设计简介

化妆品瓶盖注塑模设计

摘要:本设计题目为化妆品瓶盖注塑模设计,体现了壳体类塑料零件的设计要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者注塑模设计的基础知识,为设计更复杂的注塑模具做好了铺垫和吸取了更深刻的经验。

本设计运用塑料成型工艺及模具设计的基础知识,首先分析了塑件的成分及性能要求,为选取浇口的类型做好了准备;然后估算了塑件的体积,便于选取注塑机;最后分析了塑件的特征,确定模具的设计参数、设计要点及推出装置的选取。

本塑件属于壳体类零件,同时内侧有一个螺纹,因此设计时必须考虑螺纹塑件的脱模。本设计采用螺纹塑件的旋转脱模,因内部有止转的中空型芯,所以属于塑件内部有止转的情况,考虑到模具较小,不宜采用机动或液压等自动脱模机构,所以采用手动脱模机构。

关键词: 注塑模 浇口 型芯 脱模机构

化妆品瓶盖注塑模设计

Abstract:This design topic notes an injection mold design for the cosmetics bottle cover, body now the hull body plastics design request, contents and direction of the spare parts, there is certain design meaning.Pass the design to the spare parts' molding tool, strengthenned a design to note the injection mold foundation knowledge of design further, for design to more complicatedly note a injection molding tool to have done cushion and absorb deeper experience.

This design usage plastics models the foundation knowledge of craft and molding tool design, composition and function which analyzed a injection piece first request, sprinkle an oscular type to have done preparation for the selection;Then estimated the physical volume of injection piece, the easy to selection noted injection machine;Finally analyzed the characteristic of injection piece, make sure the design parameter, design important point of molding tool and release the selection of device.

This injection piece belongs to the hull body spare parts, the seamy side contains a thread in the meantime, so design have to consider the thread injection take off of piece a mold.This design adoption thread injection revolve of piece takes off a mold and have because of the inner part turn of hollow type Xin, so belong to a injection piece inner part to have the circumstance for turn, in consideration of the molding tool is smaller, not proper adoption mobile or the liquid press etc. automatically take off mold organization, so the adoption moves to take off mold organization.

