设计简介

端盖产品模具设计

摘 要

系统介绍了塑艺及模具成型结构对塑件质量的影响分析,浇注系统的设计,模具成型部分和总装结构的设计。介绍了端盖注塑模具设计时要注意的要点,并较多的考虑了模具结构的调整性、易更换性及模具成本。从控制制件尺寸精度出发,对端盖注塑模的各主要尺寸进行了理论计算,以确定各工作零件的尺寸,从模具设计到零部件的加工工艺以及装配工艺等进行详细的阐述,并应用CAD进行各重要零件的设计。

关键词:工艺分析;塑件成型;浇注系统;模具结构。

End Cover plastic injecting mold design

Abstract

The molding process of plastic parts, the effect analysis to plastic parts quality caused by molding structure, as well as the casting system design, partial and general design of mold moulding introduced respectively. The critical points of mold for plastic design are introduced, and the adjustable character of molding structure、exchange character as well as the molding costs are all considered farther. Starting from controlling dimensional accuracy, the carry the cover to the main dimensions of injection molding are carried out so as to determine the size of different parts, the molding design and the process of parts as well as assembling process and etc of injection molding are stated in details.

Key words: process analysis; plastic parts moulding; casting system; molding structure.

目录

0 绪论…………………………………………………………………………1

0.1国内塑料模的现状和发展趋势…………………………………………1

0.2国外的注塑模的发展情况………………………………………………3

1 模塑工艺规程的编制………………………………………………………5

1.1塑件的工艺性分…………………………………………………………5

1.1.1塑件的原材料分析……………………………………………………5

1.2.1塑件的结构和尺寸精度及表面质量分析……………………………5

1.3塑件注塑工艺参数的确定………………………………………………6

1.4.塑料成型设备的选取……………………………………………………7

2 注塑模的结构设计……………………………………………………………9

2.1分型面选择………………………………………………………………9

2.2确定型腔的数目及排列方式……………………………………………11

2.3浇注系统设计……………………………………………………………11

2.4抽芯机构设计……………………………………………………………13

2.5推出机构设计……………………………………………………………14

2.6成型零件结构设计………………………………………………………15

3 端盖注塑模具的有关计算…………………………………………………18

4 模具加热和冷却系统的设计………………………………………………20

5 模具闭合高度的确定………………………………………………………21

6 注塑机有关参数的校核……………………………………………………22

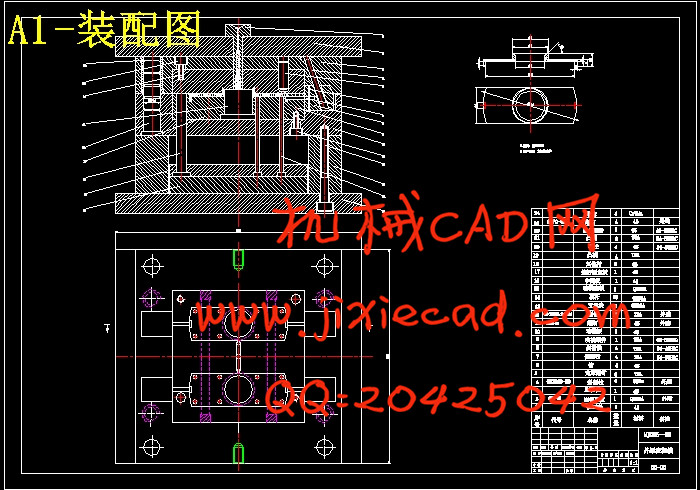

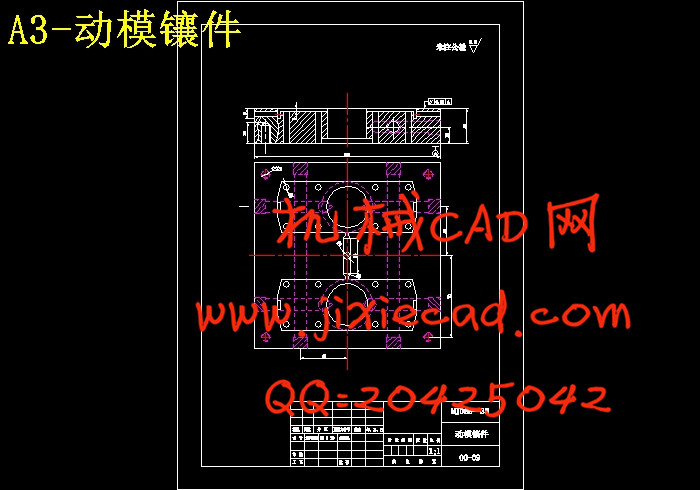

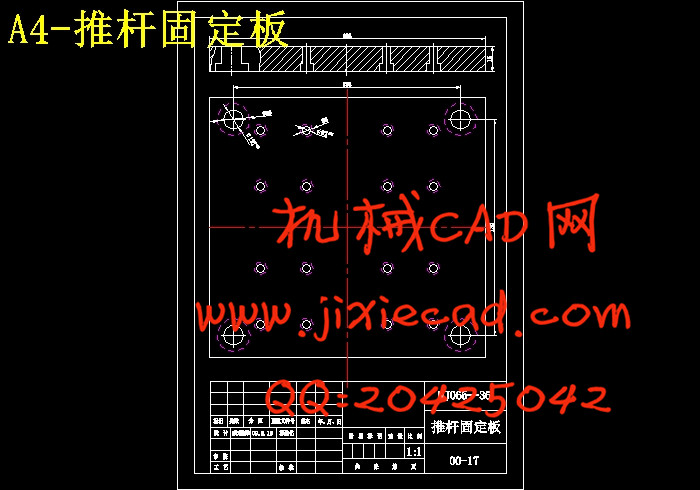

7 绘制模具总装配图和非标准零件工作图…………………………………23

8 模具主要零件加工工艺规程的编制………………………………………24

9 注塑模具的安装和试模……………………………………………………26

9.1 模具安装………………………………………………………………26

9.2试模……………………………………………………………………26

