设计简介

基于ProToolkit的齿轮注塑模

三维参数化设计

摘要

随着塑料制品的大量使用,注塑模的应用越来越广。注塑模具是一种结构复杂、零件精度要求很高的工艺装备,传统设计方法无法使模具满足塑件的高精度要求。参数化设计作为一种智能化、自动化的机械设计方法,可使模具的设计水平达到新高度。本论文根据注塑模具的设计原理,在Windows XP环境下,基于Pro/E野火4.0软件平台,采用Microsoft SQL Server数据库,利用Microsoft Visual Studio 2005编译器和Pro/E自带的功能丰富的二次开发工具Pro/TOOLKIT,通过Pro/E强大的Parameters和Relations功能,开发一套界面友好、交互性强的直齿渐开线锥齿轮注塑模CAD系统。 论文通过对锥齿轮结构的详细分析,采用基于特征的参数化造型方法建立标准渐开线锥齿轮的三维模型,并依据注塑模设计理论选择注塑机、确定其合理的模具结构,达到模具设计步骤规范化。 论文对锥齿轮注塑模CAD系统的整体框架进行规划,建立锥齿轮参数化设计、选择注塑机、成型零件参数化设计、推出机构参数化设计、模板类零件参数化设计、其它零件参数化设计、锥齿轮模具总装图设计七大模块。分别对各模块的零件尺寸建立驱动方程,利用Pro/E的参数和关系功能将各模块零部件的尺寸仅由锥齿轮的基本参数驱动。 论文通过分析Pro/E软件、Microsoft Visual Studio 2005编译器、数据库之间的通信及有关接口技术要点,研究MFC可视化对话框设计、Pro/TOOLKIT菜单设计、MFC ODBC数据库访问等关键技术,建立本系统各模块的对话框、菜单和信息资源文件,创建管理各模块零部件标准尺寸的Microsoft SQL Server数据库,实现锥齿轮注塑模CAD系统的可视化界面设计。 论文在Microsoft Visual Studio 2005环境下编制本系统各模块的主程序,实现编程模块化,从而把实体模型、菜单和界面联系起来,最终实现锥齿轮注塑模CAD系统各模块的参数化设计。

关键词:参数化设计、 锥齿轮、 注塑模、CAD系统、 Pro/TOOLKIT 、Microsoft SQL Server

Gear Injection Mold Pro Toolkit 3D parametric design

Abstract

With the extensive use of plastic products, injection mold used more and more. The injection mold is a complex structure, precision parts requires high technology and equipment, traditional design methods can not mold to meet the precision requirements of the plastic parts. Parametric design as an intelligent, automated mechanical design allows mold design standards to new heights. This thesis is based on the injection mold design principle, under the Windows XP environment, based on Pro / E Wildfire 4.0 software platform, Microsoft SQL Server database using Microsoft Visual Studio 2005 compiler and Pro / E comes secondary development tool Pro / TOOLKIT, by the powerful Pro / E Parameters and Relations function to develop a friendly interface, interactive, straight teeth involute line of bevel gears injection mold CAD system. Through a detailed analysis of the bevel gear structure, the use of feature-based parametric modeling methods to establish the standard three-dimensional model of involute bevel gears, and based on the injection mold design theory to select injection molding machines, to determine the reasonable structure of the mold, to mold design steps standardized. Paper to plan the overall framework of the injection mold CAD system of the bevel gear, establish the bevel gear parametric design, injection molding machines, molding parametric design, the introduction of parametric design, parametric design of a template class, and other parametric design, bevel gear mold assembly diagram design of the seven modules. Part size of each module, the driver equation, the use of Pro / E parameters and relationships function the size of the module components only by the basic parameters of the bevel gear drive. Thesis by analyzing the Pro / E software, the Microsoft Visual Studio 2005 compiler, the points of communication between the database and related interface technology, research MFC visualization dialog design, Pro / TOOLKIT menu design, the MFC ODBC database access and other key technologies, the establishment of module in the system dialog box, menu, and information resource file, create a management standard size for each module components of Microsoft SQL Server database, the visual interface design bevel gear injection mold CAD system. Papers prepared under the Microsoft Visual Studio 2005 environment, the main program of the system module, programmed modular, so that the solid model, the menu and interface are linked, and ultimately the design of the bevel gear injection mold CAD system module parameters.

