设计简介

摘 要

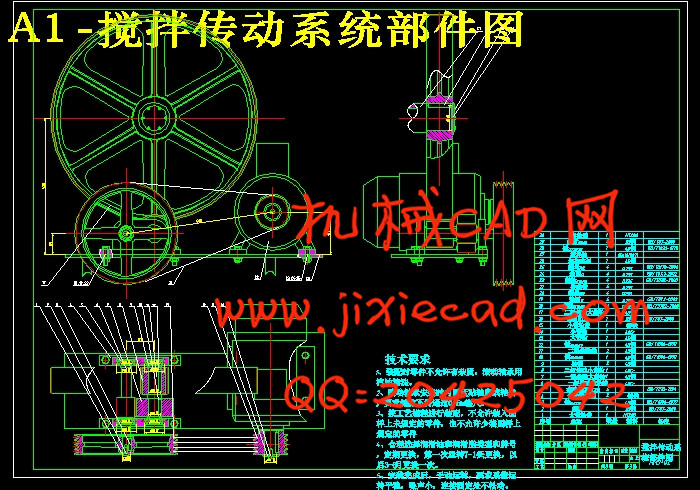

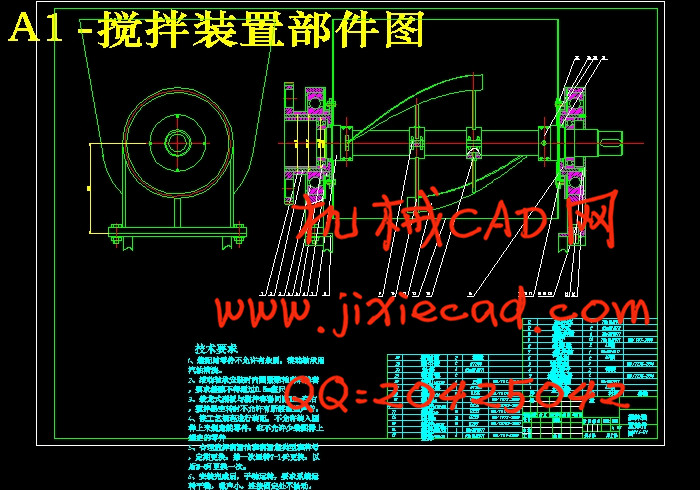

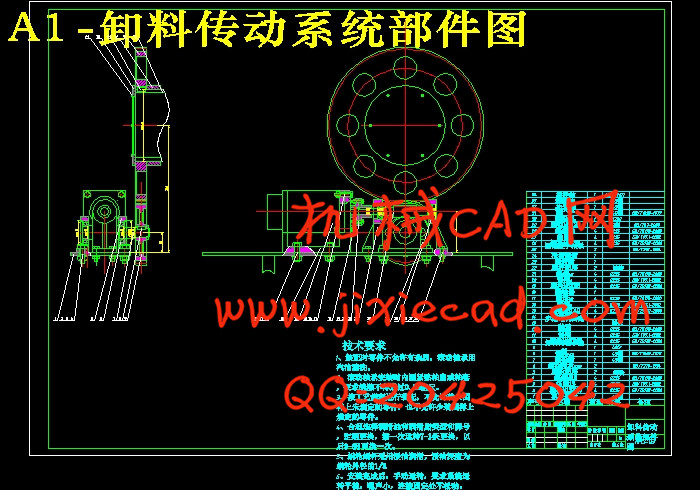

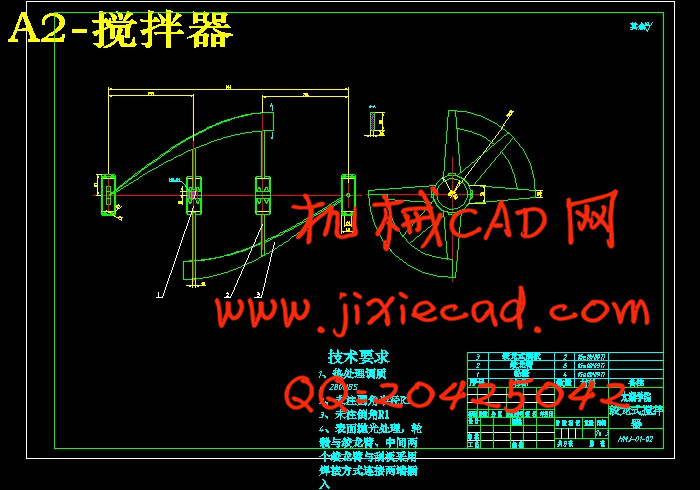

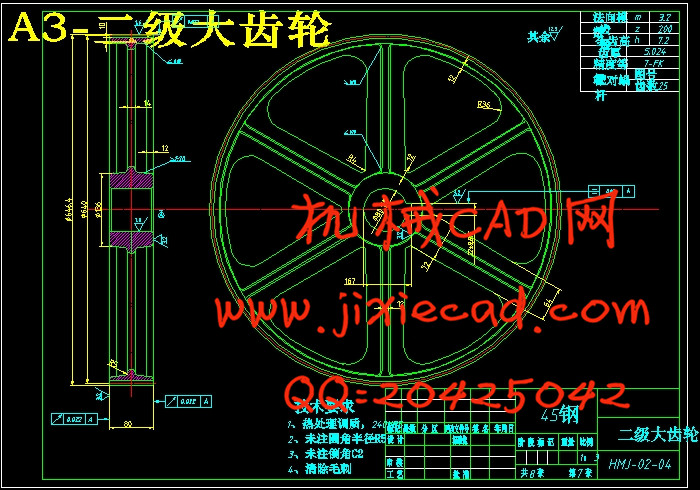

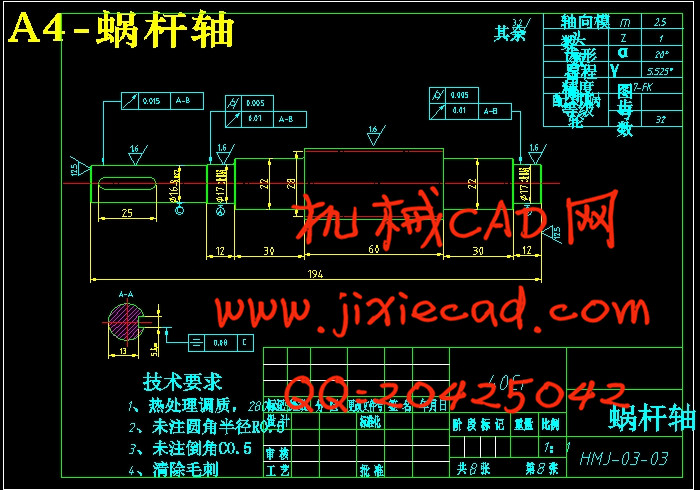

和面机的作用是进行各种性质不同面团的调制,即将各种原、辅料加水搅拌,调制成既符合质量要求,又适台机械加工成形的面团,主要用于面包、饼干、糕点、膨松食品、面条、饺子等食品的加工,其混合好的面团质量直接影响到食品的品质。设计对和面机,包括和面机的工作原理、分类、各类结构组成、操作要求和方法、常见故障和排除方法、和面机的维护和保养、以及和面机的技术要求进行了概述,并详细设计了50kg/次和面机,包括搅拌装置、搅拌传动系统、卸料传动系统并画出了和面机设备总装图,部分重点零件图及部件图。设计机型采用双绞龙卧式和面机,一次调粉容量为50kg,适合调制各种面团。其设计过程参照了T-66型卧式和面机,主要特点是搅拌系统选择了绞龙式搅拌器;搅拌系统减速装置选用三相异步电机,采用带轮和两级齿轮传动;翻缸系统减速装置选用步进电机,采用用蜗轮蜗杆传动及齿轮传动。和面机结构简单紧凑,操作简单,维护方便,和面效率较高。

关键词:绞龙;翻转卸料;和面机

Abstract

Dough kneader's function is carrying on the modulation of each pasta with different nature , filling various primaries with water, making since of quality request and suitable machine work taking shape. It mainly used for the transform of bread, biscuit, pastry and Peng loose provisionses, such as provisions, noodles and dumpling...etc. The quality of maxed dough directly effects the character of provisions. The design aim at dough kneader, Including the operate priniple, sort, each kind of structure of the including, dough kneader composition, operation request, the maintenance and upkeep, the familiar fault and removal method, the support and maintain of dough kneader, The technique requests of dough kneader. Detailed