设计简介

摘要

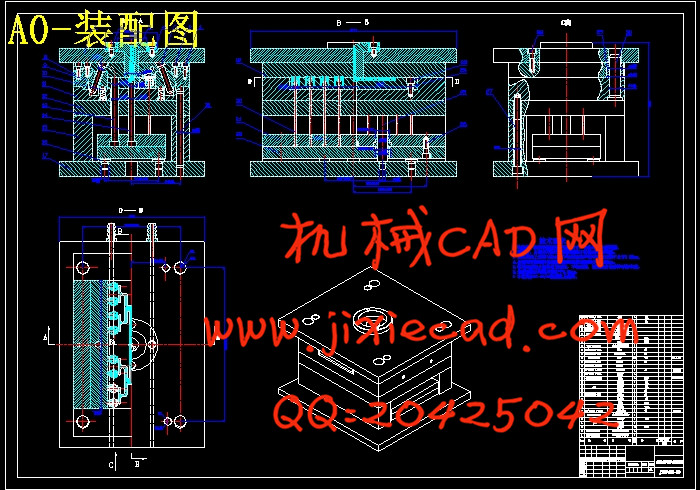

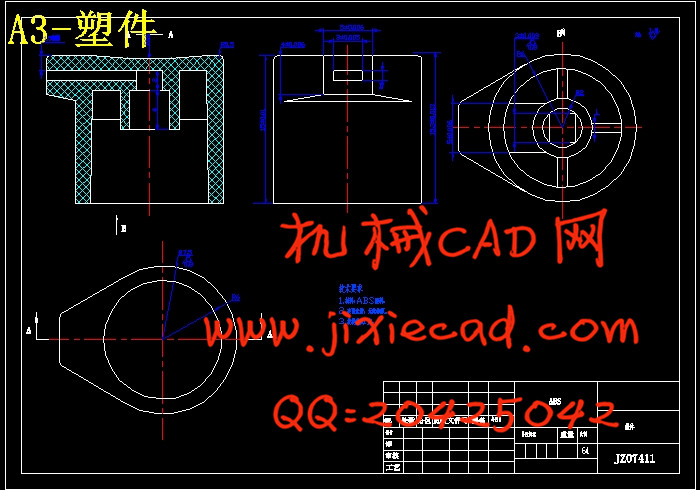

本课题主要是针对喷头的模具设计,通过对所设计的塑件进行工艺的分析和方案比较,最终设计出一副注塑模具。该课题从产品结构工艺性,具体模具结构出发,对模具的型腔数、浇注系统、模具成型部分的结构、顶出系统、冷却系统、注塑机的选择及有关参数的校核、都有详细的设计。针对喷头的具体结构分析比较,该模具是点浇口的单分型面注射模具,由于喷头体积较小,所以应采取一模多腔结构,以实现高效率生产,本注塑模对型腔采用双排平衡式排列,以便采用平衡式浇注系统,其优点在于简化机构,使模具外形对称,从而可以得到尺寸正确,外表美观,物理性能良好的塑件制品。由于塑件具有侧向喷嘴,所以必须设置斜导柱,采用侧向抽芯的结构形式。

关键词 塑料模具,化妆品喷头,侧向抽芯

Abstract

本课题主要是针对喷头的模具设计,通过对所设计的塑件进行工艺的分析和方案比较,最终设计出一副注塑模具。该课题从产品结构工艺性,具体模具结构出发,对模具的型腔数、浇注系统、模具成型部分的结构、顶出系统、冷却系统、注塑机的选择及有关参数的校核、都有详细的设计。针对喷头的具体结构分析比较,该模具是点浇口的单分型面注射模具,由于喷头体积较小,所以应采取一模多腔结构,以实现高效率生产,本注塑模对型腔采用双排平衡式排列,以便采用平衡式浇注系统,其优点在于简化机构,使模具外形对称,从而可以得到尺寸正确,外表美观,物理性能良好的塑件制品。由于塑件具有侧向喷嘴,所以必须设置斜导柱,采用侧向抽芯的结构形式。

关键词 塑料模具,化妆品喷头,侧向抽芯

Abstract

This topic mainly aimed at the mold design of shower nozzle. Through the analysis and comparison of the plastic product which comes from your design , the plastic mold was designed. This topic came from the technology capability of product, the structure of the mold embarks,the Type cavity number. the pours system, the injection molding system and the related parameter examination have detailed design . Concrete structure specifically for the shower nozzle, be a mould's turn to be that mark of type injects a mould face to face count the running gate Shan, since shower nozzle volume is less therefore should adopt one multiple-cavity model structure, to realize high efficiency giving birth to a child, produce plastic articles by injection moulding the model adopt pair of rows to balance style arranging to type cavity , that whose merit is lain in makes mould external form symmetrical to adopt balance style to pour system, can get correct, have a fine exterior, Physical fine dimension function .Since moulding have a spray nozzle , therefore must interpose tilted guide pin, strengthen the structure form adopt side direction to take a core out.

