设计简介

(盒盖注塑模设计与制造)

摘要

本设计的成品为一薄壁罩盖,论述了采用斜杆导滑的斜滑块内侧抽芯的注射模结构设计和工作过程。在设计过程中按以下步骤设计模具:罩盖注塑模工艺规程的编制—注塑模的结构设计—模具设计的有关计算—模具加热与冷却系统设计—模具闭合高度的确定—注塑机有关参数的校核,最后是绘制模具总装配图。在注塑模工艺规程的编制的过程中,要着重分析制品原材料(PS)的各项成型工艺参数;在模具结构设计中应注意的是斜滑块起成型兼顶出的作用,解决了该件内侧有四个小凸台不易脱模的问题;模具设计计算的要点是型腔与型芯径向尺寸及深度方向尺寸的计算,型腔与型芯的计算在整个设计过程中显得尤为重要,因为它们直接关系到制品的尺寸精度;模具总装图和非标准零件图用AutoCAD画出,图中需标注的各项参数如尺寸,公差,技术要求,图纸布局等均应按国家标准设计。设计中出现的标准件如推板,螺钉等的零件图无需一一画出,但应参照文献查出其具体结构尺寸。模具结构紧凑,动作可靠,制造成本低。

关键词:罩盖,注射模,工艺规程,AutoCAD,国家标准

(the note of box cover moulds design and manufacture )

Abstract

Summary

The finished product originally designed is covered and covered for one thin wall, have expounded the fact that adopts the down tube to lead the slippery oblique slippery inboard inject mould structural design and working course of smoking the cores. Design the mould according to the following step in the course of designing: Is it overlay note mould establishment - structural design - mold design that note mould , craft of rules about calculate - mould is it close sureness of height with cooling system design - mould to heat to put on- The check about the parameter of the moulding plastics machine, draw the total installation diagram of mould at the end. While the note moulds establishment of the craft rules , should analyse every shaping craft parameter of the products raw materials (PS ) emphatically; The ones that should notice are to slip on a function of playing shaping and concurrently carrying out obliquly in the structural design of the mould, have solved the problem of having four pieces of small protruding difficult drawing of patterns of platform of this inboard; Main point that mold design calculate type and type core foot-path calculation of size toward size and depth, the calculation of the core with the type of of the type seems particularly important in the course of designing entirely, because they concern the precision of size of the products directly; Mould assembly is pursued to be drawn with the non-standard part picture with AutoCAD, every parameter of needing to mark in the picture is like the size, public errand , specification requirement , the overall arrangement of the drawing,etc. should be designed according to the national standard. The standard component appearing in the design, like pushing the board, the part pictures of screw ,etc. do not need to draw one by one, but should find its concrete physical dimension according to documents . The structure of the mould is compact, movements are reliable , it is with low costs to make.

Keyword: Cover and cover, inject the mould , craft rules, AutoCAD, national standard

