设计简介

活塞—完爆器阀

摘 要

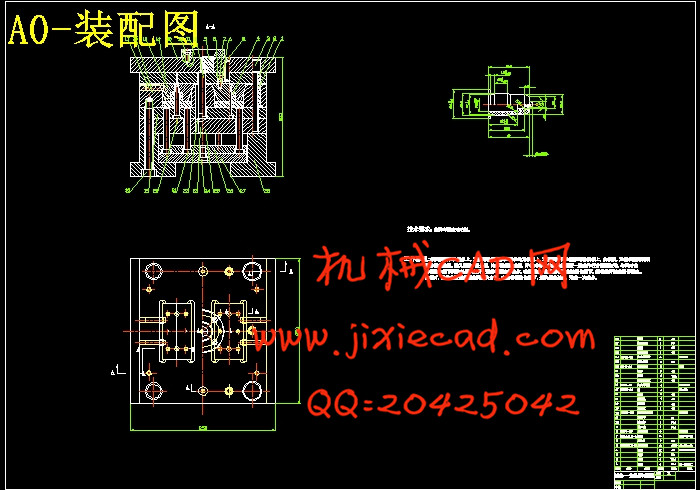

本次设计系统的介绍了注塑制品与注塑模具的设计原理与设计的全过程。从分析原材料(PA6GF30%)开始设计,从塑件的尺寸结构分析初步确定所选用的注塑机和模具的总体结构开始,逐步设计构成模具的各个零部件,包括是:型腔的排列、主流道的设计、主流道衬套的设计、定位环的设计、分流道的设计、抽芯斜滑块的确定、成型零部件的设计等,而且对组成模具结构的成型零件、侧向抽芯机构、型腔壁厚和底板厚度及加热和冷却系统等零部件作了详细的尺寸计算,从而得出这些组成模具结构的零部件在模具框架中准确位置。而且在设计中查阅许多和塑料模设计与制造相的关书籍,讯问很多良师益友。标准模架的选用,使模具的设计趋于简单,为模具的机构构造了骨架,这些零件的正确选用为这次设计能准确无误的完成打下基础。

关键字: 分析原材料、 注塑机、 模具结构

This design system introduction has cast the product with to cast the mold the principle of design and the design entire process. (PA6GF30%) starts from the analysis raw material to design, from models the injection molding machine and the mold overall structure which the size structure analysis preliminary determination selects starts, the step-by-step design constitutes the mold each spare part, including is: The cavity arrangement, the host flow channel design, the host flow channel bushing design, the locating ring design, is divided the flow channel the design, pulls out the core slanting slide the determination, takes shape the spare part design and so on, moreover to composed the mold structure to take shape the components, lateral pulls out the core organization, cavity wall thickness and ledger wall thickness and heats up with spare part and so on cooling system has made the detailed size computation, thus obtained these composition mold structures the spare part in the mold frame the accurate position. Moreover consults many and the plastic mold design and the manufacture pass books in the design, inquires very many good teachers and helpful friends. Standard mold selection, enable the mold the design to tend to simply, for the mold organization structure skeleton, these components has correctly selected for this design can be accurate unmistakably completes builds the foundation.

