设计简介

监控球塑料注射模具设计

摘 要

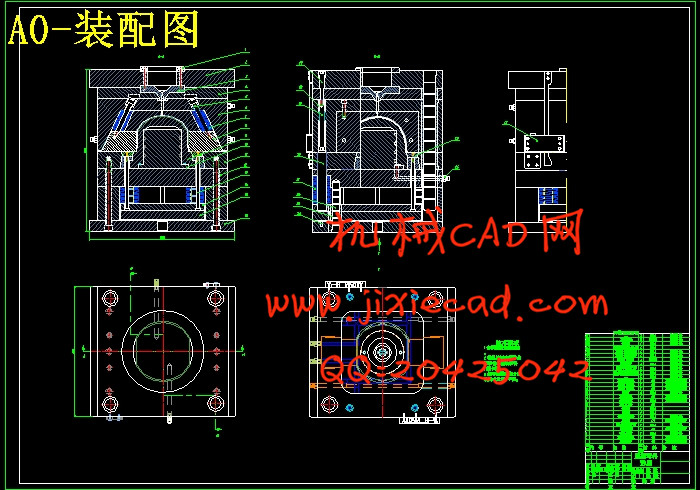

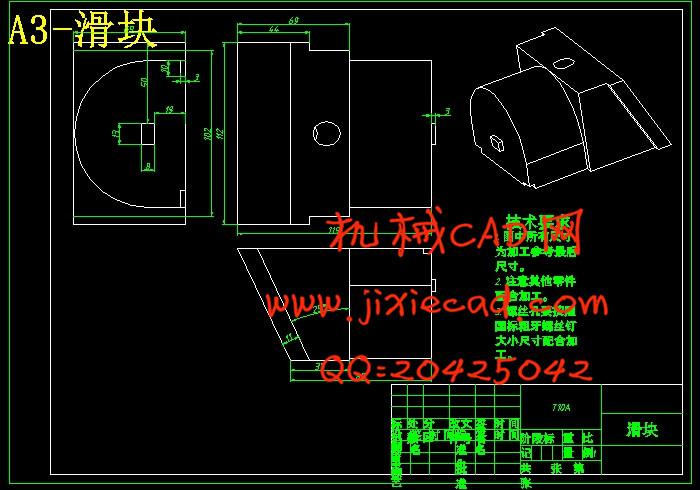

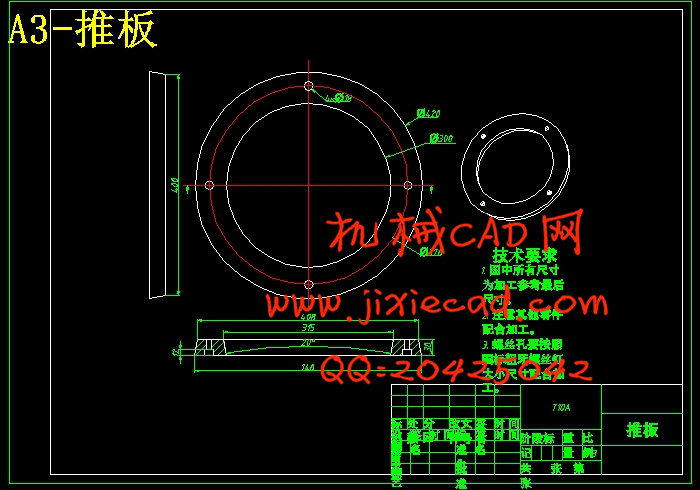

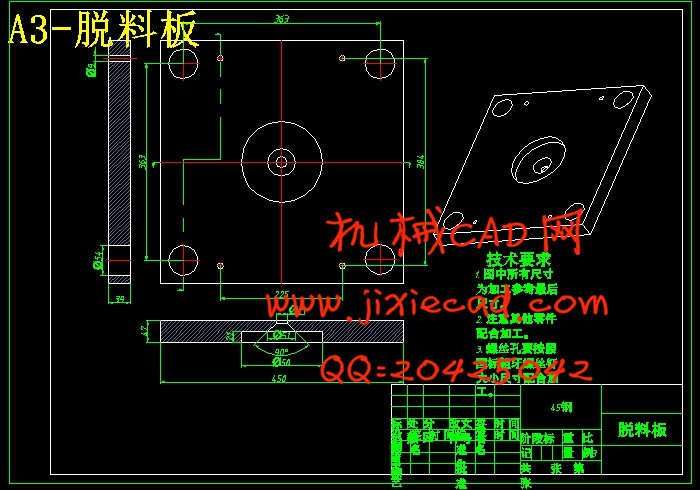

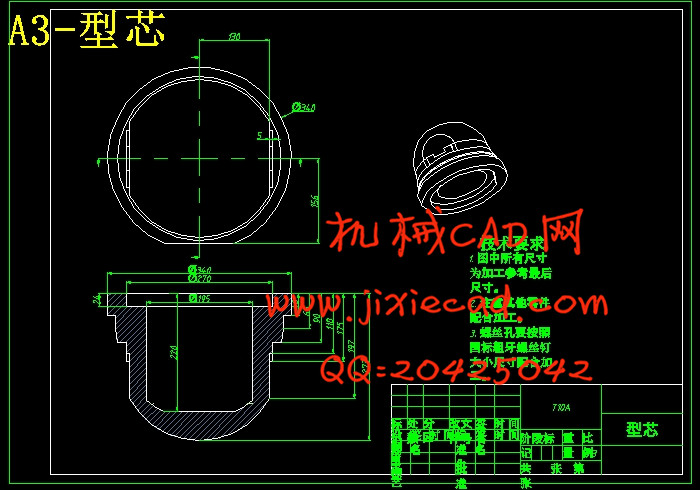

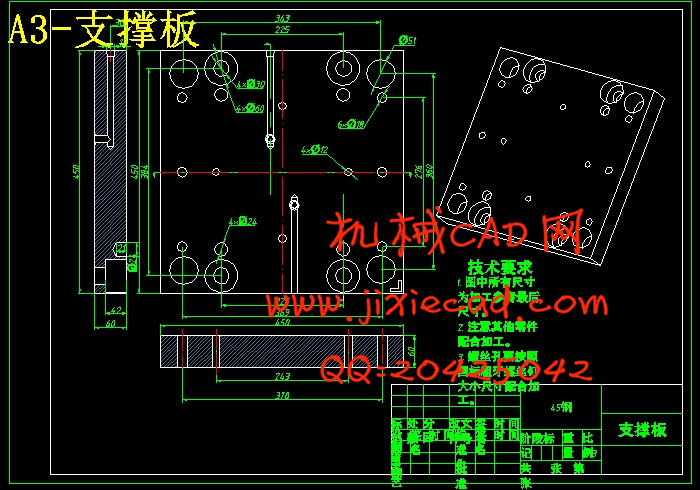

本文主要介绍了监控球塑料件的注射模设计,其材料为ABS。根据ABS塑料的工艺特性和产品的使用要求,分析了监控球的结构特点和成型工艺。本设计采用CAD技术进行模具装配图及零件图的绘制。对模具进行了成型零部件、浇注系统、侧向抽芯机构、推出脱模机构及冷却系统的设计分析。其中浇注系统使用直浇道点浇口,侧抽芯机构使用斜导柱、侧滑块配合完成,推出脱模机构使用顶杆带动顶板推出,冷却系统使用交叉网络式循环水道,均匀分布在型腔及型芯上。经过对塑件成型工艺性的分析,对注塑机及模具部分零部件的计算和校核。最后,完成模具总装图设计及主要零件图的绘制,从而确保模具结构的可靠性、合理性和实用性。

关键词:塑料;模具设计;CAD

Intelligent Ball plastic injecting mold design

Abstract

This paper mainly describes the intelligent ball plastic's injection mold design which is made of ABS. Based on the process performance and the operation requirements of the ABS there comes the analysis of structural features and forming process of the intelligent ball . This design uses the CAD technology to carry on the mold assembly drawing and the detail drawing plan. Then showing the design analysis of the formation part, the gating system to the mold, lateral to pull out the core organization , promote the mold emptier and cooling system. Including gating system using straight runner point runner, side core-pulling mechanism used inclined guide pin, lateral spreads block to cooperate to complete, roll out using top stem drive demoulding mechanism, cooling systems use roof launch cross network circulation channel, evenly distributed in cavity and cores. Through the analysis about the manufacturability of the plastic molding and the calculation and verification of the main part inside the injection molding machines then complete the assembly drawing design and the mapping of the main components at last. So that we can ensure the reliability, the rationality and the usability of the mold structure.