Key words : Plastic mold, Cosmetics shower nozzle,Side direction to take a core out

目 录

1 引言................................................................1Key words : Plastic mold, Cosmetics shower nozzle,Side direction to take a core out

目 录

2 产品技术要求和工艺分析..............................................2

2.1 产品技术要求....................................................2

2.1.1 产品设计图..................................................2

2.1.2 产品技术要求................................................2

2.2 塑件的工艺分析..................................................3

2.2.1 塑件结构工艺性..............................................3

2.2.2 塑件工艺性分析..............................................3

2.3 塑件材质工艺性..................................................3

2.4 成型工艺性......................................................3

2.4.1 ABS塑料主要的性能指标.......................................3

2.4.2 塑件的体积重量..............................................4

2.4.3 ABS的注射成型工艺参数.......................................5

3 拟定成型方案........................................................6

3.1 分型面位置的确定................................................6

3.2 成型方案的列出..................................................7

3.2.1 分型面的选择................................................7

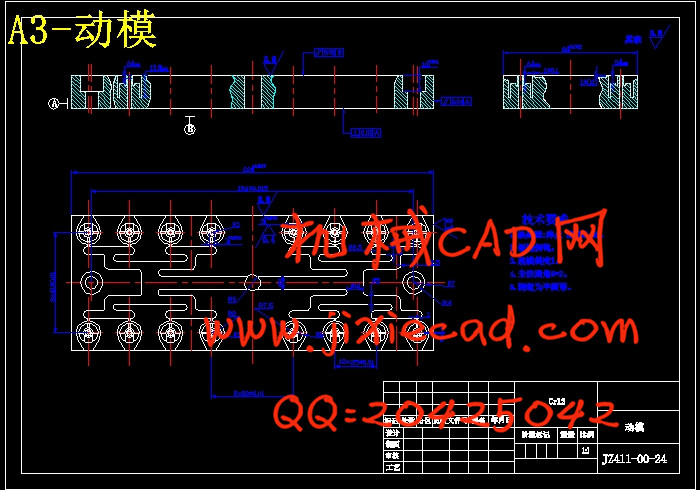

3.2.2 型腔数的确定................................................8

3.2.3 确定型腔的排列..............................................9

3.2.4 浇注系统的设计..............................................9

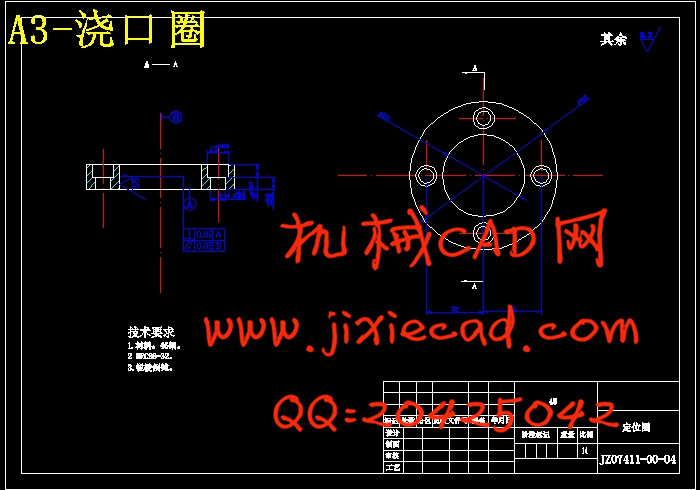

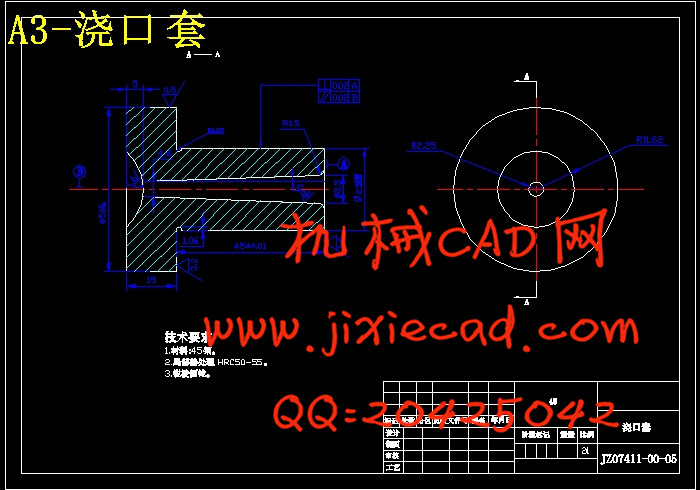

3.2.4.1 主流道的设计............................................9

3.2.4.2 冷料井的设计...........................................10

3.2.4.3 分流道的设计...........................................11

3.2.4.4 浇口的设计.............................................13

3.2.5 排气、温度调节系统的设计与计算.............................14

3.2.5.1 排气系统的设计与计算...................................14

3.2.5.2 冷却系统的设计与计算...................................14

3.2.5.3 模具加热系统的设计.....................................15

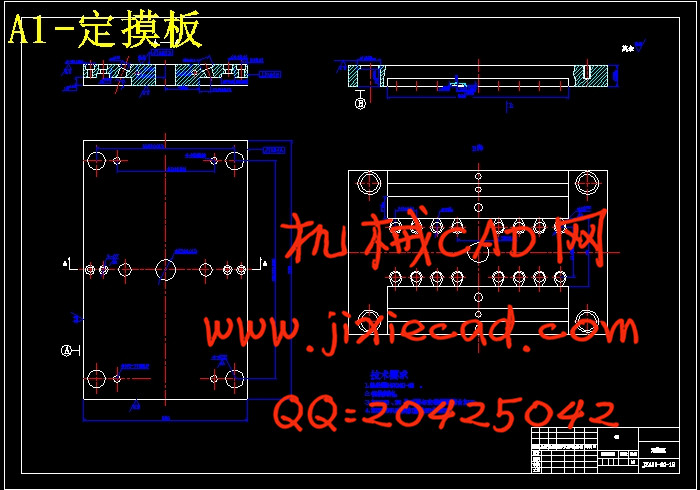

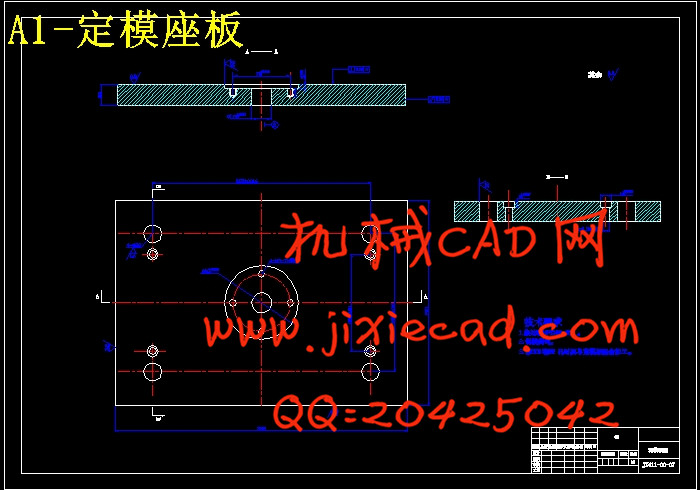

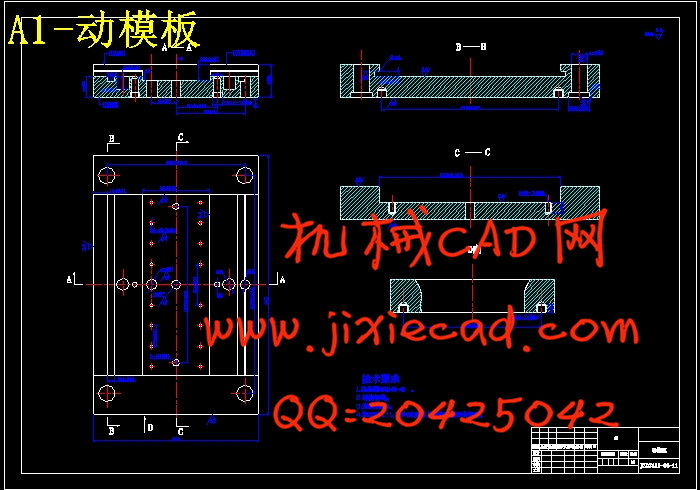

3.3 模架的选定.....................................................15

4 模具工作零件的设计与计算...........................................17

4.1 凹模的结构.......................................................17

4.2 凹模厚度的计算.................................................18

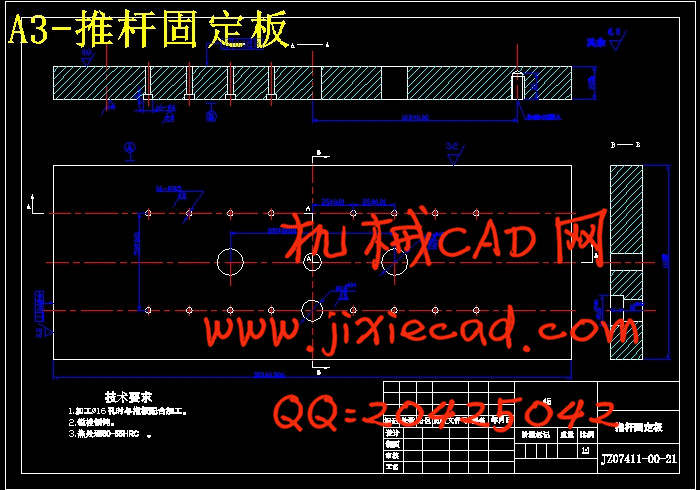

