设计简介

摘 要

本次设计分析了电话接线座的塑件工艺特点,熟悉注射模具设计的一般流程,掌握注射模具的结构特点及设计计算方法,能用计算机编制相应的工程计算、分析和优化的程序并进行塑料产品三维造型及设计出其模具;详细介绍了电话接线座的结构设计和模具设计的过程以及要点。重点介绍了电话接线座的塑件结构的设计方法,分析和阐述了注射机的选择,模具型腔数目的确定,模架的选择方法,模具分型面,排气系统,浇注系统等的设计过程:设计的全过程都在计算机上进行,所用的绘图软件有Pro/ENGINEER Wildfire4.0和AutoCAD2006, 用Microsoft Word 2003完成了说明书的整理;对以前所学相关课程有了一个全面的了解,自己的知识和技能也得到了提高。

关键词:电话接线座; 塑料注射模; 模具结构; 绘图软件。

Abstract: The Design analyse a telephone wiring Block characteristics of plastic parts process . It made me acquaint the general flow of injection mould design and know the structure characteristics and the design calculating of injection mould; It also ask me use computer to workout the process of which relevant the engineering calculate, engineering analyze and engineering optimize, and put up 3D sculpt to the plastic product, moreover design the mould of it. And the detailed information on telephone wiring blocks the structural design of the process and mound design as well as the points . I focuses on the telephone Plastic Block Design Structure , analyses the choice of injection molding machine, to determine the number of mold cavity, the choice of method of mold, mold surface, exhaust system, gating system design process and etc. The whole design process were going along in computer, the plot software had used are Pro/ENGINEER Wildfire4.0 and AutoCAD2006 . And then I achieved the illuminate book on Microsoft Word 2003.Comprehensive knowing all the mutuality courses have learnt before,my knowledge and skill have improved too.

Key words: Telephone junction block plastic injection mold mold structure the plot software

