设计简介

摘 要

本设计是骨架注塑模,特点为薄壁骨架,采用材料为聚苯乙烯,模具采用延时弯销机构,产品自动脱落,无需顶出板。这样使模具结构更简单化,重量减轻,而且省材。工作过程为:塑料粉末送至料斗,开始加热,加热温度为265——500F之间。模具闭合,螺杆前行在压力作用下熔融塑料进入模具型腔。注塑完毕,动模具后退,模具打开,产品落下。模具闭合,由复位杆复位,准备下一次的注塑。

关键词: 模具 骨架 注塑模

Abstract

This topic is injection mold for framework. The charactoristice is a thin wall framework. PS are use by this plastics .This mold adoption bend to sell the organization. The part may be down off and don’t need ejector plate and ejector retainer plate. This make the stmcture of the mold turned more simple,the weight ease ,and the provinle material. Plastic powder is loaded into the feed hopper and a centain amount feed into the heating chamber when the planger draws back. Heating temperatures range from 265to500F. After the mold is closed the plunger moves forward ,forcing some of the fluid plastic ynto the mold cavity under pressures. When this over ,the part may be down off when the mold opens. Returns the ejector plate back to its original podition when the mold is colsed. And ready for next.

Keyword: mold framework injection mold

目 录

绪论…………………………………………………….1

一、 模具工艺规程的编制………………………………………3

1.1 塑件的工艺性分析………………………………………….3

1.2 塑件的体积和质量的计算………………………………….4

1.3 塑件注塑工艺参数的确定………………………………….4

二、注塑模的机构设计……………………………………………5

2.1 分型面的选择………………………………………………...5

2.2 确定型腔的排列方式………………………………………...6

2.3 浇注系统的设计……………………………………………...7

2.4 抽芯机构的设计…………………………………………….10

2.5 成型零件的结构设计……………………………………….11

三、模具设计的有关计算………………………………………..12

四、模具加热和冷却系统的设计………………………………..13

五、模具闭合高度的确定………………………………………..14

六、注塑机有关参数的校核……………………………………...15

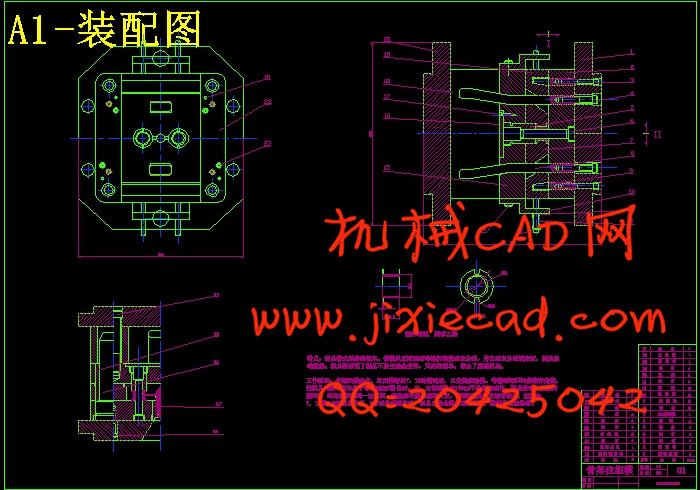

七、模具装配图和非标准零件图的绘制…………………………15

八、注塑模具的装配和审核………………………………………16

8.1 注塑模的装配技术要求…………………………………….16

8.2 注塑模的审核……………………………………………….16

8.2.1基本结构方面……………………………………………….16

8.2.2计图纸方面………………………………………………….17

8.2.3射模设计质量……………………………………………….17

8.2.4安装及搬运条件方面……………………………………….18

九、注塑模主要零件加工工艺规程的编制……………………..18

十、设计心得……………………………………………………..19

参考文献……………………………………………………..20

致谢…………………………………………………………..21

本设计是骨架注塑模,特点为薄壁骨架,采用材料为聚苯乙烯,模具采用延时弯销机构,产品自动脱落,无需顶出板。这样使模具结构更简单化,重量减轻,而且省材。工作过程为:塑料粉末送至料斗,开始加热,加热温度为265——500F之间。模具闭合,螺杆前行在压力作用下熔融塑料进入模具型腔。注塑完毕,动模具后退,模具打开,产品落下。模具闭合,由复位杆复位,准备下一次的注塑。

关键词: 模具 骨架 注塑模

Abstract

This topic is injection mold for framework. The charactoristice is a thin wall framework. PS are use by this plastics .This mold adoption bend to sell the organization. The part may be down off and don’t need ejector plate and ejector retainer plate. This make the stmcture of the mold turned more simple,the weight ease ,and the provinle material. Plastic powder is loaded into the feed hopper and a centain amount feed into the heating chamber when the planger draws back. Heating temperatures range from 265to500F. After the mold is closed the plunger moves forward ,forcing some of the fluid plastic ynto the mold cavity under pressures. When this over ,the part may be down off when the mold opens. Returns the ejector plate back to its original podition when the mold is colsed. And ready for next.

Keyword: mold framework injection mold

目 录

绪论…………………………………………………….1

一、 模具工艺规程的编制………………………………………3

1.1 塑件的工艺性分析………………………………………….3

1.2 塑件的体积和质量的计算………………………………….4

1.3 塑件注塑工艺参数的确定………………………………….4

二、注塑模的机构设计……………………………………………5

2.1 分型面的选择………………………………………………...5

2.2 确定型腔的排列方式………………………………………...6

2.3 浇注系统的设计……………………………………………...7

2.4 抽芯机构的设计…………………………………………….10

2.5 成型零件的结构设计……………………………………….11

三、模具设计的有关计算………………………………………..12

四、模具加热和冷却系统的设计………………………………..13

五、模具闭合高度的确定………………………………………..14

六、注塑机有关参数的校核……………………………………...15

七、模具装配图和非标准零件图的绘制…………………………15

八、注塑模具的装配和审核………………………………………16

8.1 注塑模的装配技术要求…………………………………….16

8.2 注塑模的审核……………………………………………….16

8.2.1基本结构方面……………………………………………….16

8.2.2计图纸方面………………………………………………….17

8.2.3射模设计质量……………………………………………….17

8.2.4安装及搬运条件方面……………………………………….18

九、注塑模主要零件加工工艺规程的编制……………………..18

十、设计心得……………………………………………………..19

参考文献……………………………………………………..20

致谢…………………………………………………………..21