5 脱模结构的设计与计算...............................................19

5.1 脱模力的计算...................................................19

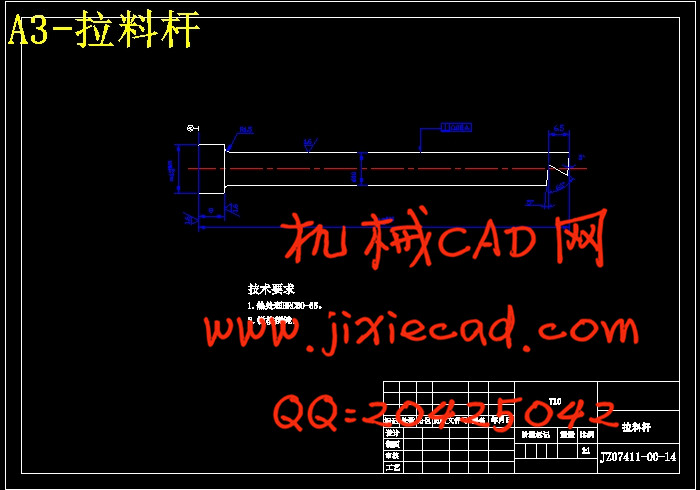

5.2 推杆直径的计算.................................................19

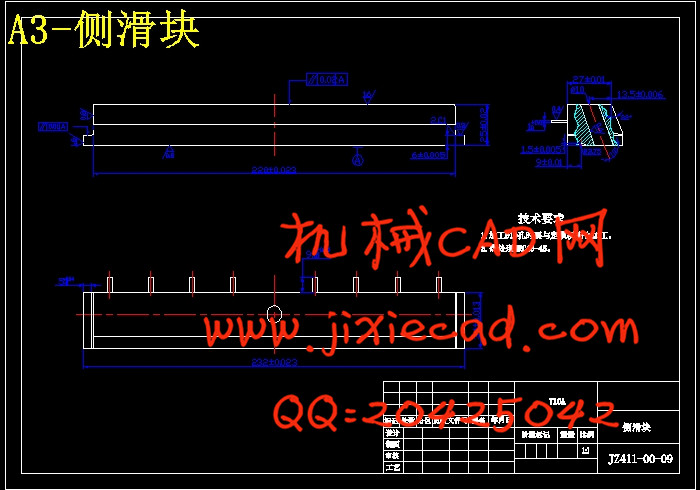

5.3 侧抽芯与侧向分型机构...........................................20

5.3.1 斜导柱直径的确定...........................................21

5.3.2 斜导柱长度计算和最小开模行程计算...........................22

6 注射机与模具各参数的校核...........................................24

6.1 工艺参数的校核.................................................24

6.1.1 注射量的校核...............................................24

6.1.2 锁模力的校核...............................................24

6.1.3 最大注射压和的校核.........................................24

6.2 安装参数校核...................................................25

7 模具的装配.........................................................26

7.1 模具装配顺序...................................................26

7.2 开模过程分析...................................................27

8 总结.........................................................28

致谢...............................................................29

参考文献.............................................................30