设计简介

摘要

热水集水器是使用范围很广的一种化工生产和换热站流体循环设备,其中,在居民采暖系统中的,集水器管理着若干的支路管道,在空调水系统和工业水系统中的,同样管理若干的支路管道,分别包括回水支路和供水支路,但其较大多位DN350-DN1500不等,用钢板制作,属于专业类压力容器[1]。多个容器之间需要安装压力调节阀,且需要有自动旁通管路辅助。可见在生活生产和众多领域中,热水集水器都表现出它非同寻常的作用。在合理的结构设计与完善的加工工艺流程下,所制作出的热水集水器更能保证工业的安全生产和生活上的舒适便捷。所以热水集水器的结构设计和加工工艺创新优化就尤为重要。

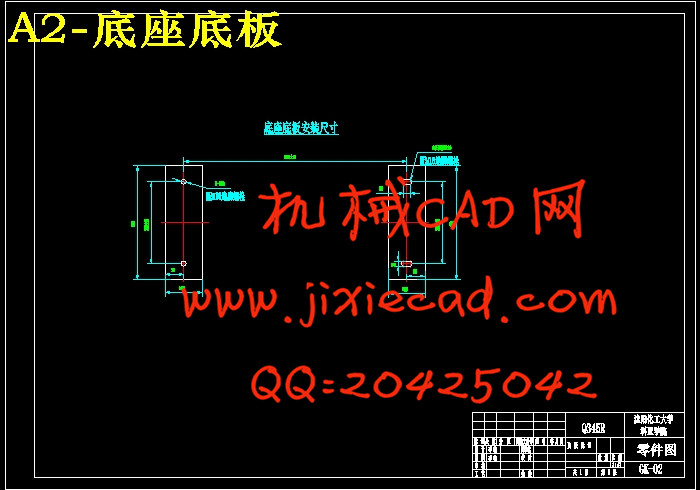

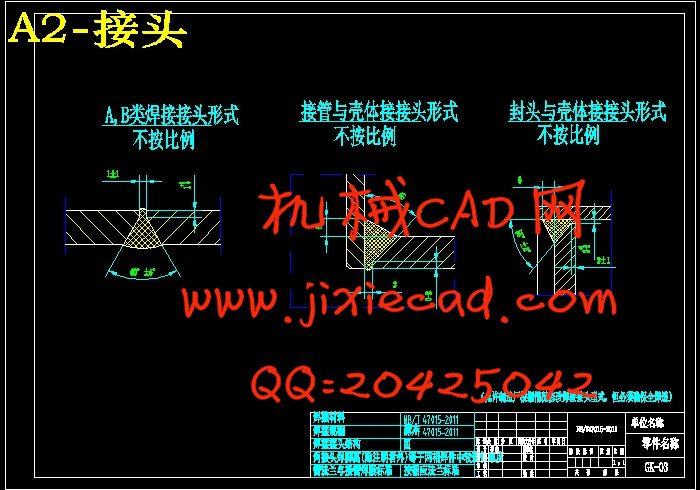

本设计任务主要是根据生产加工要求,设计制作卧式热水集水器。卧式热水集水器的优点是制作流程简单,安装方便,安全系数高。本次热水集水器的设计主要是在压力为0.2MPa,介质温度为80℃,筒体内直径 Di为500mm,筒体长度L为1500mm的条件下罐体材料的选择,工艺流程的规范,封头形式的确定以及各部位的强度计算和整体应力校核(结构设计中的标准件可以参照国家标准根据设计条件直接选取;非标准件,设计完结构后必须进行相应的应力校核)

在次设计中明确了各种管材的形式及其国家规定的应用范围,重点阐述了热水集水器的设计理念、设计标准。在罐体材料选择方面,对多种钢材的性能进行了多角度的对比。选择出的板材既符合了质量技术要求又节约了生产成本。

关键字: 热水集水器; 结构设计; 强度计算; 应力校核

Abstract

Catchment water heater is using a wide range of chemical industry production and heat exchange station fluid circulation devices. Among them, in residents of heating system, water collector manages a number of branch pipe and in air conditioning water system and industrial water system, management of the same number of branch pipeline, respectively include a backwater branch and water supply branch, but the large number of DN350-DN1500 ranging, the use made of steel plate, which belongs to the professional class pressure vessel. A plurality of containers between the need to install a pressure regulating valve, and the need to automatically bypass pipeline auxiliary[2]. Visible in the production and life in many fields, hot water collector showed its extraordinary role in reasonable Structure design and perfect processing flow, produced by the hot water collector more assurance of industrial safety in production and the life convenient and comfortable[3]. So the catchment water heater structure design and process optimization and innovation is particularly important.

