设计简介

摘 要

驱动桥作为汽车四大总成之一,它的性能的好坏直接影响整车性能,而对于各种汽车显得尤为重要。当采用大功率发动机输出大的转矩以满足目前载重汽车的快速、重载的高效率、高效益的需要时,必须要搭配一个高效、可靠的驱动桥。

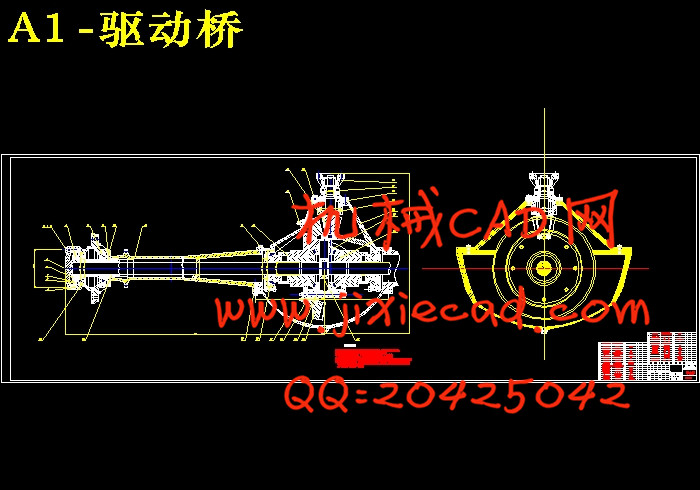

驱动桥处于动力传动系的末端,其基本功能是增大由传动轴或变速器传来的转矩,并将动力合理的分配给左、右车轮,另外还承受作用于路面和车架或车身之间的垂直力、纵向力和横向力。驱动桥一般由主减速器、差速器、车轮传动装置和驱动桥壳等组成。汽车驱动桥是汽车的重大总成,承载着汽车的满载簧荷重及地面经车轮、车架及承载式车身经悬架给予的铅垂力、纵向力、横向力及其力矩,以及冲击载荷;驱动桥还传递着传动系中的最大转矩,桥壳还承受着反作用力矩。汽车驱动桥结构型式和设计参数除对汽车的可靠性与耐久性有重要影响外,还对汽车的行驶性能如动力性、经济性、平顺性、通过性、机动性和操作稳定性等有直接影响。

本设计参照传统驱动桥的设计方法进行了载重汽车驱动桥的设计。本设计首先确定主要部件的结构型式和主要设计参数;然后参考类似驱动桥的结构,确定出总体设计方案;最后对主,从动锥齿轮,差速器圆锥行星齿轮,半轴齿轮,全浮式半轴和整体式桥壳的强度进行校核以及对支承轴承进行了寿命校核。本设计不是采用传统的双曲面锥齿轮作为载重汽车的主减速器而是采用弧齿锥齿轮,希望这能作为一个课题继续研究下去。

关键字:驱动桥;驱动桥;单级减速器;锥齿轮;半轴

ABSTRACT

Drive axle is the one of automobile four important assemblies. It` performance directly influence on the entire automobile,especially for the heavy truck .Because using the big power engine with the big driving torque satisfied the need of high speed,heavy-loaded, high efficiency, high benefit today`heavy truck, single reduction final drive axle is.

Driving axle in power transmission, the basic function of the end of the drive shaft or transmission increases is by the torque,and from the power of the reasonable assigned to the right and left the drive wheels, also take effect on the pavement and frame or bo dy between the vertical and lateral and longitudinal strength and power. Generally by the reducer drive,differential and wheel transmission device and driving axle shell etc.car driving axle is the major car assembly, carrying a full load and reed car wheels.frame, and the ground monocoque body the suspension of the lead to vertical force, longitudinal force, transverse force and torque,and impact load; Driving axle also passed the transmission of the maximum torque, bridge is under adverse effect moment shell.car driving axle structure and design parameters in addition to the rellability of the parameters in addition to the reliablilty of the automobile and durability has a significant effect on the outside , also for the automobile driving performance such as power, economy smooth, through the sex,mobility and exercise has a direct impact on the dynamic stability, ect

This design following the traditional designing method of the drive axle. First ,make up the main parts`structure and the key designing parameters; thus reference to the similar driving axle structure , decide the entire designing project ; fanially check the strength of the axle drive bevel pinion ,bevel gear wheel , the differentional planetary pinion, differential side gear , full-floating axle shaft and the banjo axle housing , and the life expection of carrier bearing . The designing take the spiral bevel gear for the tradional hypoid gear ,as the gear type of heavy truck`s final drive,with the expection of the question being discussed, further .

