设计简介

街道护栏自动清洗机构(工作装置设计)

摘要

随着我国经济的快速发展,高等级公路的建设也逐步加快。为保证交通及车辆分道

行驶的安全性,高速公路都设置了防撞护栏。在护栏的使用过程中,由于车辆的尾气排

放、风沙雨水侵蚀及其它自然或人为原因,护栏表面会出现灰尘污染,久而久之还会出

现结垢,其不仅会使护栏标志不洁而失效,更容易造成交通事故,而且也会使其失去

美观,影响路容路貌。护栏的整洁关系到城市的市容市貌,也更是国家形象的体现。因

此护栏的清洗是各地环卫部门的重要工作。

目前国内护栏清洗作业多由人工完成,劳动强度大、作业效率低,并且大部分护栏

置于道路的中央,清洗时容易发生安全事故。因此,设计一种高效的护栏清洗车,不仅

具有宽广的市场空间,也具有良好的社会效益。

关键词:护栏;清洗车;滚刷;公路;机械

Automatic cleaning mechanism of street guardrails

(DESIGN OF DEVICE)

ABSTRACT

With the rapid development of our economy, the high grade highway construction speeded up. To ensure traffic and vehicle lane.Driving safety, highway guardrail are provided. In the process of using guardrail, due to vehicle exhaust.Put the wind, rain and other natural or man-made causes, guardrail surface will appear dust pollution, in the course of time will be a At this scale, it will not only make the guardrail mark unclean and failure, more likely to cause traffic accidents, but also make them lose the Beautiful, affect the appearance of road road. Guardrail clean related to the city's appearance, also is the embodiment of the image of the nation. Because of Cleaning the guardrail is an important work around the sanitation department..

At present, guardrail cleaning work done by hand, large labor intensity, low operation efficiency, and most of the guardrail.In the road central, prone to accidents when cleaning. Therefore, the design of an efficient cleaning vehicle, not only.Has a broad market space, but also have good social benefit.

Keywords: barrier; vehicle cleaning brush; highway; machinery;