The design task is mainly according to the requirements of production and processing, design and production of horizontal catchment water heater. Advantages of horizontal catchment water heater is making process is simple, the installation is convenient, high safety coefficient. The hot water collector design is mainly in the pressure of 0.2MPa, medium temperature of 80 DEG C, the cylinder diameter Di is 500mm, the cylinder length L for the choice of the material of tank under conditions of 1500mm, process specification, forms of head and various parts of the strength calculation and overall should be checking (structure design of standard parts can be according to the national standard of the design according to the direct selection; non standard parts to complete the design After the structure must be carried out the corresponding stress check.

Made clear the scope of application of various pipes form and the provisions of the state in the design, focusing on the catchment water heater design philosophy, design standard. In the tank material selection, the performance of a variety of steel products are multi angle comparison. The selected sheet is in line with the quality and technical requirements and save the production cost.

Keywords: Hot water collector; Structural design; Strength calculation; Stress check

目 录

第一章 综述 1

1.1 热水集水器概述 1

1.2 热水集水器及附件设计 1

1.2.1 热水集水器的进出水口 1

1.2.2 在热水集水器之前的供水连接管道 1

1.2.3 热水集水器的旁通管 2

1.2.4 热水集水器排气阀 2

1.3 热水集水器的种类 2

1.3.1 普通型热水集水器 2

1.3.2 自动功能型热水集水器 2

1.4 热水集水器的设计 3

1.5 系统设计 3

1.5.1 系统设计标准以及平衡阀要求 3

1.5.2 热水集水器支管温控器及热电执行器 3

1.6 热电执行器及温控阀 3

1.7 热水集水器结构和功能及自动化 4

1.8 热水集水器维护 5

1.8.1 热水集水器材料 5

1.8.2 热水集水器密封性 5

1.9 热水集水器标准及技术要求 5

1.9.1 热水集水器的设计标准和技术要求 5

1.9.2 热水集水器的技术要求及实物图 6

第二章 管材介绍 7

2.1 管道的介绍 7

2.1.1 管道的材质和分类 7

2.2 管件的种类及连接方式 7

2.2.1 金属管道的连接 7

2.2.2 非金属管道的连接 8

2.3 管道附件及施工前准备 8

2.3.1 管道附件分为配水附件和控制附件 8

2.3.2 管道施工前的准备 8

2.4 管道的分类与分级 9

2.4.1 管道分类 9

2.4.2 管道的分级 10

第三章 制造材料介绍 11

3.1 Q345R的介绍 11

3.2 16Mn的介绍 11

3.3 Q235的介绍 12

3.4 20号钢的介绍 13

3.5 20G无缝钢管的介绍 14

3.6 高压锅炉钢管介绍 14

3.7 冲击功试验及效果 14

第四章 具体强度计算与应力校核 16

4.1 计算条件 16

4.2 内压圆筒校核 17

4.3 左右封头、筒体、平盖厚度计算 18

4.5 卧式容器(双鞍座) 19

4.6支座反力计算与筒体弯矩计算 20

4.7筒体的轴向应力计算 21

4.8鞍座处圆筒周向应力与鞍座应力计算 22

4.9 开孔补强计算 23

4.9.1 N4开孔补强计算 23

4.12.2 N5开孔补强计算 24

4.12.2 N1、N2、N3、N6开孔补强计算 25

第五章 总结 26

参考文献 27

致谢 28

热水集水器是使用范围很广的一种化工生产和换热站流体循环设备,其中,在居民采暖系统中的,集水器管理着若干的支路管道,在空调水系统和工业水系统中的,同样管理若干的支路管道,分别包括回水支路和供水支路,但其较大多位DN350-DN1500不等,用钢板制作,属于专业类压力容器[1]。多个容器之间需要安装压力调节阀,且需要有自动旁通管路辅助。可见在生活生产和众多领域中,热水集水器都表现出它非同寻常的作用。在合理的结构设计与完善的加工工艺流程下,所制作出的热水集水器更能保证工业的安全生产和生活上的舒适便捷。所以热水集水器的结构设计和加工工艺创新优化就尤为重要。

本设计任务主要是根据生产加工要求,设计制作卧式热水集水器。卧式热水集水器的优点是制作流程简单,安装方便,安全系数高。本次热水集水器的设计主要是在压力为0.2MPa,介质温度为80℃,筒体内直径 Di为500mm,筒体长度L为1500mm的条件下罐体材料的选择,工艺流程的规范,封头形式的确定以及各部位的强度计算和整体应力校核(结构设计中的标准件可以参照国家标准根据设计条件直接选取;非标准件,设计完结构后必须进行相应的应力校核)