Key words:Analysis raw material, injection molding machine, mold structure,

目录

绪 论……………………………………………………………………………1

第1章 塑料制件及模具设计的依据……………………………………3

1.1 塑件的工艺性分析 …………………………………………………3

1.2 计算塑件的体积和质量 ……………………………………………4

1.3 塑件注塑工艺参数的确定 …………………………………………4

第2章 模具结构设计 ……………………………………………………5

2.1 分型面的选择 ………………………………………………………5

2.2 确定型腔的排列 ……………………………………………………5

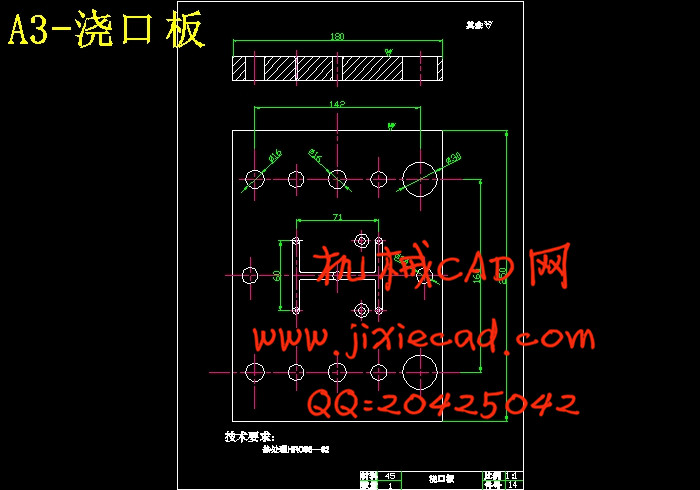

2.3 浇注系统的设计 ……………………………………………………6

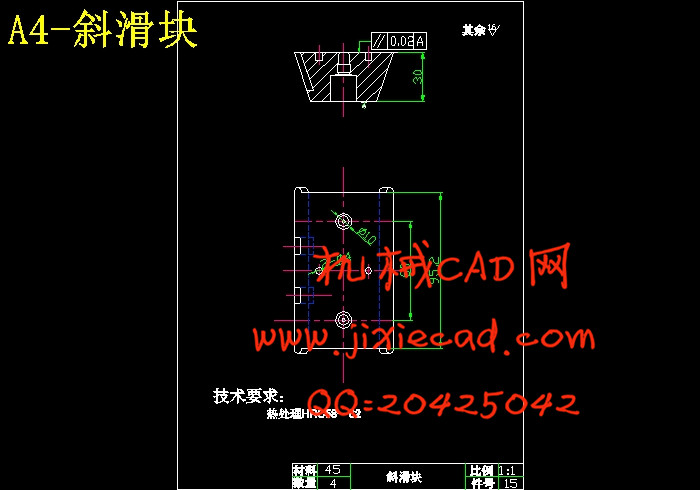

2.4 抽芯机构的设计 ……………………………………………………9

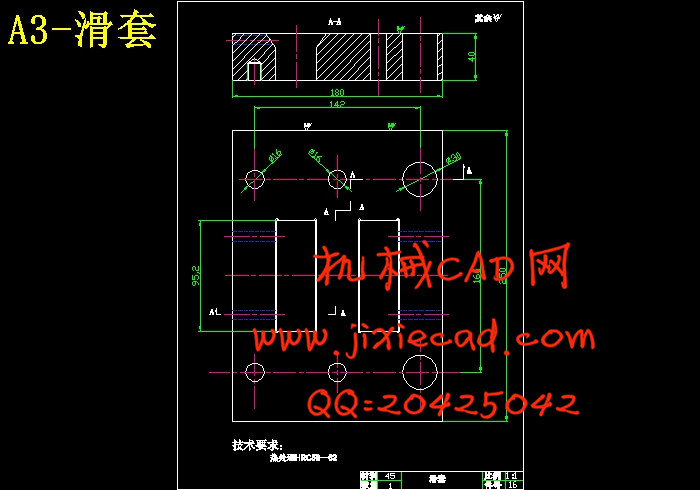

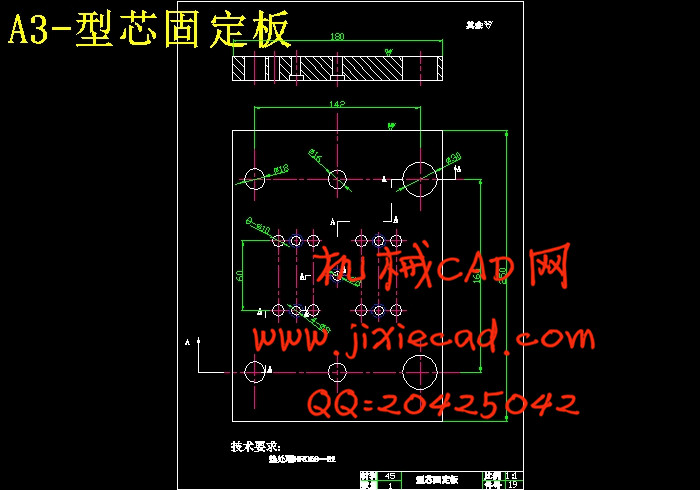

2.5 成型零件结构设计 …………………………………………………10

第3章 模具设计的有关计算……………………………………………11

3.1 型腔、型芯工作尺寸计算 …………………………………………11

3.2 型腔侧壁厚度和底板计算 …………………………………………12

3.2 型腔侧壁厚度和底板计算 …………………………………………12

第4章 模具加热与冷却系统的计算 …………………………………13

4.1 求塑件在硬化时每小时释放的热量 ………………………………13

4.2 求冷却水的体积流量 ………………………………………………13

第5章 模具闭合高度的确定 …………………………………………14

第6章 注塑机有关参数的校核 ………………………………………15

第7章 模具的工作原理 ………………………………………………16

结论. ……………………………………………………………………………17

致谢 ……………………………………………………………………………18

参考文献 …………………………………………………………………… 19

摘 要

本次设计系统的介绍了注塑制品与注塑模具的设计原理与设计的全过程。从分析原材料(PA6GF30%)开始设计,从塑件的尺寸结构分析初步确定所选用的注塑机和模具的总体结构开始,逐步设计构成模具的各个零部件,包括是:型腔的排列、主流道的设计、主流道衬套的设计、定位环的设计、分流道的设计、抽芯斜滑块的确定、成型零部件的设计等,而且对组成模具结构的成型零件、侧向抽芯机构、型腔壁厚和底板厚度及加热和冷却系统等零部件作了详细的尺寸计算,从而得出这些组成模具结构的零部件在模具框架中准确位置。而且在设计中查阅许多和塑料模设计与制造相的关书籍,讯问很多良师益友。标准模架的选用,使模具的设计趋于简单,为模具的机构构造了骨架,这些零件的正确选用为这次设计能准确无误的完成打下基础。

关键字: 分析原材料、 注塑机、 模具结构

Piston- finish to explode the machine valve

AbstractThis design system introduction has cast the product with to cast the mold the principle of design and the design entire process. (PA6GF30%) starts from the analysis raw material to design, from models the injection molding machine and the mold overall structure which the size structure analysis preliminary determination selects starts, the step-by-step design constitutes the