Key words: Drive Axle; Rrducer; Differential; Automotive Design; Half Shaft

目 录

摘要 ...................................................................I

ABSTRACT....................................................................II

第1章 绪 论.........................................................1

1.1 本课题的目的和意义..............................................1

1.2 驱动桥的分类...................................................1

1.2.1 非断开式驱动桥..............................................2

1.2.2 断开式驱动桥................................................2

1.2.3多桥驱动的布置..............................................3

1.3 主要内容.................................................................3

第2章 驱动桥结构方案分析...........................................5

2.1 主减速器的类型...................................................5

2.2 设计驱动桥的基本要求...........................................5

2.3非断开式驱动桥....................................................6

2.4 断开式驱动桥..........................................................7

2.5本章小结...................................................7

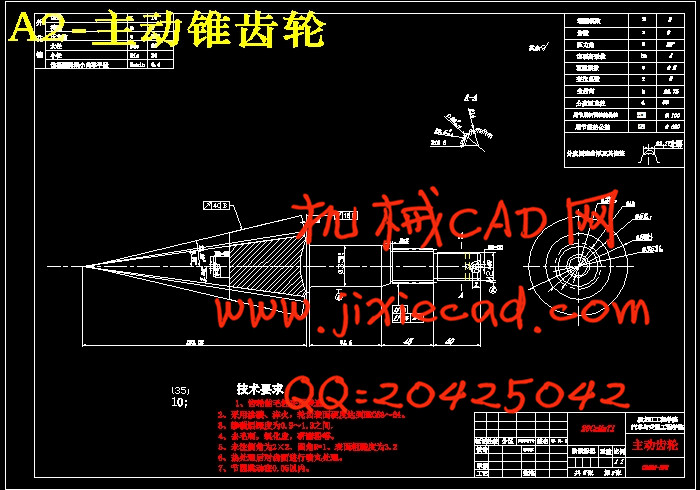

第3章 主减速器设计..................................................8

3.1 主减速器的结构形式.............................................8

3.1.1 主减速器的齿轮类型..........................................8

3.1.2 主减速器的减速形式.......................................8

3.1.3 主减速器主,从动锥齿轮的支撑形式..........................8

3.2 主减速比的计算...............................9

3.2.1 主减速器计算载荷的确定.....................................9

