设计简介

隔弧板成型工艺及模具设计

摘 要

本设计题目为隔弧板注塑模设计,体现了基本塑料模具的设计要求、内容及方向,具有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者对注塑模设计的基础知识,为设计更复杂的注塑模具做好了铺垫和知识的积累。

本设计运用塑料成型工艺及模具设计的基础知识,首先分析了塑件的结构及性能要求,为选取浇口的类型做好了准备;然后估算了塑件的体积,便于选取注塑机及确定型腔数量;最后分析了塑件的特征,确定模具的设计参数、设计要点及推出装置的设计。

本塑件的两面都有盲孔,且塑件较大,但其侧面没有凸台,故不用斜抽芯。直接用顶杆作为推出机构就行,有利于模具的简化,且是自动脱模取件,工作效率明显提高,这是这种模具的方便之处。没有侧抽芯的问题,这种机构脱模可靠,设计方便简单常用,非常适合在本副模具中使用。

关键词: 盲孔 阶梯孔 斜扇形 外轮廓

Every arc plate injection mold design

Abstract

The design of the subject for every arc plate injection mold design, plastic mold embodies the fundamental design requirements, content and direction of the design has a certain significance. Through the design of the die parts to further enhance the design of injection mold designers of the basic knowledge for the design of more complex injection molds and do a good job of paving the way for the accumulation of knowledge.

The use of plastic molding process design and die design of the basic knowledge, the first analysis of the plastic parts of the structure and performance requirements, in order to select the type of gate ready; and then estimated the volume of plastic parts for injection molding machine to select and determine the type cavity number; the final analysis of the characteristics of plastic parts, molds to determine the design parameters, design features and the introduction of device design.

Both sides of the plastic parts have blind holes, and large plastic parts, but there is no boss side, so no core pulling ramp. Mandril directly on the line as the introduction of institutions will help simplify the mold, and is automatically Demoulding pickup, improved efficiency, it is the convenience of such of the mold. Core Pulling no side issues, such institutions Demoulding reliable, accessible and user-friendly design used is very suitable for the use of the die deputy.

Key words: injection mold blind hole hole ladder ramp outside the outline of a fan

