设计简介

摘 要

塑料成型制品是以塑料为主要结构材料经成型加工获得的制品,又称塑料制件,简称塑件。塑料成型制品应用广泛,特别是在电子仪表、电器设备、通信工具、生活用品等方面获得大量应用。如各种受力不大的壳体、支架、机座、结构件、装饰件等;建筑中所大量使用的各种塑料管材、板材以及门窗异型材;塑料中空容器和各种生活用塑料制品等。作为塑料制品的主要生产基础工艺装备的塑料模具,在国民经济中占有重要的地位,模具技术也已成为衡量一个国家产品制造水平的重要标志之一。进入21世纪以来,我国在模具行业发展迅猛。模具行业为推动我国的经济生活各领域的发展做出巨大贡献。随着我国进入“十二五”快速发展时期,在机械、汽车、家电、电子信息和建筑建材等领域对塑料模具的强烈市场需求推动下,塑料模具的发展前景一片光明。其中复杂、高精度、多功能复合型模具成为未来模具行业发展的重点。我国从改革开放开始,对国外先进技术的消化吸收,特别是计算机技术在整个制造领域的成功应用更是大大地推动了模具行业的飞速发展。近年来我国在模具行业取得长足进步,新材料、新工艺、先进加工设备不断出现。模具零件的标准化、专业化和商品化已达到较高的水平。如今世界模具工业的发展速度超过了新兴的电子工业,已实现了模具专业化、标准化和商业化,因而深受赞誉。模具又因其生产效率高、产品质量好、材料消耗低、生产成本低而获得广泛应用,与其他加工制造业所无法比拟的。当然近年来,我国模具行业一直保持着良好的发展,已经驶入发展快车道。尤其我国模具工业在政府十分重视及关怀下,并提出相应的优惠政策进行模具技术开发,在模具工业中大量采用先进技术和设备,努力提高模具设计和制造水平,取得显著的经济效益。

本文设计的内容是底板注塑模具。塑件的材料为聚丙烯(PP)。根据地板的结构形状特点以及现有的注塑成型工艺,为实现塑件的快速成型、脱模,采用点浇口的浇注方式。本文对注塑模具进行简要介绍,注塑模具中的主要零件进行了设计计算,并在设计过程中着重考虑了生产实际中的经济性和合理性。

Abstract

In the 21st century, the mold industry of China has rapid development. Mold industry contributes greatly to promote China's economic development in all areas of life. As China into the "second Five-Year" period of rapid development in machinery, automobile, home appliances, electronic information and the field of building materials such as plastic mold, are driven by strong market demand, and these give plastic mold industry bright prospects. The future development of the industry focuses on the complex, high precision, functional composite mold. The reform and opening up of China for digestion and absorption of foreign advanced technology, especially in the field of computer technology in the successful application of the entire manufacturing has greatly promoted the rapid development of the mold industry. In recent years, China has made great progress in the mold industry, new materials, new technology and advanced processing equipment. Mold parts standardization, specialization and commercialization have reached a higher level.The content of this paper is to design the injection mold for a toothpaste cap. The material is polyethylene plastic (PE). According to the shape characteristics of toothpaste cap structure and the existing injection molding process, the use of gear and rack as the screw-separating mechanism, this paper designs an efficient spin injection mold with auto-off thread. Unscrewing institutions include spur gears, the rack, straight bevel gears and the screw core. To achieve rapid forming of plastic parts and mold opening, a point gate and secondary mold opening structure of three-plate molds are used. This paper briefly describes the injection mold, the auto-off thread process and principles of mold design. Unscrewing of the gear and rack driving system for the mold design and the main parts of the plastic injection mold are calculated, and the actual production of economic rationality is also considered in the design process.