3.2.2 主减速器基本参数的选择....................................10

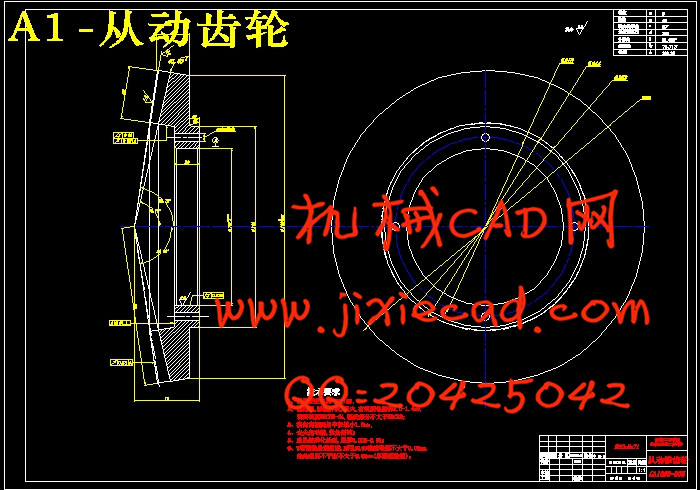

3.2.3主减速器圆弧锥齿轮几何尺寸计算............................12

3.2.4 主减速器圆弧锥齿轮的强度计算..............................14

3.2.5 主减速器轴承的计算........................................17

3.3 本章小结..............................................................22

第4章 差速器设计...................................................23

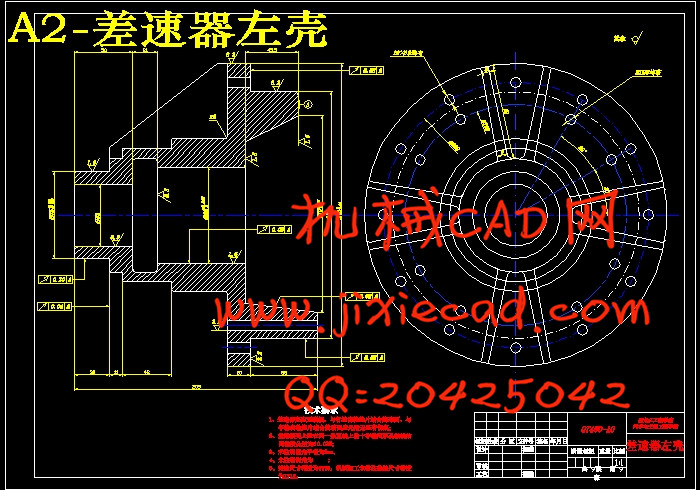

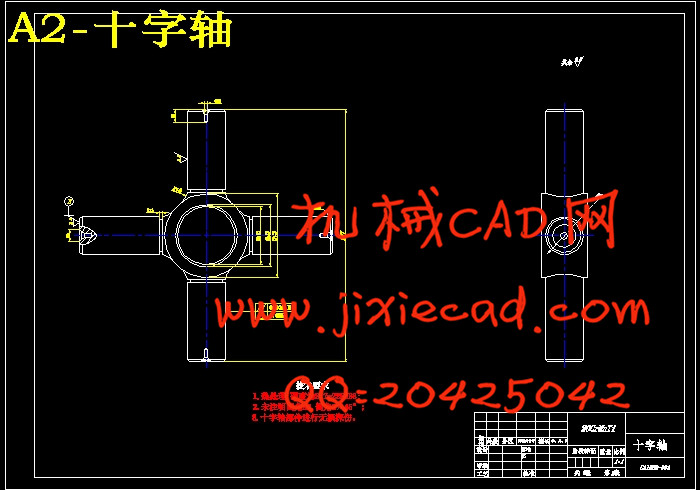

4.1 对称式圆锥行星齿轮差速器的结构............................23

4.2 对称式圆锥行星齿轮差速器的设计................................23

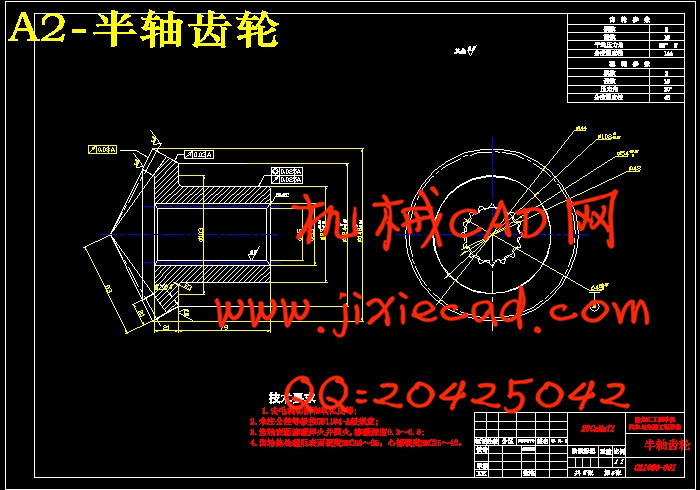

4.2. 1差速器齿轮的基本参数选择...................................24

4.2.2 差速器齿轮的几何计算.......................................26

4.2.3 差速器齿轮的强度计算.......................................28

4.3本章小结...............................................................29

第5章 驱动半轴的设计...............................................30

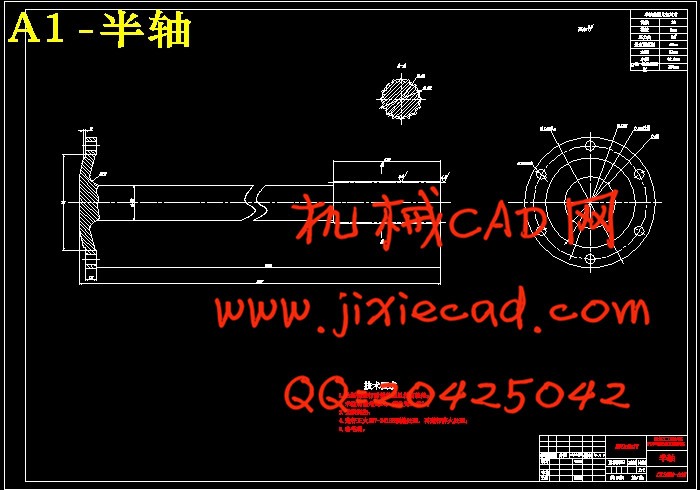

5.1 全浮式半轴计算载荷的确定........................................31

5.2 全浮式半轴的杆部直径的初选......................................31

5.3 全浮式半轴的强度计算.........................................32

5.4半轴花键的强度计算.........................................32

5.5 本章小结...............................................................33

第6章 驱动桥壳的设计...............................................34

6.1 铸造整体式桥壳的结构..........................................34

6.2 桥壳的受力分析与强度计算......................................35

