设计简介

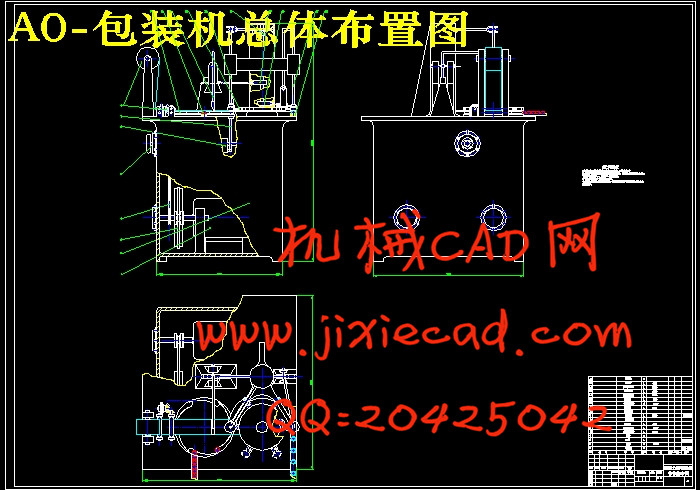

摘要:颗粒状糖果包装机设计是典型的机械系统设计,它不仅包括机构的尺寸、强度设计,还包

括了传动机械系统设计。本设计主要是针对圆台柱状巧克力糖的铝箔纸包装。设计主要内容有三

方面:设计方案设计、机械手及进出糖机构设计与传动系统链设计。

机械手及进出糖机构设计是本设计功能能否执行的灵魂,它也是本设计的设计重点之一。它

要实现巧克力糖的输入、折边、抄底边、等等功能,直到最后由输送带输出。整个系统功能实现

中,机械手要实现的是夹糖、折边、转送等重要功能,因此对机械手的形状、夹紧力及转位角度

也提出了不同的设计要求,设计机械手时,也始终回绕着这几点进行。

传动系统设计,作为一个动作执行系统,动力是必不可少的,当然对动力的传递系统也就显得

尤其重要了。系统功能中要实现机械手转位、送糖盘转位、供纸、剪纸、抄纸、接糖、顶糖及拨

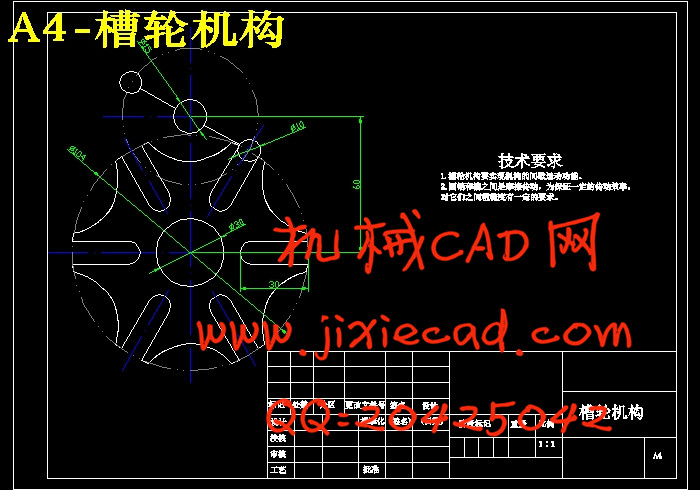

糖等功能,它们都需要不同大小的动力,这就需要传动系统的调节。如在机械手的转位功能中,

为实现间歇的转位功能就得通过传动链中的槽轮机构来实现,该机构要保证机械手在转到位后,

有一定的停留时间,从而为顶糖、接糖及拨糖功能的实现提供必要的机械动作执行时间。设计好

的包装机机构正常的生产率为120r/min,且其生产率可在70~130r/min.

关键词:包装机,巧克力糖包装,机械手。

Abstract: The grain candy packer design is a typical machine system design.

It not only included the organization's size, strength...etc. the design. And

itstillincludedthedesignofthetransmissionsystem.Thisdesignprimarily

aims at the circle pillar chocolates' aluminum foil packing. The design only

contents contain three sides: Design project design, machine hand and I/O

sugar mechanism design and the transmission system design.

