设计简介

摘要

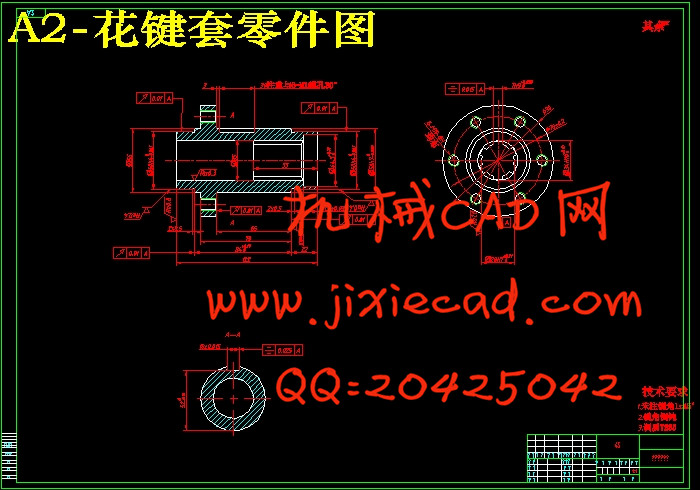

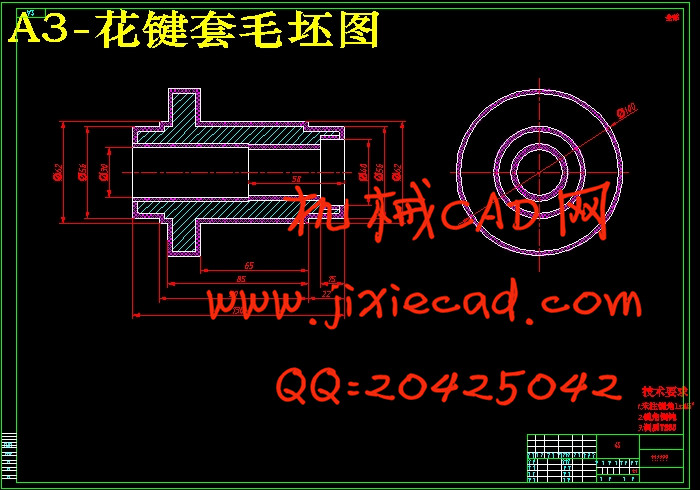

本文首先对花键套的零件进行分析,通过对花键套进行的研究和分析,描述了它的毛坯制造形式、机械加工余量、基准选择、工序尺寸和毛坯尺寸的确定,以及切削用量和工时的计算等相关内容。为了提高劳动生产率,降低劳动强度,保证加工质量,与指导老协商后,觉得用编程比较合适。在这次毕业设计中,根据课题所给的零件图、技术要求,通过查阅相关资料和书籍,了解和掌握了的机械加工工艺和编程的一般方法和步骤,并运用这些方法和步骤进行了花键套的机械加工工艺规程与编程设计。

关键词:花键套 工序 工艺规程 编程

目 录

摘 要

第一章 前言 ··········································································01

第二章 花键套的结构工艺性分析 ················································01

2.1 零件的作用 ····················································································03

2.2 零件的结构特点分析 ········································································03

2.3 零件的主要技术要求 ········································································03

2.4 零件加工工艺分析 ···········································································03

第三章 花键套加工工艺设计 ······················································05

3.1 确定毛坯的制造形式 ········································································07

3.2 基面的选择 ····················································································09

3.3 加工阶段的划分 ··············································································13

3.3.1划分准则 ·················································································15

3.3.2时效处理的安排 ········································································17

3.4 制定工艺路线 ·················································································20

3.5 加工机床及刀具的选择 ·····································································22

3.6 机械加工余量、工序尺寸及毛坯尺寸的确定 ··········································23

3.7 确定切削用量和工时计算 ··································································25

第四章 花键套的编程 ·······························································27

4.1 半精车

4.2 粗车、半精车

第五章 结论 ···········································································32

第六章 致谢 ···········································································33

第七章 参考文献 ·····································································34