Key Words:Plastic;mould;design;CAD

目录

1 绪论 1摘 要

本文主要介绍了监控球塑料件的注射模设计,其材料为ABS。根据ABS塑料的工艺特性和产品的使用要求,分析了监控球的结构特点和成型工艺。本设计采用CAD技术进行模具装配图及零件图的绘制。对模具进行了成型零部件、浇注系统、侧向抽芯机构、推出脱模机构及冷却系统的设计分析。其中浇注系统使用直浇道点浇口,侧抽芯机构使用斜导柱、侧滑块配合完成,推出脱模机构使用顶杆带动顶板推出,冷却系统使用交叉网络式循环水道,均匀分布在型腔及型芯上。经过对塑件成型工艺性的分析,对注塑机及模具部分零部件的计算和校核。最后,完成模具总装图设计及主要零件图的绘制,从而确保模具结构的可靠性、合理性和实用性。

关键词:塑料;模具设计;CAD

Intelligent Ball plastic injecting mold design

Abstract

This paper mainly describes the intelligent ball plastic's injection mold design which is made of ABS. Based on the process performance and the operation requirements of the ABS there comes the analysis of structural features and forming process of the intelligent ball . This design uses the CAD technology to carry on the mold assembly drawing and the detail drawing plan. Then showing the design analysis of the formation part, the gating system to the mold, lateral to pull out the core organization , promote the mold emptier and cooling system. Including gating system using straight runner point runner, side core-pulling mechanism used inclined guide pin, lateral spreads block to cooperate to complete, roll out using top stem drive demoulding mechanism, cooling systems use roof launch cross network circulation channel, evenly distributed in cavity and cores. Through the analysis about the manufacturability of the plastic molding and the calculation and verification of the main part inside the injection molding machines then complete the assembly drawing design and the mapping of the main components at last. So that we can ensure the reliability, the rationality and the usability of the mold structure.

