设计简介

摘 要

随着计算机技术的不断发展和现代设计方法的不断丰富,设计智能化已经成为机械设计中热门的研究课题之一。本文针对造纸机中的卷纸机部分进行了研究,开发了一套完整的参数化设计系统。

参数化设计和特征建模技术是CAD技术继续发展和适应工业发展要求的两项重要技术。参数化设计技术有利于建立和管理产品零件库,极大的提高了产品的开发效率。而应用特征建模技术建立的产品特征模型,从产品整个生命周期各阶段的不同要求来描述产品,完整的提供了产品信息,使得各应用系统可以直接从产品模型中抽出所需的信息,这就极大的满足了CAD/CAM/CAE集成系统的要求。

本文是在对卷纸机的工作原理特别了解的基础上以Visua1C++为工具,运用数学中的优化方法对卷纸机中的结构进行优化,并且利用Pro旧专业绘图软件,实现了卷纸机零件的参数化绘图,精确绘出各个零件的几何形状和二维工程图。最后,该软件绘制出卷纸机的三维实体为卷纸机在结构方面进行有限元分析以及数控加工打下了基础。

本文通过完整的卷纸机优化程序,参数化建模绘图,大大缩短了卷纸机的设计周期,降低了卷纸机的研制成本,这对轻工业机械的研制有积极的帮助。

关键词: 卷纸机 优化设计 参数化 有限元分析

Abstract

With computer technology developing modern designing method becoming more abundance, the designing intelligence has become a Popular researching aspect. This paper is mainly about reeler of paper manufacture machine,researching and developing a designing expert system.

Parametric design and Feature Molding technology are the two important technologies in subsequent development of CAD. The Parametric design technology is favor of establishment and management of products and it can improve design efficiency of products. The product feature model established by Feature Modeling technology describes the product from the each stage in life,and provides whole information of the product. Every system can gain its information from product mold and this can satisfied the requirement of CAD/CAM system.

This paper is on the foundation for the working principle special understanding of reeler use Visual C++ carry out optimization for the paper manufacture machine structure,and draw using Pro/E special field software,have realized the parameter of paper manufacture machine element draw,paint paper manufacture machine accurately in the geometry shape of every element and drawing. Finally,this software draw the three-dimensional entity of paper manufacture machine have established foundation for the Processing of numerical control as well as the structural analysis of paper machine.

This paper passes through complete reeler optimization program,parameter drawing,has shortened the design period of reeler greatly,has reduced the cost of R&D of reeler,this has positive help for the R&D of light industry mechanism.

Key words: paper manufacture machine optimization design Pro/Engineer parametric finite element analysis

随着计算机技术的不断发展和现代设计方法的不断丰富,设计智能化已经成为机械设计中热门的研究课题之一。本文针对造纸机中的卷纸机部分进行了研究,开发了一套完整的参数化设计系统。

参数化设计和特征建模技术是CAD技术继续发展和适应工业发展要求的两项重要技术。参数化设计技术有利于建立和管理产品零件库,极大的提高了产品的开发效率。而应用特征建模技术建立的产品特征模型,从产品整个生命周期各阶段的不同要求来描述产品,完整的提供了产品信息,使得各应用系统可以直接从产品模型中抽出所需的信息,这就极大的满足了CAD/CAM/CAE集成系统的要求。

本文是在对卷纸机的工作原理特别了解的基础上以Visua1C++为工具,运用数学中的优化方法对卷纸机中的结构进行优化,并且利用Pro旧专业绘图软件,实现了卷纸机零件的参数化绘图,精确绘出各个零件的几何形状和二维工程图。最后,该软件绘制出卷纸机的三维实体为卷纸机在结构方面进行有限元分析以及数控加工打下了基础。

本文通过完整的卷纸机优化程序,参数化建模绘图,大大缩短了卷纸机的设计周期,降低了卷纸机的研制成本,这对轻工业机械的研制有积极的帮助。

关键词: 卷纸机 优化设计 参数化 有限元分析

Abstract

With computer technology developing modern designing method becoming more abundance, the designing intelligence has become a Popular researching aspect. This paper is mainly about reeler of paper manufacture machine,researching and developing a designing expert system.

Parametric design and Feature Molding technology are the two important technologies in subsequent development of CAD. The Parametric design technology is favor of establishment and management of products and it can improve design efficiency of products. The product feature model established by Feature Modeling technology describes the product from the each stage in life,and provides whole information of the product. Every system can gain its information from product mold and this can satisfied the requirement of CAD/CAM system.

This paper is on the foundation for the working principle special understanding of reeler use Visual C++ carry out optimization for the paper manufacture machine structure,and draw using Pro/E special field software,have realized the parameter of paper manufacture machine element draw,paint paper manufacture machine accurately in the geometry shape of every element and drawing. Finally,this software draw the three-dimensional entity of paper manufacture machine have established foundation for the Processing of numerical control as well as the structural analysis of paper machine.

This paper passes through complete reeler optimization program,parameter drawing,has shortened the design period of reeler greatly,has reduced the cost of R&D of reeler,this has positive help for the R&D of light industry mechanism.

