设计简介

随着工业水平的发展,重要的大型焊接结构件的应用越来越多,其中大量的焊接工作必须在现场作业,如集装箱波纹板焊接机器人、大型舰船舱体、甲板的焊接、大型球罐(储罐)的焊接等。而这些焊接场合下,焊接机器人要适应焊缝的变化,才能做到提高焊接自动化的水平。无疑,将机器人技术和焊缝跟踪技术结合将有效地解决大型结构件野外作业的自动化焊接难题。因此机器人的设计对于解决这一难题至关重要。

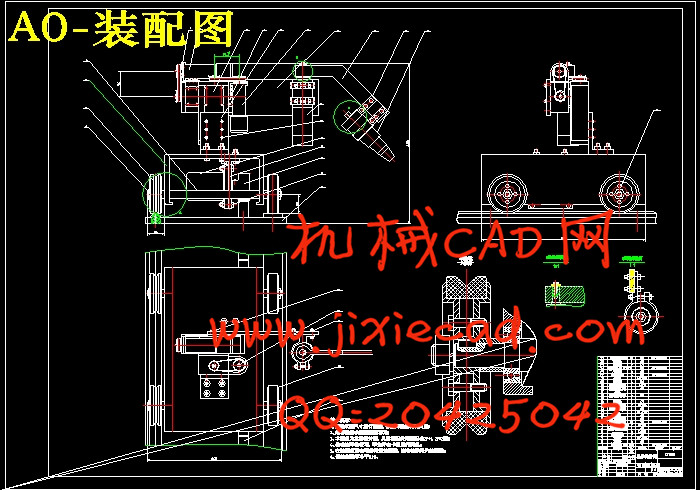

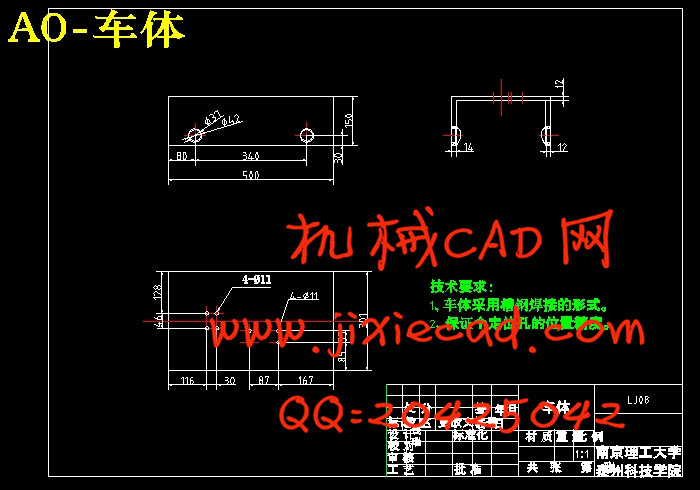

本课题主要完成机器人运动学的逆解、车体的总体设计、电机的选择等方面。主要从机器人运动学逆解的角度完成一个周期内的运动学逆解,求出三个关节应按照什么运动规律进行运动,还有三个关节的运动之间的函数关系,进而完成对整个机器人的总体设。通过对小车的受力分析完成对车轮、车体的设计。根据实际操作中遇到的问题对完成对电机的选择。最后对所选的齿轮进行校核,使之能完成具体的操作要求。

关键词 机器人技术 机构设计 运动学逆解 强度校核

Abstract

With the development of industrial level, it is important to large-scale structure of the application of welding more and more, including a large number of welding operations must be at the scene, such as robot welding corrugated containers, large ship cabin, the deck of the welding, a large spherical tank (tank), such as welding. These welding occasion, the welding robot to adapt to changes in weld, welding can be done to improve the level of automation. There is no doubt that technology and robot seam tracking technology to effectively solve large-scale structure of the automation field welding problems. Therefore the design of the robot is essential for the solution to this problem.

The main subject of the completion of the robot inverse kinematics solution, the body design, the choice of motor and so on. The main robot inverse kinematics from the perspective of a cycle through the end of the known actuator position posture against the solution of the coordinates of the joints, and then completed the whole set up of the robot. Force analysis of the completed car wheels, car body design. According to the actual problems encountered in the operation of the completion of the motor choice. Finally, the gear selected for verification, so that it can complete the specific operating requirements.

Keywords Robot technology Organization is designed The kinematics goes against solution he intensity is proofreaded

目 录

1 绪论 1

1.1 选题的依据及意义 1

1.2 研究现状及发展趋势 1

1.3 本课题的研究设计内容及方法 3

1.4 课题的完成情况 5

2 焊接机器人机构运动学分析 6

2.1 运动学分析数学基础-齐次变换(D-H变换) 6

2.2 变换方程的建立 7

2.3 运动学分析处理方法 9

2.4 逆解过程 10

2.5 本章小结 28

3 结构设计 30

3.1 小车行走结构设计 30

3.2 摆动关节电机选择 36

3.3 本章小结 36

结束语 38

致 谢 39

参考文献 40

附 录 41

本课题主要完成机器人运动学的逆解、车体的总体设计、电机的选择等方面。主要从机器人运动学逆解的角度完成一个周期内的运动学逆解,求出三个关节应按照什么运动规律进行运动,还有三个关节的运动之间的函数关系,进而完成对整个机器人的总体设。通过对小车的受力分析完成对车轮、车体的设计。根据实际操作中遇到的问题对完成对电机的选择。最后对所选的齿轮进行校核,使之能完成具体的操作要求。

关键词 机器人技术 机构设计 运动学逆解 强度校核

Abstract

With the development of industrial level, it is important to large-scale structure of the application of welding more and more, including a large number of welding operations must be at the scene, such as robot welding corrugated containers, large ship cabin, the deck of the welding, a large spherical tank (tank), such as welding. These welding occasion, the welding robot to adapt to changes in weld, welding can be done to improve the level of automation. There is no doubt that technology and robot seam tracking technology to effectively solve large-scale structure of the automation field welding problems. Therefore the design of the robot is essential for the solution to this problem.

The main subject of the completion of the robot inverse kinematics solution, the body design, the choice of motor and so on. The main robot inverse kinematics from the perspective of a cycle through the end of the known actuator position posture against the solution of the coordinates of the joints, and then completed the whole set up of the robot. Force analysis of the completed car wheels, car body design. According to the actual problems encountered in the operation of the completion of the motor choice. Finally, the gear selected for verification, so that it can complete the specific operating requirements.

Keywords Robot technology Organization is designed The kinematics goes against solution he intensity is proofreaded

目 录

1 绪论 1

1.1 选题的依据及意义 1

1.2 研究现状及发展趋势 1

1.3 本课题的研究设计内容及方法 3

1.4 课题的完成情况 5

2 焊接机器人机构运动学分析 6

2.1 运动学分析数学基础-齐次变换(D-H变换) 6

2.2 变换方程的建立 7

2.3 运动学分析处理方法 9

2.4 逆解过程 10

2.5 本章小结 28

3 结构设计 30

3.1 小车行走结构设计 30

3.2 摆动关节电机选择 36

3.3 本章小结 36

结束语 38

致 谢 39

参考文献 40

附 录 41