设计简介

摘要

本课题首先分析了盒形塑件的工艺特点,文中介绍了盒形塑件注塑成型模具设计要点及模具的工作过程。重点说明了电器盒的塑件结构的设计包括分析和阐述了电器盒塑件的壁厚选择及工艺特点;针对塑件的工艺特点进行模具的设计包括模具型腔数目的确定,注塑机的选择,模具分型面、冷却系统、浇注系统、分型抽芯机构等的设计过程。还对注塑模具成型零件工作尺寸的计算并介绍了模具的主要零件加工工艺及模具的装配工艺。

关键词:电器盒 工艺分析 注塑模具 模具结构

Abstract

The injection technological characteristics of box cover and analyzed, and the design main points and working process are also introduced. The design method of plastic strcuture is mainly introduced . The selection of the sidewall thickness, the decision of the mould cavity number, the selection of injection machine, and the designing process of the parting plane, the exhaust system, cool material cave and pin gate are stated. The design structure characteristics of box cover and parting plane with pin gate style, and side core-drawing structure. Analysis of the calculating the working dimensions of the forming parts of injection mould and the

Conventional manufacturing processes of the main parts of the injection mould .

[Key words]:

box cover technology analyse

injection mould mould structure

目 录

摘要

前言····································································································································(1)

第一章 塑料制件的设计···································································································(3)

1.1 塑件材料的性能··································································································(3)

1.2 塑件的体积与重量······························································································(5)

1.3 塑件工艺分析及结构设计··················································································(6)

第二章 总体设计方案的确定··························································································(8)

2.1 分型面的选择·······································································································(8)

2.2 排气方式的确定···································································································(8)

2.3 型腔数目和排列方式的确定···············································································(9)

2.4 注塑机的选择·······································································································(9)

第三章 浇注系统的设计及计算······················································································(11)

3.1 流道设计············································································································(11)

3.2 浇口设计············································································································(11)

3.3 流动比校核········································································································(12)