Keyword: The injection mold sprinkle Core Take off mold organization

目录

1. 绪 论……………………………………………………………………………1

1.1国内模具的现状和发展趋势……………………………………………………1

1.1.1国内模具的现状………………………………………………………………1

1.1.2 国内模具的发展趋势………………………………………………………2

1.2 国外模具的现状和发展趋势……………………………………………………3

1.3 化妆品瓶盖模具设计与制造方面………………………………………………4

1.3.1 化妆品瓶盖模具设计的设计思路……………………………………………4

1.3.2 化妆品瓶盖模具设计的进度…………………………………………………5

2. 化妆品瓶盖工艺性分析…………………………………………………………6

2.1塑件的工艺性分析………………………………………………………………6

2.2 塑件的结构和尺寸精度及表面质量分析………………………………………8

2.3 计算塑件的体积质量……………………………………………………………8

2.4 塑件注塑工艺参数确定…………………………………………………………8

3. 注塑模结构设计…………………………………………………………………10

3.1 分型面选择……………………………………………………………………10

3.2 确定型腔排列方式……………………………………………………………11

3.3 浇注系统的设计………………………………………………………………11

3.3.1主流道的设计………………………………………………………………11

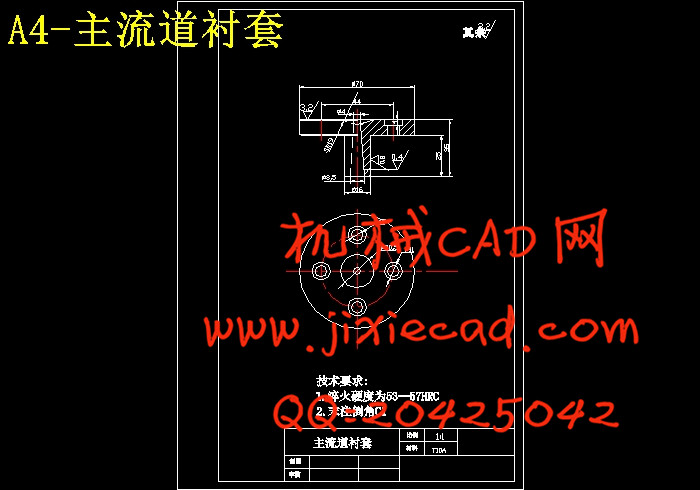

3.3.2主流道衬套的设计…………………………………………………………11

3.3.3 分流道设计…………………………………………………………………13

3.3.4浇口设计……………………………………………………………………13

3.4 排气结构的设计………………………………………………………………13

3.5 螺纹脱模结构的设计…………………………………………………………13

3.6 成型零件结构设计……………………………………………………………15

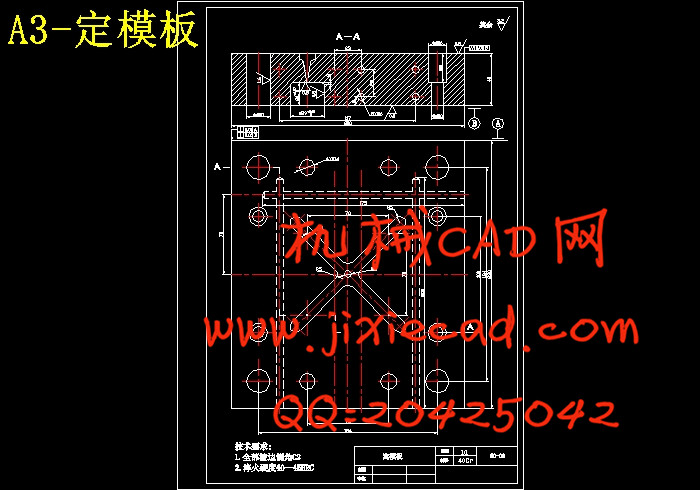

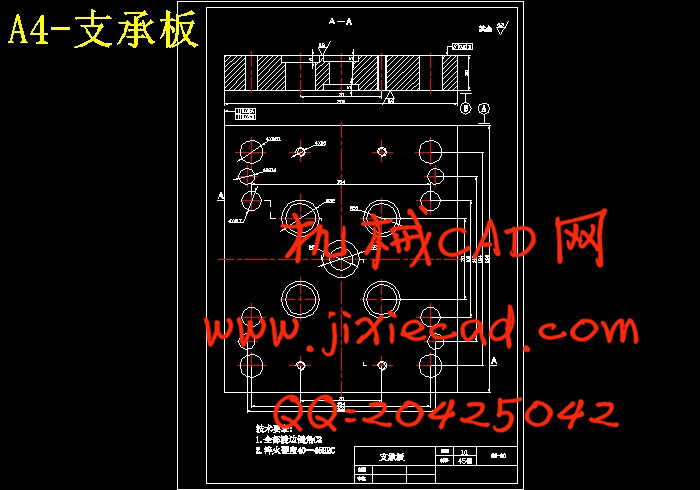

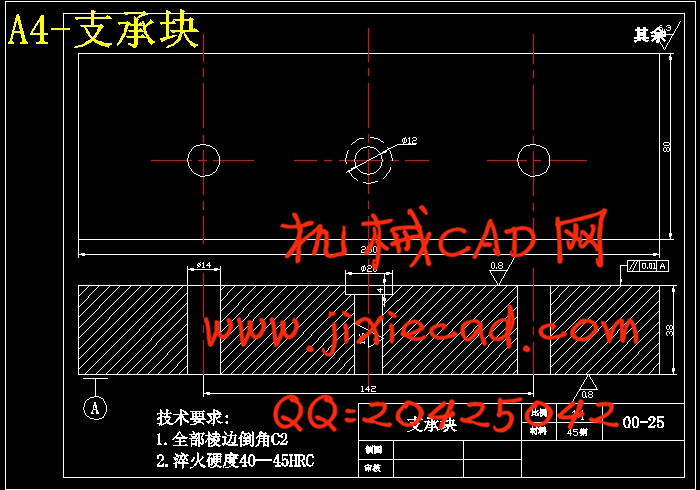

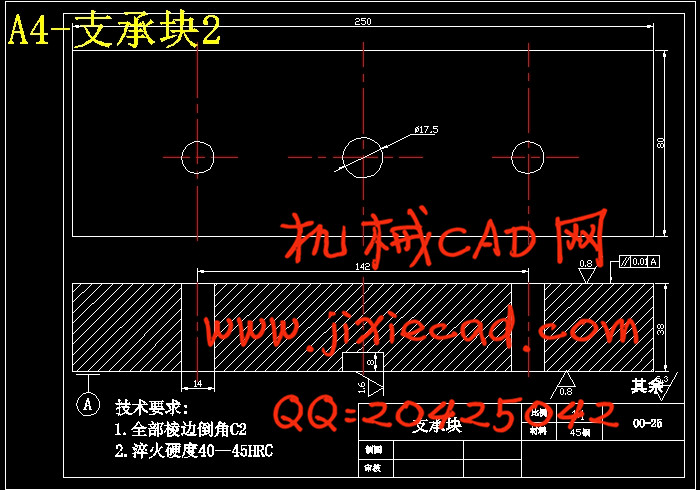

3.6.1凹模结构设计………………………………………………………………15

