设计简介

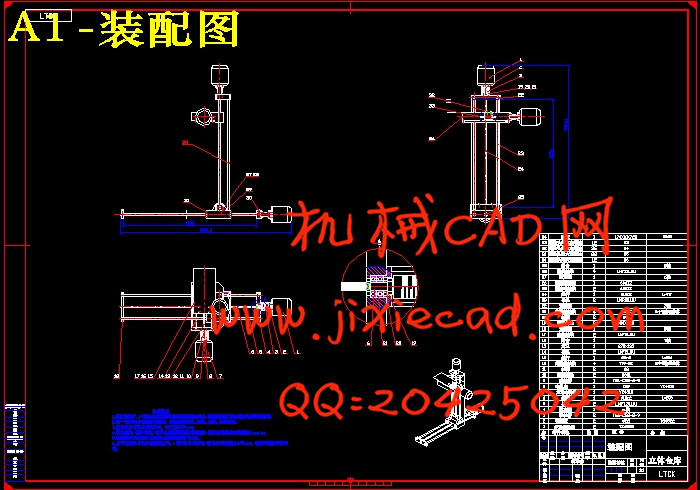

教学型立体仓库提升与送物部分设计

摘 要

自动化立体仓库是一种集信息、储存、管理于一体的高技术密集型机电一体化产品,涉及的领域很广。通过对立体仓库自动控制系统硬件的设计,基本上达到了采用计算机自动控制技术提高立体仓库的管理水平,提高立体仓库的可靠性和可维修性,从而提高企业生产率和经济效益的目的。

出于对成本和自动化立体仓库功能单一的考虑,过去中小企业多数使用传统的仓库。随着外资企业物流管理模式的普及和近十年自动化立体仓库系统功能的完善,小型多功能自动化立体仓库迅速增加。

自动化立体化仓库具有储存能力大、适用性强、稳定性高、经济性好等优点。

自动化仓库系统一般由巷道堆垛机、高层货架、托盘、周边输送系统、计算机管理与控制系统、信息采集系统、执行机构等部分组成。

自动化立体仓库实现了所需自制件和外购件都在立体库集中管理;有效利用了空间,节省了仓库占地面积;严格了账目管理,提高了管理水平;信息反馈及时准确,为决策提供了可靠依据;采用计算机管理与控制,为企业计算机联网创造了条件。

关键词:自动化,立体仓库,计算机联网

Teaching 3D Warehouse Upgrade and to Send Material Part Design

Abstract

Automated warehouse is a collection of information, storage, and management in one of the high-tech intensive mechatronic products, wide range of areas involved. Automated Storage control system hardware design, basically meeting the purpose of computer automatic control technology to improve the level of three-dimensional warehouse management, improve reliability and maintainability of the three-dimensional warehouse, in order to improve productivity and economic.

For a single consideration the cost and automated warehouse functions SMEs most traditional warehouse. With the popularity of foreign-funded logistics management mode, and nearly a decade automated warehouse system, improve the function of the mini-warehouse automation rapid increase in.

Automated three-dimensional warehouse has a large storage capacity, strong applicability, high stability, good economic benefits.

The automated warehouse system in general by the retrieval machine, top shelves, trays, the surrounding transportation system, computer management and control systems, information collection system, executive body parts.

Automated warehouse to achieve the required homemade and purchased parts are concentrated in the three-dimensional library management; efficient use of space, warehouse covers an area of savings; strict account management, to improve the management level; timely and accurate feedback for decision-making reliable basis; the use of computer management and control to create the conditions for enterprise computer networking.

Key words: Automation, Warehouse, Computer networking

目 录

1 绪论………………………………………………………………………………………… 1

1.1课题的背景及目的…………………………………………………………………… 1

1.2国内外自动化立体仓库的发展状况………………………………………...………….1

1.3自动化立体仓库的分类及其特点……………………………………………..……… 2

1.4自动化立体仓库的应用……………………………………………………..………… 2

2总体方案设计………………………………………………………………………………4

2.1提升与送物部分外形尺寸及重量估算………………………………………..……… 4

2.2直线轴承的计算与选择 …………………………………………………….…………5

2.2.1直线轴承箱式SC系列的型号选择.........................................................................5

2.2.2直线轴承的型号选择................................................................................................7

2.2.3轴支座的型号选择....................................................................................................9