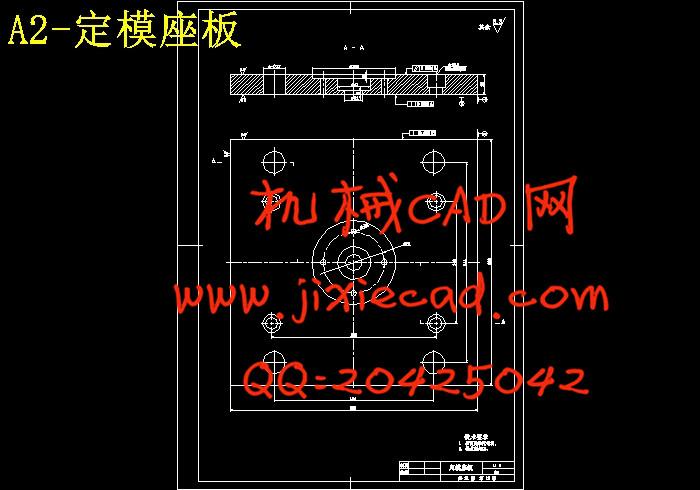

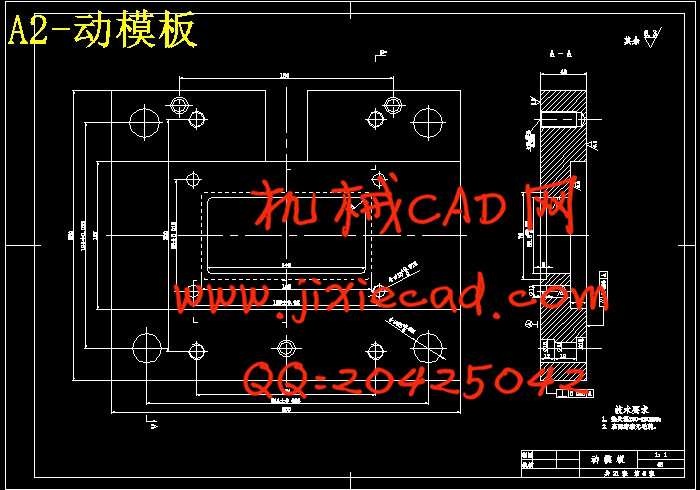

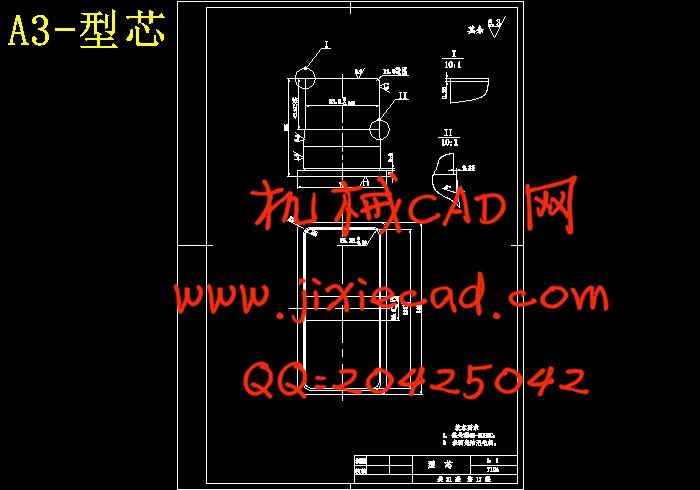

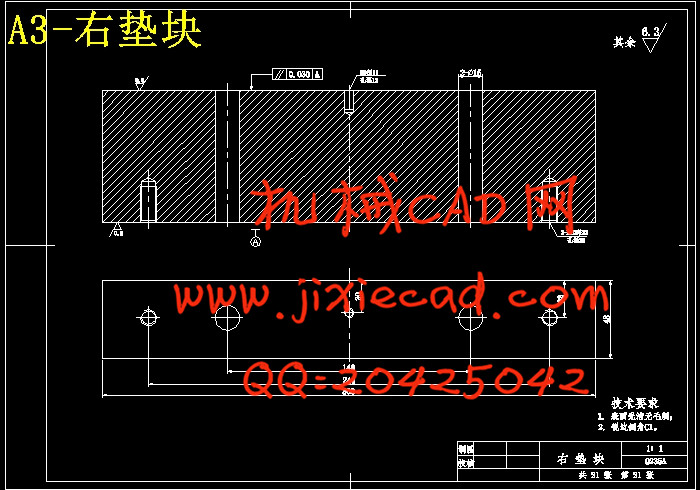

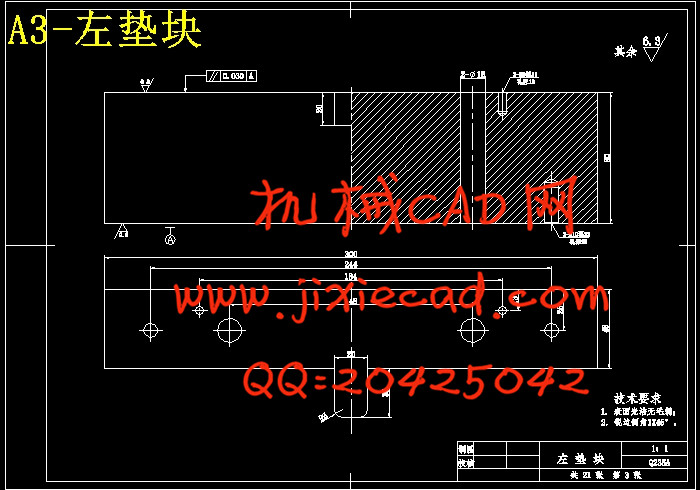

第四章 成型零件设计·····································································································(13)