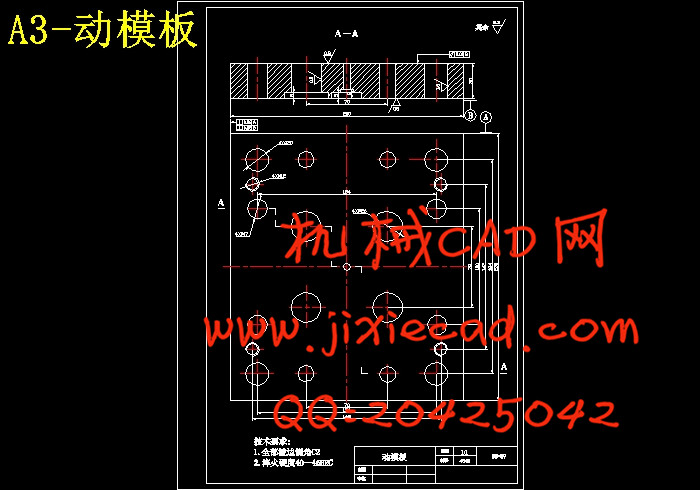

3.6.2 型芯的设计…………………………………………………………………16

3.7模具加热与冷却水道设计……………………………………………………17

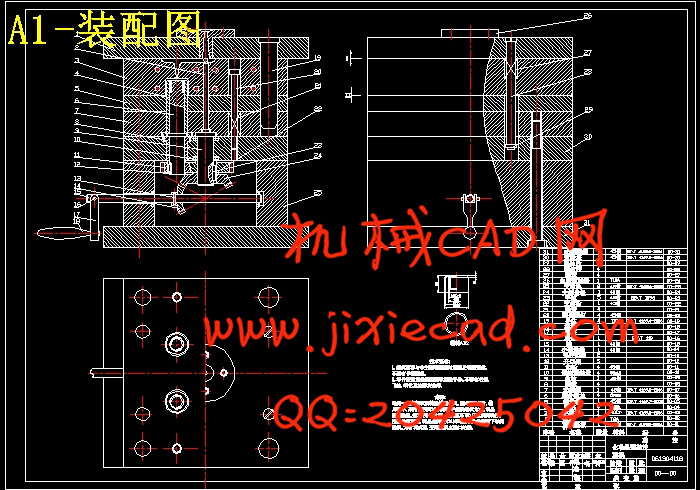

4. 模具整体设计…………………………………………………………………18

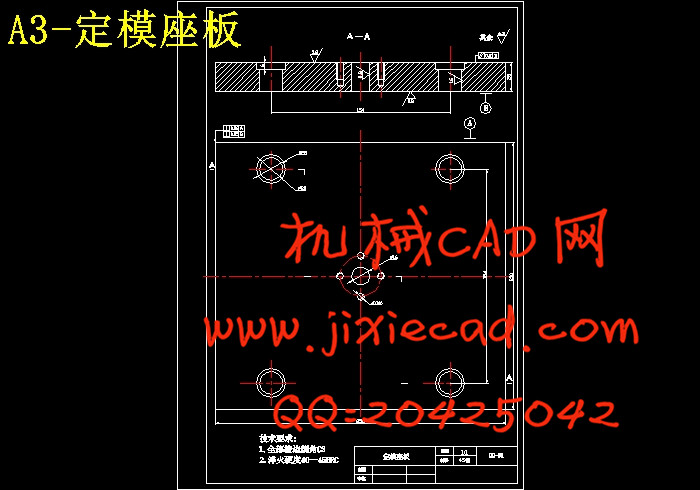

4.1 模架的选择……………………………………………………………………18

6.1.2 凹模的深度尺寸计算………………………………………………………20

6.2 凸模工作尺寸的计算…………………………………………………………21

7. 模具闭合高度的确定…………………………………………………………23

8. 注塑机有关参数校核…………………………………………………………24

9. 绘制模具总装图………………………………………………………………25

10.结束语…………………………………………………………………………27

致谢…………………………………………………………………………………29

参考文献……………………………………………………………………………30

摘要:本设计题目为化妆品瓶盖注塑模设计,体现了壳体类塑料零件的设计要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者注塑模设计的基础知识,为设计更复杂的注塑模具做好了铺垫和吸取了更深刻的经验。

本设计运用塑料成型工艺及模具设计的基础知识,首先分析了塑件的成分及性能要求,为选取浇口的类型做好了准备;然后估算了塑件的体积,便于选取注塑机;最后分析了塑件的特征,确定模具的设计参数、设计要点及推出装置的选取。

本塑件属于壳体类零件,同时内侧有一个螺纹,因此设计时必须考虑螺纹塑件的脱模。本设计采用螺纹塑件的旋转脱模,因内部有止转的中空型芯,所以属于塑件内部有止转的情况,考虑到模具较小,不宜采用机动或液压等自动脱模机构,所以采用手动脱模机构。

关键词: 注塑模 浇口 型芯 脱模机构

化妆品瓶盖注塑模设计

Abstract:This design topic notes an injection mold design for the cosmetics bottle cover, body now the hull body plastics design request, contents and direction of the spare parts, there is certain design meaning.Pass the design to the spare parts' molding tool, strengthenned a design to note the injection mold foundation knowledge of design further, for design to more complicatedly note a injection molding tool to have done cushion and absorb deeper experience.

This design usage plastics models the foundation knowledge of craft and molding tool design, composition and function which analyzed a injection piece first request, sprinkle an oscular type to have done preparation for the selection;Then estimated the physical volume of injection piece, the easy to selection noted injection machine;Finally analyzed the characteristic of injection piece, make sure the design parameter, design important point of molding tool and release the selection of device.

This injection piece belongs to the hull body spare parts, the seamy side contains a thread in the meantime, so design have to consider the thread injection take off of piece a mold.This design adoption thread injection revolve of piece takes off a mold and have because of the inner part turn of hollow type Xin, so belong to a injection piece inner part to have the circumstance for turn, in consideration of the molding tool is smaller, not proper adoption mobile or the liquid press etc. automatically take off mold organization, so the adoption moves to take off mold organization.