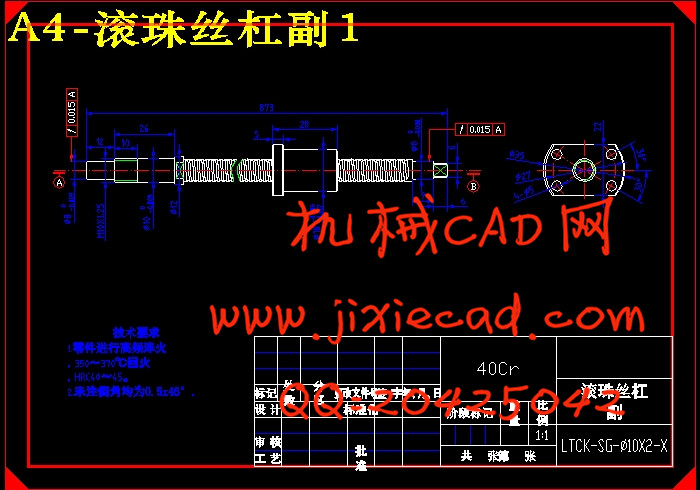

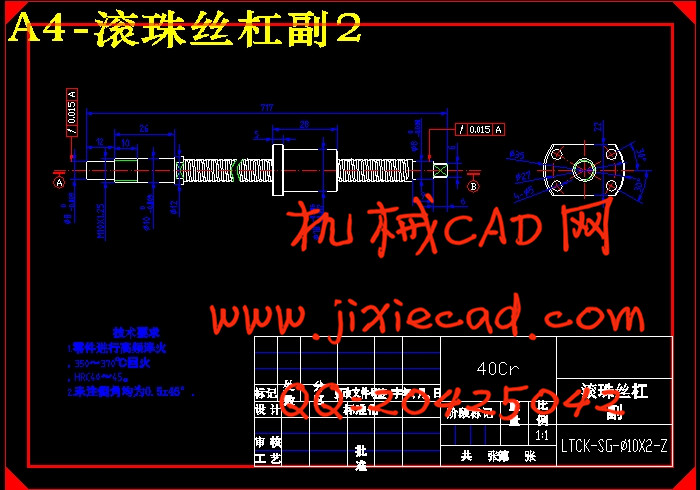

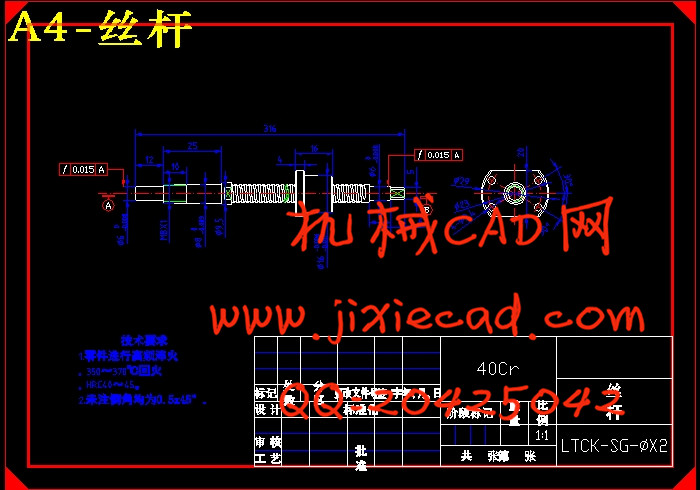

2.3滚珠丝杠的设计及计算.................................................................................................10

2.4步进电机的选用.............................................................................................................14

2.5联轴器的选择.................................................................................................................17

结论 ………………………………………………………………………………………… 19

致谢 ………………………………………………………………………………………… 20

参考文献 …………………………………………………………………………………… 21

摘 要

自动化立体仓库是一种集信息、储存、管理于一体的高技术密集型机电一体化产品,涉及的领域很广。通过对立体仓库自动控制系统硬件的设计,基本上达到了采用计算机自动控制技术提高立体仓库的管理水平,提高立体仓库的可靠性和可维修性,从而提高企业生产率和经济效益的目的。

出于对成本和自动化立体仓库功能单一的考虑,过去中小企业多数使用传统的仓库。随着外资企业物流管理模式的普及和近十年自动化立体仓库系统功能的完善,小型多功能自动化立体仓库迅速增加。

自动化立体化仓库具有储存能力大、适用性强、稳定性高、经济性好等优点。

自动化仓库系统一般由巷道堆垛机、高层货架、托盘、周边输送系统、计算机管理与控制系统、信息采集系统、执行机构等部分组成。

自动化立体仓库实现了所需自制件和外购件都在立体库集中管理;有效利用了空间,节省了仓库占地面积;严格了账目管理,提高了管理水平;信息反馈及时准确,为决策提供了可靠依据;采用计算机管理与控制,为企业计算机联网创造了条件。

关键词:自动化,立体仓库,计算机联网

Teaching 3D Warehouse Upgrade and to Send Material Part Design

Abstract

Automated warehouse is a collection of information, storage, and management in one of the high-tech intensive mechatronic products, wide range of areas involved. Automated Storage control system hardware design, basically meeting the purpose of computer automatic control technology to improve the level of three-dimensional warehouse management, improve reliability and maintainability of the three-dimensional warehouse, in order to improve productivity and economic.

For a single consideration the cost and automated warehouse functions SMEs most traditional warehouse. With the popularity of foreign-funded logistics management mode, and nearly a decade automated warehouse system, improve the function of the mini-warehouse automation rapid increase in.

Automated three-dimensional warehouse has a large storage capacity, strong applicability, high stability, good economic benefits.