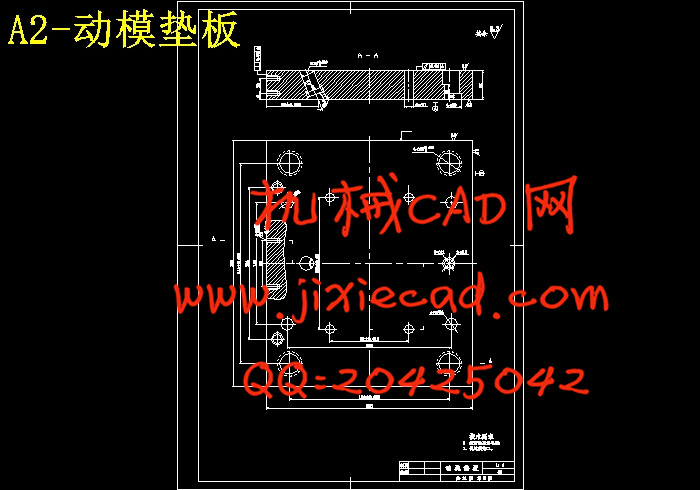

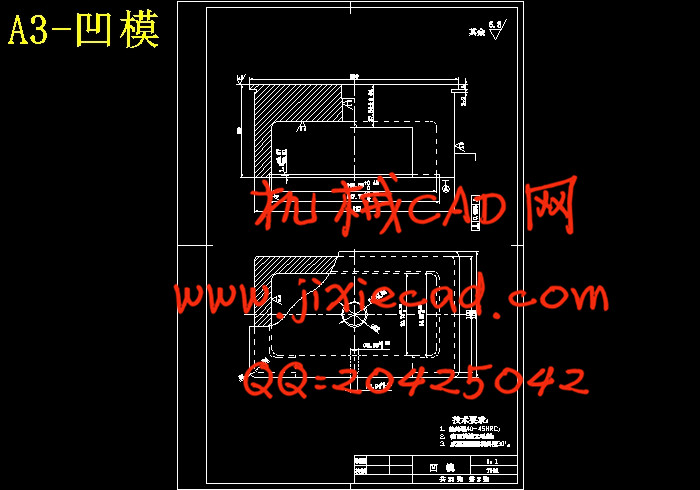

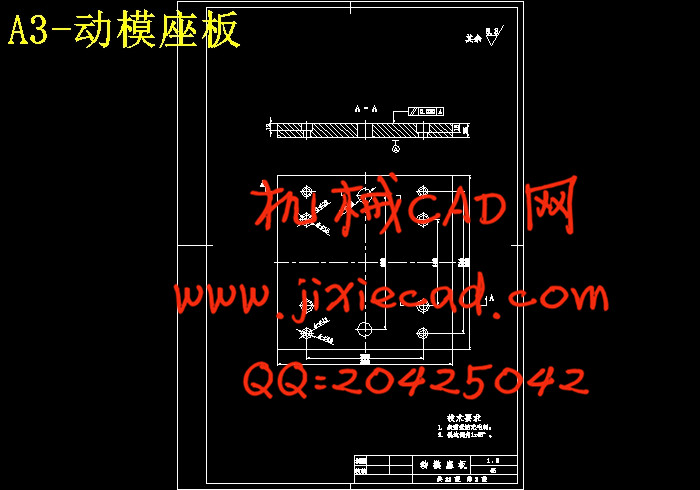

4.1 成型零件结构设计····························································································(13)

4.2 成型零件工作尺寸计算····················································································(13)

4.3 成型零件的力学计算························································································(18)

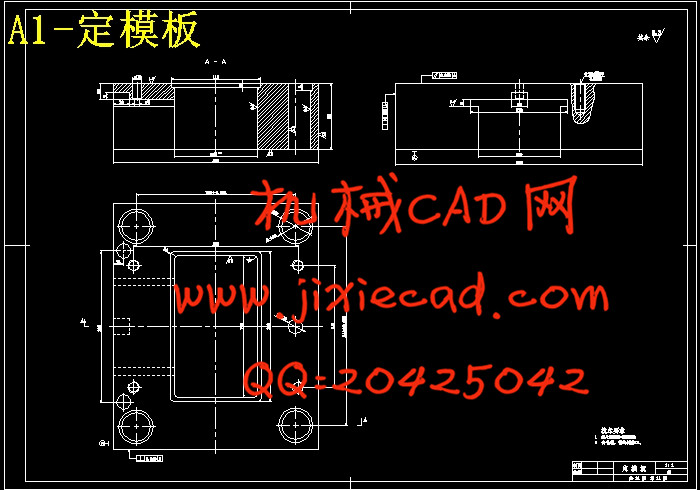

第五章 导向与定位机构设计·························································································(21)