目录

第一章 绪论…………………………………………………………….5

1.1课题背景与目的………………………………………………………….5

1.1.1课题背景…………………………………………………………5

1.1.2课题目的………………………………………………………….5

1.2国内外研究状况………………………………………………………….5

1.2.1国外现状………………………………………………………….5

1.2.2国内现状………………………………………………………….6

1.3发展趋势………………………………………………………………….6

第二章 护栏清洗机构的设计…………………………………..7

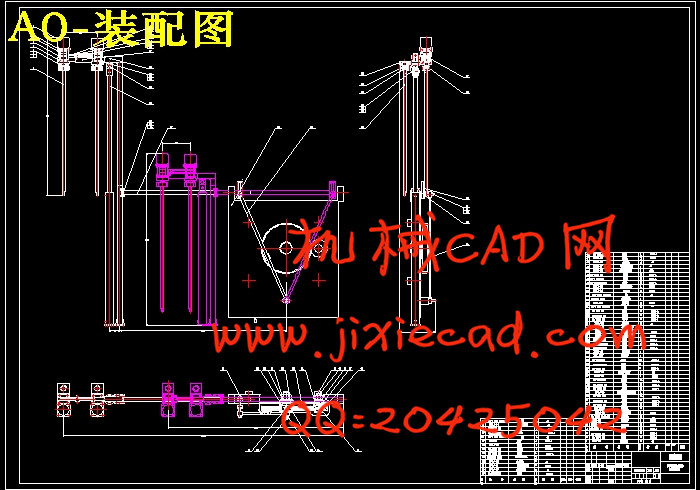

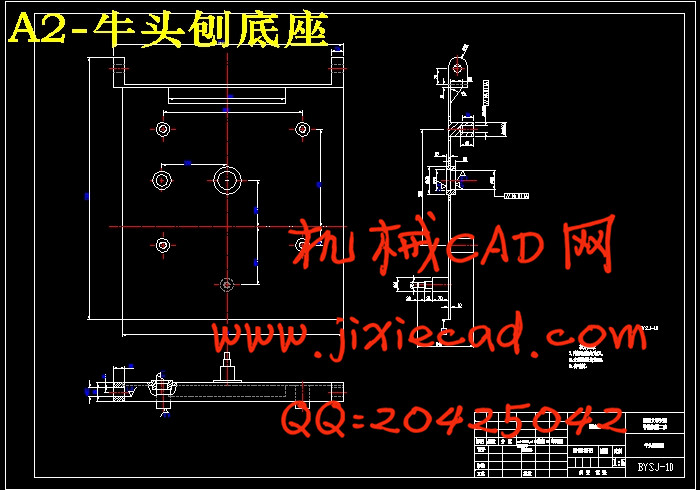

2.1工作装置设计…………………………………………………………….7

2.1.1工作速度的确定……………………………………………………………….7

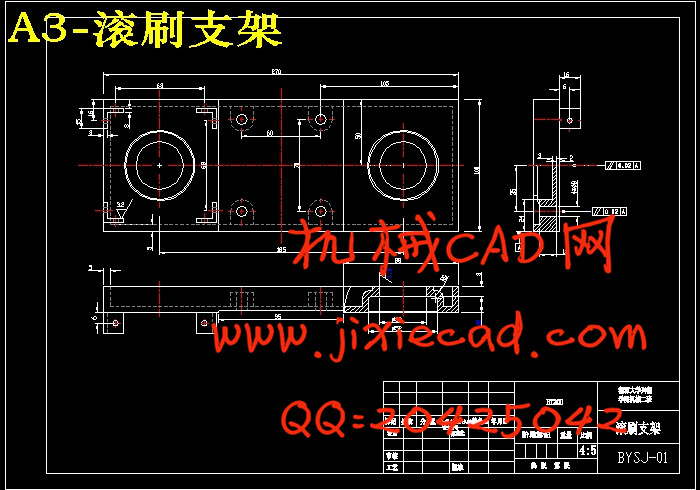

2.1.2滚刷结构参数及转速....................................................................7

2.1.3滚刷材料的选取............................................................................8

2.1.4滚刷电机的选取............................................................................9

2.2同步带传动的设计.....................................................................................10

