设计简介

摘要

压力容器在石油、化工以及冶金等领域应用广泛,结构虽然简单,但受力情况却很复杂,一旦投入使用就要连续运行,还具有爆炸的危险。随着科学技术的发展,压力容器制造水平越来越高,压力容器涉及多个学科,综合性很强,一台压力容器从参数确定到投入正常使用,要通过很多的环节及相关部门的各类工程技术人员的共同努力才能实现。因此,重视压力容器设计具有重要的意义。本论文简述了压力容器结构标准,主要探讨压力容器设计的一般要求。通过查阅压力容器工艺手册,我们发现压力容器的每个部分都需要确定使用的材料与工艺,不可忽视每一个很小的环节,否则将会有生命的危险。这样多种性的操作特点给压力容器从选材、制造、检验到使用、维护以致管理等诸方面造成了复杂性,因此对压力容器的制造、现场组焊、检验等诸多环节提出了越来越高的要求。

关键词: 压力容器 设计要求 结构标准 工艺

ABSTRACT

The pressure vessel is widely used in petroleum, chemical, metallurgy and other fields.

Although its structure is simple, the force is very complex. Once put into use ,it is necessary to run continuously, and also has a risk of explosion. With the development of science and technology, the level of pressure vessel manufacturing increasingly high.The pressure vessel involves multiple disciplines and highly integrated.A pressure vessel,from the determination of the parameters to put into regular use, can be achieved through the joint efforts of many links and relevant departments of the various types of engineering and technical personnel. Therefore, the emphasis on pressure vessel design is of great significance. This paper outlines the pressure vessel structural standards,mainly has discussed the design requirements of pressure vessels.Through the inspection of pressure vessel technology manual, we found that each part of the pressure vessel needs to determine the use the materials and craft and each a small part can not be ignored, otherwise there will be lives at risk.Such a variety of operating characteristics result in the pressure vessel from the selection of materials, manufacture, examination to the use, maintenanceand complexity.Therefore,to the manufacture, scene group welded, examination and so many other aspects of the pressure vessel set the more and more high demands.

Keywords :pressure vessel;design requirements ;structural standards;craft

目录压力容器在石油、化工以及冶金等领域应用广泛,结构虽然简单,但受力情况却很复杂,一旦投入使用就要连续运行,还具有爆炸的危险。随着科学技术的发展,压力容器制造水平越来越高,压力容器涉及多个学科,综合性很强,一台压力容器从参数确定到投入正常使用,要通过很多的环节及相关部门的各类工程技术人员的共同努力才能实现。因此,重视压力容器设计具有重要的意义。本论文简述了压力容器结构标准,主要探讨压力容器设计的一般要求。通过查阅压力容器工艺手册,我们发现压力容器的每个部分都需要确定使用的材料与工艺,不可忽视每一个很小的环节,否则将会有生命的危险。这样多种性的操作特点给压力容器从选材、制造、检验到使用、维护以致管理等诸方面造成了复杂性,因此对压力容器的制造、现场组焊、检验等诸多环节提出了越来越高的要求。

关键词: 压力容器 设计要求 结构标准 工艺

ABSTRACT

The pressure vessel is widely used in petroleum, chemical, metallurgy and other fields.

Although its structure is simple, the force is very complex. Once put into use ,it is necessary to run continuously, and also has a risk of explosion. With the development of science and technology, the level of pressure vessel manufacturing increasingly high.The pressure vessel involves multiple disciplines and highly integrated.A pressure vessel,from the determination of the parameters to put into regular use, can be achieved through the joint efforts of many links and relevant departments of the various types of engineering and technical personnel. Therefore, the emphasis on pressure vessel design is of great significance. This paper outlines the pressure vessel structural standards,mainly has discussed the design requirements of pressure vessels.Through the inspection of pressure vessel technology manual, we found that each part of the pressure vessel needs to determine the use the materials and craft and each a small part can not be ignored, otherwise there will be lives at risk.Such a variety of operating characteristics result in the pressure vessel from the selection of materials, manufacture, examination to the use, maintenanceand complexity.Therefore,to the manufacture, scene group welded, examination and so many other aspects of the pressure vessel set the more and more high demands.

Keywords :pressure vessel;design requirements ;structural standards;craft

中文摘要 I

英文摘要 II

前言 1

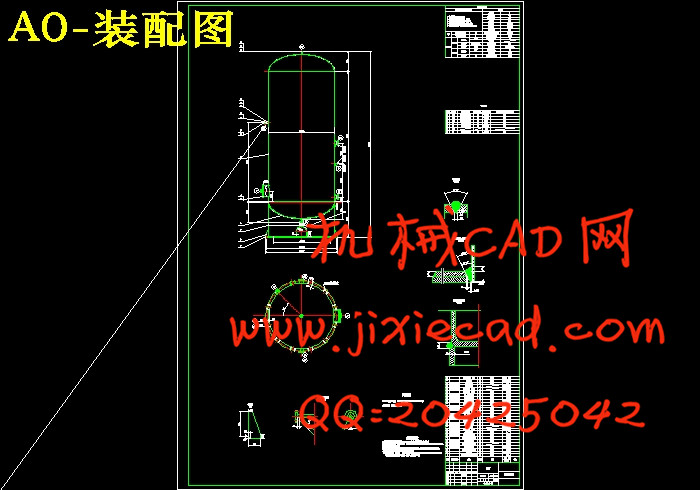

第1章 压力容器 2

1.1 压力容器的结构与分类 2

1.2 压力容器的失效和设计要求 3

1.3 设计参数的规定 3

第2章 容器的选型和选材 5

2.1 筒体的选材及结构 5

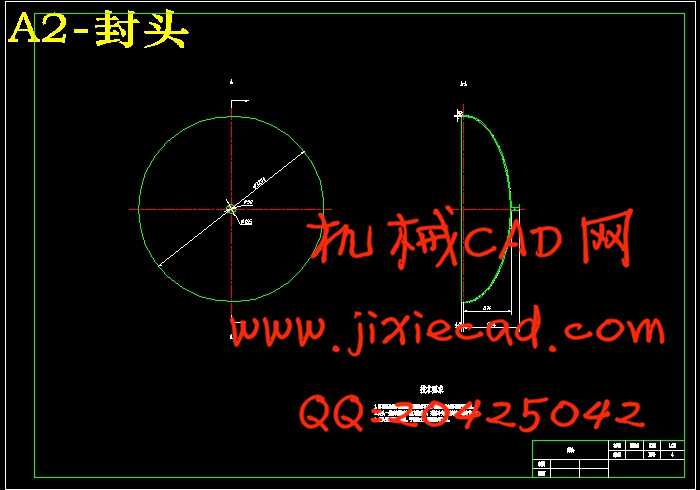

2.2 封头的结构及选材 5

第3章 设计计算 6

3.1 筒体壁厚计算 6

3.2 封头壁厚计算 6

3.3 压力试验 7

第4章 容器的开孔及补强 8

4.1 容器的开孔 8

4.2 容器的补强 9

第5章 支座的选择 13

5.1 支座结构和材料的选取 13

5.2 裙座设计 13

5.2.1 座体设计 13

5.2.2基础环设计 14

5.2.3 螺栓座的设计 15

第6章 容器焊缝标准 16

6.1 压力容器焊接结构设计要求 16

6.2 筒体与椭圆封头的焊接接头 16

6.3 管法兰与接管的焊接接头 16

6.4 接管与壳体的焊接接头 16

结束语 18

参考文献 19

致谢 20