5.1 导向机构的设计································································································(21)

5.2 定位机构设计····································································································(22)

第六章 脱模机构设计···································································································(23)

6.1 脱模力的计算····································································································(23)

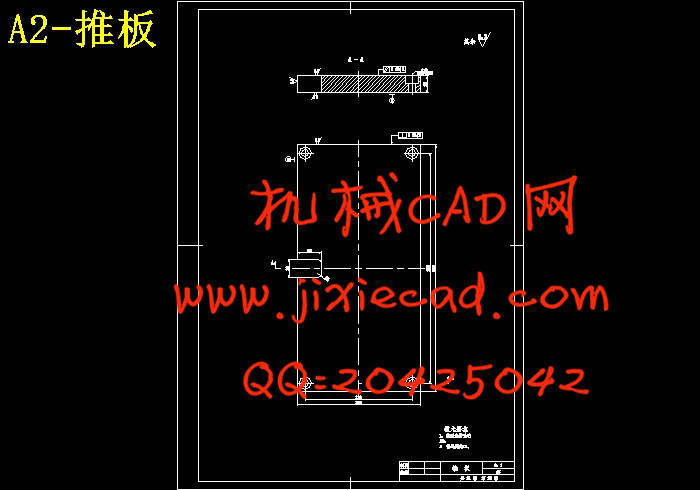

6.2 推出机构形式的确定························································································(24)

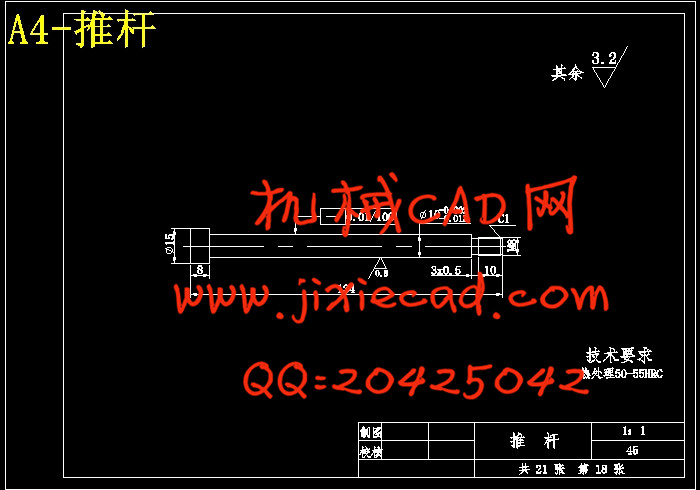

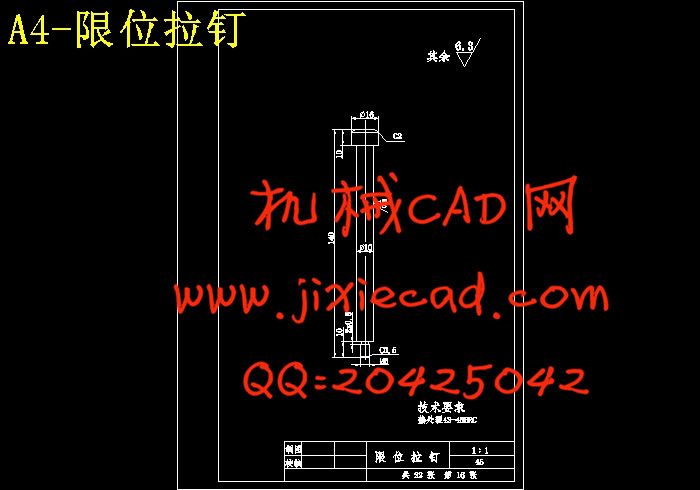

6.3 推出零件尺寸的确定························································································(24)