It is Soul whether the function of the machine hand and I/O sugar

mechanism’s design can carry out in this design. It is also one of the design

points of this design. It wants to realize the importation, fold of the

chocolates the sides, etc. the function. Until it finally be output by belt

conveyer. In whole system function realizes, the machine hand realizes many

important function, for example: clip the sugar, fold of the chocolates the

sides, transfer...etc. Therefore to the shape of the machine hand, clip the

tight dint and turn the angle also bring upped the different design request.

When designed the machine hand, it is also proceeding with the center of these

points.

System, motive is necessary. Certainly it is particularly important of

the power transmission system. In the system function, it must realize moving

the machine hand, moving the sugar dish, providing the paper, cutting paper,

curling, connecting the sugar, crest the sugar and dialing the sugar etc. All

these functions need the different power. It can be controlled with the

transmission system. Such as the function of turning machine hand, for

realizing a function of intermittent turning it needs the sheave of the

transmission to regulate. After the machine turned the assurance position,

the mechanism wants to have certainly stop over time, it can take enough time

to crest sugar, connect the sugar and dial sugar. The transmission system

still guaranteed the normal rate of production of packer to 120 r/ min .At

the same time it can be controlled the rate of production at 70 ~ 130 r/ min.

Key words:Packer, chocolates packing, machine hand.

目录

前言

........................................................................................................................................7

第一章 糖果包装机方案设计

............................................................................8

1.1 设计任务抽象化 ................................................................................................................... 8

1.1.1建立黑箱.................................................................................................................................... 8

1.1.2功能分解.................................................................................................................................... 9

1.2确定工艺原理.......................................................................................................................... 9

1.3确定技术过程........................................................................................................................ 10

1.4引进技术系统,确定边界 ............................................................................................. 10

1.5确定功能结构.........................................................................................................................11

1.5.1 总功能..................................................................................................................................... 11

1.5.2 功能分解 ............................................................................................................................... 11

1.6方案确定 .................................................................................................................................. 12

1.6.1寻找技术物理效应和功能载体,功能元求解目录表........................................................... 12

1.6.2巧克力糖包装系统解 .............................................................................................................. 12

1.6.3巧克力糖包装装置的评价表 .................................................................................................. 14

1.6.4确定最佳方案 .......................................................................................................................... 14

第二章 传动系统设计.............................................................................................15

2.1传动系统结构简图 ............................................................................................................. 15

2.2 选用电机................................................................................................................................. 15

2.3带轮设计 .................................................................................................................................. 16

2.3.1带轮优缺点 .............................................................................................................................. 16

2.3.2 选用带轮要求 ......................................................................................................................... 16

2.3.3 带轮设计要求 ......................................................................................................................... 17

2.3.4 带轮设计过程 ......................................................................................................................... 17

2.4链轮设计 .................................................................................................................................. 21

2.4.1链传动优缺点 .......................................................................................................................... 21

2.4.2链传动的设计过程 .................................................................................................................. 21

2.5齿轮的设计............................................................................................................................. 25

2.5.1齿轮材料.................................................................................................................................. 25

2.5.2 分配轴上螺旋齿轮的尺寸计算 ............................................................................................. 25

2.5.3 机械手及送糖轴上的螺旋齿轮的尺寸计算 ......................................................................... 26

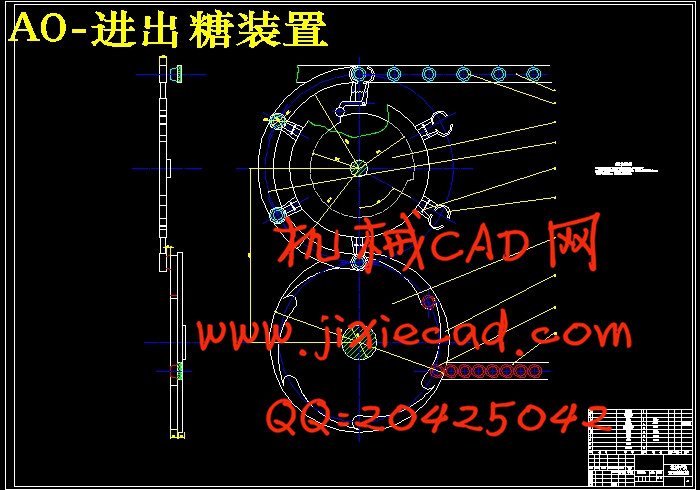

第三章 机械手及进出糖机构设计...............................................................27

3.1夹持装置设计........................................................................................................................ 27