The automated warehouse system in general by the retrieval machine, top shelves, trays, the surrounding transportation system, computer management and control systems, information collection system, executive body parts.

Automated warehouse to achieve the required homemade and purchased parts are concentrated in the three-dimensional library management; efficient use of space, warehouse covers an area of savings; strict account management, to improve the management level; timely and accurate feedback for decision-making reliable basis; the use of computer management and control to create the conditions for enterprise computer networking.

Key words: Automation, Warehouse, Computer networking

目 录

1 绪论………………………………………………………………………………………… 1

1.1课题的背景及目的…………………………………………………………………… 1

1.2国内外自动化立体仓库的发展状况………………………………………...………….1

1.3自动化立体仓库的分类及其特点……………………………………………..……… 2

1.4自动化立体仓库的应用……………………………………………………..………… 2

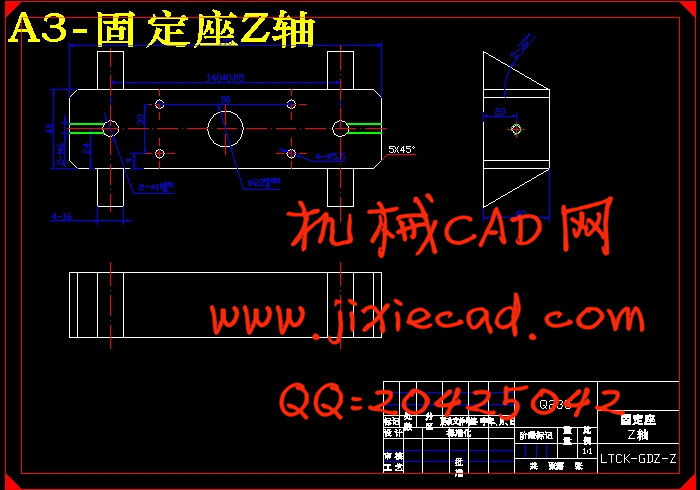

2总体方案设计………………………………………………………………………………4

2.1提升与送物部分外形尺寸及重量估算………………………………………..……… 4

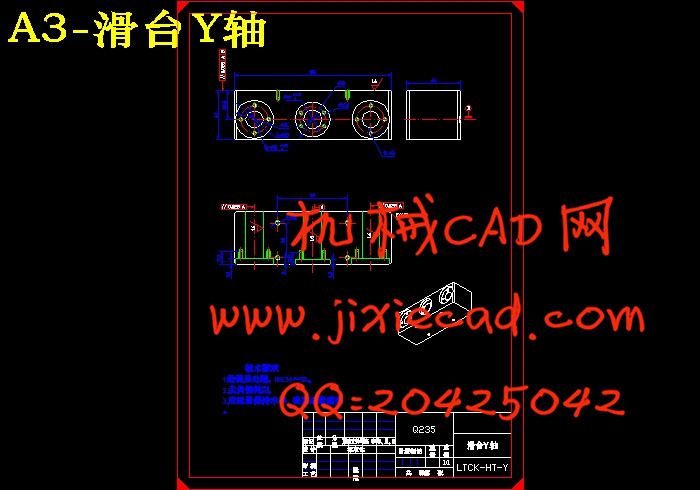

2.2直线轴承的计算与选择 …………………………………………………….…………5

2.2.1直线轴承箱式SC系列的型号选择.........................................................................5

2.2.2直线轴承的型号选择................................................................................................7

2.2.3轴支座的型号选择....................................................................................................9

2.3滚珠丝杠的设计及计算.................................................................................................10

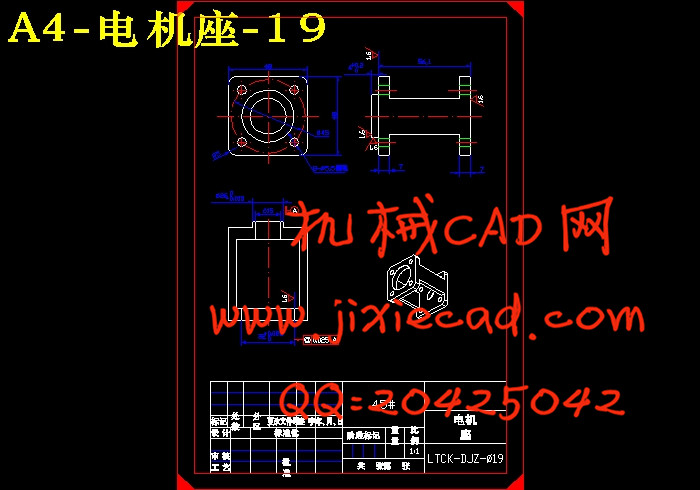

2.4步进电机的选用.............................................................................................................14

2.5联轴器的选择.................................................................................................................17

结论 ………………………………………………………………………………………… 19

致谢 ………………………………………………………………………………………… 20

参考文献 …………………………………………………………………………………… 21