6.2.1 在不平路面冲击载荷作用下桥壳强度计算.......................36

6.2.2 汽车以最大牵引力行驶时的桥壳强度计算.......................36

6.2.3 汽车紧急制动时的桥壳强度计算...............................38

6.3 本章小结...............................................................40

结论..................................................................41

致谢...............................................................42

参考文献..............................................................43

附录..................................................................44

驱动桥作为汽车四大总成之一,它的性能的好坏直接影响整车性能,而对于各种汽车显得尤为重要。当采用大功率发动机输出大的转矩以满足目前载重汽车的快速、重载的高效率、高效益的需要时,必须要搭配一个高效、可靠的驱动桥。

驱动桥处于动力传动系的末端,其基本功能是增大由传动轴或变速器传来的转矩,并将动力合理的分配给左、右车轮,另外还承受作用于路面和车架或车身之间的垂直力、纵向力和横向力。驱动桥一般由主减速器、差速器、车轮传动装置和驱动桥壳等组成。汽车驱动桥是汽车的重大总成,承载着汽车的满载簧荷重及地面经车轮、车架及承载式车身经悬架给予的铅垂力、纵向力、横向力及其力矩,以及冲击载荷;驱动桥还传递着传动系中的最大转矩,桥壳还承受着反作用力矩。汽车驱动桥结构型式和设计参数除对汽车的可靠性与耐久性有重要影响外,还对汽车的行驶性能如动力性、经济性、平顺性、通过性、机动性和操作稳定性等有直接影响。

本设计参照传统驱动桥的设计方法进行了载重汽车驱动桥的设计。本设计首先确定主要部件的结构型式和主要设计参数;然后参考类似驱动桥的结构,确定出总体设计方案;最后对主,从动锥齿轮,差速器圆锥行星齿轮,半轴齿轮,全浮式半轴和整体式桥壳的强度进行校核以及对支承轴承进行了寿命校核。本设计不是采用传统的双曲面锥齿轮作为载重汽车的主减速器而是采用弧齿锥齿轮,希望这能作为一个课题继续研究下去。

关键字:驱动桥;驱动桥;单级减速器;锥齿轮;半轴

ABSTRACT

Drive axle is the one of automobile four important assemblies. It` performance directly influence on the entire automobile,especially for the heavy truck .Because using the big power engine with the big driving torque satisfied the need of high speed,heavy-loaded, high efficiency, high benefit today`heavy truck, single reduction final drive axle is.