3.1.1 设计要求................................................................................................................................... 27

3.1.2 基本结构如图 ......................................................................................................................... 27

3.1.3夹紧力P夹计算.......................................................................................................................... 27

3.1.4 弹簧力P弹簧计算..................................................................................................................... 28

3.1.5 开闭角а的计算 ................................................................................................................... 29

3.2凸轮设计 .................................................................................................................................. 29

3.2.1 选择凸轮类型 ......................................................................................................................... 29

3.2.2 凸轮材料选择 ......................................................................................................................... 30

3.2.3凸轮尺寸计算 .......................................................................................................................... 30

3.2.4 凸轮强度计算 ......................................................................................................................... 31

3.3棘轮设计 .................................................................................................................................. 32

3.3.1棘轮材料选择 .......................................................................................................................... 32

3.3.2棘轮形状确定 .......................................................................................................................... 32

3.4 六槽槽轮机构设计............................................................................................................ 33

3.4.1 槽轮分类及材料选择 ............................................................................................................. 33

3.4.2 槽轮结构设计及尺寸计算 ..................................................................................................... 33

第四章 其它机构原理.............................................................................................36

4.1 顶糖、接糖机构示意图 ................................................................................................. 36

4.2抄纸和拨糖机构示意图 .................................................................................................. 37

第五章 巧克力糖包装机工作循环图............................................................38

5.1 机械手Ⅰ工位段 ................................................................................................................. 38

5.2 机械手Ⅱ工位段 ................................................................................................................. 39

致 谢..............................................................................................................................40

参考文献

括了传动机械系统设计。本设计主要是针对圆台柱状巧克力糖的铝箔纸包装。设计主要内容有三

方面:设计方案设计、机械手及进出糖机构设计与传动系统链设计。

机械手及进出糖机构设计是本设计功能能否执行的灵魂,它也是本设计的设计重点之一。它

要实现巧克力糖的输入、折边、抄底边、等等功能,直到最后由输送带输出。整个系统功能实现

中,机械手要实现的是夹糖、折边、转送等重要功能,因此对机械手的形状、夹紧力及转位角度

也提出了不同的设计要求,设计机械手时,也始终回绕着这几点进行。

传动系统设计,作为一个动作执行系统,动力是必不可少的,当然对动力的传递系统也就显得

尤其重要了。系统功能中要实现机械手转位、送糖盘转位、供纸、剪纸、抄纸、接糖、顶糖及拨

糖等功能,它们都需要不同大小的动力,这就需要传动系统的调节。如在机械手的转位功能中,

为实现间歇的转位功能就得通过传动链中的槽轮机构来实现,该机构要保证机械手在转到位后,

有一定的停留时间,从而为顶糖、接糖及拨糖功能的实现提供必要的机械动作执行时间。设计好

的包装机机构正常的生产率为120r/min,且其生产率可在70~130r/min.

关键词:包装机,巧克力糖包装,机械手。

Abstract: The grain candy packer design is a typical machine system design.

It not only included the organization's size, strength...etc. the design. And

itstillincludedthedesignofthetransmissionsystem.Thisdesignprimarily

aims at the circle pillar chocolates' aluminum foil packing. The design only

contents contain three sides: Design project design, machine hand and I/O

sugar mechanism design and the transmission system design.

It is Soul whether the function of the machine hand and I/O sugar

mechanism’s design can carry out in this design. It is also one of the design

points of this design. It wants to realize the importation, fold of the

chocolates the sides, etc. the function. Until it finally be output by belt

conveyer. In whole system function realizes, the machine hand realizes many

important function, for example: clip the sugar, fold of the chocolates the

sides, transfer...etc. Therefore to the shape of the machine hand, clip the

tight dint and turn the angle also bring upped the different design request.

When designed the machine hand, it is also proceeding with the center of these

points.

