设计简介

中英文摘要

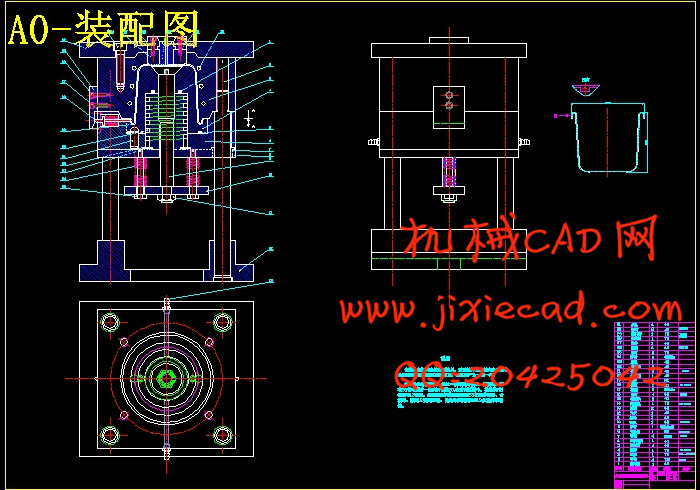

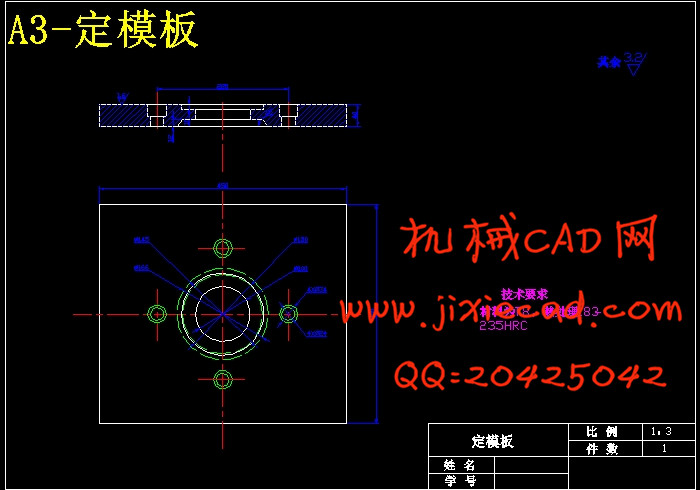

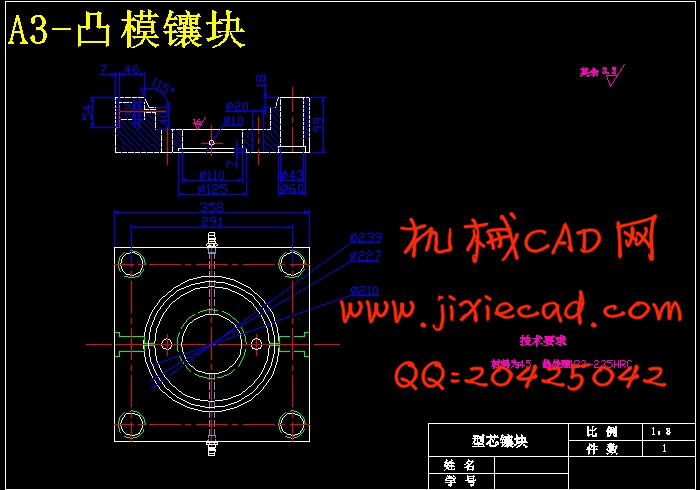

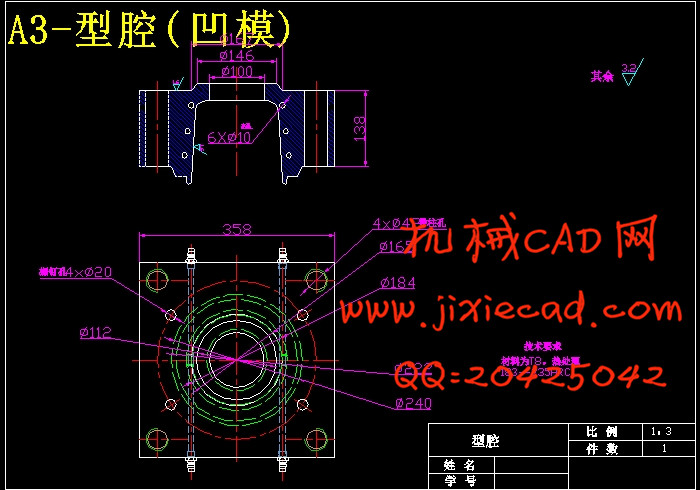

摘要:熟悉注射模具设计的一般流程,掌握注射模具的结构特点及设计计算方法,能用计算机编制相应的工程计算、分析和优化的程序并进行塑料产品三维造型及设计出其模具; 分析了塑料保护盖的结构特点及其成型材料的成型特征,介绍了如何设计该塑件的注射模具结构,着重介绍了斜导柱侧向分型与抽芯机构的设计计算;设计的全过程都在计算机上进行,所用的绘图软件有Solidworks2003和AutoCAD2004, 用Microsoft Word 2003完成了说明书的整理;对以前所学相关课程有了一个全面的了解,自己的知识和技能也得到了提高。

