设计简介

摘要:模具工业的发展,日益受到人们的重视和关注。“模具式工业生产的基础工艺装备”也已经取得了共识。在电子、汽车、电机、电器、仪器、仪表、家电和通信等产品中,60%~80%的部件都要依靠模具成型。本论文介绍的是电磁继电器外壳的注塑模具设计。

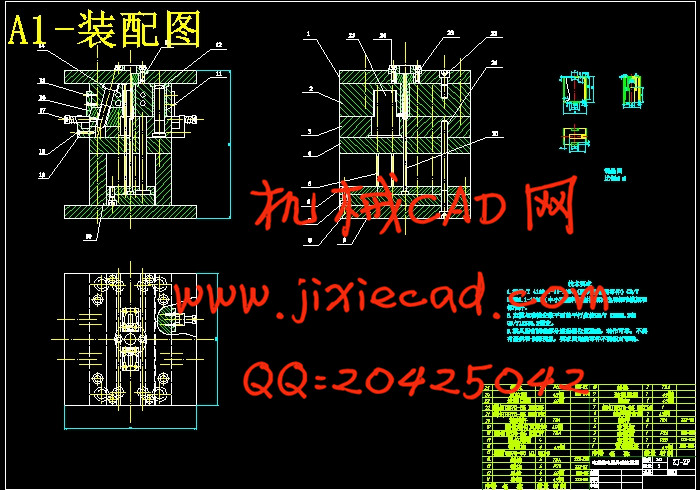

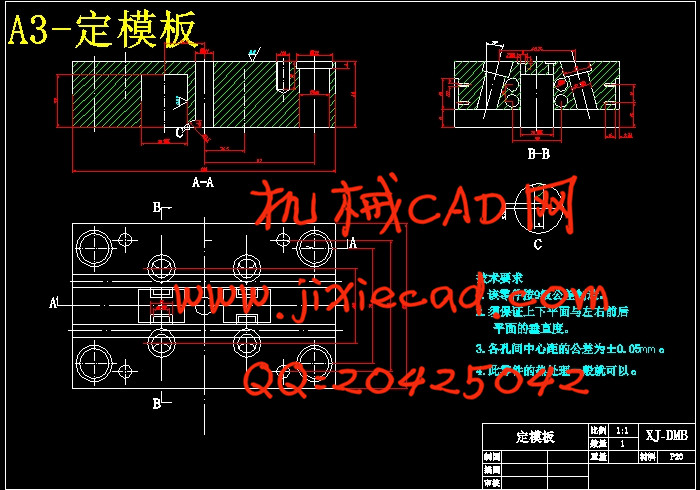

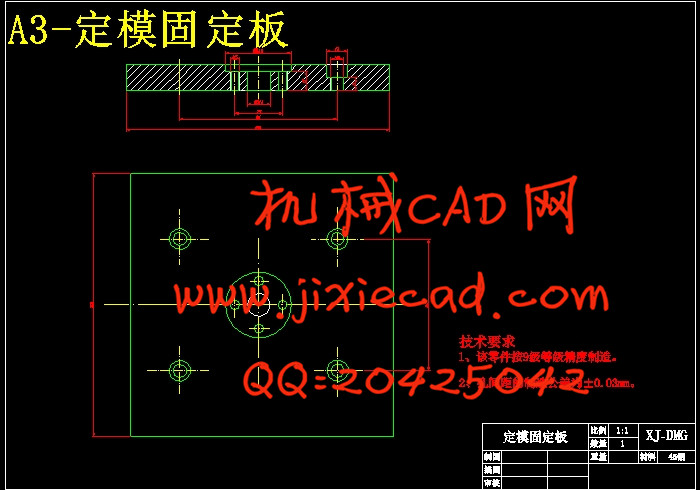

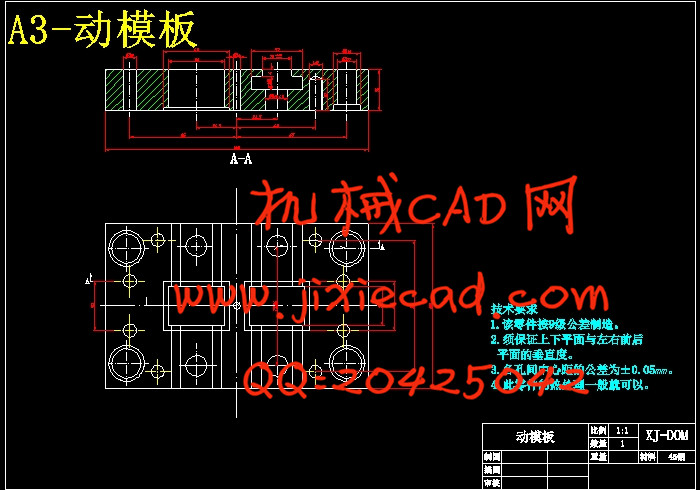

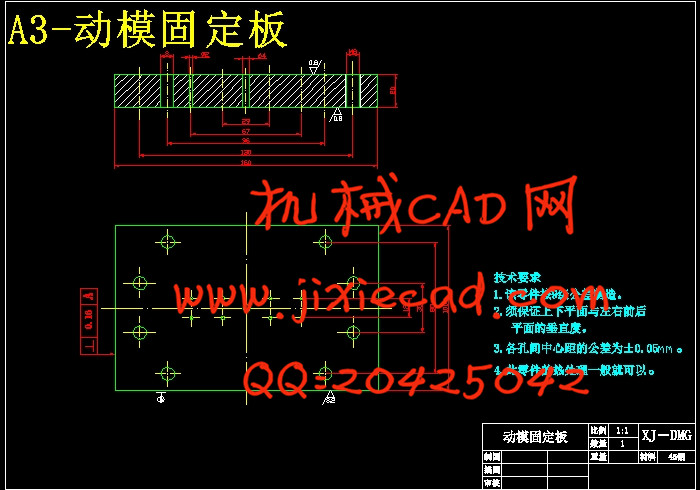

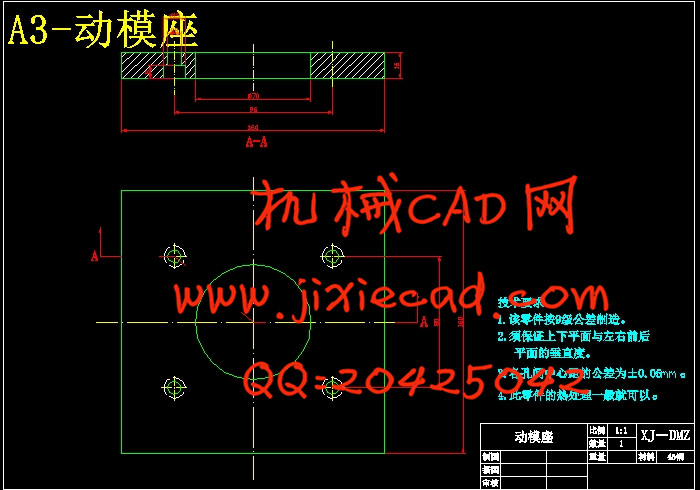

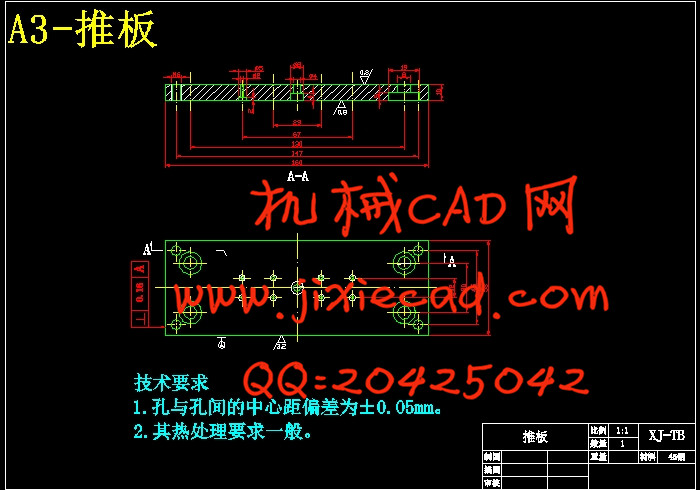

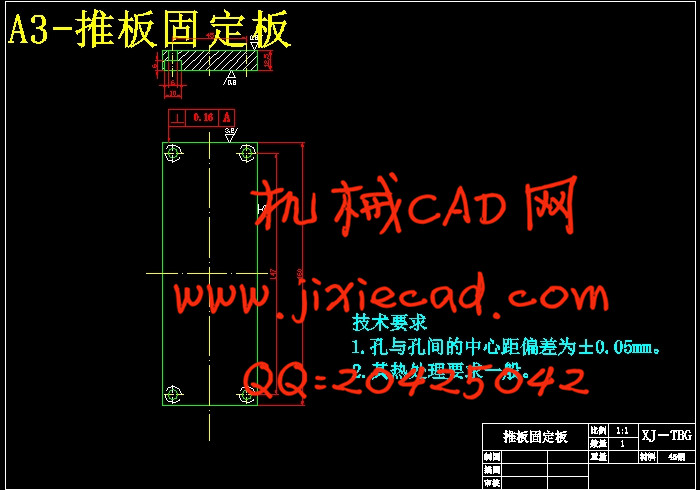

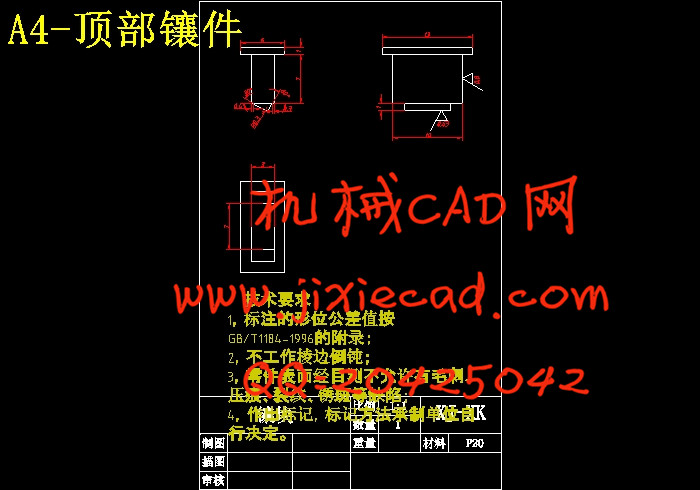

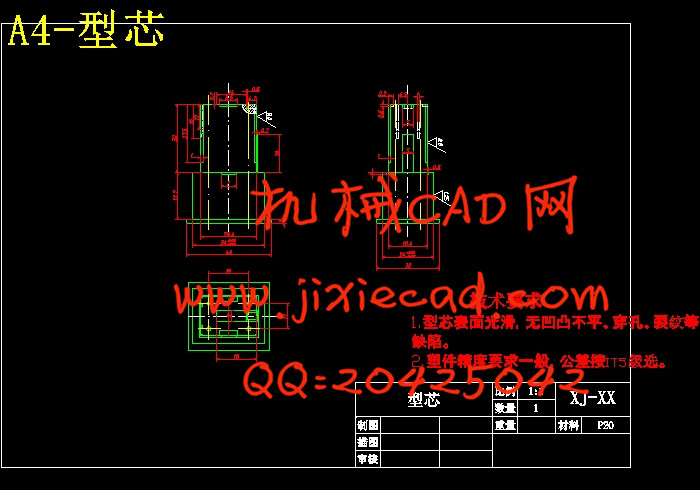

本论文详细介绍了整个模具的设计过程,对各机构和系统进行了详尽的分析,包括模具结构设计、浇注系统的设计、冷却系统设计、脱模机构设计、排气系统设计、抽芯机构设计,合模机构设计,导向机构设计等。除此之外还介绍了注塑材料成型工艺和性能,以及注塑机的选用和对部分参数的校核。

此设计多采用标准件,结构设计紧凑,目的为了降低模具的制造成本,提高生产效率。设计过程中使用了AutoCAD, UG等计算机辅助软件绘制了各主要零件图、制品图、以及大量结构设计图,大大缩短了设计的周期。

关键词:注塑模具 PS 继电器外壳

Abstract: The development of die and mould industry,Increasing attention and concern。"The mold type industrial production process equipment foundation" has achieved consensus. In electronics, automobile, motor, electric appliances, instruments and meters, home appliance and communication products, 60% ~ 80% of its molding part should rely on. This paper introduces the electromagnetic relay is the shell injection mold design。

This paper introduced the design process, the mould of organizations and system for a detailed analysis, including the design of die structure and the design of gating system, cooling system design, design, exhaust system demoulding mechanism design, core-pulling mechanism design, mould design, the design of steering mechanism etc. In addition also introduces the injection molding technology and material performance, as well as the selection and injection of some parameters of the check.

This design is used more compact structure design, mould, in order to reduce the cost of manufacture, improve production efficiency. The design process using AutoCAD, UG software rendering such computer aided the major parts graph, products and design, structural design, greatly shorten the cycle.