目 录

1绪论 ……………………………………………………………………………1

1.1我国塑料模具的发展现状 …………………………………………………1

1.2国外模具的现状和发展趋势 ………………………………………………3

2 隔弧板塑料模毕业设计任务书 ………………………………………………5

设计要求…………………………………………………………………………5

3 工艺分析和却定…………………………………………………………………7

3.1隔弧板模具设计的设计分析…………………………………………………7

3.2 隔弧板工艺性分析 …………………………………………………………7

3.3 结构分析………………………………………………………………………9

3.4 尺寸精度分析…………………………………………………………………9

3.5计算塑件的体积质量…………………………………………………………10

3.6 塑件工艺参数的确定…………………………………………………………10

3.7塑料成型设备的选取 ………………………………………………………11

4 注塑模结构设计 …………………………………………………………………12

4.1 分型面选择……………………………………………………………………12

4.2确定型腔排列方式 …………………………………………………………12

4.3 浇注系统的设计………………………………………………………………13

4.4塑件脱模方式的确定 ……………………………………………………15

4.5成型零件的结构设计…………………………………………………………16

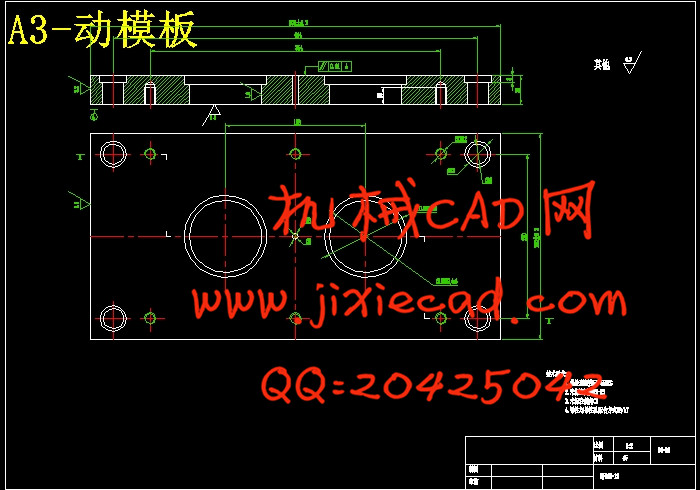

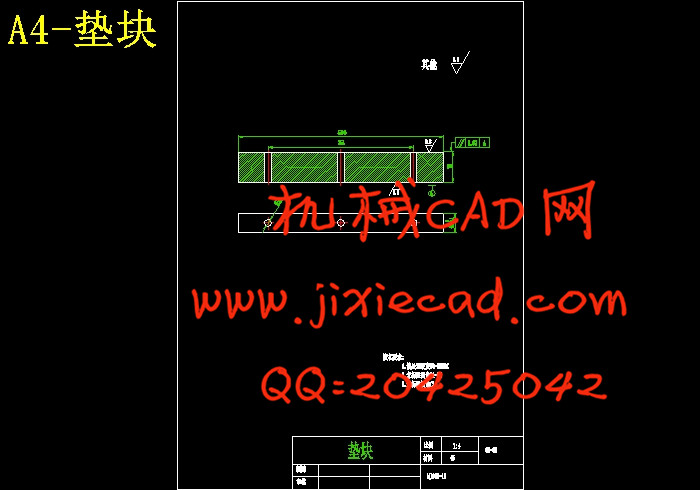

4.6模架的选择 ……………………………………………………………………17

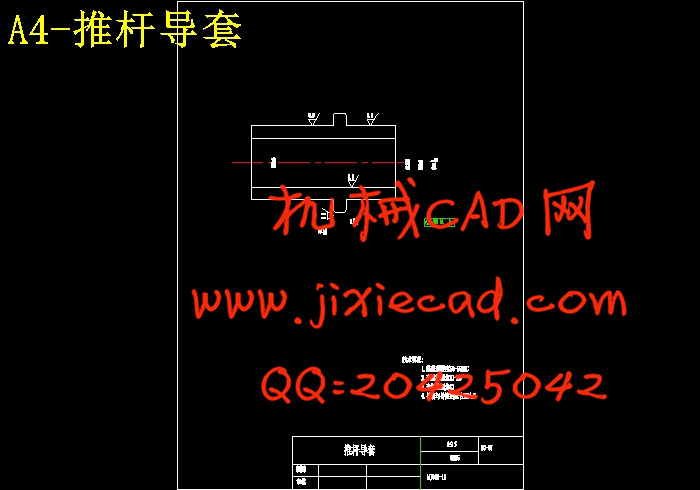

4.7导柱导套的选择 ………………………………………………………………17

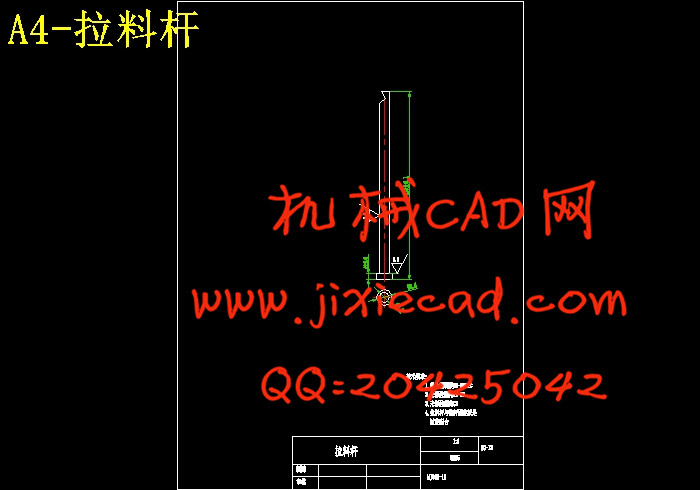

4.8拉料杆的设计 …………………………………………………………………18

4.9模具加热和冷却系统设计 ……………………………………………………19

5.注射机的校核 ……………………………………………………………………21

6.模具的装配与调试 ………………………………………………………………23

6.1模具的安装 …………………………………………………………………23

6.2模具的调试要点 ……………………………………………………………23

7.模具闭合高度的确定…………………………………………………………………25

8.注塑机有关参数校核 …………………………………………………………26

8.1模具合模时校核 ……………………………………………………………26

8.2模具开模时校核………………………………………………………………26

9. 绘制模具总装图和非标零件工作图 …………………………………………27

9.1本模具总装图和非标零件工作图……………………………………………27

9.2模具的工作原理 ……………………………………………………………27

结束语……………………………………………………………………………………28

致谢………………………………………………………………………………………29

参考文献 ……………………………………………………………………………30

摘 要

本设计题目为隔弧板注塑模设计,体现了基本塑料模具的设计要求、内容及方向,具有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者对注塑模设计的基础知识,为设计更复杂的注塑模具做好了铺垫和知识的积累。