Key words: parametric design, bevel gears, injection molds, CAD systems, Pro / TOOLKIT, the Microsoft SQL Server

1 引言 3

2 塑料齿轮结构设计 5

3 齿轮塑件材料的选择 5

4 注塑机的选择 8

4.1 注射量的校核 8

4.2 注射压力的校核 8

4.3 锁模力的校核 9

4.4 模具开模行程校核 9

4.5 模具厚度校核 10

5 模具结构分析与设计 10

5.1 分型面的选择与确定 10

5.2 型腔数目的确定及排列 11

5.3 浇注系统设计 11

5.4 成型零件结构设计 13

5.5 推出机构的设计 15

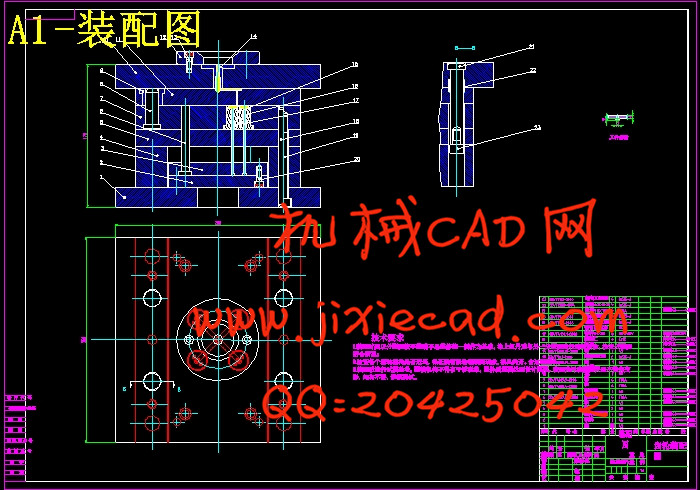

5.6 模具结构 16

6 齿轮注塑模 CAD 系统的模块设计 17

6.1 系统设计思路 17

6.2 零件建模 18

6.2.1齿轮设计 18

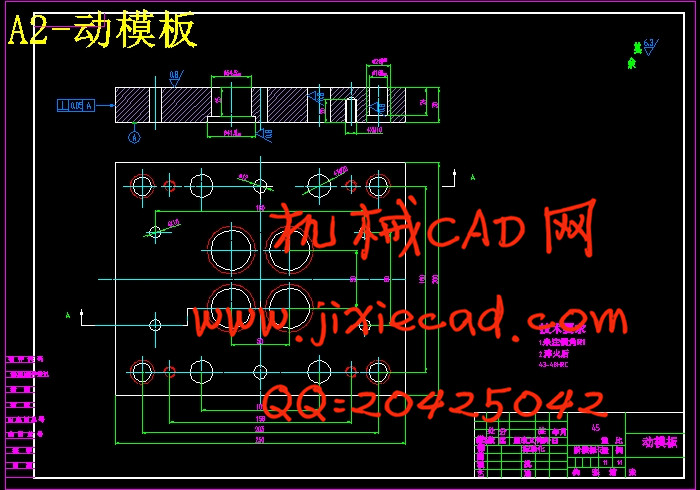

6.2.2模板设计 20

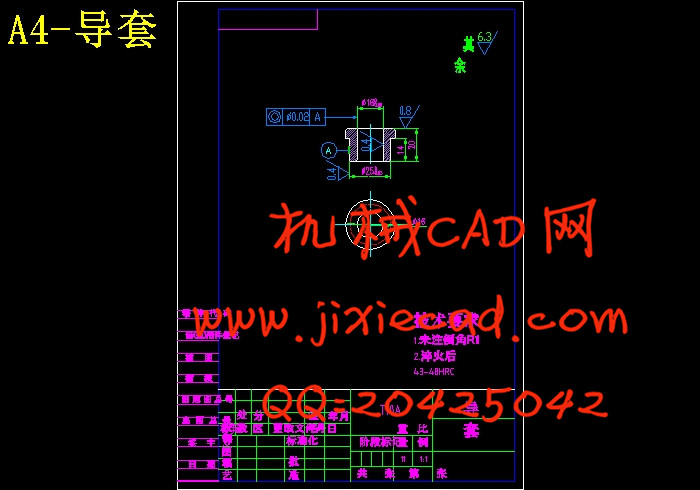

6.2.3 杆类零件 20

6.3 程序设计 21

6.3.1设计思路 21

6.3.2 添加菜单 21

6.4 注塑模各模块设计 24

6.4.1 定模模块 24

6.4.2零件数据库建立 27

6.5 编写注册文件 32

设 计 总 结 33

致 谢 34

参 考 文 献 35

三维参数化设计

摘要

随着塑料制品的大量使用,注塑模的应用越来越广。注塑模具是一种结构复杂、零件精度要求很高的工艺装备,传统设计方法无法使模具满足塑件的高精度要求。参数化设计作为一种智能化、自动化的机械设计方法,可使模具的设计水平达到新高度。本论文根据注塑模具的设计原理,在Windows XP环境下,基于Pro/E野火4.0软件平台,采用Microsoft SQL Server数据库,利用Microsoft Visual Studio 2005编译器和Pro/E自带的功能丰富的二次开发工具Pro/TOOLKIT,通过Pro/E强大的Parameters和Relations功能,开发一套界面友好、交互性强的直齿渐开线锥齿轮注塑模CAD系统。 论文通过对锥齿轮结构的详细分析,采用基于特征的参数化造型方法建立标准渐开线锥齿轮的三维模型,并依据注塑模设计理论选择注塑机、确定其合理的模具结构,达到模具设计步骤规范化。 论文对锥齿轮注塑模CAD系统的整体框架进行规划,建立锥齿轮参数化设计、选择注塑机、成型零件参数化设计、推出机构参数化设计、模板类零件参数化设计、其它零件参数化设计、锥齿轮模具总装图设计七大模块。分别对各模块的零件尺寸建立驱动方程,利用Pro/E的参数和关系功能将各模块零部件的尺寸仅由锥齿轮的基本参数驱动。 论文通过分析Pro/E软件、Microsoft Visual Studio 2005编译器、数据库之间的通信及有关接口技术要点,研究MFC可视化对话框设计、Pro/TOOLKIT菜单设计、MFC ODBC数据库访问等关键技术,建立本系统各模块的对话框、菜单和信息资源文件,创建管理各模块零部件标准尺寸的Microsoft SQL Server数据库,实现锥齿轮注塑模CAD系统的可视化界面设计。 论文在Microsoft Visual Studio 2005环境下编制本系统各模块的主程序,实现编程模块化,从而把实体模型、菜单和界面联系起来,最终实现锥齿轮注塑模CAD系统各模块的参数化设计。

关键词:参数化设计、 锥齿轮、 注塑模、CAD系统、 Pro/TOOLKIT 、Microsoft SQL Server

Gear Injection Mold Pro Toolkit 3D parametric design

Abstract

With the extensive use of plastic products, injection mold used more and more. The injection mold is a complex structure, precision parts requires high technology and equipment, traditional design methods can not mold to meet the precision requirements of the plastic parts. Parametric design as an intelligent, automated mechanical design allows mold design standards to new heights. This thesis is based on the injection mold design principle, under the Windows XP environment, based on Pro / E Wildfire 4.0 software platform, Microsoft SQL Server database using Microsoft Visual Studio 2005 compiler and Pro / E comes secondary development tool Pro / TOOLKIT, by the powerful Pro / E Parameters and Relations function to