目 录

1.1 引言 - 1 -

1.2 概述 - 1 -

1.2.1注塑模具分类 - 1 -

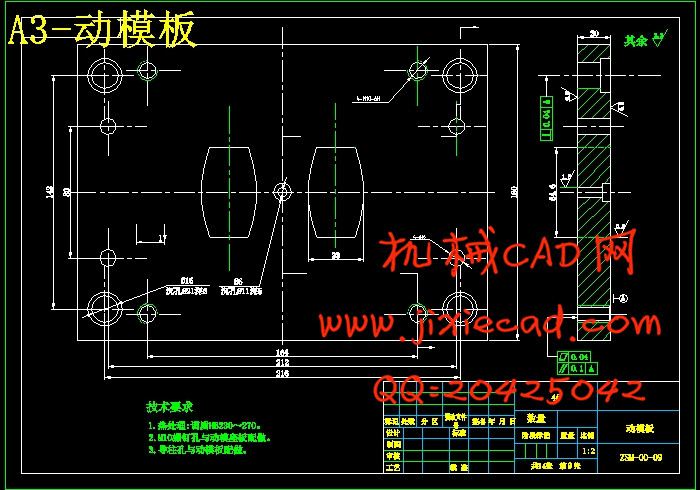

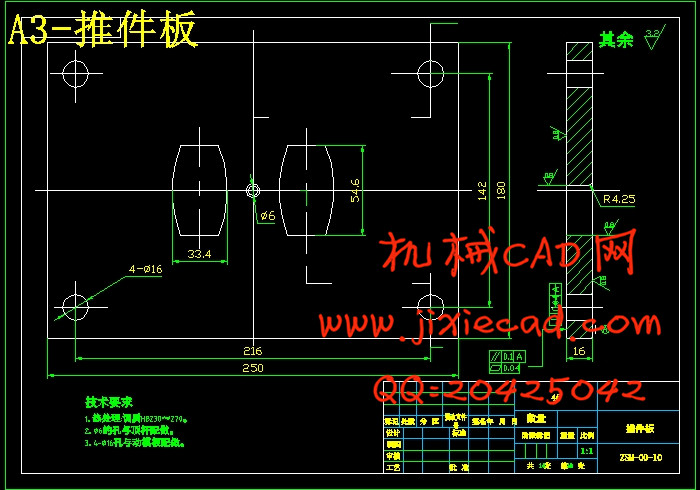

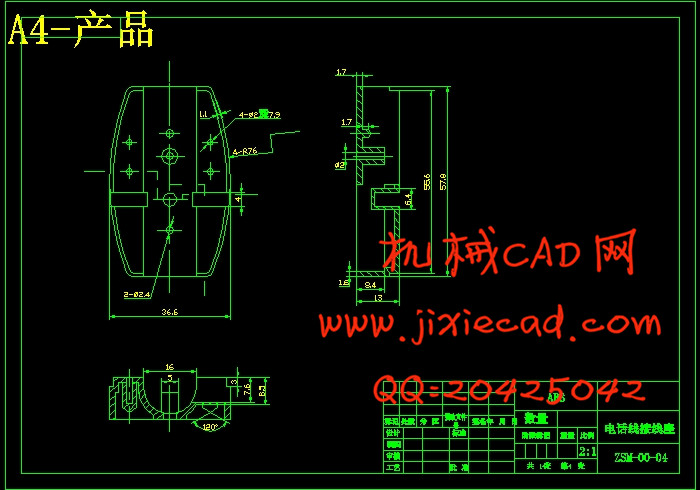

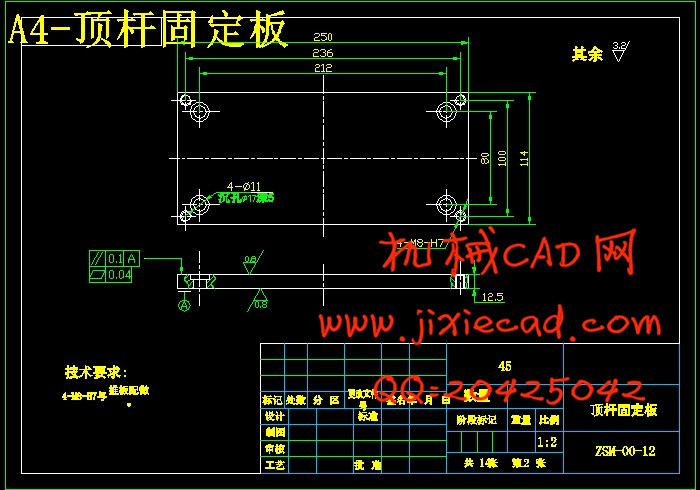

2.1 设计内容:电话接线座 - 3 -

3.1确定塑件的有关参数 - 5 -

3.1.1 塑件特性分析 - 5 -

3.1.2 ABS成型条件 - 5 -

3.2 注塑机的选择 - 5 -

3.2.1 注塑机的选择 - 5 -

3.3型腔的排布 - 7 -

3.4 分型面的确定 - 8 -

3.5 浇注系统设计 - 8 -

3.5.1 主流道设计 - 8 -

3.5.2 分流道设计 - 8 -

3.5.3 浇口设计 - 8 -

3.6 排溢系统 - 9 -

3.7型腔型芯设计 - 10 -

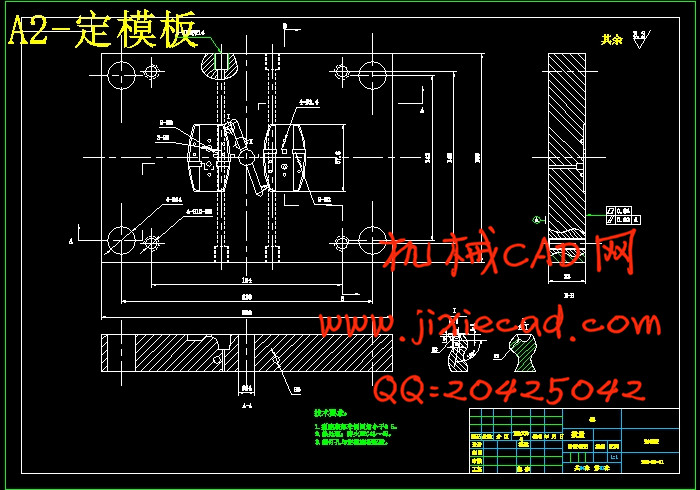

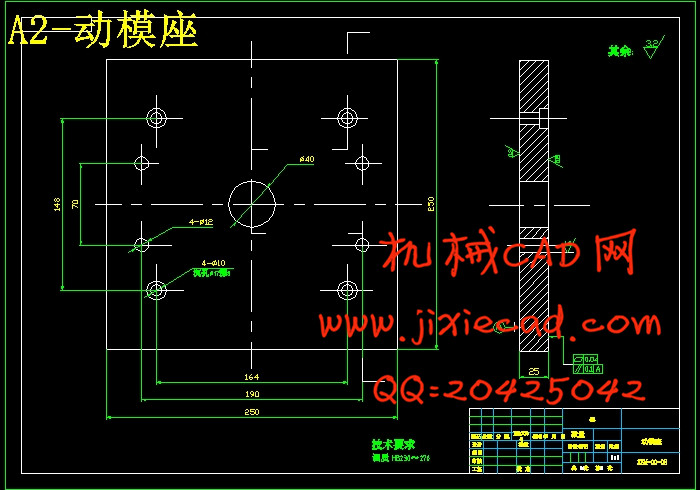

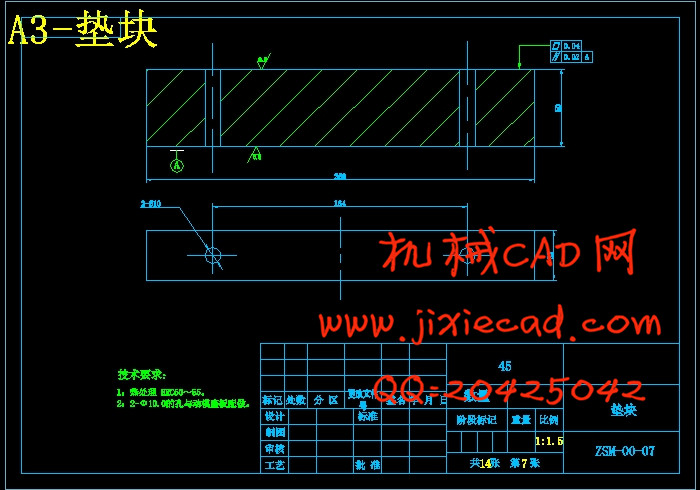

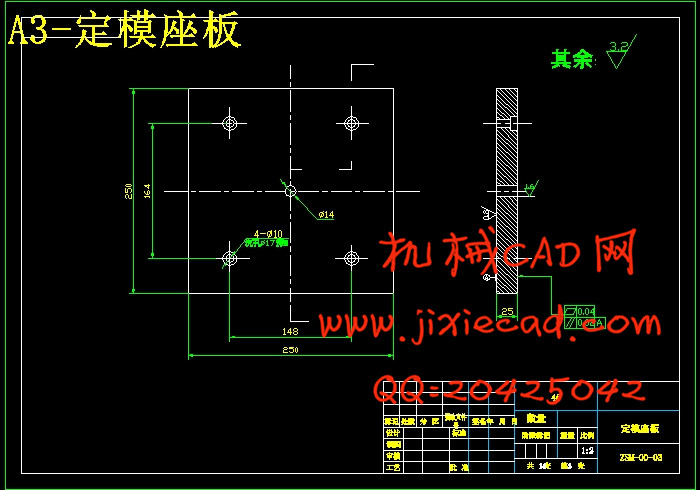

3.7.1设计型腔和型芯的结构形式 - 10 -

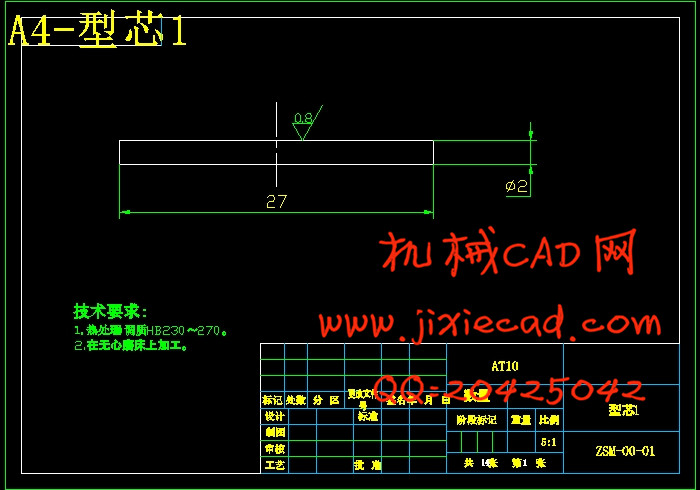

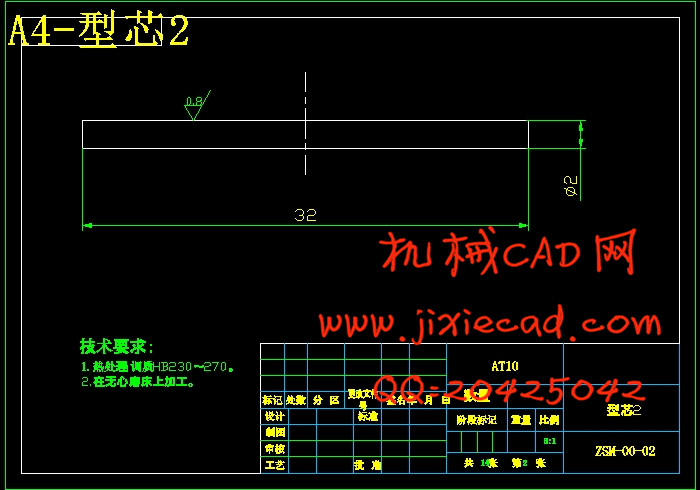

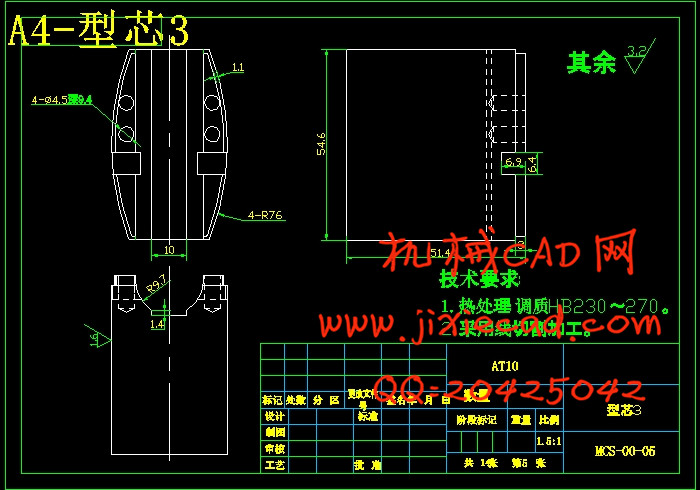

3.7.2 型芯和型腔设计 - 10 -

3.8 型腔、型芯工作尺寸的计算 - 12 -