目 录

绪论.......................................................1

1.设计前的准备工作.......................................6

1.1 明确设计任务和准备必要的技术条件.....................6

1.2 分析研究原材料的工艺特性和成型性能 ..................6

2.盒盖注塑模工艺规程的编制..............................8

2.1 模具工艺规程的编制 ..................................8

2.2 根据塑件形状尺寸,估算塑件体积和重量.................11

3.模腔的选择与设计......................................14

4.浇注系统设计..........................................14

4.1 主流道设计..........................................14

4.2 分流道设计..........................................15

4.3 冷料井及拉料杆设计..................................16

4.4 浇口设计............................................16

5.分型面的选择设计.................................18

6.排气结构的设计...................................19

7.合模导向机构的设计...............................19

8.注射设备的选择...................................21

9.模架的选择与设计................................... 22

9.1 特点和用途 .........................................22

9.2 塑料注射模标准模架标准的尺寸组合....................23

9.3 模架的规格系列......................................23

9.4 中小型模架的标记方法................................23

10.顶出脱模机构设计....................................23

10.1 推出脱模机构的选取用原则 ..........................24

10.2 推出脱模机构分类...................................24

10.3 推板推出脱模机构...................................25

11.侧抽芯机构的设计....................................26

11.1 设计斜滑块分型与抽芯机构应注意的问题...............26

11.2 见图3-88斜导杆导滑的内侧分型抽芯机构..............27

11.3 斜滑块的导滑与组合形式.............................27

12.成型零部件的设计与计算............................ 28

12.1 成型零部件的性能 ..................................29

12.2 凹模的结构设计.....................................29

12.3 凸模的结构设计 ....................................30

12.4 成型零部件工作尺寸计算 ............................30

13.温调系统设计 ....................................... 32

13.1 模具温度调节的重要性...............................32

13.2 冷却系统的设计计算 ................................33

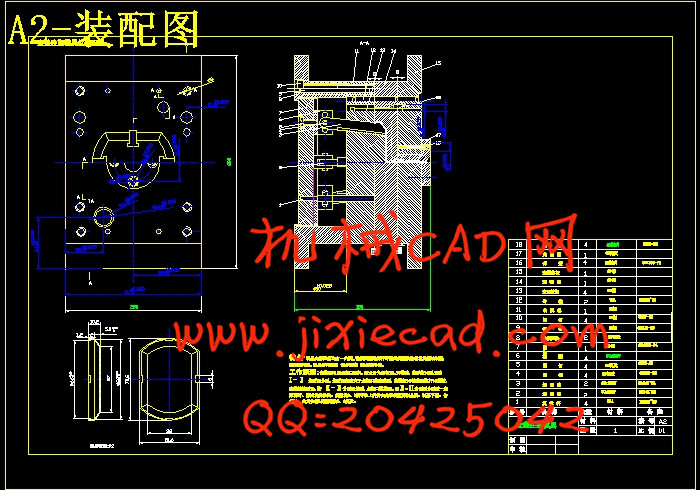

14.绘制模具的总装图(见图纸).........................33

15.模具的工作原理和动作过程........................33

16.塑料模具的安装.......................................34

16.1 模具的装配及调试见下表.............................34

16.2 装配调试的工艺要求及注意问题.......................35

17.结论..................................................38

17.1 扎实的基础课,专业课是模具设计的基础 ..............38

17.2 理论与实践相结合的重要性...........................38

17.3 对模具设计中的安全性,经济性加深了认识.............39

17.4 电脑成为设计中重要的辅助工具.......................39

17.5 设计态度直接决定着设计质量.........................39

致谢 .....................................................40

参考文献.................................................41

摘要

本设计的成品为一薄壁罩盖,论述了采用斜杆导滑的斜滑块内侧抽芯的注射模结构设计和工作过程。在设计过程中按以下步骤设计模具:罩盖注塑模工艺规程的编制—注塑模的结构设计—模具设计的有关计算—模具加热与冷却系统设计—模具闭合高度的确定—注塑机有关参数的校核,最后是绘制模具总装配图。在注塑模工艺规程的编制的过程中,要着重分析制品原材料(PS)的各项成型工艺参数;在模具结构设计中应注意的是斜滑块起成型兼顶出的作用,解决了该件内侧有四个小凸台不易脱模的问题;模具设计计算的要点是型腔与型芯径向尺寸及深度方向尺寸的计算,型腔与型芯的计算在整个设计过程中显得尤为重要,因为它们直接关系到制品的尺寸精度;模具总装图和非标准零件图用AutoCAD画出,图中需标注的各项参数如尺寸,公差,技术要求,图纸布局等均应按国家标准设计。设计中出现的标准件如推板,螺钉等的零件图无需一一画出,但应参照文献查出其具体结构尺寸。模具结构紧凑,动作可靠,制造成本低。

关键词:罩盖,注射模,工艺规程,AutoCAD,国家标准

(the note of box cover moulds design and manufacture )

