设计简介

摘 要

振动钻削是振动切削的一个分支

关键词:振动钻削;电机;带传动;偏心轴;主轴

ABSTRACT

Vibration drilling is a branch of vibratory cutting, and it is the difference between ordinary drilling borehole process through the vibrating device bit with workpiece occurs between the relative motion of controllable. There are three main vibration mode, namely axial vibration (vibration direction and drill axis torsional vibration (same), with bits direction of vibration rotation direction the same) and complex vibration (axial vibration and torsional vibration superposition). Among them, the axial vibration easy to realize and good results, in process of vibration drilling dominant. The incentive ways mainly have the vibration ultrasonic vibration, mechanical vibration, hydraulic vibration and electromagnetic vibration. Among them, the ultrasonic vibration frequency usually 16kHz above, so in high frequency vibration drilling, also called; The other three vibration mode frequency general for hundreds of Hertz so called the low frequency vibration drilling. Vibration drilling has changed the traditional drilling cutting mechanism. In vibration drilling process, when the main cutting edge with workpiece are not isolated (not separated type vibration drilling), cutting speed, cutting parameters such as periodic changes direction produced; When the Lord when the cutting edges and workpiece when separated type cut from (vibration drilling), cutting process into pulsing concentres cutting. When the vibration parameters (vibration frequency and amplitude), feeding, reasonable selection of spindle speed etc, can obviously increase the penetration positioning accuracy and pore size precision, roundness and surface quality and reduce export burr, reduce the temperature of cutting force and cutting, prolong drill life. Good vibration drilling process effect by the domestic and international researchers already popular attention.

Key words: vibration drilling; motor; Belt transmission; Eccentric shaft; spindle