3.9 型腔壁厚计算: - 13 -

3.10 导向机构的设计 - 13 -

3.11 脱模与复位机构设计 - 14 -

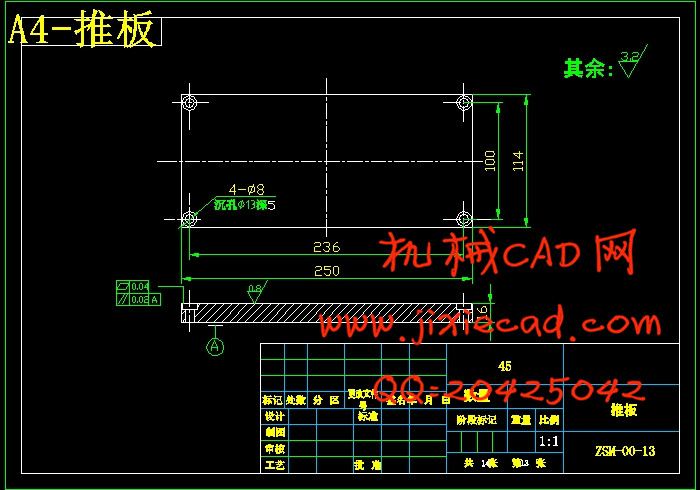

3.11.1脱模机构设计 - 14 -

3.12 冷却系统设计 - 15 -

3.13整体设计 - 16 -

参考文献........................................................ -18-

致谢............................................................ -19-

本次设计分析了电话接线座的塑件工艺特点,熟悉注射模具设计的一般流程,掌握注射模具的结构特点及设计计算方法,能用计算机编制相应的工程计算、分析和优化的程序并进行塑料产品三维造型及设计出其模具;详细介绍了电话接线座的结构设计和模具设计的过程以及要点。重点介绍了电话接线座的塑件结构的设计方法,分析和阐述了注射机的选择,模具型腔数目的确定,模架的选择方法,模具分型面,排气系统,浇注系统等的设计过程:设计的全过程都在计算机上进行,所用的绘图软件有Pro/ENGINEER Wildfire4.0和AutoCAD2006, 用Microsoft Word 2003完成了说明书的整理;对以前所学相关课程有了一个全面的了解,自己的知识和技能也得到了提高。

关键词:电话接线座; 塑料注射模; 模具结构; 绘图软件。

Abstract: The Design analyse a telephone wiring Block characteristics of plastic parts process . It made me acquaint the general flow of injection mould design and know the structure