Abstract: Acquaint the general flow of injection mould design; Know the structure characteristics and the design calculating of injection mould; Can use computer to workout the process of which relevant the engineering calculate, engineering analyze and engineering optimize, and put up 3D sculpt to the plastic product, moreover design the mould of it. The structure characteristics and the forming characteristics of the forming material of the protective cap were analyzed; How to design the structure of the injection mould were introduced; The design calculating of angle guide pillars of side parting and core-pulling system were stated in detail. The whole design process were going along in computer, the plot software had used are Solidworks2003 and AutoCAD2004, achieved the illuminate book on Microsoft Word 2003.Comprehensive know all the mutuality courses have learnt before, knowledge and skill have improved too.

关键词:水桶、注射模、侧向分型、侧向抽芯

Key words: bucket, injection mould,side parting ,side core pulling.

目 录

中文摘要 4

第一章.前 言 5

第二章.塑件的工艺分析 7

2.1塑件原材料分析 9

2.2塑件结构、尺寸精度及表面质量分析 10

2.3塑件的体积与重量 11

2.4塑件注塑工艺参数的确定 12

第三章.拟定成型方案 13

3.1分型面的选择 13

3.2确定型腔布置 15

3.3浇注系统的设计 15

3.3.1主流道的设计 15

3.3.2浇口设计 17

第四章.模具成型零件的设计与计算 18

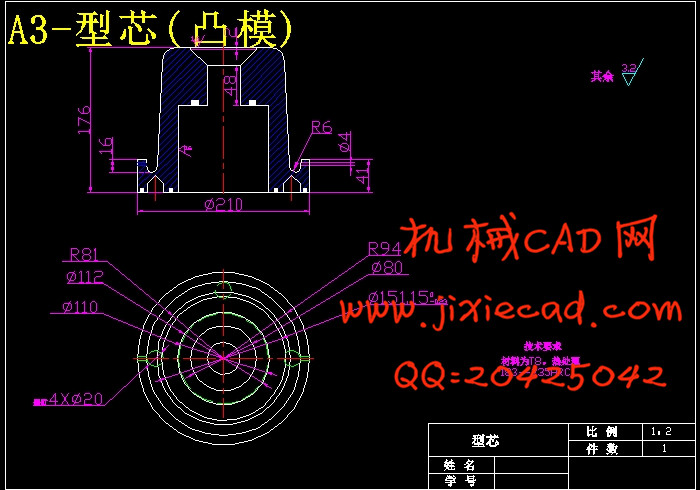

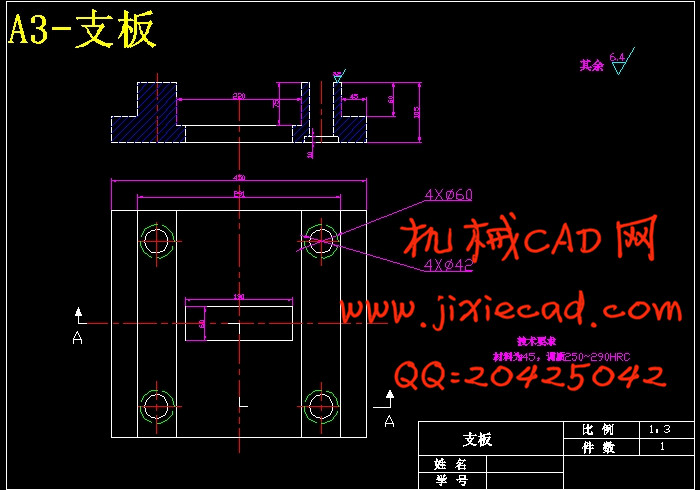

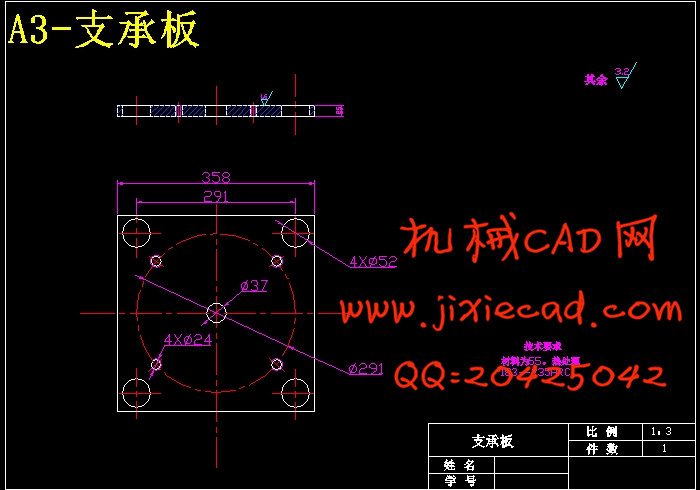

4.1凸模、凹模、型芯设计与计算 19

4.2型腔侧壁厚度的计算 22

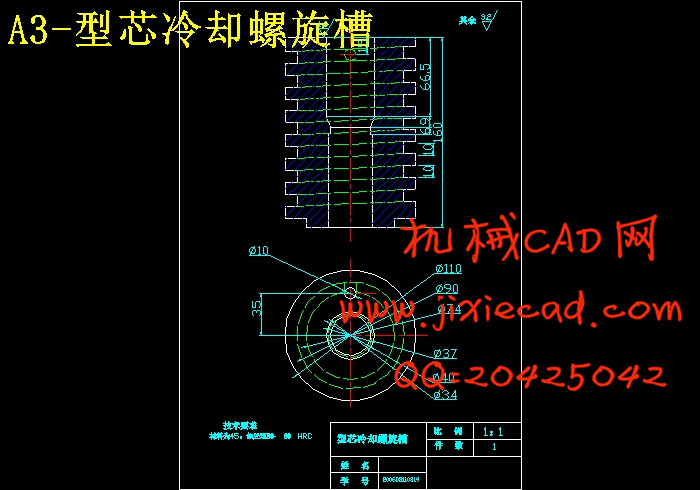

4.3螺旋槽的用途 23

第五章.脱模机构的设计与计算 24

5.1脱模机构的设计原则 25

5.2脱模力的计算 25

第六章.合模导向机构设计 27

第七章.退出机构 28

第八章.注塑机的选定与相关参数的校核 30

8.1注塑机初步的选定 30

8.2注塑机相关参数的校核 31

第九章.温度调节系统(冷却系统)的设计 33

第十章.设计小结 37

参考文献 37

