设计简介

摘要

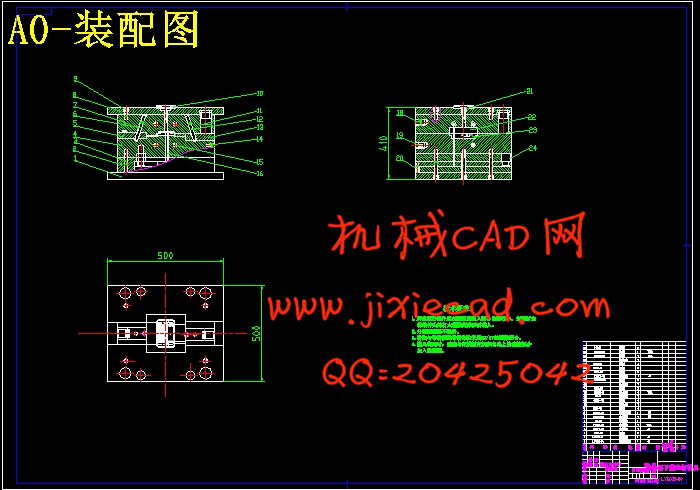

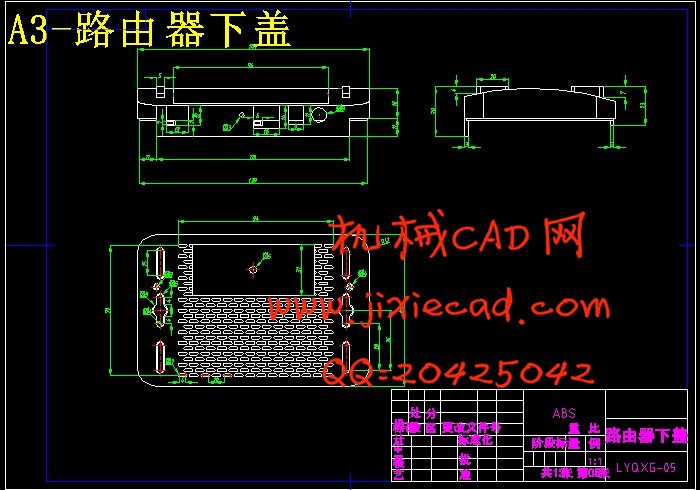

注射成型时塑料成型的一种重要方法,它主要适用于热塑性塑料的成型,可以一次成型形状复杂的精密塑件。本课题就是将路由器下盖作为设计模型,将注射模具的相关知识作为依据,阐述塑料注射模具的设计过程。通过对路由器下盖成型工艺的正确分析,设计了一副一模一腔的塑料模具。模具中决定塑件几何形状和尺寸的零部件称为成型零件。成型零部件再工作时直接与塑料接触,在一定的温度下承受熔体的高温和高压,因此必须要有合理的结构、较高的强度和刚度、较好的耐磨性、正确的几何形状、较高的尺寸精度和较低的表面粗糙度。重要零件的工艺参数的选择与计算,推出机构与浇注系统以其它结构的设计过程。

设计成型零部件时,应根据塑料的特性、塑件的结构和使用要求,确定型腔的总体布局,选择分型面,确定脱模方式,设计浇注系统等,然后根据加工工艺和装配工艺的要求进行成型零部件的结构设计,计算成型零部件的工作尺寸。

关键词: 塑料模具;注射成型;分型面

Abstract:

Injection molding plastic molding is an important method, which is mainly applied to the thermoplastic plastic molding, molding can be a complex shape of precision plastic parts. This topic is to router under cover as a design model, the injection mold-related knowledge as a basis, elaborates the design process of plastic injection mold.The router to lower cover forming the correct analysis of the technology, design a pair of a model of a cavity of the plastic mold. Mold plastic parts in geometry and dimensions of the parts called molding parts. Molding parts to work directly with the plastic contact, in a certain temperature to melt under high temperature and high pressure, so there must be a reasonable structure, high strength and rigidity, good wear resistance, the correct geometry, high size precision and low surface roughness. An important part of the process parameter selection and calculation, the agency launched and gating system to other structural design process.

