设计简介

摘 要

塑料制品具有原料来源丰富,价格低廉,性能优良等特点。它在电脑、手机、汽车、电机、电器、仪器仪表、家电和通讯产品制造中具有不可替代的作用,应用极其广泛。注射成型是成形热塑性塑料制件的主要成型方法,因此应用范围很广。

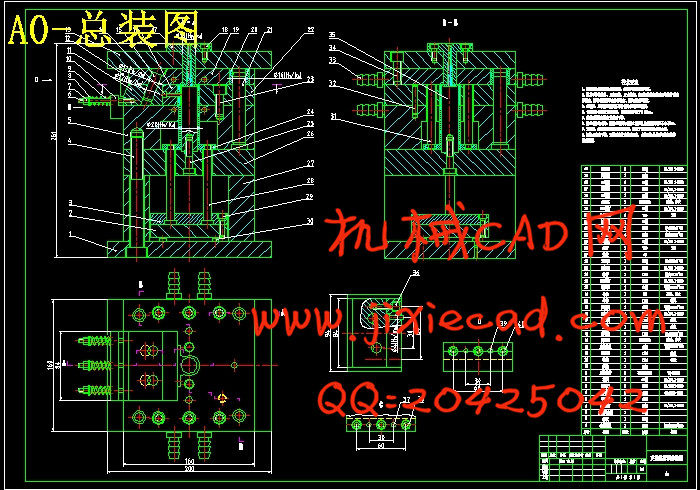

本文阐述了对发夹产品的设计到整个注射模的大体的设计过程,在设计过程中也进行了必要的计算包括成型零件尺寸的计算和对注射机的锁模力、最大注射量、注射压力、开模行程和模具与注射机安装部分相关尺寸的校核。同时,也对产品的工艺性进行分析,主要分析了塑料件的形状特点、尺寸大小、尺寸标注方法、精度要求、表面质量和材料性质等因素,最后绘制完整的模具装配总图和主要的模具非标准零件图。

关键词:注射成型、锁模力、注射压力、装配总图

Abstract

Here to enter the need to turn over a source of plastic materials, low price, quality and performance characteristics. it is in computers and mobile phones, cars and electrical and electronics, instruments, appliance and products manufacturing is an alternative to the role of the most widely used. an injection is a thermoplastic - concrete shape of the main method, the scope of application is very large.

In this paper, plastic Hairpin product of the injection mold design to the general design process, During the design process also includes forming necessarily computing components and the calculation of the size of the clamping force injection molding machine, the largest injection volume, injection pressure, the itinerary and mold and mold injection machine parts related to the size of the installation check. At the same time, the product of the process of analysis, the main analysis of the characteristics of the shape of plastic pieces, the size, dimensioning methods, accuracy, surface quality and material properties and other factors, Finally a complete mold assembly drawing general plan and the main non-standard mold parts diagram.

Key words: injection;force injection molding machine;injection pressure;assembly drawing

塑料制品具有原料来源丰富,价格低廉,性能优良等特点。它在电脑、手机、汽车、电机、电器、仪器仪表、家电和通讯产品制造中具有不可替代的作用,应用极其广泛。注射成型是成形热塑性塑料制件的主要成型方法,因此应用范围很广。

本文阐述了对发夹产品的设计到整个注射模的大体的设计过程,在设计过程中也进行了必要的计算包括成型零件尺寸的计算和对注射机的锁模力、最大注射量、注射压力、开模行程和模具与注射机安装部分相关尺寸的校核。同时,也对产品的工艺性进行分析,主要分析了塑料件的形状特点、尺寸大小、尺寸标注方法、精度要求、表面质量和材料性质等因素,最后绘制完整的模具装配总图和主要的模具非标准零件图。

关键词:注射成型、锁模力、注射压力、装配总图

Abstract

Here to enter the need to turn over a source of plastic materials, low price, quality and performance characteristics. it is in computers and mobile phones, cars and electrical and electronics, instruments, appliance and products manufacturing is an alternative to the role of the most widely used. an injection is a thermoplastic - concrete shape of the main method, the scope of application is very large.

In this paper, plastic Hairpin product of the injection mold design to the general design process, During the design process also includes forming necessarily computing components and the calculation of the size of the clamping force injection molding machine, the largest injection volume, injection pressure, the itinerary and mold and mold injection machine parts related to the size of the installation check. At the same time, the product of the process of analysis, the main analysis of the characteristics of the shape of plastic pieces, the size, dimensioning methods, accuracy, surface quality and material properties and other factors, Finally a complete mold assembly drawing general plan and the main non-standard mold parts diagram.

Key words: injection;force injection molding machine;injection pressure;assembly drawing