设计简介

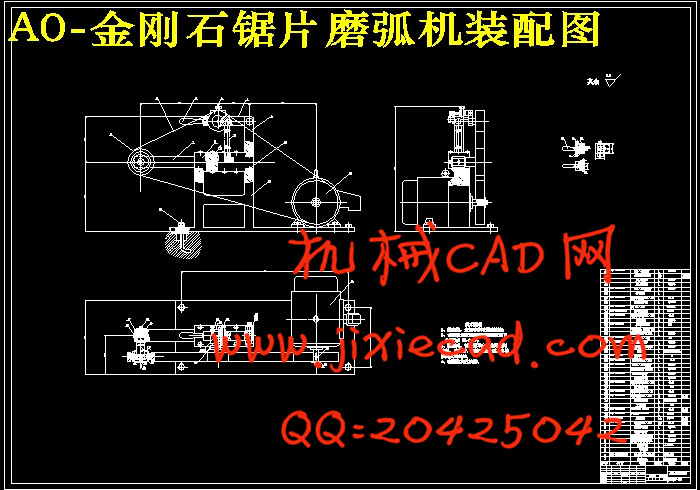

金刚石锯片磨弧机设计

摘 要

近几年我国金刚石制品和硬质合金工具业发展很快,给金刚石行业的发展带来了机遇。特别是金刚石锯片的使用使加工行业走到了一个新的领域,早期的金刚石锯片是一种用手工镶嵌天然金刚石而成的,但由于天然金刚石价格昂贵,早期不能大规模应用于生产。1930年以后,随着粉末冶金技术的发展,产生了焊接式金刚石圆锯片。人造金刚石的诞生,使得金刚石工具制造业得到迅速发展,金刚石圆锯片开始大规模应用于石材加工等行业。

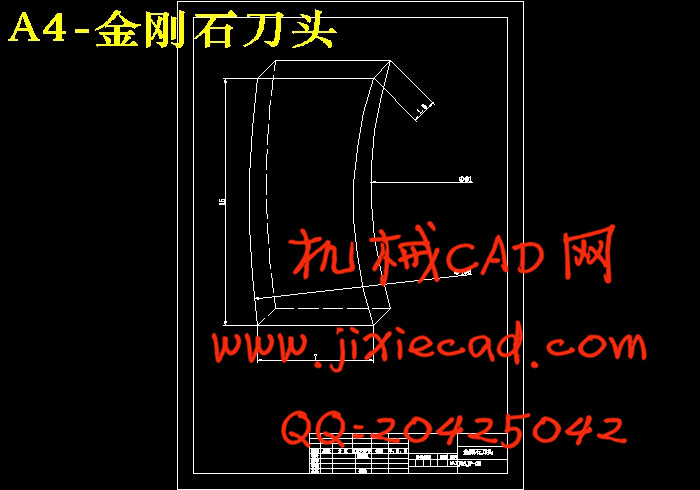

现在采用激光焊接方式制造金刚石锯片是近年来发展起来的新技术,与传统钎焊或压制烧结锯片相比,焊出的锯片不但外观好,锯片精度和强度也大大提高。激光焊金刚石锯片刀头内圆弧面的加工是生产过程中的关键工序,激光焊金刚石锯片对刀头圆弧面的要求比普通锯片要高,圆弧面加工质量的好坏直接影响锯片的性能和寿命,良好的圆弧面可以提高锯片的几何形状和尺寸精度,降低锯片的偏摆量,提高焊接强度,防止脱齿,从而大大改善锯片的使用性能和寿命。目前,国内不少厂家进口了激光焊金刚石锯片生产线,其配备的磨弧机均为砂轮磨弧机,使用过程中调整麻烦,精度难以保证,砂轮经常堵塞,效率低,严重制约了生产线的能力发挥。因此设计一种用砂带来磨金刚石锯片的机器将会有更好的效果。

关键词:高速切削,金刚石锯片,高效,加工质量

Diamond saw blades grinding arc machine design

Abstract

Diamond products in China in recent years and carbide tools industry development soon, to the development of the diamond industry creates opportunity. Especially the diamond saw blades with processing industry come to a new field, early diamond saw blades is a kind of manual Mosaic natural diamond and become, but because the natural diamond expensive, early can't large-scale used in production. 1930 years later, with the development of powder metallurgical technology, and produced the welding type diamond circular saw blades. The birth of artificial diamond, diamond tool industry that is rapidly developing, diamond circular saw blades started mass used in stone processing industries.