Design of molding parts, according to the characteristics of plastics, plastic parts of the structure and use requirements, identify cavity overall layout, choice of parting surface, determine the release mode, design of gating system, then according to the machining process and assembly process for forming components of the structural design, calculation of the working dimensions of molding parts.

Key words: Plastic mold ;Injection molding;Parting surface

目录

AbstractI

前 言 1

第1部分 设计内容及设计目的 2

第2部分 模具设计 3

2.1、产品工艺性分析 3

2.1.1、材料性能 3

2.1.2 ABS成型条件 3

2.2 注射机型号的确定 4

第3部分 确定模具基本结构 6

第4部分 模具结构设计 6

4.1 确定型腔数目及配置 6

4.2选择分型面 6

4.3浇注系统设计 7

4.4排溢系统设计 8

4.5 确定型腔、型芯的结构及固定方式 8

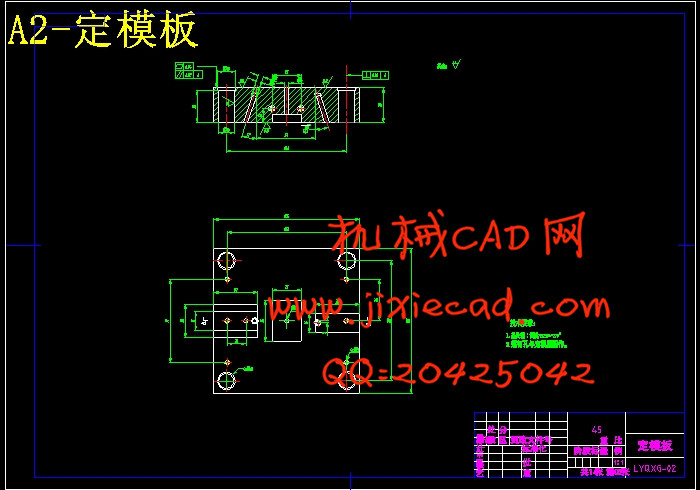

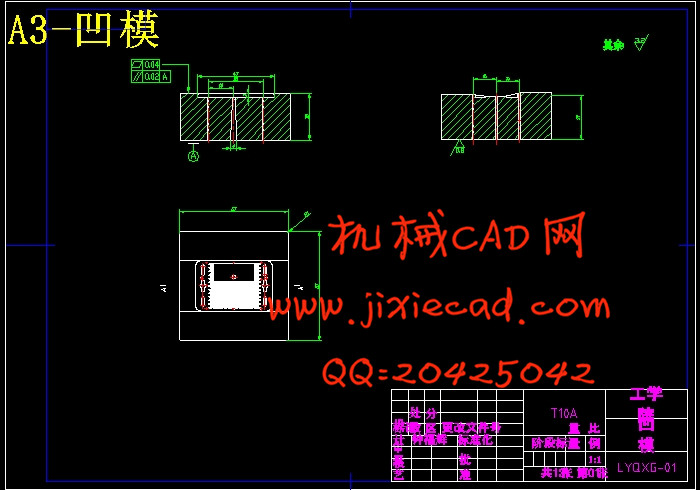

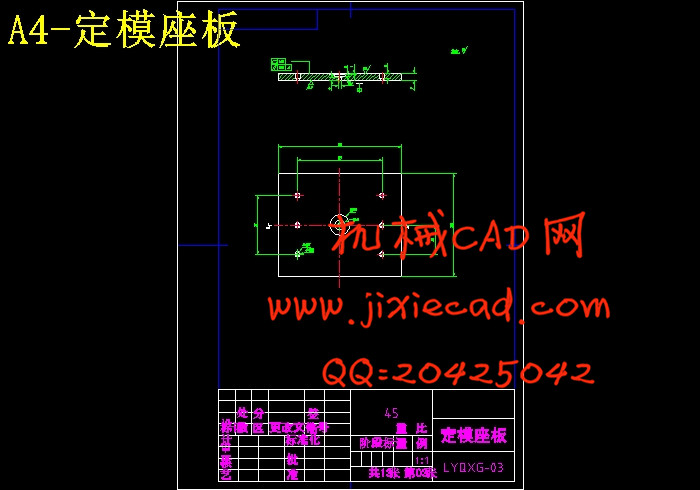

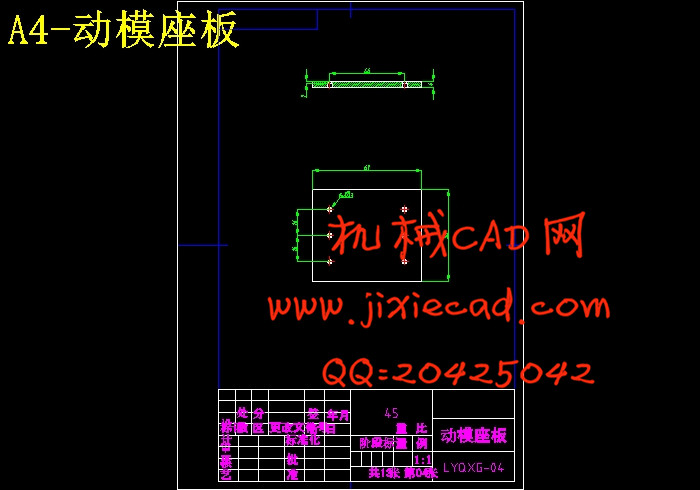

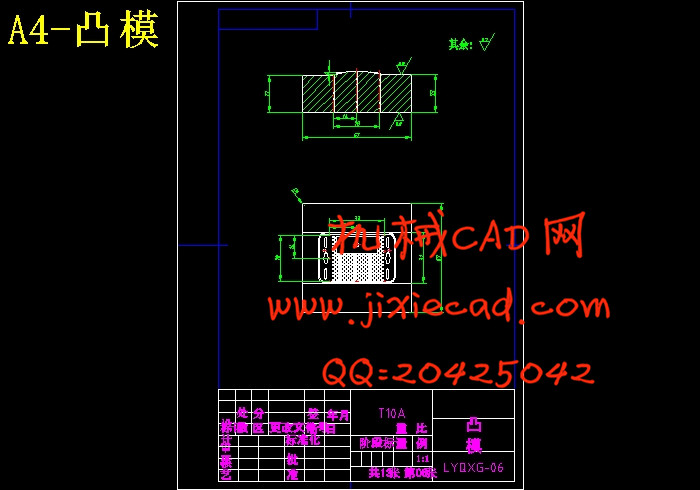

4.8 型芯和型腔具体结构设计 10

4.8.1型芯设计 10

4.8.2型腔设计 10

4.9型腔、型芯工作尺寸的计算 11

4.10型腔壁厚计算 12

4.11导向机构的设计 14

4.12 冷却系统设计 14

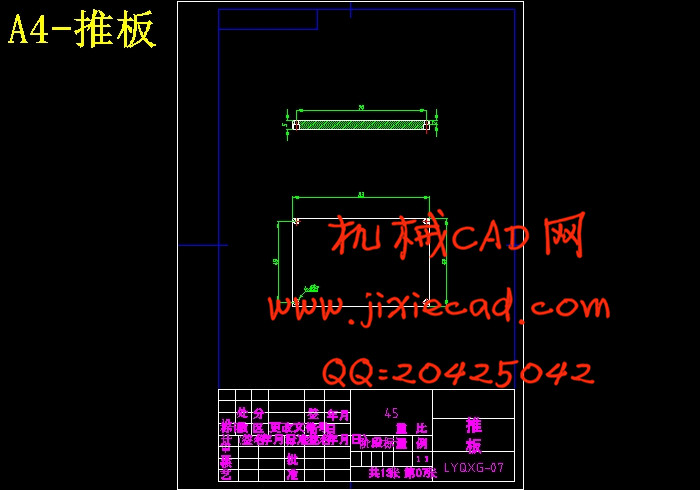

第5部分 模具整体设计 15

总 结 16

参考文献: 17

致谢 18