目 录

1 绪 论 1

1.1 振动钻削技术的发展历史 2

1.2 振动钻削的机理 1

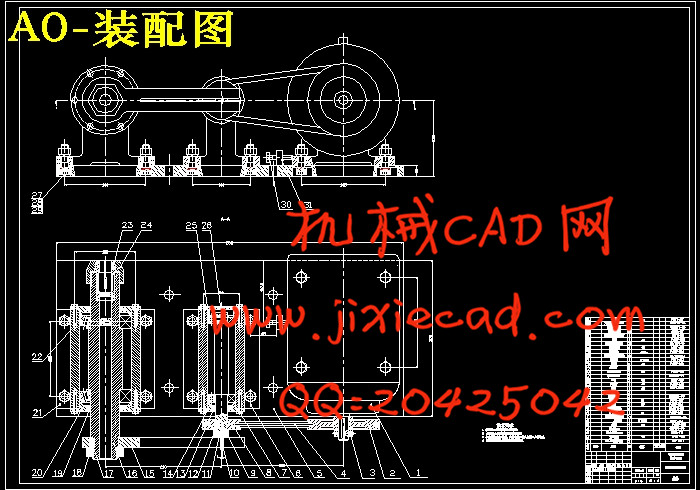

2 装置设计 4

2.1 装置总体方案 4

2.2 电机的选择 6

2.3 带传动设计 8

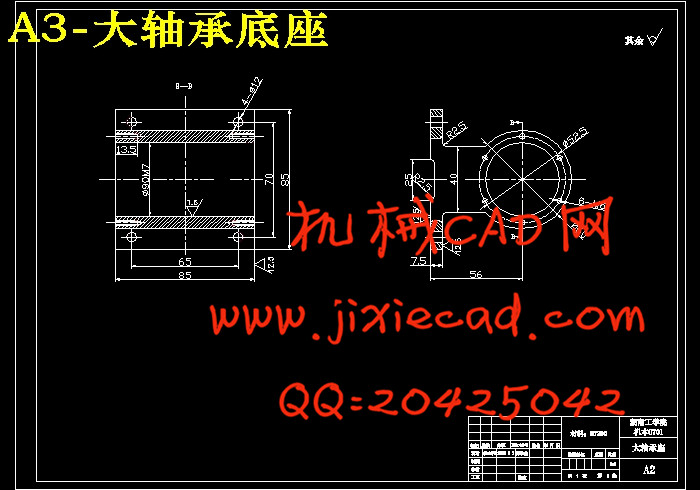

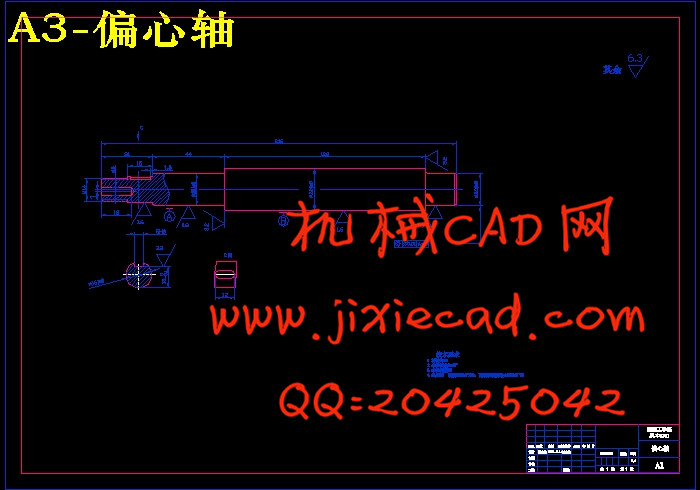

2.4 偏心轴及其附件设计 12

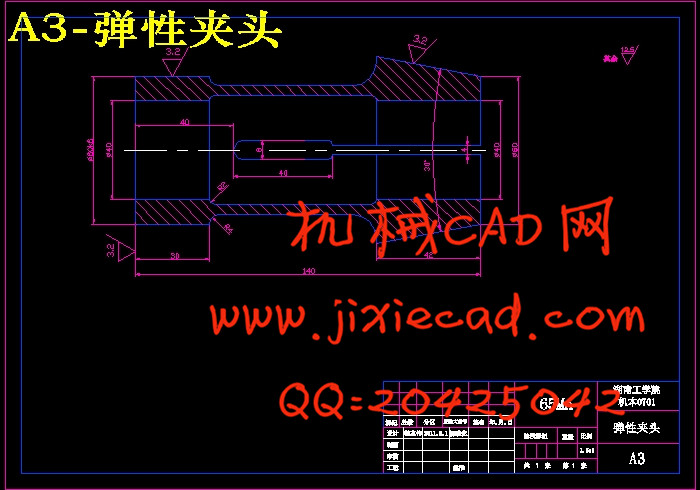

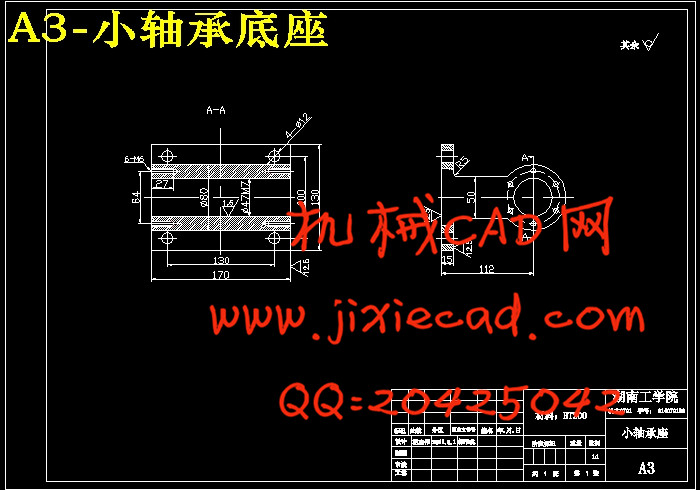

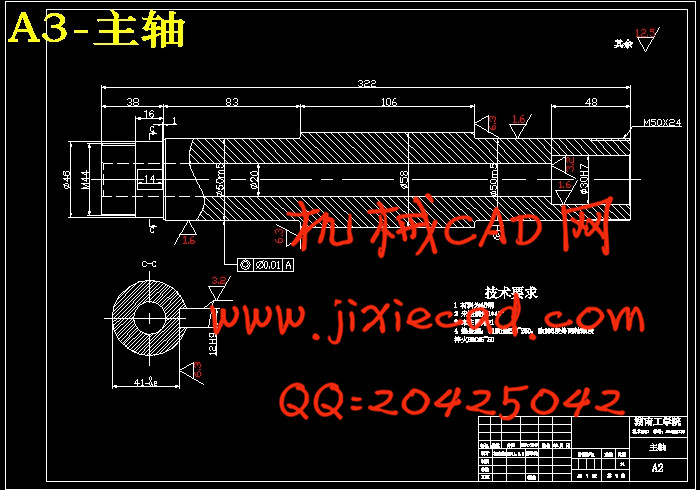

2.5 主轴及其附件设计 18

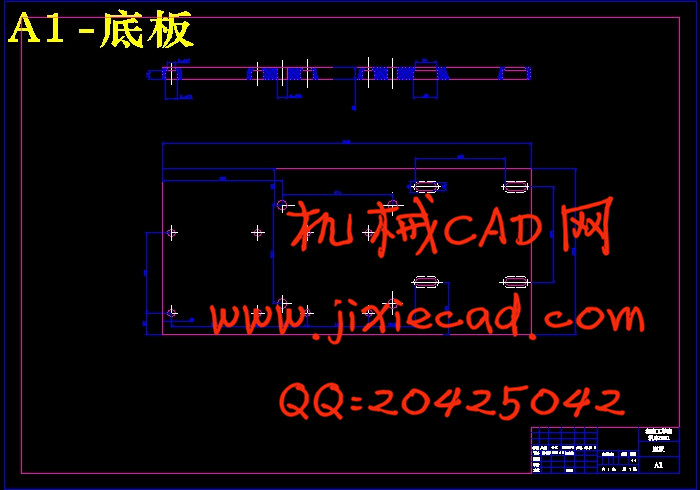

2.6 底板设计 23

参考文献 24

致 谢 25

附 录 26

振动钻削是振动切削的一个分支

关键词:振动钻削;电机;带传动;偏心轴;主轴

ABSTRACT

Vibration drilling is a branch of vibratory cutting, and it is the difference between ordinary drilling borehole process through the vibrating device bit with workpiece occurs between the relative motion of controllable. There are three main vibration mode, namely axial vibration (vibration direction and drill axis torsional vibration (same), with bits direction of vibration rotation direction the same) and complex vibration (axial vibration and torsional vibration superposition). Among them, the axial vibration easy to realize and good results, in process of vibration drilling dominant. The incentive ways mainly have the vibration ultrasonic vibration, mechanical vibration, hydraulic vibration and electromagnetic vibration. Among them, the ultrasonic vibration frequency usually 16kHz