设计简介

摘 要

捷达轿车在我国应用十分广泛,而变速器是整车的关键总成之一。其功用是在不同的使用条件下, 改变发动机传到驱动轮上的转矩和转速, 使汽车得到不同的牵引力和速度, 同时使发动机在最有利的工况范围内工作。通过捷达轿车变速器的设计,使其变速器性能更好具有一定的实际意义。我设计的变速器主要内容:

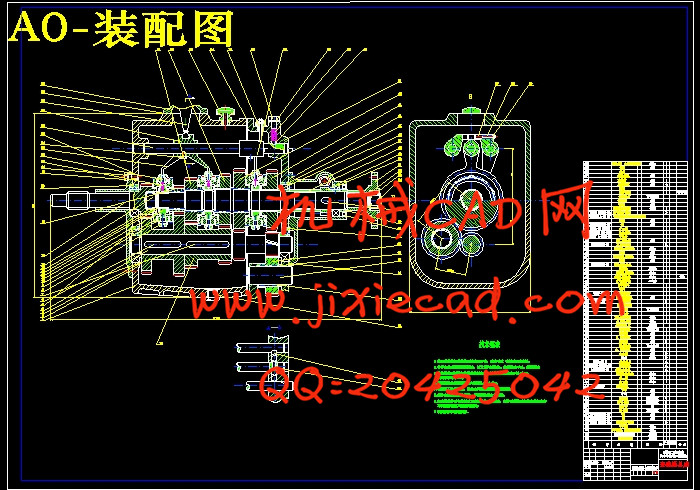

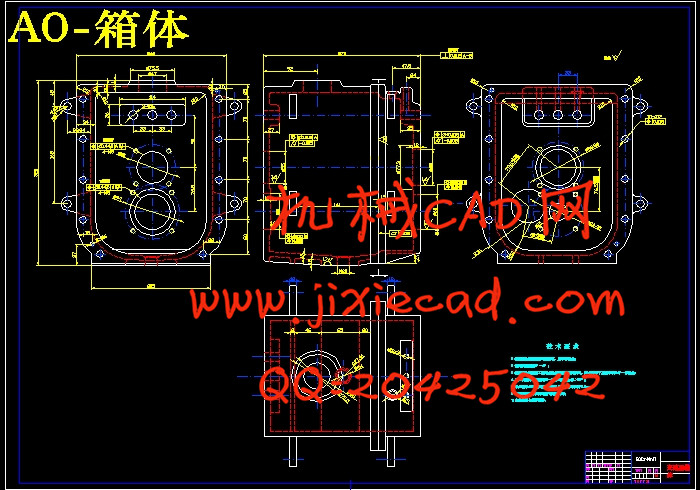

1.变速器的总体的方案的确定。对变速器的功能和要求进行确定,对结构方案确定,和变速器主要零件结构的方案分析。

2.变速器主要参数的选择与主要零件的设计。对变速器主要参数进行选择,对各档传动比及其齿轮齿数的确定,齿轮边位系数的选择。

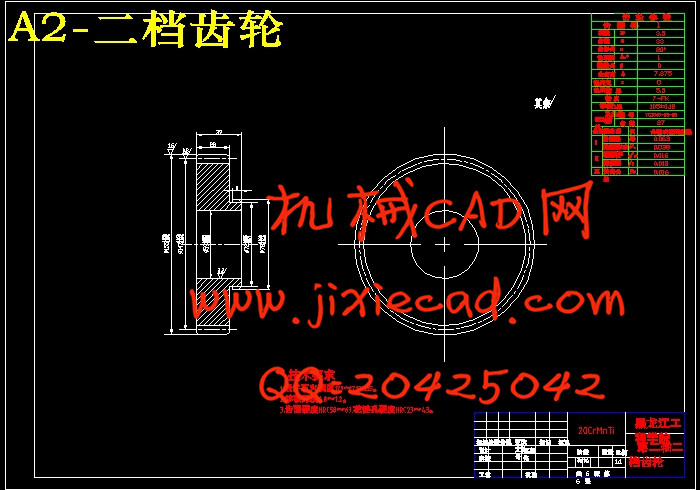

3.变速器齿轮的强度计算与材料的选择。对齿轮的损坏原因及形式的确定,对齿轮的强度计算与校核。

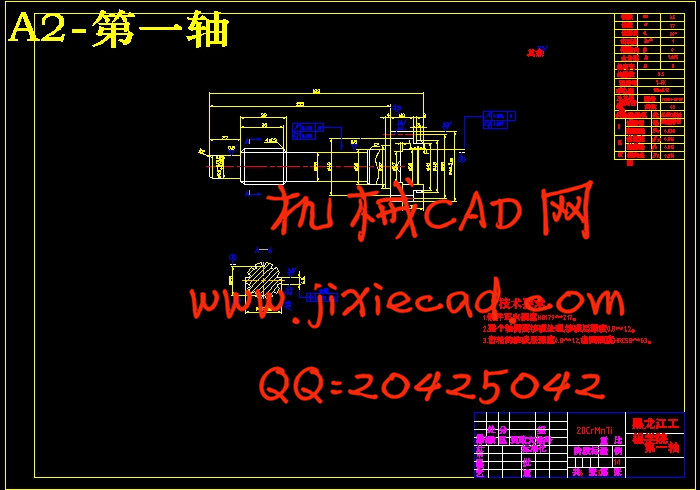

4.变速器轴的强度计算与校核。变速器轴的结构和尺寸的计算,对轴的校核。

5.变速器同步器的设计和操纵机构。对同步器的结构的确定,同步器同步环主要参数的确定,变速器的操纵机构的选择和确定。

关键词:捷达;变速器;主要参数;零件;校核

ABSTRACT

The jetta cars used widely in our country, and the key is the vehicle transmission is one of the assembly. Its function is used in different conditions, changes to the drive wheels on the engine torque ancd rotational speed, make cars get different traction and the engine speed, and at the same time at the most favorable conditions range work. Through the jetta car transmission design, make its transmission better performance has certain practical significance. I designed the transmission main contents:

1. The transmission of the overall plan is affirmatory. The function and requirement of the transmission determined to structure plan, and the structure of main parts and the transmission scheme analysis.

2. The main parameter selection and transmission of main parts design. Of the transmission main parameters of each gear transmission choice, and determine the pinion gear, gear edge position coefficients choice.

3. Transmission gear strength calculation and material selection. The damage of gear determination of reason and form of gear, strength calculation and checking.

4. Transmission shaft strength calculation and checking. Transmission shaft structure and size of the calculation and shaft dynamicrigidity.

5. Transmission synchronizer design and operation. The structure of synchronizer determination of synchronizer synchronous ring, main parameter is determined, the transmission of the choice and determination of manipulated mechanism.

