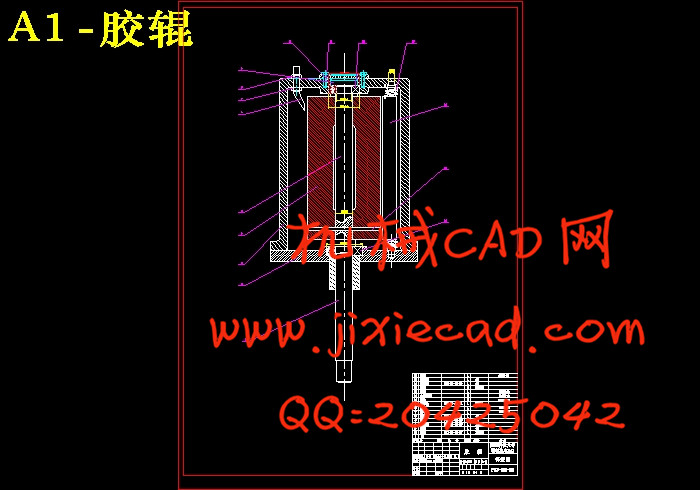

6.2 胶辊装置…………………………………………………………..……....22

6.3 传动装置………………...……………………………………………..….22

7 使用说明………………………………………..…………………………….…..23

总结……...…………………………………………………………………………..25

致谢………………….………………………………………………………………26

参考文献…...………………………………………………………………………..27

摘 要

本设计主要介绍了一种包装机械,贴标机的工作原理及(后标部分)主要零部件的设计过程,对其传动系统进行设计比校核,且对本次设计有重大影响(凸轮)分瓶供送螺杆进行了详细的计算设计。本次设计主要用于贴圆柱身瓶的纸质标签。

本机主要有托瓶台、进瓶星轮、前后标签盒,其中包括前后取标装置、松标装置、胶滚、刮胶板等部件。

本机的特点是能够完成自动贴标、抚平等工作,生产效率高。主要技术特点:输瓶带与本机同步驱动全自动工作进度控制,胶水薄膜厚度有可调机构控制,无瓶——无胶——无标签电子测距装置。

关键词:自动,贴标

Beer labeler

ABSTRACT

This design has chiefly been introduced one kind of packing machinery ,and the work principle of mark machine reaches (back marks part)chiefly design process of parts,design the school and examine to his transmission system ,and to this have great to influence branch bottle supplies the stud sending has been in progress detail the calculation design .the major paper nature that is used to paste the cylinder body bottle of this design.

This machine chiefly holds in the palm bottle platform and advances a bottle star wheel and from beginning to end label box is taken the mark device around among them including and send mark device and glue rolls and scrapes the parts such as offset plate etc .The characteristic of this machine is accomplish pasting voluntarily marking and comforts equal work ,and production efficiency is high .

The major technology characteristic :Losing the bottle belt control with the full automatic working rate of progress of synchronical drive of this machine ,and that mucilage film thickness has can transfer the organization to control,and does not have bottle-nothing glue-nothing label electronics distance measuring equipment.

KEY WORDS: Automation, Being pasted marks

目 录

摘要 ……………………………………………………………………..…………....I

ABSTRACT ………………………………………………………………………….II

1 绪论………………………………………………………………………………...1

1.1贴标机简介……………………………………………………………….....1

1.2贴标机的发展现状…………………………………………………….....…2

2 典型贴标机械…………………………………………………………………...…4

2.1直线式贴标机…………………………………………..…………………...4

2.2回转式贴标机………………………………………..……………………...5

3 贴标机的主要装置………………...……………………………………………... 6

3.1 标签供送装置….………………………………………..……………...…..6

3.2 标签传送装置……………………………………………………………....6

3.3 涂胶装置………………………………………………………………...….7

3.4 贴标整理装置………………………………………………………..……..7

3.5 检测连锁控制装置………………………………………………………....7

3.6 装置的总体设计……………………………………………………..……..7

4 贴标机的设计计算……………………..………………………………………...10

4.1任务分析…………………………………………………………….….….10

4.2 回转式贴标机的工作原理………………………………………….….…11

4.3取标机构的工作原理………………………………………………….......11

4.4 贴标机构的工作运动计算……………………………………………..…12

5 主要零部件设计计算………………………………………………………….....14

5.1 基本尺寸计算………………………………………………………...…...14

5.2 部分机构设计………………………………………………...…………...14

6 设计说明……………………………….…………………………………………22

6.1 夹标装置………………………………………………………………......22

6.2 胶辊装置…………………………………………………………..……....22

6.3 传动装置………………...……………………………………………..….22

7 使用说明………………………………………..…………………………….…..23

总结……...…………………………………………………………………………..25

致谢………………….………………………………………………………………26

参考文献…...………………………………………………………………………..27