above, so in high frequency vibration drilling, also called; The other three vibration mode frequency general for hundreds of Hertz so called the low frequency vibration drilling. Vibration drilling has changed the traditional drilling cutting mechanism. In vibration drilling process, when the main cutting edge with workpiece are not isolated (not separated type vibration drilling), cutting speed, cutting parameters such as periodic changes direction produced; When the Lord when the cutting edges and workpiece when separated type cut from (vibration drilling), cutting process into pulsing concentres cutting. When the vibration parameters (vibration frequency and amplitude), feeding, reasonable selection of spindle speed etc, can obviously increase the penetration positioning accuracy and pore size precision, roundness and surface quality and reduce export burr, reduce the temperature of cutting force and cutting, prolong drill life. Good vibration drilling process effect by the domestic and international researchers already popular attention.

Key words: vibration drilling; motor; Belt transmission; Eccentric shaft; spindle

目 录

1 绪 论 1

1.1 振动钻削技术的发展历史 2

1.2 振动钻削的机理 1

2 装置设计 4

2.1 装置总体方案 4

2.2 电机的选择 6

2.3 带传动设计 8

2.4 偏心轴及其附件设计 12

2.5 主轴及其附件设计 18

2.6 底板设计 23

参考文献 24

致 谢 25

附 录 26