mold each spare part, including is: The cavity arrangement, the host flow channel design, the host flow channel bushing design, the locating ring design, is divided the flow channel the design, pulls out the core slanting slide the determination, takes shape the spare part design and so on, moreover to composed the mold structure to take shape the components, lateral pulls out the core organization, cavity wall thickness and ledger wall thickness and heats up with spare part and so on cooling system has made the detailed size computation, thus obtained these composition mold structures the spare part in the mold frame the accurate position. Moreover consults many and the plastic mold design and the manufacture pass books in the design, inquires very many good teachers and helpful friends. Standard mold selection, enable the mold the design to tend to simply, for the mold organization structure skeleton, these components has correctly selected for this design can be accurate unmistakably completes builds the foundation.

Key words:Analysis raw material, injection molding machine, mold structure,

目录

绪 论……………………………………………………………………………1

第1章 塑料制件及模具设计的依据……………………………………3

1.1 塑件的工艺性分析 …………………………………………………3

1.2 计算塑件的体积和质量 ……………………………………………4

1.3 塑件注塑工艺参数的确定 …………………………………………4

第2章 模具结构设计 ……………………………………………………5

2.1 分型面的选择 ………………………………………………………5

2.2 确定型腔的排列 ……………………………………………………5

2.3 浇注系统的设计 ……………………………………………………6

2.4 抽芯机构的设计 ……………………………………………………9

2.5 成型零件结构设计 …………………………………………………10

第3章 模具设计的有关计算……………………………………………11

3.1 型腔、型芯工作尺寸计算 …………………………………………11

第4章 模具加热与冷却系统的计算 …………………………………13

4.1 求塑件在硬化时每小时释放的热量 ………………………………13

4.2 求冷却水的体积流量 ………………………………………………13

第5章 模具闭合高度的确定 …………………………………………14

第6章 注塑机有关参数的校核 ………………………………………15

第7章 模具的工作原理 ………………………………………………16

结论. ……………………………………………………………………………17

致谢 ……………………………………………………………………………18

参考文献 …………………………………………………………………… 19