Abstract

Summary

The finished product originally designed is covered and covered for one thin wall, have expounded the fact that adopts the down tube to lead the slippery oblique slippery inboard inject mould structural design and working course of smoking the cores. Design the mould according to the following step in the course of designing: Is it overlay note mould establishment - structural design - mold design that note mould , craft of rules about calculate - mould is it close sureness of height with cooling system design - mould to heat to put on- The check about the parameter of the moulding plastics machine, draw the total installation diagram of mould at the end. While the note moulds establishment of the craft rules , should analyse every shaping craft parameter of the products raw materials (PS ) emphatically; The ones that should notice are to slip on a function of playing shaping and concurrently carrying out obliquly in the structural design of the mould, have solved the problem of having four pieces of small protruding difficult drawing of patterns of platform of this inboard; Main point that mold design calculate type and type core foot-path calculation of size toward size and depth, the calculation of the core with the type of of the type seems particularly important in the course of designing entirely, because they concern the precision of size of the products directly; Mould assembly is pursued to be drawn with the non-standard part picture with AutoCAD, every parameter of needing to mark in the picture is like the size, public errand , specification requirement , the overall arrangement of the drawing,etc. should be designed according to the national standard. The standard component appearing in the design, like pushing the board, the part pictures of screw ,etc. do not need to draw one by one, but should find its concrete physical dimension according to documents . The structure of the mould is compact, movements are reliable , it is with low costs to make.

Keyword: Cover and cover, inject the mould , craft rules, AutoCAD, national standard

目 录

绪论.......................................................1

1.设计前的准备工作.......................................6

1.1 明确设计任务和准备必要的技术条件.....................6

1.2 分析研究原材料的工艺特性和成型性能 ..................6

2.盒盖注塑模工艺规程的编制..............................8

2.1 模具工艺规程的编制 ..................................8

2.2 根据塑件形状尺寸,估算塑件体积和重量.................11

3.模腔的选择与设计......................................14

4.浇注系统设计..........................................14

4.1 主流道设计..........................................14

4.2 分流道设计..........................................15

4.3 冷料井及拉料杆设计..................................16

4.4 浇口设计............................................16

5.分型面的选择设计.................................18

6.排气结构的设计...................................19

7.合模导向机构的设计...............................19

8.注射设备的选择...................................21

9.模架的选择与设计................................... 22

9.1 特点和用途 .........................................22

9.2 塑料注射模标准模架标准的尺寸组合....................23

9.3 模架的规格系列......................................23

9.4 中小型模架的标记方法................................23

10.顶出脱模机构设计....................................23

10.1 推出脱模机构的选取用原则 ..........................24

10.2 推出脱模机构分类...................................24

10.3 推板推出脱模机构...................................25

11.侧抽芯机构的设计....................................26

11.1 设计斜滑块分型与抽芯机构应注意的问题...............26

11.2 见图3-88斜导杆导滑的内侧分型抽芯机构..............27

11.3 斜滑块的导滑与组合形式.............................27

12.成型零部件的设计与计算............................ 28

12.1 成型零部件的性能 ..................................29

12.2 凹模的结构设计.....................................29

12.3 凸模的结构设计 ....................................30

12.4 成型零部件工作尺寸计算 ............................30

13.温调系统设计 ....................................... 32

13.1 模具温度调节的重要性...............................32

13.2 冷却系统的设计计算 ................................33

14.绘制模具的总装图(见图纸).........................33

15.模具的工作原理和动作过程........................33

16.塑料模具的安装.......................................34

16.1 模具的装配及调试见下表.............................34

16.2 装配调试的工艺要求及注意问题.......................35

17.结论..................................................38

17.1 扎实的基础课,专业课是模具设计的基础 ..............38

17.2 理论与实践相结合的重要性...........................38

17.3 对模具设计中的安全性,经济性加深了认识.............39

17.4 电脑成为设计中重要的辅助工具.......................39

17.5 设计态度直接决定着设计质量.........................39

致谢 .....................................................40

参考文献.................................................41