设计简介

摘要

在塑料模设计制造中全面推广应用CAD/CAM/CAE技术。CAD/CAM技术已发展成为一项比较成熟的共性技术,近年来模具CAD/CAM技术的硬件与软件价格已降低到中小企业普遍可以接受的程度,为其进一步普及创造了良好的条件;基于网络的CAD/CAM/CAE一体化系统结构初见端倪,其将解决传统混合型CAD/CAM系统无法满足实际生产过程分工协作要求的问题;CAD/CAM软件的智能化程度将逐步提高;塑料制件及模具的3D设计与成型过程的3D分析将在我国塑料模具工业中发挥越来越重要的作用。提高塑料模标准化水平和标准件的使用率。我国模具标准件水平和模具标准化程度仍较低,与国外差距甚大,在一定程度上制约着我国模具工业的发展,为提高模具质量和降低模具制造成本,模具标准件的应用要大力推广。为此,首先要制订统一的国家标准,并严格按标准生产;其次要逐步形成规模生产、提高商品化程度、提高标准件质量、降低成本;再次是要进一步增加标准件规格品种。应用优质模具材料和先进的表面处理技术,开发新的塑料成型工艺和快速经济模具。以适应多品种、少批量的生产方式。

目前,我国经济仍处于高速发展阶段,国际上经济全球化发展趋势日趋明显,这为我国模具工业高速发展提供了良好的条件和机遇。一方面,国内模具市场将继续高速发展,另一方面,模具制造也逐渐向我国转移以及跨国集团到我国进行模具采购趋向也十分明显。因此,放眼未来,国际、国内的模具市场总体发展趋势前景看好,预计中国模具将在良好的市场环境下得到高速发展,我国不但会成为模具大国,而且一定逐步向模具制造强国的行列迈进。

关键词:信息网络 信息化 自动化 综合性

目录

摘要··················································(2)

绪论··················································(4)

一.塑件分析···········································(5)

二.分型面的设计·······································(8)

三.注射机的选择·······································(8)

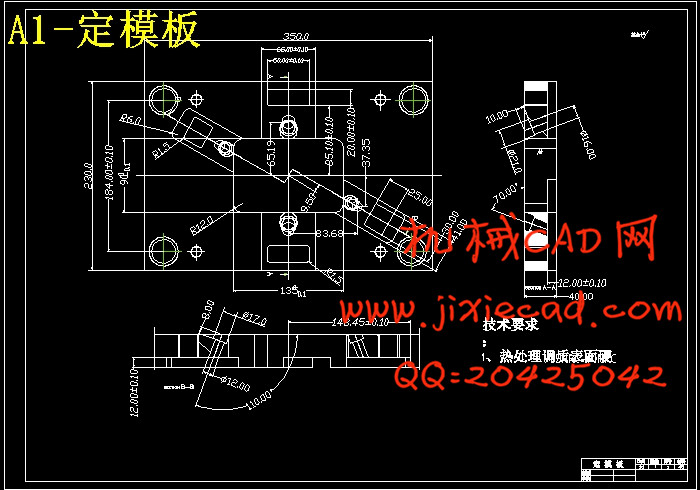

四.根据制品尺寸,设计成型零部件·······················(10)

五.型腔壁厚计算······································(13)

六.浇注系统的设计····································(13)

七.推出机构的设计·····································(17)

八.导柱导向机构的设计································(18)

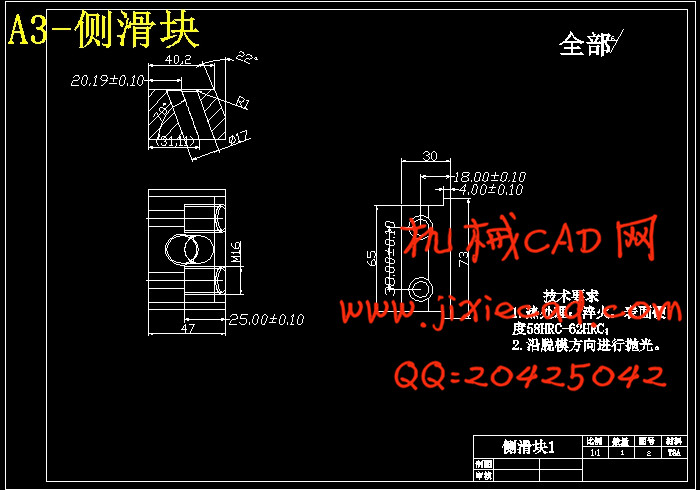

九.侧向分型与抽芯机构·································(20)

十.温度调节系统的设计与计算···························(22)

十一.模架的选择·······································(22)

十二.设计说明·········································(24)

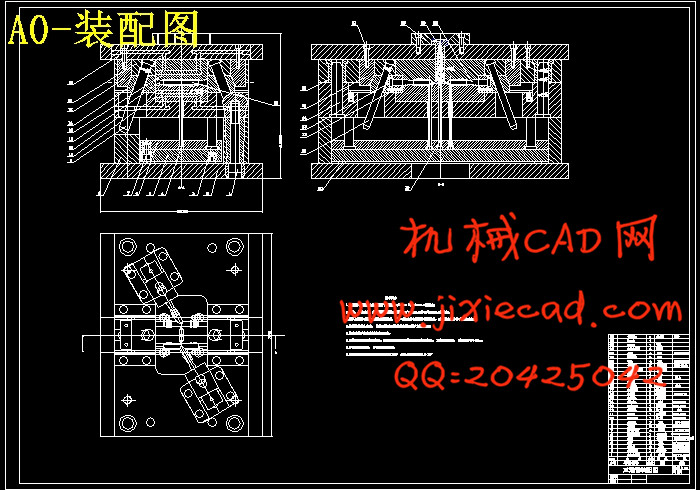

十三.模具的装配·······································(26)

十四.试模·············································(26)

十五.修模·············································(27)

后记··················································(29)

参考文献··············································(30)