develop a friendly interface, interactive, straight teeth involute line of bevel gears injection mold CAD system. Through a detailed analysis of the bevel gear structure, the use of feature-based parametric modeling methods to establish the standard three-dimensional model of involute bevel gears, and based on the injection mold design theory to select injection molding machines, to determine the reasonable structure of the mold, to mold design steps standardized. Paper to plan the overall framework of the injection mold CAD system of the bevel gear, establish the bevel gear parametric design, injection molding machines, molding parametric design, the introduction of parametric design, parametric design of a template class, and other parametric design, bevel gear mold assembly diagram design of the seven modules. Part size of each module, the driver equation, the use of Pro / E parameters and relationships function the size of the module components only by the basic parameters of the bevel gear drive. Thesis by analyzing the Pro / E software, the Microsoft Visual Studio 2005 compiler, the points of communication between the database and related interface technology, research MFC visualization dialog design, Pro / TOOLKIT menu design, the MFC ODBC database access and other key technologies, the establishment of module in the system dialog box, menu, and information resource file, create a management standard size for each module components of Microsoft SQL Server database, the visual interface design bevel gear injection mold CAD system. Papers prepared under the Microsoft Visual Studio 2005 environment, the main program of the system module, programmed modular, so that the solid model, the menu and interface are linked, and ultimately the design of the bevel gear injection mold CAD system module parameters.

Key words: parametric design, bevel gears, injection molds, CAD systems, Pro / TOOLKIT, the Microsoft SQL Server

目 录

1 引言 3

2 塑料齿轮结构设计 5

3 齿轮塑件材料的选择 5

4 注塑机的选择 8

4.1 注射量的校核 8

4.2 注射压力的校核 8

4.3 锁模力的校核 9

4.4 模具开模行程校核 9

4.5 模具厚度校核 10

5 模具结构分析与设计 10

5.1 分型面的选择与确定 10

5.2 型腔数目的确定及排列 11

5.3 浇注系统设计 11

5.4 成型零件结构设计 13

5.5 推出机构的设计 15

5.6 模具结构 16

6 齿轮注塑模 CAD 系统的模块设计 17

6.1 系统设计思路 17

6.2 零件建模 18

6.2.1齿轮设计 18

6.2.2模板设计 20

6.2.3 杆类零件 20

6.3 程序设计 21

6.3.1设计思路 21

6.3.2 添加菜单 21

6.4 注塑模各模块设计 24

6.4.1 定模模块 24

6.4.2零件数据库建立 27

6.5 编写注册文件 32

设 计 总 结 33

致 谢 34

参 考 文 献 35