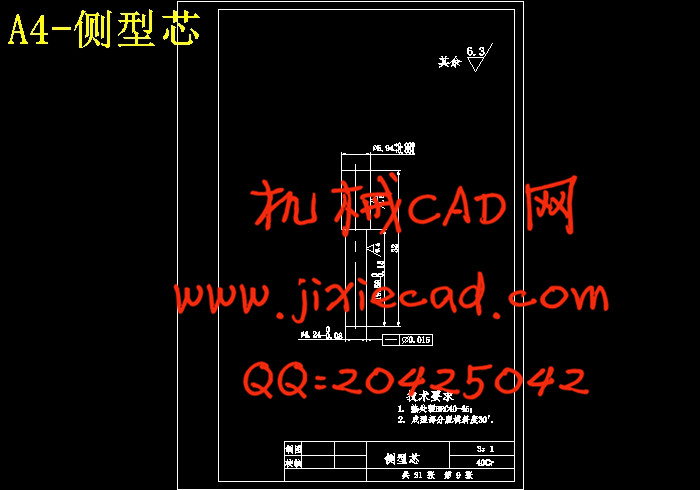

第七章 侧向分型与抽芯机构设计···············································································(26)

7.1 侧向分型和抽芯机构的类型············································································(26)

7.2 抽拔距的确定····································································································(26)

7.3 抽拔力的计算····································································································(26)

7.4 斜导柱的设计····································································································(27)

7.5 滑块与导滑槽设计····························································································(29)

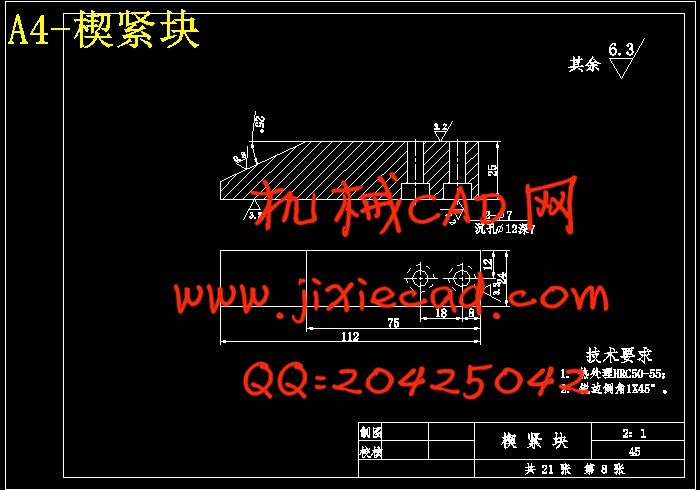

7.6 楔紧块的设计····································································································(29)

第八章 温度调节系统的设计·························································································(30)

8.1 求塑件在固化时每小时释放的热量Q····························································(30)

8.2 求冷却水的体积流量························································································(30)

第九章 标准模架的选用··································································································(31)

第十章 注塑机参数校核··································································································(32)

10.1 最大注塑量校核······························································································(32)

10.2 锁模力校核······································································································(32)

10.3 模具与注塑机安装部分相关尺寸校核··························································(33)

10.4 开模行程校核··································································································(33)

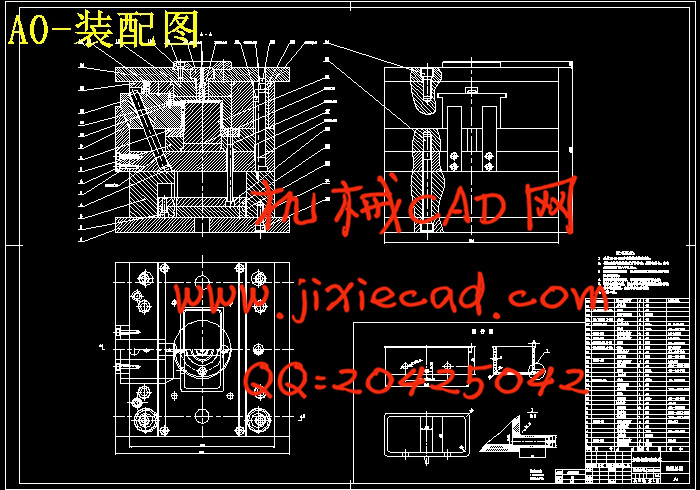

第十一章 模具装配与试模······························································································(34)