Keywords: jetta; Transmission; Main parameters; Parts; checking

Absteact………………………………………………………………………………………...Ⅱ

第1章 前言………………………………………………………………………………….1

1.1选题背景目的………………………………………………………………………...1

1.2 发展现状………………………………………………………………………………1

1.3意义……………………………………………………………………………………..2

1.4设计内容……………………………………………………………………………….3

第2章 捷达变速器的总体方案的确定…………………………………………….4

2.1 变速器的功用和要求……………………………………………………………….4

2.2 变速器结构方案的确定…………………………………………………………....4

2.2.1 变速器传动机构的结构分析与型式选择……………………………...5

2.2.2 倒档传动方案………………………………………………………………..9

2.3 变速器主要零件结构的方案分析……………………………………………….9

2.3.1 齿轮型式……………………………………………………………………..9

2.3.2 换档结构型式……………………………………………………………...10

2.4 本章小结……………………………………………………………………………12

第3章 变速器主要参数的选择与主要零件的设计……………………….13

3.1 变速器主要参数的选择…………………………………………………………13

3.1.1 倒档和传动比…………………………………………………………….13

3.1.2 中心距……………………………………………………………………...14

3.1.3 轴向尺寸…………………………………………………………………..14

3.1.4 齿轮参数…………………………………………………………………..15

3.2 各档传动比及其齿轮齿数的确定……………………………………………..16

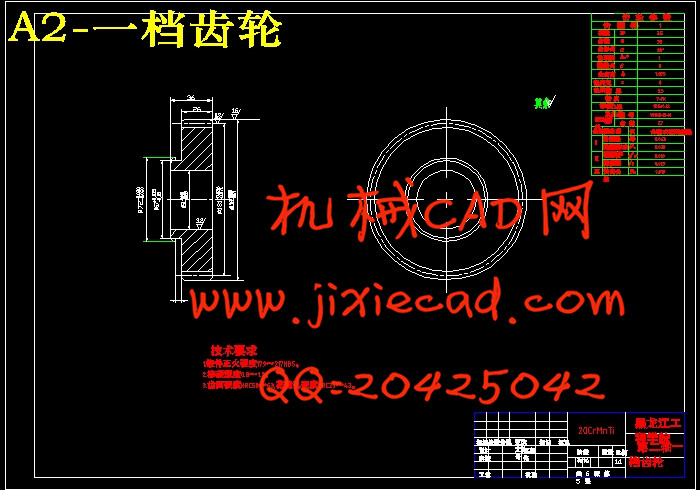

3.2.1 确定一档齿轮的齿数…………………………………………………...16

3.2.2 确定常啮合齿轮副的齿数…...................................................................17

3.2.3 确定其他档位的齿数……………………………………………………17

3.2.4 确定倒挡齿轮的齿数……………………………………………………18

3.3 齿轮变位系数的选择……………………………………………………………18

3.4本章小结……………………………………………………………………………..19

第4章 变速器齿轮的强度计算与材料的选择………………………………..20

4.1 齿轮的损坏原因及形式………………………………………………………….20

4.2 齿轮的强度计算与校核………………………………………………………….20

4.2.1 齿轮弯曲强度计算…..............................................................................20

4.2.2 齿轮接触应力…........................................................................................22

4.3本章小结…………………………………………………………………………….23

第5章 变速器轴的强度计算与校核………………………………………….......24

5.1 变速器轴的结构和尺寸…………………………………………………………24

5.1.1 轴的结构…………………………………………………………………...24

5.1.2 确定轴的尺寸………………………………………………………….....24

5.2 轴的校核…………………………………………………………………………...25

5.2.1 第一轴的强度与刚度校核……………………………………………..25

5.2.2 第二轴的校核计算………………………………………………………26

5.3本章小结…………………………………………………………………………….28

第6章 变速器同步器的设计和操纵机构……………………………………...29

6.1同步器的结构……………………………………………………………………. .29

6.2同步环主要参数的确定………………………………………………………….30

6.3变速器的操纵机构………………………………………………………………..32

结论…………………………………………………………………………………………......33

参考文献………………………………………………………………………………………34

致谢……………………………………………………………………………………………...35

捷达轿车在我国应用十分广泛,而变速器是整车的关键总成之一。其功用是在不同的使用条件下, 改变发动机传到驱动轮上的转矩和转速, 使汽车得到不同的牵引力和速度, 同时使发动机在最有利的工况范围内工作。通过捷达轿车变速器的设计,使其变速器性能更好具有一定的实际意义。我设计的变速器主要内容:

1.变速器的总体的方案的确定。对变速器的功能和要求进行确定,对结构方案确定,和变速器主要零件结构的方案分析。

2.变速器主要参数的选择与主要零件的设计。对变速器主要参数进行选择,对各档传动比及其齿轮齿数的确定,齿轮边位系数的选择。

3.变速器齿轮的强度计算与材料的选择。对齿轮的损坏原因及形式的确定,对齿轮的强度计算与校核。

4.变速器轴的强度计算与校核。变速器轴的结构和尺寸的计算,对轴的校核。

5.变速器同步器的设计和操纵机构。对同步器的结构的确定,同步器同步环主要参数的确定,变速器的操纵机构的选择和确定。

关键词:捷达;变速器;主要参数;零件;校核

ABSTRACT

The jetta cars used widely in our country, and the key is the vehicle transmission is one of the assembly. Its function is used in different conditions, changes to the drive wheels on the engine torque ancd rotational speed, make cars get different traction and the engine speed, and at the same time at the most favorable conditions range work. Through the jetta car transmission design, make its transmission better performance has certain practical significance. I designed the transmission main contents:

1. The transmission of the overall plan is affirmatory. The function and requirement of the transmission determined to structure plan, and the structure of main parts and the transmission scheme analysis.