Now the laser welding process manufacturing diamond saw blades is developed in recent years to new technology, and traditional qian welding or suppression than sintering saw blades, welding of the blades not only look good, saw blade precision and strength also greatly improved. Laser welding diamond saw blades in the manufacturing is head of circular arc the key process working procedure, laser welding diamond saw blades for the head of circular arc than ordinary higher requirements blades, circular arc surface processing quality direct impact on the performance of the blades and life expectancy, good surface can improve the circular arc of the blades of geometry shape and size precision, lower blades of a partial quantity, improve the welding strength, prevent to take off the tooth, thereby greatly improve the blades of use function and life. At present, the domestic many manufacturers imported laser welding diamond saw blades production line, the grinding machine are equipped with the arc for grinding wheel grinding arc machine, use process adjustment trouble, hard to ensure accuracy, grinding wheel often jams, low efficiency, seriously restricted the production line of the ability to play. So the design of a sand grinding diamond saw blades with bring machine will have better effect.

Keywords :High speed cutting,diamond saw blades,efficiency,processing quality

目 录

1、金刚石锯片介绍 1

1.1 金刚石锯片的用途和特点 1

1.2 运输和存放 1

1.3 金刚石圆锯片的(焊接)加工 1

2、砂带磨削技术的介绍 3

2.1 砂带磨削的定义 3

2.2 砂带磨削原理 3

2.2.1 主轴传动装置 3

2.2.2 砂带张紧装置 3

2.2.3 砂带导向装置 4

2.2.4 接触轮 4

2.3 砂带磨削特点 4

2.3.1 加工效率高 4

2.3.2 加工表面质量高 4

2.3.3 工艺灵活性大, 适应性强 5

2.3.4 抗振性好 5

2.3.5 经济性好 5

3、机床的设计及计算 6

3.1 机床的总体结构设计 6

3.1.1 传动设计 6

3.1.2 主要机构设计 6

3.2 传动部分的设计 7

3.2.1 电机的选择 7

3.2.2 砂带的选择及计算 7

3.2.3 砂带磨削过程中的受力分析 8

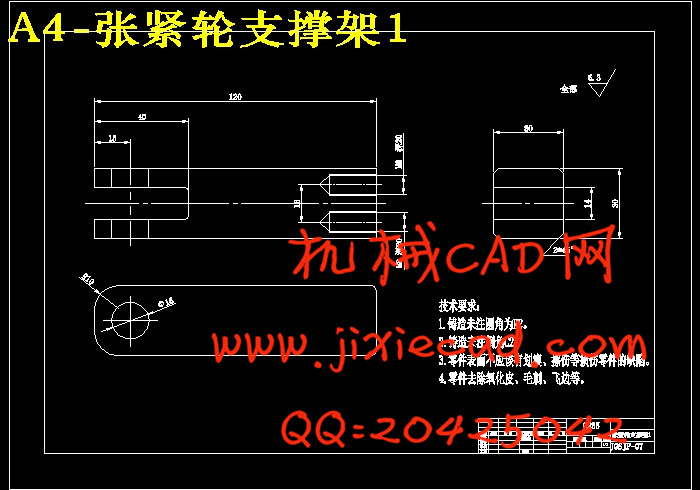

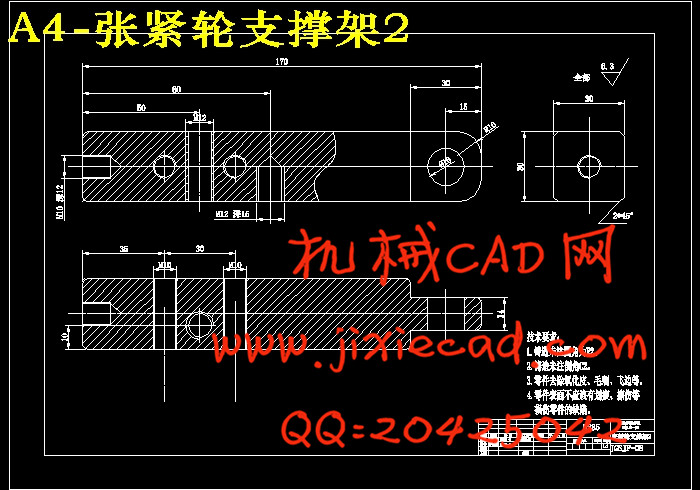

3.3 张紧机构及快换操纵机构和调偏机构 9

3.4 接触轮主轴设计 10

3.4.1 选择轴的材料 10

3.4.2 所承受的扭矩初估计轴的最小直径 10

3.4.3 轴的结构设计 10

3.4.4 轴的受力分析 11

3.4.5 轴的疲劳强度安全系数校核计算 12

3.5 张紧轮 16

4、夹具的设计 17

4.1 问题提出 17

4.2 夹具结构设计 17

结论 19

致谢 20

参考文献 21

摘 要

近几年我国金刚石制品和硬质合金工具业发展很快,给金刚石行业的发展带来了机遇。特别是金刚石锯片的使用使加工行业走到了一个新的领域,早期的金刚石锯片是一种用手工镶嵌天然金刚石而成的,但由于天然金刚石价格昂贵,早期不能大规模应用于生产。1930年以后,随着粉末冶金技术的发展,产生了焊接式金刚石圆锯片。人造金刚石的诞生,使得金刚石工具制造业得到迅速发展,金刚石圆锯片开始大规模应用于石材加工等行业。