Keyword: The injection mold sprinkle Core Take off mold organization

目录

1. 绪 论……………………………………………………………………………1

1.1国内模具的现状和发展趋势……………………………………………………1

1.1.1国内模具的现状………………………………………………………………1

1.1.2 国内模具的发展趋势………………………………………………………2

1.2 国外模具的现状和发展趋势……………………………………………………3

1.3 化妆品瓶盖模具设计与制造方面………………………………………………4

1.3.1 化妆品瓶盖模具设计的设计思路……………………………………………4

1.3.2 化妆品瓶盖模具设计的进度…………………………………………………5

2. 化妆品瓶盖工艺性分析…………………………………………………………6

2.1塑件的工艺性分析………………………………………………………………6

2.2 塑件的结构和尺寸精度及表面质量分析………………………………………8

2.3 计算塑件的体积质量……………………………………………………………8

2.4 塑件注塑工艺参数确定…………………………………………………………8

3. 注塑模结构设计…………………………………………………………………10

3.1 分型面选择……………………………………………………………………10

3.2 确定型腔排列方式……………………………………………………………11

3.3 浇注系统的设计………………………………………………………………11

3.3.1主流道的设计………………………………………………………………11

3.3.2主流道衬套的设计…………………………………………………………11

3.3.3 分流道设计…………………………………………………………………13

3.3.4浇口设计……………………………………………………………………13

3.4 排气结构的设计………………………………………………………………13

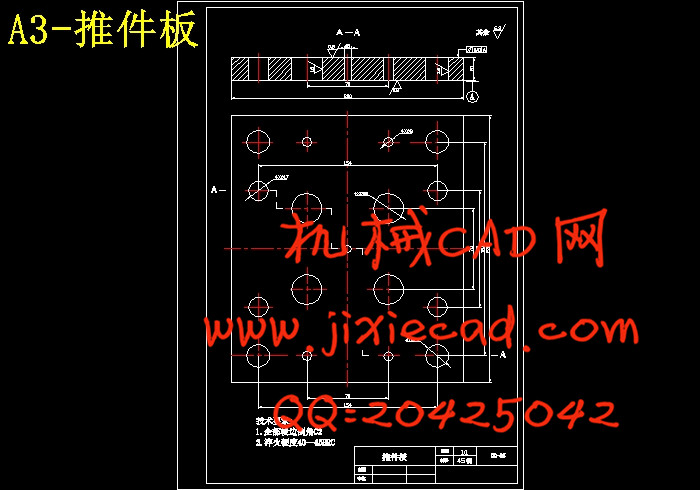