Key Words:Plastic;mould;design;CAD

目录

2 方案设计 2

2.1设计内容 2

2.1.1课题背景和意义 2

2.1.2设计的主要技术指标 2

2.2塑件分析 2

2.2.1结构分析 2

2.2.2成形工艺方法分析 3

3 模具方案分析 5

3.1拟定模具的型腔数量 5

3.2确定分型面和型芯 5

3.3确定浇注系统 6

3.3.1浇注系统的作用和分类 6

3.3.2浇注系统的组成 6

3.3.3浇注系统的设计原则 6

3.4导向机构的方案设计 7

3.4.1导向机构的作用 7

3.4.2 导向机构的设计原则 8

3.4.3导柱、导套的设计 8

3.5 脱模机构的设计 9

3.5.1 脱模机构的设计原则 9

3.5.2脱模机构的选择 9

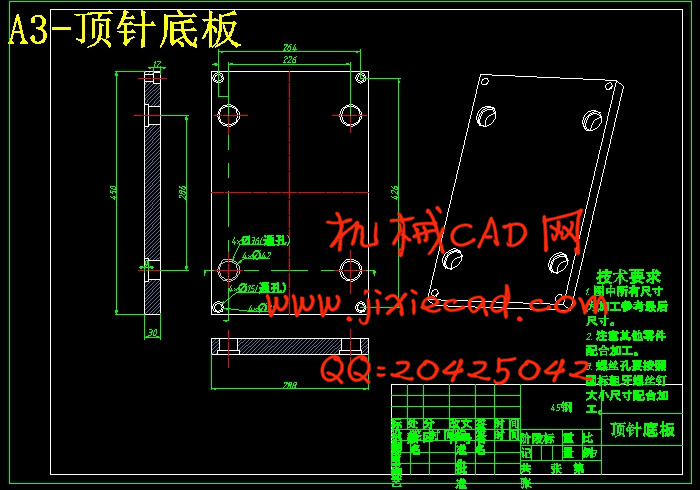

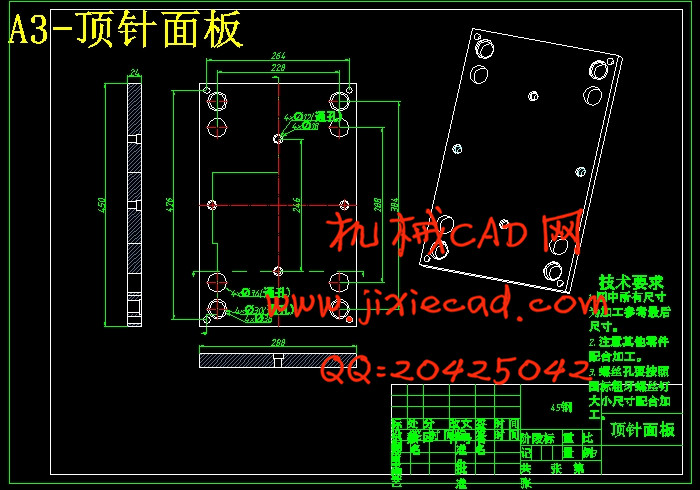

3.5.3 顶板顶出机构的设计 10

4 模具的设计 11

4.1选择塑件材料 11

4.2选定注射机 12

4.2.1计算最大注射量 12

4.2.2计算额定锁模力 12

4.3 注射机的校核 13

4.3.1 最大注塑量的校核 13

4.3.2锁模力的校核 13

4.3.3 喷嘴尺寸校核 14

4.3.4模具外形尺寸校核 14

4.3.5模具厚度校核 14

4.3.6模具安装尺寸校核 14

4.3.7开模行程校核 15

4.4浇注系统的设计 15

4.4.1主浇道 15

4.5分型面的设计 18

4.5.1分型面的选择原则: 18

4.5.2 型腔的结构设计 18

4.5.3动模垫板厚度的计算 19

4.5.4成型零件工作尺寸的计算 20

4.6导柱导套、复位杆、拉料杆的设计 21

4.6.1导柱导套的设计 21

4.6.2复位杆 22

5 注塑模具的机械设计 23

5.1注塑模具的工作原理 23

5.2结构设计及计算 23

5.2.1模具方案的设计 23

5.2.2注射机的选择 24

6 结论 26

参考文献 27

致 谢 29