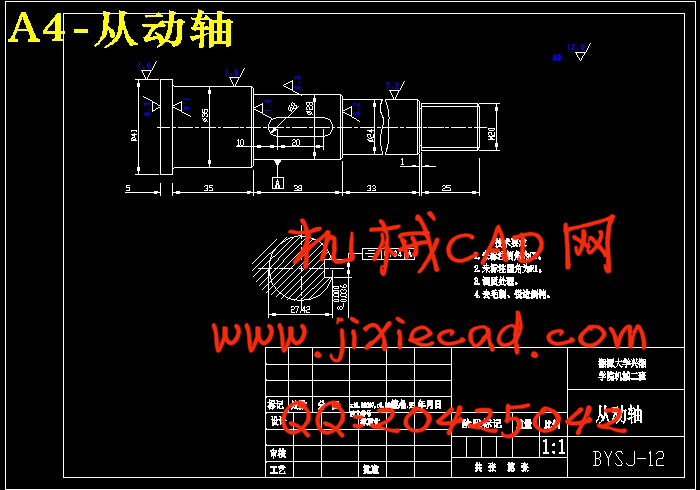

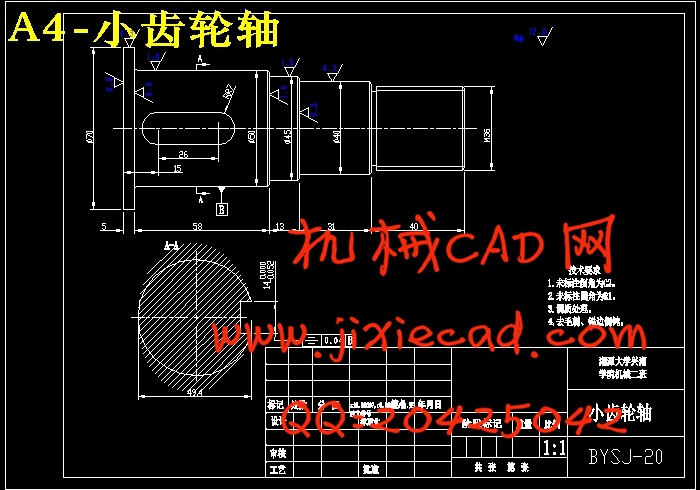

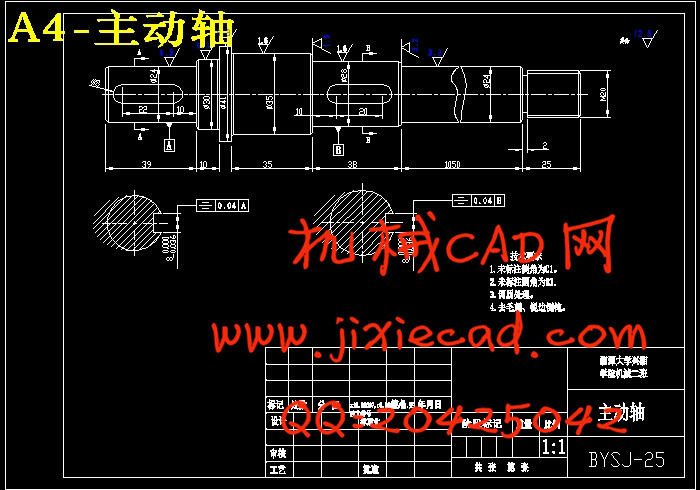

2.3滚刷轴的设计与计算.................................................................................13

2.4 横杆的设计与计算....................................................................................14

2.5提升液压缸的设计与计算..........................................................................18

2.6水平往复机构设计与分析..........................................................................20

第三章 结语.................................................................................................22

参考文献..........................................................................................................24

致谢....................................................................................................................25

摘要

随着我国经济的快速发展,高等级公路的建设也逐步加快。为保证交通及车辆分道

行驶的安全性,高速公路都设置了防撞护栏。在护栏的使用过程中,由于车辆的尾气排

放、风沙雨水侵蚀及其它自然或人为原因,护栏表面会出现灰尘污染,久而久之还会出

现结垢,其不仅会使护栏标志不洁而失效,更容易造成交通事故,而且也会使其失去

美观,影响路容路貌。护栏的整洁关系到城市的市容市貌,也更是国家形象的体现。因

此护栏的清洗是各地环卫部门的重要工作。

目前国内护栏清洗作业多由人工完成,劳动强度大、作业效率低,并且大部分护栏

置于道路的中央,清洗时容易发生安全事故。因此,设计一种高效的护栏清洗车,不仅

具有宽广的市场空间,也具有良好的社会效益。

关键词:护栏;清洗车;滚刷;公路;机械

Automatic cleaning mechanism of street guardrails

(DESIGN OF DEVICE)

ABSTRACT

With the rapid development of our economy, the high grade highway construction speeded up. To ensure traffic and vehicle lane.Driving safety, highway guardrail are provided. In the process of using guardrail, due to vehicle exhaust.Put the wind, rain and other natural or man-made causes, guardrail surface will appear dust pollution, in the course of time will be a At this scale, it will not only make the guardrail mark unclean and failure, more likely to cause traffic accidents, but also make them lose the Beautiful, affect the appearance of road road. Guardrail clean related to the city's appearance, also is the embodiment of the image of the nation. Because of Cleaning the guardrail is an important work around the sanitation department..

At present, guardrail cleaning work done by hand, large labor intensity, low operation efficiency, and most of the guardrail.In the road central, prone to accidents when cleaning. Therefore, the design of an efficient cleaning vehicle, not only.Has a broad market space, but also have good social benefit.