Keywords: Injection mold PS Relay shell

目录

1 引言

1.1 模具生产的重要性.........................................1

1.2 我国塑料模具技术现状.....................................1

1.3 模具技术的发展趋势.......................................2

2 电磁继电器外壳注塑模具设计

2.1 制品工艺性能分析.........................................7

2.2 PS的加工工艺及成型性能..................................9

2.3 分型面的选择............................................10

2.4 型腔数目的确定..........................................11

2.5 浇注系统的设计..........................................11

2.5.1 浇注系统的组成......................................11

2.5.2 浇注系统的布置......................................12

2.5.3 主流道的设计........................................12

2.5.4 分流道的设计........................................13

2.5.5 浇口的设计..........................................13

2.6 注塑机的选择............................................14

2.6.1 最大的注塑量........................................14

2.6.2 注塑压力............................................14

2.6.3 锁模力..............................................15

2.6.4 模板尺寸的确定......................................16

2.6.5 模具安装板的校核....................................17

2.6.6 开模行程的校核......................................17

2.7 侧抽芯与侧分型面机构的设计..............................17

2.8 排气问题................................................18

2.9 合模导向机构的设计......................................19

2.9.1 导向机构的作用......................................19

2.9.2 模架的选择..........................................20

2.9.3 导柱导向机构的设计..................................20

2.10 顶出机构的设计.........................................21

2.10.1 顶出机构的驱动方式..................................22

2.10.2 顶出机构的设计原则..................................22

2.10.3 顶出行程............................................23

2.10.4 顶出位置的设置......................................23

2.10.5 脱模力的计算........................................24

2.10.6 导向装置............................................24

2.10.7 顶杆的形式..........................................24

2.11 复位机构的设置.........................................24

2.12 温度调节系统对塑料件质量的影响.........................25

2.13 模具的作用原理.........................................27

结论......................................................... 28

致谢......................................................... 29

参考文献.................................................. 30

本论文详细介绍了整个模具的设计过程,对各机构和系统进行了详尽的分析,包括模具结构设计、浇注系统的设计、冷却系统设计、脱模机构设计、排气系统设计、抽芯机构设计,合模机构设计,导向机构设计等。除此之外还介绍了注塑材料成型工艺和性能,以及注塑机的选用和对部分参数的校核。

此设计多采用标准件,结构设计紧凑,目的为了降低模具的制造成本,提高生产效率。设计过程中使用了AutoCAD, UG等计算机辅助软件绘制了各主要零件图、制品图、以及大量结构设计图,大大缩短了设计的周期。

关键词:注塑模具 PS 继电器外壳

Abstract: The development of die and mould industry,Increasing attention and concern。"The mold type industrial production process equipment foundation" has achieved consensus. In electronics, automobile, motor, electric appliances, instruments and meters, home appliance and communication products, 60% ~ 80% of its molding part should rely on. This paper introduces the electromagnetic relay is the shell injection mold design。

This paper introduced the design process, the mould of organizations and system for a detailed analysis, including the design of die structure and the design of gating system, cooling system design, design, exhaust system demoulding mechanism design, core-pulling mechanism design, mould design, the design of steering mechanism etc. In addition also introduces the injection molding technology and material performance, as well as the selection and injection of some parameters of the check.

This design is used more compact structure design, mould, in order to reduce the cost of manufacture, improve production efficiency. The design process using AutoCAD, UG software rendering such computer aided the major parts graph, products and design, structural design, greatly shorten the cycle.

Keywords: Injection mold PS Relay shell

目录

1 引言

1.1 模具生产的重要性.........................................1

1.2 我国塑料模具技术现状.....................................1

1.3 模具技术的发展趋势.......................................2

2 电磁继电器外壳注塑模具设计

2.1 制品工艺性能分析.........................................7

2.2 PS的加工工艺及成型性能..................................9

2.3 分型面的选择............................................10

2.4 型腔数目的确定..........................................11

2.5 浇注系统的设计..........................................11

2.5.1 浇注系统的组成......................................11

2.5.2 浇注系统的布置......................................12

2.5.3 主流道的设计........................................12

2.5.4 分流道的设计........................................13

2.5.5 浇口的设计..........................................13

2.6 注塑机的选择............................................14

2.6.1 最大的注塑量........................................14

2.6.2 注塑压力............................................14

2.6.3 锁模力..............................................15

2.6.4 模板尺寸的确定......................................16

2.6.5 模具安装板的校核....................................17

2.6.6 开模行程的校核......................................17

2.7 侧抽芯与侧分型面机构的设计..............................17

2.8 排气问题................................................18

2.9 合模导向机构的设计......................................19

2.9.1 导向机构的作用......................................19

2.9.2 模架的选择..........................................20

2.9.3 导柱导向机构的设计..................................20

2.10 顶出机构的设计.........................................21

2.10.1 顶出机构的驱动方式..................................22

2.10.2 顶出机构的设计原则..................................22

2.10.3 顶出行程............................................23

2.10.4 顶出位置的设置......................................23

2.10.5 脱模力的计算........................................24

2.10.6 导向装置............................................24

2.10.7 顶杆的形式..........................................24

2.11 复位机构的设置.........................................24

2.12 温度调节系统对塑料件质量的影响.........................25

2.13 模具的作用原理.........................................27

结论......................................................... 28

致谢......................................................... 29

参考文献.................................................. 30