characteristics and the design calculating of injection mould; It also ask me use computer to workout the process of which relevant the engineering calculate, engineering analyze and engineering optimize, and put up 3D sculpt to the plastic product, moreover design the mould of it. And the detailed information on telephone wiring blocks the structural design of the process and mound design as well as the points . I focuses on the telephone Plastic Block Design Structure , analyses the choice of injection molding machine, to determine the number of mold cavity, the choice of method of mold, mold surface, exhaust system, gating system design process and etc. The whole design process were going along in computer, the plot software had used are Pro/ENGINEER Wildfire4.0 and AutoCAD2006 . And then I achieved the illuminate book on Microsoft Word 2003.Comprehensive knowing all the mutuality courses have learnt before,my knowledge and skill have improved too.

Key words: Telephone junction block plastic injection mold mold structure the plot software

目 录

1.1 引言 - 1 -

1.2 概述 - 1 -

1.2.1注塑模具分类 - 1 -

2.1 设计内容:电话接线座 - 3 -

3.1确定塑件的有关参数 - 5 -

3.1.1 塑件特性分析 - 5 -

3.1.2 ABS成型条件 - 5 -

3.2 注塑机的选择 - 5 -

3.2.1 注塑机的选择 - 5 -

3.3型腔的排布 - 7 -

3.4 分型面的确定 - 8 -

3.5 浇注系统设计 - 8 -

3.5.1 主流道设计 - 8 -

3.5.2 分流道设计 - 8 -

3.5.3 浇口设计 - 8 -

3.6 排溢系统 - 9 -

3.7型腔型芯设计 - 10 -

3.7.1设计型腔和型芯的结构形式 - 10 -

3.7.2 型芯和型腔设计 - 10 -

3.8 型腔、型芯工作尺寸的计算 - 12 -

3.9 型腔壁厚计算: - 13 -

3.10 导向机构的设计 - 13 -

3.11 脱模与复位机构设计 - 14 -

3.11.1脱模机构设计 - 14 -

3.12 冷却系统设计 - 15 -

3.13整体设计 - 16 -

参考文献........................................................ -18-

致谢............................................................ -19-