System, motive is necessary. Certainly it is particularly important of

the power transmission system. In the system function, it must realize moving

the machine hand, moving the sugar dish, providing the paper, cutting paper,

curling, connecting the sugar, crest the sugar and dialing the sugar etc. All

these functions need the different power. It can be controlled with the

transmission system. Such as the function of turning machine hand, for

realizing a function of intermittent turning it needs the sheave of the

transmission to regulate. After the machine turned the assurance position,

the mechanism wants to have certainly stop over time, it can take enough time

to crest sugar, connect the sugar and dial sugar. The transmission system

still guaranteed the normal rate of production of packer to 120 r/ min .At

the same time it can be controlled the rate of production at 70 ~ 130 r/ min.

Key words:Packer, chocolates packing, machine hand.

目录

前言

........................................................................................................................................7

第一章 糖果包装机方案设计

............................................................................8

1.1 设计任务抽象化 ................................................................................................................... 8

1.1.1建立黑箱.................................................................................................................................... 8

1.1.2功能分解.................................................................................................................................... 9

1.2确定工艺原理.......................................................................................................................... 9

1.3确定技术过程........................................................................................................................ 10

1.4引进技术系统,确定边界 ............................................................................................. 10

1.5确定功能结构.........................................................................................................................11

1.5.1 总功能..................................................................................................................................... 11

1.5.2 功能分解 ............................................................................................................................... 11

1.6方案确定 .................................................................................................................................. 12

1.6.1寻找技术物理效应和功能载体,功能元求解目录表........................................................... 12

1.6.2巧克力糖包装系统解 .............................................................................................................. 12

1.6.3巧克力糖包装装置的评价表 .................................................................................................. 14

1.6.4确定最佳方案 .......................................................................................................................... 14

第二章 传动系统设计.............................................................................................15

2.1传动系统结构简图 ............................................................................................................. 15

2.2 选用电机................................................................................................................................. 15

2.3带轮设计 .................................................................................................................................. 16

2.3.1带轮优缺点 .............................................................................................................................. 16

2.3.2 选用带轮要求 ......................................................................................................................... 16

2.3.3 带轮设计要求 ......................................................................................................................... 17

2.3.4 带轮设计过程 ......................................................................................................................... 17

2.4链轮设计 .................................................................................................................................. 21

2.4.1链传动优缺点 .......................................................................................................................... 21

2.4.2链传动的设计过程 .................................................................................................................. 21

2.5齿轮的设计............................................................................................................................. 25

2.5.1齿轮材料.................................................................................................................................. 25

2.5.2 分配轴上螺旋齿轮的尺寸计算 ............................................................................................. 25

2.5.3 机械手及送糖轴上的螺旋齿轮的尺寸计算 ......................................................................... 26

第三章 机械手及进出糖机构设计...............................................................27

3.1夹持装置设计........................................................................................................................ 27

3.1.1 设计要求................................................................................................................................... 27

3.1.2 基本结构如图 ......................................................................................................................... 27

3.1.3夹紧力P夹计算.......................................................................................................................... 27

3.1.4 弹簧力P弹簧计算..................................................................................................................... 28

3.1.5 开闭角а的计算 ................................................................................................................... 29

3.2凸轮设计 .................................................................................................................................. 29

3.2.1 选择凸轮类型 ......................................................................................................................... 29

3.2.2 凸轮材料选择 ......................................................................................................................... 30

3.2.3凸轮尺寸计算 .......................................................................................................................... 30

3.2.4 凸轮强度计算 ......................................................................................................................... 31

3.3棘轮设计 .................................................................................................................................. 32

3.3.1棘轮材料选择 .......................................................................................................................... 32

3.3.2棘轮形状确定 .......................................................................................................................... 32

3.4 六槽槽轮机构设计............................................................................................................ 33

3.4.1 槽轮分类及材料选择 ............................................................................................................. 33

3.4.2 槽轮结构设计及尺寸计算 ..................................................................................................... 33

第四章 其它机构原理.............................................................................................36

4.1 顶糖、接糖机构示意图 ................................................................................................. 36

4.2抄纸和拨糖机构示意图 .................................................................................................. 37

第五章 巧克力糖包装机工作循环图............................................................38

5.1 机械手Ⅰ工位段 ................................................................................................................. 38

5.2 机械手Ⅱ工位段 ................................................................................................................. 39

致 谢..............................................................................................................................40

参考文献