致谢…………………………………………………………………………30

参考文献……………………………………………………………………31

摘 要

系统介绍了塑艺及模具成型结构对塑件质量的影响分析,浇注系统的设计,模具成型部分和总装结构的设计。介绍了端盖注塑模具设计时要注意的要点,并较多的考虑了模具结构的调整性、易更换性及模具成本。从控制制件尺寸精度出发,对端盖注塑模的各主要尺寸进行了理论计算,以确定各工作零件的尺寸,从模具设计到零部件的加工工艺以及装配工艺等进行详细的阐述,并应用CAD进行各重要零件的设计。

关键词:工艺分析;塑件成型;浇注系统;模具结构。

End Cover plastic injecting mold design

Abstract

The molding process of plastic parts, the effect analysis to plastic parts quality caused by molding structure, as well as the casting system design, partial and general design of mold moulding introduced respectively. The critical points of mold for plastic design are introduced, and the adjustable character of molding structure、exchange character as well as the molding costs are all considered farther. Starting from controlling dimensional accuracy, the carry the cover to the main dimensions of injection molding are carried out so as to determine the size of different parts, the molding design and the process of parts as well as assembling process and etc of injection molding are stated in details.

Key words: process analysis; plastic parts moulding; casting system; molding structure.

目录

0 绪论…………………………………………………………………………1

0.1国内塑料模的现状和发展趋势…………………………………………1

0.2国外的注塑模的发展情况………………………………………………3

1 模塑工艺规程的编制………………………………………………………5

1.1塑件的工艺性分…………………………………………………………5

1.1.1塑件的原材料分析……………………………………………………5

1.2.1塑件的结构和尺寸精度及表面质量分析……………………………5

1.3塑件注塑工艺参数的确定………………………………………………6

1.4.塑料成型设备的选取……………………………………………………7

2 注塑模的结构设计……………………………………………………………9

2.1分型面选择………………………………………………………………9

2.2确定型腔的数目及排列方式……………………………………………11

2.3浇注系统设计……………………………………………………………11

2.4抽芯机构设计……………………………………………………………13

2.5推出机构设计……………………………………………………………14

2.6成型零件结构设计………………………………………………………15

3 端盖注塑模具的有关计算…………………………………………………18

4 模具加热和冷却系统的设计………………………………………………20

5 模具闭合高度的确定………………………………………………………21

6 注塑机有关参数的校核……………………………………………………22

7 绘制模具总装配图和非标准零件工作图…………………………………23

8 模具主要零件加工工艺规程的编制………………………………………24

9 注塑模具的安装和试模……………………………………………………26

9.1 模具安装………………………………………………………………26

9.2试模……………………………………………………………………26

致谢…………………………………………………………………………30

参考文献……………………………………………………………………31