Driving axle in power transmission, the basic function of the end of the drive shaft or transmission increases is by the torque,and from the power of the reasonable assigned to the right and left the drive wheels, also take effect on the pavement and frame or bo dy between the vertical and lateral and longitudinal strength and power. Generally by the reducer drive,differential and wheel transmission device and driving axle shell etc.car driving axle is the major car assembly, carrying a full load and reed car wheels.frame, and the ground monocoque body the suspension of the lead to vertical force, longitudinal force, transverse force and torque,and impact load; Driving axle also passed the transmission of the maximum torque, bridge is under adverse effect moment shell.car driving axle structure and design parameters in addition to the rellability of the parameters in addition to the reliablilty of the automobile and durability has a significant effect on the outside , also for the automobile driving performance such as power, economy smooth, through the sex,mobility and exercise has a direct impact on the dynamic stability, ect

This design following the traditional designing method of the drive axle. First ,make up the main parts`structure and the key designing parameters; thus reference to the similar driving axle structure , decide the entire designing project ; fanially check the strength of the axle drive bevel pinion ,bevel gear wheel , the differentional planetary pinion, differential side gear , full-floating axle shaft and the banjo axle housing , and the life expection of carrier bearing . The designing take the spiral bevel gear for the tradional hypoid gear ,as the gear type of heavy truck`s final drive,with the expection of the question being discussed, further .

Key words: Drive Axle; Rrducer; Differential; Automotive Design; Half Shaft

目 录

摘要 ...................................................................I

ABSTRACT....................................................................II

第1章 绪 论.........................................................1

1.1 本课题的目的和意义..............................................1

1.2 驱动桥的分类...................................................1

1.2.1 非断开式驱动桥..............................................2

1.2.2 断开式驱动桥................................................2

1.2.3多桥驱动的布置..............................................3

1.3 主要内容.................................................................3

第2章 驱动桥结构方案分析...........................................5

2.1 主减速器的类型...................................................5

2.2 设计驱动桥的基本要求...........................................5

2.3非断开式驱动桥....................................................6

2.4 断开式驱动桥..........................................................7

2.5本章小结...................................................7

第3章 主减速器设计..................................................8

3.1 主减速器的结构形式.............................................8

3.1.1 主减速器的齿轮类型..........................................8

3.1.2 主减速器的减速形式.......................................8

3.1.3 主减速器主,从动锥齿轮的支撑形式..........................8

3.2 主减速比的计算...............................9

3.2.1 主减速器计算载荷的确定.....................................9

3.2.2 主减速器基本参数的选择....................................10

3.2.3主减速器圆弧锥齿轮几何尺寸计算............................12

3.2.4 主减速器圆弧锥齿轮的强度计算..............................14

3.2.5 主减速器轴承的计算........................................17

3.3 本章小结..............................................................22

第4章 差速器设计...................................................23

4.1 对称式圆锥行星齿轮差速器的结构............................23

4.2 对称式圆锥行星齿轮差速器的设计................................23

4.2. 1差速器齿轮的基本参数选择...................................24

4.2.2 差速器齿轮的几何计算.......................................26

4.2.3 差速器齿轮的强度计算.......................................28

4.3本章小结...............................................................29

第5章 驱动半轴的设计...............................................30

5.1 全浮式半轴计算载荷的确定........................................31

5.2 全浮式半轴的杆部直径的初选......................................31

5.3 全浮式半轴的强度计算.........................................32

5.4半轴花键的强度计算.........................................32

5.5 本章小结...............................................................33

第6章 驱动桥壳的设计...............................................34

6.1 铸造整体式桥壳的结构..........................................34

6.2 桥壳的受力分析与强度计算......................................35

6.2.1 在不平路面冲击载荷作用下桥壳强度计算.......................36

6.2.2 汽车以最大牵引力行驶时的桥壳强度计算.......................36

6.2.3 汽车紧急制动时的桥壳强度计算...............................38

6.3 本章小结...............................................................40

结论..................................................................41

致谢...............................................................42

参考文献..............................................................43

附录..................................................................44