2. The main parameter selection and transmission of main parts design. Of the transmission main parameters of each gear transmission choice, and determine the pinion gear, gear edge position coefficients choice.

3. Transmission gear strength calculation and material selection. The damage of gear determination of reason and form of gear, strength calculation and checking.

4. Transmission shaft strength calculation and checking. Transmission shaft structure and size of the calculation and shaft dynamicrigidity.

5. Transmission synchronizer design and operation. The structure of synchronizer determination of synchronizer synchronous ring, main parameter is determined, the transmission of the choice and determination of manipulated mechanism.

Keywords: jetta; Transmission; Main parameters; Parts; checking

目 录

摘要……………………………………………………………………………………………...ⅠAbsteact………………………………………………………………………………………...Ⅱ

第1章 前言………………………………………………………………………………….1

1.1选题背景目的………………………………………………………………………...1

1.2 发展现状………………………………………………………………………………1

1.3意义……………………………………………………………………………………..2

1.4设计内容……………………………………………………………………………….3

第2章 捷达变速器的总体方案的确定…………………………………………….4

2.1 变速器的功用和要求……………………………………………………………….4

2.2 变速器结构方案的确定…………………………………………………………....4

2.2.1 变速器传动机构的结构分析与型式选择……………………………...5

2.2.2 倒档传动方案………………………………………………………………..9

2.3 变速器主要零件结构的方案分析……………………………………………….9

2.3.1 齿轮型式……………………………………………………………………..9

2.3.2 换档结构型式……………………………………………………………...10

2.4 本章小结……………………………………………………………………………12

第3章 变速器主要参数的选择与主要零件的设计……………………….13

3.1 变速器主要参数的选择…………………………………………………………13

3.1.1 倒档和传动比…………………………………………………………….13

3.1.2 中心距……………………………………………………………………...14

3.1.3 轴向尺寸…………………………………………………………………..14

3.1.4 齿轮参数…………………………………………………………………..15

3.2 各档传动比及其齿轮齿数的确定……………………………………………..16

3.2.1 确定一档齿轮的齿数…………………………………………………...16

3.2.2 确定常啮合齿轮副的齿数…...................................................................17

3.2.3 确定其他档位的齿数……………………………………………………17

3.2.4 确定倒挡齿轮的齿数……………………………………………………18

3.3 齿轮变位系数的选择……………………………………………………………18

3.4本章小结……………………………………………………………………………..19

第4章 变速器齿轮的强度计算与材料的选择………………………………..20

4.1 齿轮的损坏原因及形式………………………………………………………….20

4.2 齿轮的强度计算与校核………………………………………………………….20

4.2.1 齿轮弯曲强度计算…..............................................................................20

4.2.2 齿轮接触应力…........................................................................................22

4.3本章小结…………………………………………………………………………….23

第5章 变速器轴的强度计算与校核………………………………………….......24

5.1 变速器轴的结构和尺寸…………………………………………………………24

5.1.1 轴的结构…………………………………………………………………...24

5.1.2 确定轴的尺寸………………………………………………………….....24

5.2 轴的校核…………………………………………………………………………...25

5.2.1 第一轴的强度与刚度校核……………………………………………..25

5.2.2 第二轴的校核计算………………………………………………………26

5.3本章小结…………………………………………………………………………….28

第6章 变速器同步器的设计和操纵机构……………………………………...29

6.1同步器的结构……………………………………………………………………. .29

6.2同步环主要参数的确定………………………………………………………….30

6.3变速器的操纵机构………………………………………………………………..32

结论…………………………………………………………………………………………......33

参考文献………………………………………………………………………………………34

致谢……………………………………………………………………………………………...35