现在采用激光焊接方式制造金刚石锯片是近年来发展起来的新技术,与传统钎焊或压制烧结锯片相比,焊出的锯片不但外观好,锯片精度和强度也大大提高。激光焊金刚石锯片刀头内圆弧面的加工是生产过程中的关键工序,激光焊金刚石锯片对刀头圆弧面的要求比普通锯片要高,圆弧面加工质量的好坏直接影响锯片的性能和寿命,良好的圆弧面可以提高锯片的几何形状和尺寸精度,降低锯片的偏摆量,提高焊接强度,防止脱齿,从而大大改善锯片的使用性能和寿命。目前,国内不少厂家进口了激光焊金刚石锯片生产线,其配备的磨弧机均为砂轮磨弧机,使用过程中调整麻烦,精度难以保证,砂轮经常堵塞,效率低,严重制约了生产线的能力发挥。因此设计一种用砂带来磨金刚石锯片的机器将会有更好的效果。

关键词:高速切削,金刚石锯片,高效,加工质量

Diamond saw blades grinding arc machine design

Abstract

Diamond products in China in recent years and carbide tools industry development soon, to the development of the diamond industry creates opportunity. Especially the diamond saw blades with processing industry come to a new field, early diamond saw blades is a kind of manual Mosaic natural diamond and become, but because the natural diamond expensive, early can't large-scale used in production. 1930 years later, with the development of powder metallurgical technology, and produced the welding type diamond circular saw blades. The birth of artificial diamond, diamond tool industry that is rapidly developing, diamond circular saw blades started mass used in stone processing industries.

Now the laser welding process manufacturing diamond saw blades is developed in recent years to new technology, and traditional qian welding or suppression than sintering saw blades, welding of the blades not only look good, saw blade precision and strength also greatly improved. Laser welding diamond saw blades in the manufacturing is head of circular arc the key process working procedure, laser welding diamond saw blades for the head of circular arc than ordinary higher requirements blades, circular arc surface processing quality direct impact on the performance of the blades and life expectancy, good surface can improve the circular arc of the blades of geometry shape and size precision, lower blades of a partial quantity, improve the welding strength, prevent to take off the tooth, thereby greatly improve the blades of use function and life. At present, the domestic many manufacturers imported laser welding diamond saw blades production line, the grinding machine are equipped with the arc for grinding wheel grinding arc machine, use process adjustment trouble, hard to ensure accuracy, grinding wheel often jams, low efficiency, seriously restricted the production line of the ability to play. So the design of a sand grinding diamond saw blades with bring machine will have better effect.