在次设计中明确了各种管材的形式及其国家规定的应用范围,重点阐述了热水集水器的设计理念、设计标准。在罐体材料选择方面,对多种钢材的性能进行了多角度的对比。选择出的板材既符合了质量技术要求又节约了生产成本。

关键字: 热水集水器; 结构设计; 强度计算; 应力校核

Abstract

Catchment water heater is using a wide range of chemical industry production and heat exchange station fluid circulation devices. Among them, in residents of heating system, water collector manages a number of branch pipe and in air conditioning water system and industrial water system, management of the same number of branch pipeline, respectively include a backwater branch and water supply branch, but the large number of DN350-DN1500 ranging, the use made of steel plate, which belongs to the professional class pressure vessel. A plurality of containers between the need to install a pressure regulating valve, and the need to automatically bypass pipeline auxiliary[2]. Visible in the production and life in many fields, hot water collector showed its extraordinary role in reasonable Structure design and perfect processing flow, produced by the hot water collector more assurance of industrial safety in production and the life convenient and comfortable[3]. So the catchment water heater structure design and process optimization and innovation is particularly important.

The design task is mainly according to the requirements of production and processing, design and production of horizontal catchment water heater. Advantages of horizontal catchment water heater is making process is simple, the installation is convenient, high safety coefficient. The hot water collector design is mainly in the pressure of 0.2MPa, medium temperature of 80 DEG C, the cylinder diameter Di is 500mm, the cylinder length L for the choice of the material of tank under conditions of 1500mm, process specification, forms of head and various parts of the strength calculation and overall should be checking (structure design of standard parts can be according to the national standard of the design according to the direct selection; non standard parts to complete the design After the structure must be carried out the corresponding stress check.

Made clear the scope of application of various pipes form and the provisions of the state in the design, focusing on the catchment water heater design philosophy, design standard. In the tank material selection, the performance of a variety of steel products are multi angle comparison. The selected sheet is in line with the quality and technical requirements and save the production cost.

Keywords: Hot water collector; Structural design; Strength calculation; Stress check

目 录

第一章 综述 1

1.1 热水集水器概述 1

1.2 热水集水器及附件设计 1

1.2.1 热水集水器的进出水口 1

1.2.2 在热水集水器之前的供水连接管道 1

1.2.3 热水集水器的旁通管 2

1.2.4 热水集水器排气阀 2

1.3 热水集水器的种类 2

1.3.1 普通型热水集水器 2

1.3.2 自动功能型热水集水器 2

1.4 热水集水器的设计 3

1.5 系统设计 3

1.5.1 系统设计标准以及平衡阀要求 3

1.5.2 热水集水器支管温控器及热电执行器 3

1.6 热电执行器及温控阀 3

1.7 热水集水器结构和功能及自动化 4

1.8 热水集水器维护 5

1.8.1 热水集水器材料 5

1.8.2 热水集水器密封性 5

1.9 热水集水器标准及技术要求 5

1.9.1 热水集水器的设计标准和技术要求 5

1.9.2 热水集水器的技术要求及实物图 6

第二章 管材介绍 7

2.1 管道的介绍 7

2.1.1 管道的材质和分类 7

2.2 管件的种类及连接方式 7

2.2.1 金属管道的连接 7

2.2.2 非金属管道的连接 8

2.3 管道附件及施工前准备 8

2.3.1 管道附件分为配水附件和控制附件 8

2.3.2 管道施工前的准备 8

2.4 管道的分类与分级 9

2.4.1 管道分类 9

2.4.2 管道的分级 10

第三章 制造材料介绍 11

3.1 Q345R的介绍 11

3.2 16Mn的介绍 11

3.3 Q235的介绍 12

3.4 20号钢的介绍 13

3.5 20G无缝钢管的介绍 14

3.6 高压锅炉钢管介绍 14

3.7 冲击功试验及效果 14

第四章 具体强度计算与应力校核 16

4.1 计算条件 16

4.2 内压圆筒校核 17

4.3 左右封头、筒体、平盖厚度计算 18

4.5 卧式容器(双鞍座) 19

4.6支座反力计算与筒体弯矩计算 20

4.7筒体的轴向应力计算 21

4.8鞍座处圆筒周向应力与鞍座应力计算 22

4.9 开孔补强计算 23

4.9.1 N4开孔补强计算 23

4.12.2 N5开孔补强计算 24

4.12.2 N1、N2、N3、N6开孔补强计算 25

第五章 总结 26

参考文献 27

致谢 28