Keywords: barrier; vehicle cleaning brush; highway; machinery;

目录

第一章 绪论…………………………………………………………….5

1.1课题背景与目的………………………………………………………….5

1.1.1课题背景…………………………………………………………5

1.1.2课题目的………………………………………………………….5

1.2国内外研究状况………………………………………………………….5

1.2.1国外现状………………………………………………………….5

1.2.2国内现状………………………………………………………….6

1.3发展趋势………………………………………………………………….6

第二章 护栏清洗机构的设计…………………………………..7

2.1工作装置设计…………………………………………………………….7

2.1.1工作速度的确定……………………………………………………………….7

2.1.2滚刷结构参数及转速....................................................................7

2.1.3滚刷材料的选取............................................................................8

2.1.4滚刷电机的选取............................................................................9

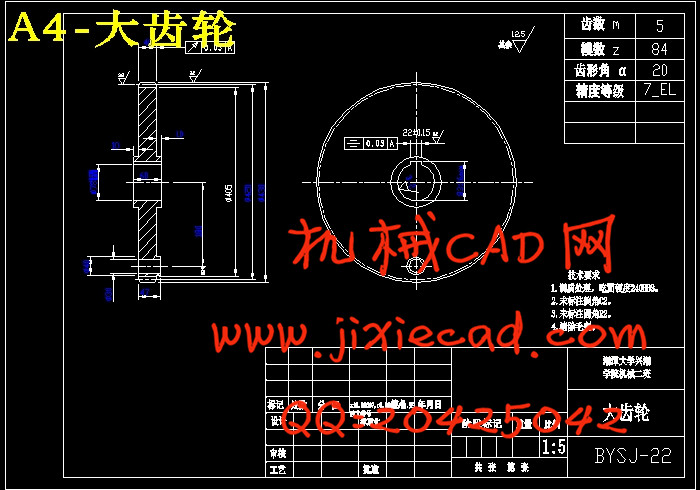

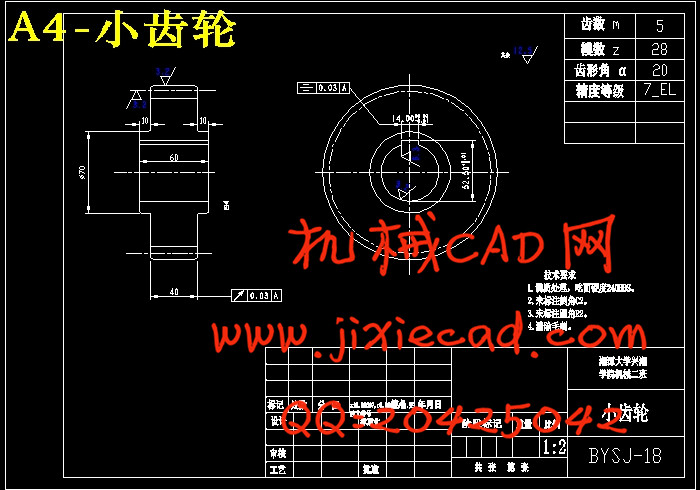

2.2同步带传动的设计.....................................................................................10

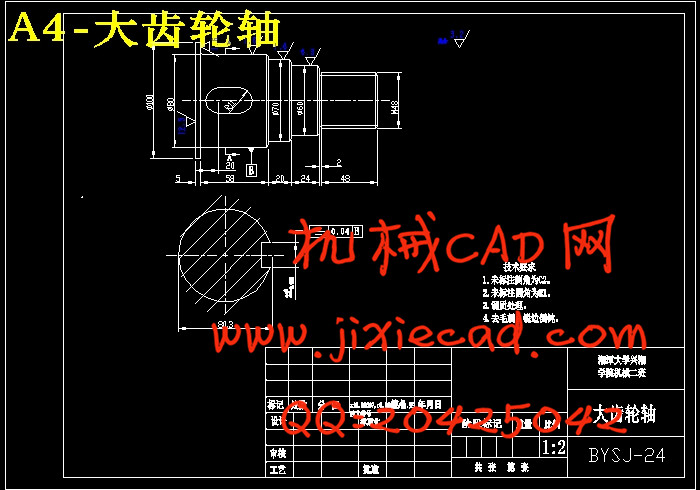

2.3滚刷轴的设计与计算.................................................................................13

2.4 横杆的设计与计算....................................................................................14

2.5提升液压缸的设计与计算..........................................................................18

2.6水平往复机构设计与分析..........................................................................20

第三章 结语.................................................................................................22

参考文献..........................................................................................................24

致谢....................................................................................................................25