Keywords :High speed cutting,diamond saw blades,efficiency,processing quality

目 录

1、金刚石锯片介绍 1

1.1 金刚石锯片的用途和特点 1

1.2 运输和存放 1

1.3 金刚石圆锯片的(焊接)加工 1

2、砂带磨削技术的介绍 3

2.1 砂带磨削的定义 3

2.2 砂带磨削原理 3

2.2.1 主轴传动装置 3

2.2.2 砂带张紧装置 3

2.2.3 砂带导向装置 4

2.2.4 接触轮 4

2.3 砂带磨削特点 4

2.3.1 加工效率高 4

2.3.2 加工表面质量高 4

2.3.3 工艺灵活性大, 适应性强 5

2.3.4 抗振性好 5

2.3.5 经济性好 5

3、机床的设计及计算 6

3.1 机床的总体结构设计 6

3.1.1 传动设计 6

3.1.2 主要机构设计 6

3.2 传动部分的设计 7

3.2.1 电机的选择 7

3.2.2 砂带的选择及计算 7

3.2.3 砂带磨削过程中的受力分析 8

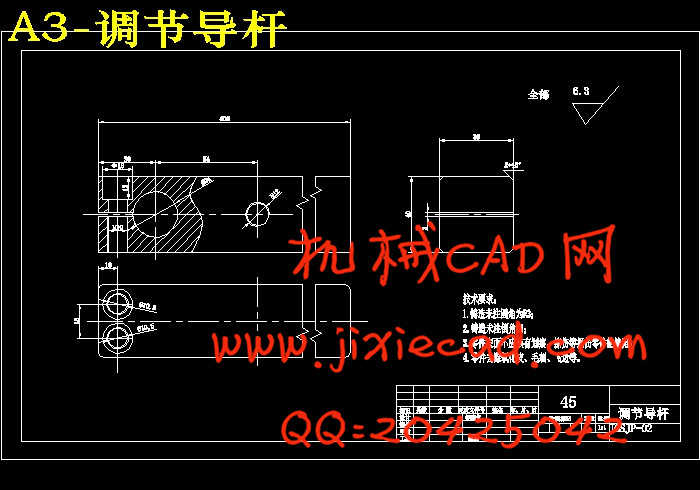

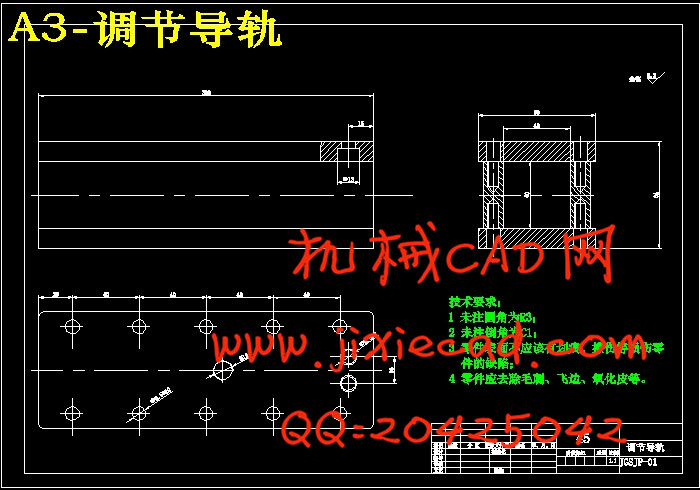

3.3 张紧机构及快换操纵机构和调偏机构 9

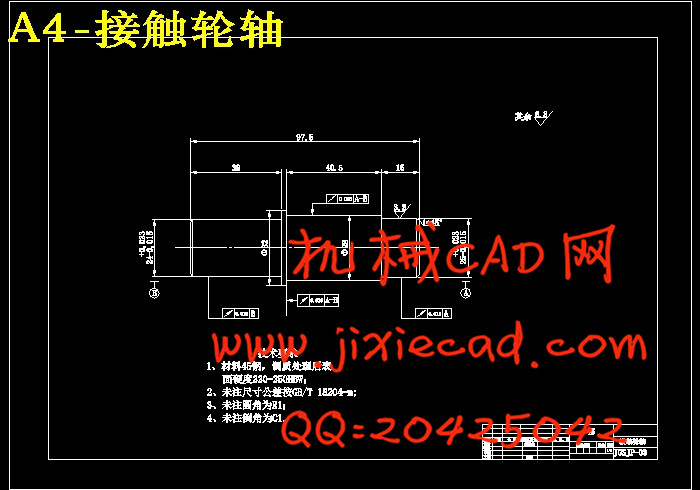

3.4 接触轮主轴设计 10

3.4.1 选择轴的材料 10

3.4.2 所承受的扭矩初估计轴的最小直径 10

3.4.3 轴的结构设计 10

3.4.4 轴的受力分析 11

3.4.5 轴的疲劳强度安全系数校核计算 12

3.5 张紧轮 16

4、夹具的设计 17

4.1 问题提出 17

4.2 夹具结构设计 17

结论 19

致谢 20

参考文献 21