摘要:熟悉注射模具设计的一般流程,掌握注射模具的结构特点及设计计算方法,能用计算机编制相应的工程计算、分析和优化的程序并进行塑料产品三维造型及设计出其模具; 分析了塑料保护盖的结构特点及其成型材料的成型特征,介绍了如何设计该塑件的注射模具结构,着重介绍了斜导柱侧向分型与抽芯机构的设计计算;设计的全过程都在计算机上进行,所用的绘图软件有Solidworks2003和AutoCAD2004, 用Microsoft Word 2003完成了说明书的整理;对以前所学相关课程有了一个全面的了解,自己的知识和技能也得到了提高。

Abstract: Acquaint the general flow of injection mould design; Know the structure characteristics and the design calculating of injection mould; Can use computer to workout the process of which relevant the engineering calculate, engineering analyze and engineering optimize, and put up 3D sculpt to the plastic product, moreover design the mould of it. The structure characteristics and the forming characteristics of the forming material of the protective cap were analyzed; How to design the structure of the injection mould were introduced; The design calculating of angle guide pillars of side parting and core-pulling system were stated in detail. The whole design process were going along in computer, the plot software had used are Solidworks2003 and AutoCAD2004, achieved the illuminate book on Microsoft Word 2003.Comprehensive know all the mutuality courses have learnt before, knowledge and skill have improved too.

关键词:水桶、注射模、侧向分型、侧向抽芯

Key words: bucket, injection mould,side parting ,side core pulling.

目 录

中文摘要 4

第一章.前 言 5

第二章.塑件的工艺分析 7

2.1塑件原材料分析 9

2.2塑件结构、尺寸精度及表面质量分析 10

2.3塑件的体积与重量 11

2.4塑件注塑工艺参数的确定 12

第三章.拟定成型方案 13

3.1分型面的选择 13

3.2确定型腔布置 15

3.3浇注系统的设计 15

3.3.1主流道的设计 15

3.3.2浇口设计 17

第四章.模具成型零件的设计与计算 18

4.1凸模、凹模、型芯设计与计算 19

4.2型腔侧壁厚度的计算 22

4.3螺旋槽的用途 23

第五章.脱模机构的设计与计算 24

5.1脱模机构的设计原则 25

5.2脱模力的计算 25

第六章.合模导向机构设计 27

第七章.退出机构 28

第八章.注塑机的选定与相关参数的校核 30

8.1注塑机初步的选定 30

8.2注塑机相关参数的校核 31

第九章.温度调节系统(冷却系统)的设计 33

第十章.设计小结 37

参考文献 37