design dough kneader of 50 kgs/time, including mix device, mix drive system, unloading drive system and drawing out the total assembling drawing, some important parts and part assembling drawing. In the design, dough kneader uses double twist, adjust powder capacity to 50 kgs at a time, suitable to make various pasta. Its design process according to type T-66 lay type and surfaced machine. the main features is to mix blend system to select double the lay Long Shi's stirrer. Turn over an urn of system reduction gear choice stepping dynamo, using worm gear worm drive and gear drive. Dough kneader structure simple tightly packed, operate in brief, support convenience, is as higher as surface efficiency.

Key words: dragon; the rollover unloads to anticipate; dough kneader

目 录

摘 要 IIIAbstract IV

目 录 V

1 绪论 1

1.1 本课题的研究内容和意义 1

1.2 国内外的发展概况 1

1.3 本课题应达到的要求 1

2 绞龙式和面机设计 2

2.1 设计参考 2

2.1.1 和面机调制基本过程 2

2.1.2 和面机分类 2

2.1.3 和面机的主要零部件 4

2.2 绞龙卧式和面机设计 7

2.2.1 选择和面机容量,以每次调和面粉的重量为准 7

2.2.2 总体方案设计 7

2.2.3 搅拌装置设计 9

2.2.4 搅拌传动系统设计 12

2.2.5 翻缸装置设计 25

2.2.6 其它装置设计 32

2.2.7 绞龙式和面机装配图 32

3 和面机操作及故障分析 34

3.1 和面操作要求 34

3.2 和面操作方法 34

3.3 和面机常见故障及排除方法 35

4 和面机的维护和保养 36

4.1 机器设备保养的意义 36

4.2 机器设备保养等级的划分 36

5 和面机的技术要求 38

5.1 一般技术要求 38

5.2 工作条件 38

5.3 使用性能 38

5.4 主要零部件质量要求 38

5.5 装配要求 39

5.6 整机性能 39

5.7 电动机功率与耗电量 39

5.8 电气 39

5.9 外观要求 39

6 结论与展望 41

6.1 结论 41

6.2 不足之处及未来展望 41

致谢 42

参考文献 43