Key words: paper manufacture machine optimization design Pro/Engineer parametric finite element analysis

目 录

第一章 绪 论 5

1.1卷纸机介绍 5

1.1.1 卷纸机概述 5

1.1.2 卷纸机分类 5

1.2 卷纸机的发展概况 6

1.3国内发展概况 7

第二章 卷纸机的功能结构分析 9

2.1 卷纸机的工作原理 9

2.2 卷纸机的结构和功能分析 10

2.3 卷纸机关键件的若干技术要求 11

2.4 卷纸机性能参数的设定 12

第三章 叉架倾转机构的设计与优化 14

3.1 叉架倾转机构的设计与计算 14

3.1.1 结构原理及特点 14

3.1.2 倾转力矩的计算 15

3.2优化设计概述 19

3.2.1 优化设计数学模型 19

3.2.2 优化设计方法 20

3.3卷纸机的优化设计 22

3.3.1 卷纸机机构设计 22

3.3.2 机构最优化设计 24

3.3.3 卷纸机优化设计 25

第四章 卷纸机的参数化建模 29

4.1 参数化建模技术 29

4.2 参数化建模方法 29

4.2 卷纸机三维实体模型的参数化建模 30

4.2.1 参数化设计的一般过程 30

4.2.2 主机架模型的建立 31

4.2.3 卷纸缸模型的建立 31

4.3 工程图的建立 35

4.3.1 主机架工程图 35

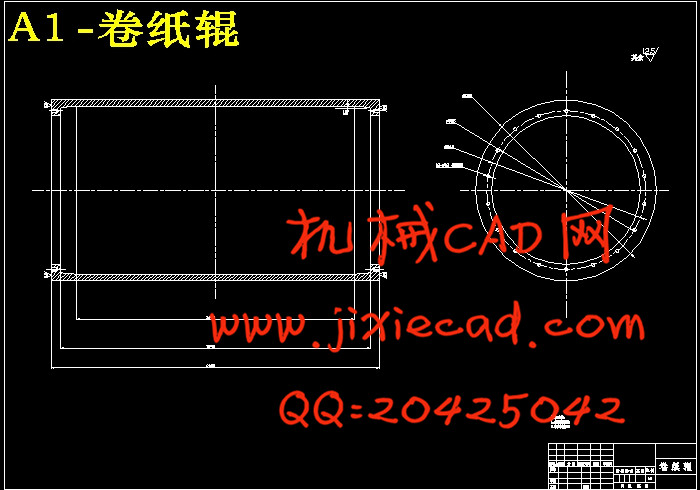

4.3.2 卷纸辊工程图 35

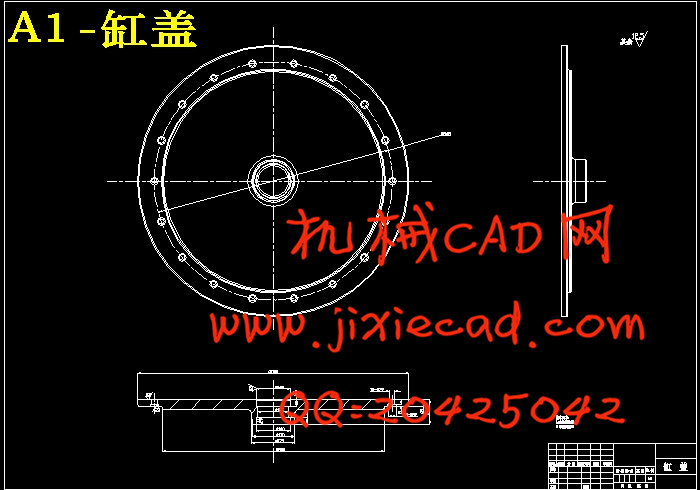

4.3.3 缸盖工程图 36

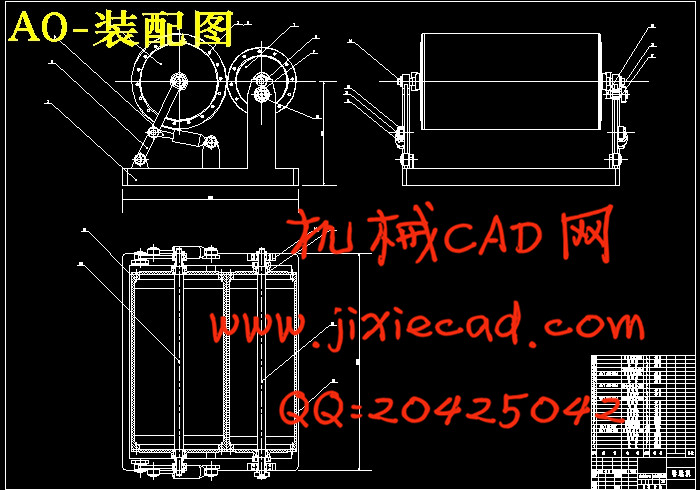

4.3.4 卷纸机装配图 37

第五章 卷纸机零件的有限元分析 38

5.1 数据的转换 38

5.1.1 数据转换标准 38

5.1.2 ANSYS中的1GES标准转换方式 38

5.2 模型的修改 39

5.3 卷纸缸的有限元分析 39

5.3.1 单元类型与网格划分 39

5.3.2 边界约束与载荷 39

5.3.3 结果处理 40

第六章 结论与展望 41

参考文献 43