本设计运用塑料成型工艺及模具设计的基础知识,首先分析了塑件的结构及性能要求,为选取浇口的类型做好了准备;然后估算了塑件的体积,便于选取注塑机及确定型腔数量;最后分析了塑件的特征,确定模具的设计参数、设计要点及推出装置的设计。

本塑件的两面都有盲孔,且塑件较大,但其侧面没有凸台,故不用斜抽芯。直接用顶杆作为推出机构就行,有利于模具的简化,且是自动脱模取件,工作效率明显提高,这是这种模具的方便之处。没有侧抽芯的问题,这种机构脱模可靠,设计方便简单常用,非常适合在本副模具中使用。

关键词: 盲孔 阶梯孔 斜扇形 外轮廓

Every arc plate injection mold design

Abstract

The design of the subject for every arc plate injection mold design, plastic mold embodies the fundamental design requirements, content and direction of the design has a certain significance. Through the design of the die parts to further enhance the design of injection mold designers of the basic knowledge for the design of more complex injection molds and do a good job of paving the way for the accumulation of knowledge.

The use of plastic molding process design and die design of the basic knowledge, the first analysis of the plastic parts of the structure and performance requirements, in order to select the type of gate ready; and then estimated the volume of plastic parts for injection molding machine to select and determine the type cavity number; the final analysis of the characteristics of plastic parts, molds to determine the design parameters, design features and the introduction of device design.

Both sides of the plastic parts have blind holes, and large plastic parts, but there is no boss side, so no core pulling ramp. Mandril directly on the line as the introduction of institutions will help simplify the mold, and is automatically Demoulding pickup, improved efficiency, it is the convenience of such of the mold. Core Pulling no side issues, such institutions Demoulding reliable, accessible and user-friendly design used is very suitable for the use of the die deputy.

Key words: injection mold blind hole hole ladder ramp outside the outline of a fan

目 录

1绪论 ……………………………………………………………………………1

1.1我国塑料模具的发展现状 …………………………………………………1

1.2国外模具的现状和发展趋势 ………………………………………………3

2 隔弧板塑料模毕业设计任务书 ………………………………………………5

设计要求…………………………………………………………………………5

3 工艺分析和却定…………………………………………………………………7

3.1隔弧板模具设计的设计分析…………………………………………………7

3.2 隔弧板工艺性分析 …………………………………………………………7

3.3 结构分析………………………………………………………………………9

3.4 尺寸精度分析…………………………………………………………………9

3.5计算塑件的体积质量…………………………………………………………10

3.6 塑件工艺参数的确定…………………………………………………………10

3.7塑料成型设备的选取 ………………………………………………………11

4 注塑模结构设计 …………………………………………………………………12

4.1 分型面选择……………………………………………………………………12

4.2确定型腔排列方式 …………………………………………………………12

4.3 浇注系统的设计………………………………………………………………13

4.4塑件脱模方式的确定 ……………………………………………………15

4.5成型零件的结构设计…………………………………………………………16

4.6模架的选择 ……………………………………………………………………17

4.7导柱导套的选择 ………………………………………………………………17

4.8拉料杆的设计 …………………………………………………………………18

4.9模具加热和冷却系统设计 ……………………………………………………19

5.注射机的校核 ……………………………………………………………………21

6.模具的装配与调试 ………………………………………………………………23

6.1模具的安装 …………………………………………………………………23

6.2模具的调试要点 ……………………………………………………………23

7.模具闭合高度的确定…………………………………………………………………25

8.注塑机有关参数校核 …………………………………………………………26

8.1模具合模时校核 ……………………………………………………………26

8.2模具开模时校核………………………………………………………………26

9. 绘制模具总装图和非标零件工作图 …………………………………………27

9.1本模具总装图和非标零件工作图……………………………………………27

9.2模具的工作原理 ……………………………………………………………27

结束语……………………………………………………………………………………28

致谢………………………………………………………………………………………29

参考文献 ……………………………………………………………………………30