11.1 模具的装配·······································································································(34)

11.2 模具的安装·······································································································(35)

11.3 试模···················································································································(35)

毕业设计总结····················································································································(36)

后记···································································································································(37)

参考文献···························································································································(38)

本课题首先分析了盒形塑件的工艺特点,文中介绍了盒形塑件注塑成型模具设计要点及模具的工作过程。重点说明了电器盒的塑件结构的设计包括分析和阐述了电器盒塑件的壁厚选择及工艺特点;针对塑件的工艺特点进行模具的设计包括模具型腔数目的确定,注塑机的选择,模具分型面、冷却系统、浇注系统、分型抽芯机构等的设计过程。还对注塑模具成型零件工作尺寸的计算并介绍了模具的主要零件加工工艺及模具的装配工艺。

关键词:电器盒 工艺分析 注塑模具 模具结构

Abstract

The injection technological characteristics of box cover and analyzed, and the design main points and working process are also introduced. The design method of plastic strcuture is mainly introduced . The selection of the sidewall thickness, the decision of the mould cavity number, the selection of injection machine, and the designing process of the parting plane, the exhaust system, cool material cave and pin gate are stated. The design structure characteristics of box cover and parting plane with pin gate style, and side core-drawing structure. Analysis of the calculating the working dimensions of the forming parts of injection mould and the

Conventional manufacturing processes of the main parts of the injection mould .

[Key words]:

box cover technology analyse

injection mould mould structure

目 录

摘要

前言····································································································································(1)

第一章 塑料制件的设计···································································································(3)

1.1 塑件材料的性能··································································································(3)

1.2 塑件的体积与重量······························································································(5)

1.3 塑件工艺分析及结构设计··················································································(6)

第二章 总体设计方案的确定··························································································(8)

2.1 分型面的选择·······································································································(8)

2.2 排气方式的确定···································································································(8)

2.3 型腔数目和排列方式的确定···············································································(9)

2.4 注塑机的选择·······································································································(9)

第三章 浇注系统的设计及计算······················································································(11)

3.1 流道设计············································································································(11)

3.2 浇口设计············································································································(11)

3.3 流动比校核········································································································(12)

第四章 成型零件设计·····································································································(13)

4.1 成型零件结构设计····························································································(13)

4.2 成型零件工作尺寸计算····················································································(13)

4.3 成型零件的力学计算························································································(18)

第五章 导向与定位机构设计·························································································(21)

5.1 导向机构的设计································································································(21)

5.2 定位机构设计····································································································(22)

第六章 脱模机构设计···································································································(23)

6.1 脱模力的计算····································································································(23)

6.2 推出机构形式的确定························································································(24)

6.3 推出零件尺寸的确定························································································(24)

第七章 侧向分型与抽芯机构设计···············································································(26)

7.1 侧向分型和抽芯机构的类型············································································(26)

7.2 抽拔距的确定····································································································(26)

7.3 抽拔力的计算····································································································(26)

7.4 斜导柱的设计····································································································(27)

7.5 滑块与导滑槽设计····························································································(29)

7.6 楔紧块的设计····································································································(29)

第八章 温度调节系统的设计·························································································(30)

8.1 求塑件在固化时每小时释放的热量Q····························································(30)

8.2 求冷却水的体积流量························································································(30)

第九章 标准模架的选用··································································································(31)

第十章 注塑机参数校核··································································································(32)

10.1 最大注塑量校核······························································································(32)

10.2 锁模力校核······································································································(32)

10.3 模具与注塑机安装部分相关尺寸校核··························································(33)

10.4 开模行程校核··································································································(33)

第十一章 模具装配与试模······························································································(34)

11.1 模具的装配·······································································································(34)

11.2 模具的安装·······································································································(35)

11.3 试模···················································································································(35)

毕业设计总结····················································································································(36)

后记···································································································································(37)

参考文献···························································································································(38)