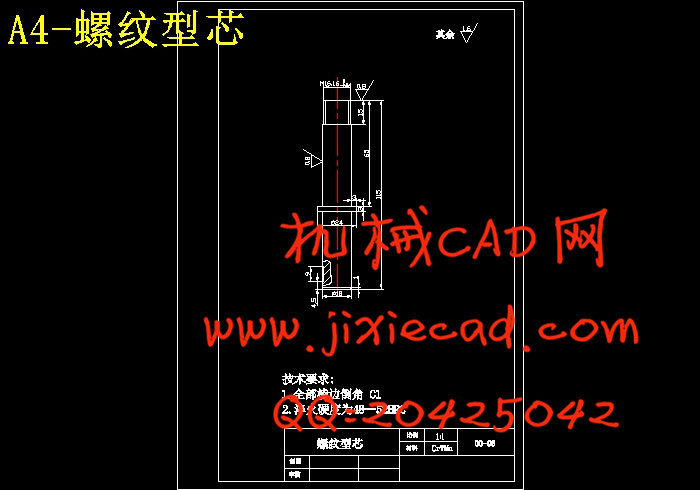

3.5 螺纹脱模结构的设计…………………………………………………………13

3.6 成型零件结构设计……………………………………………………………15

3.6.1凹模结构设计………………………………………………………………15

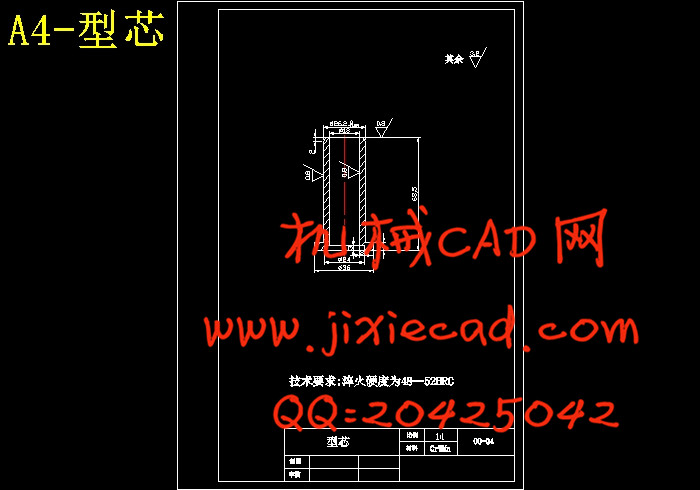

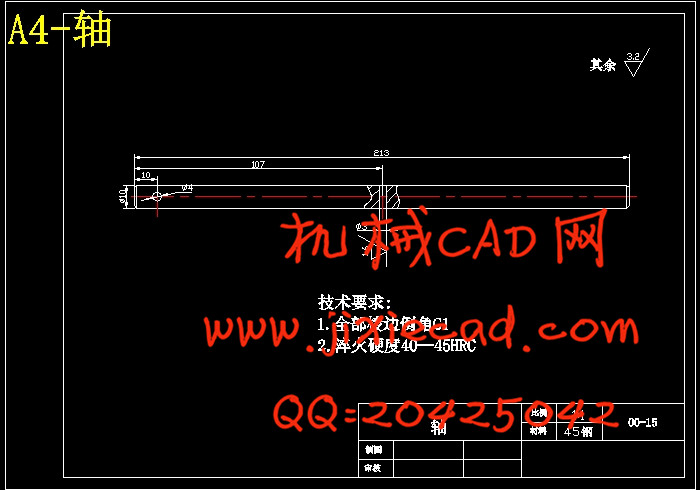

3.6.2 型芯的设计…………………………………………………………………16

3.7模具加热与冷却水道设计……………………………………………………17

4. 模具整体设计…………………………………………………………………18

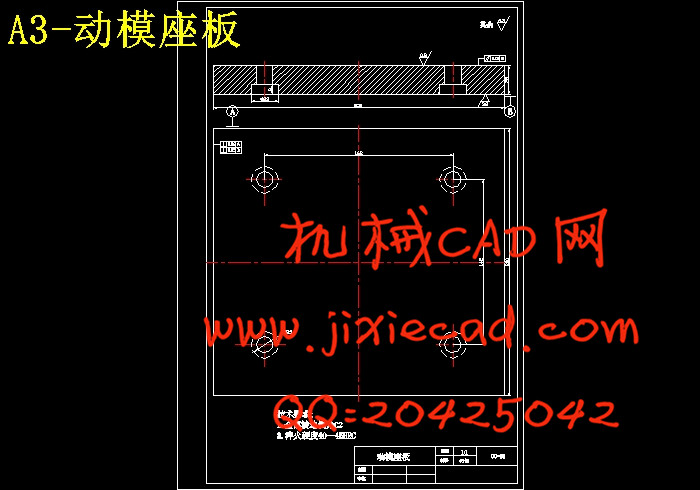

4.1 模架的选择……………………………………………………………………18

5. 结构与辅助零部件的设计……………………………………………………19

5.1 导柱的选用……………………………………………………………………19

5.2 弹簧的选用……………………………………………………………………196. 模具设计的有关计算…………………………………………………………20

6.1 型腔、型芯工作尺寸计算……………………………………………………20

6.1.1 凹模的径向尺寸计算………………………………………………………206.1.2 凹模的深度尺寸计算………………………………………………………20

6.2 凸模工作尺寸的计算…………………………………………………………21

7. 模具闭合高度的确定…………………………………………………………23

8. 注塑机有关参数校核…………………………………………………………24

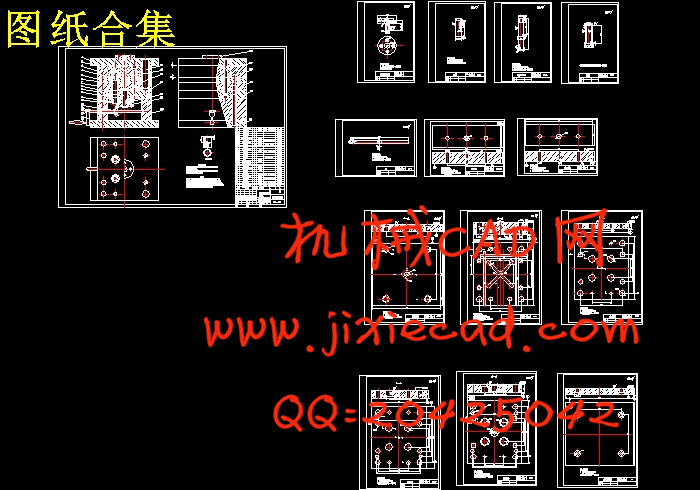

9. 绘制模具总装图………………………………………………………………25

10.结束语…………………………………………………………………………27

致谢…………………………………………………………………………………29

参考文献……………………………………………………………………………30