Key Words:Injection mold;Internal thread;Point gate;Gear rack mechanism

目录

Abstract II

引 言 1

1 塑料模具及塑料模具行业 2

1.1 塑料模具简介 2

1.2 塑料模具行业的现状及发展方向 2

2 注塑成型工艺与设备 5

2.1 注塑模的组成及各部分作用 5

2.2 注塑成型过程 5

2.3 注塑机 7

3 模具分析与设计 8

3.1 设计任务要求 8

3.2 塑件介绍及塑件材料 9

3.2.1 塑件介绍 9

3.2.2 塑件材料分析介绍 9

3.3 分型面选择 10

3.4 型腔布置方案 10

3.5 注塑机的选择 11

3.6 模具浇注系统设计和浇口的设计 12

3.6.1 主流道的设计 13

3.6.2 定位环的设计 14

3.6.3 分流道设计 14

3.6.4 浇口的设计 15

3.7 合模导向机构和定位机构 15

3.7.1 导向机构的总体设计 15

3.7.2 导柱设计 15

3.7.3 导套设计 16

3.8 浇注冷却系统的设计 17

3.9 脱模推出机构的设计 18

3.9.2复位杆的设计 20

3.10拉料杆的设计 20

3.11排气系统设计 21

3.11 模架的选择 21

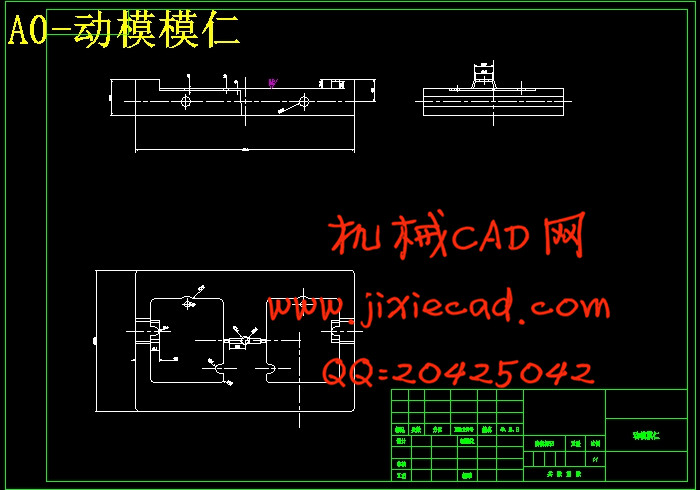

4 模具零件的设计计算 22

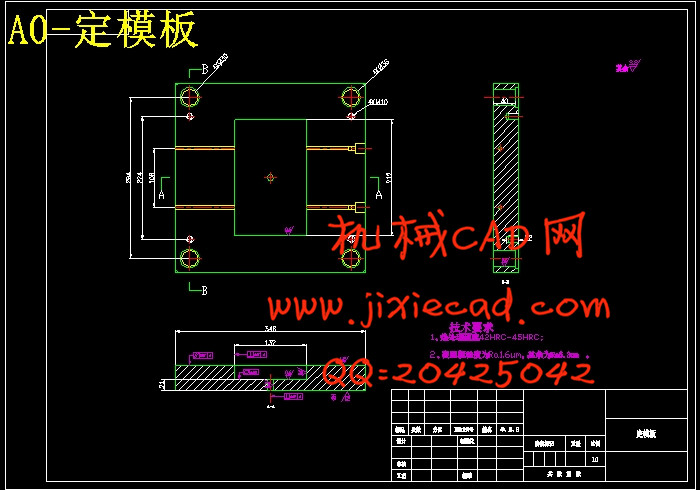

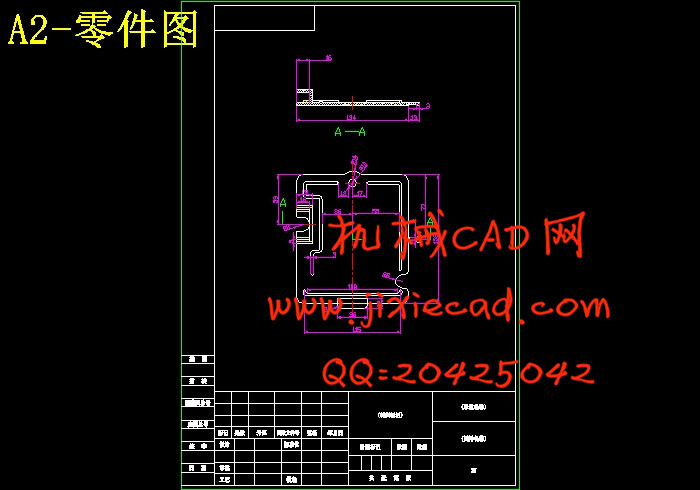

4.1 定模板尺寸的设计计算 22

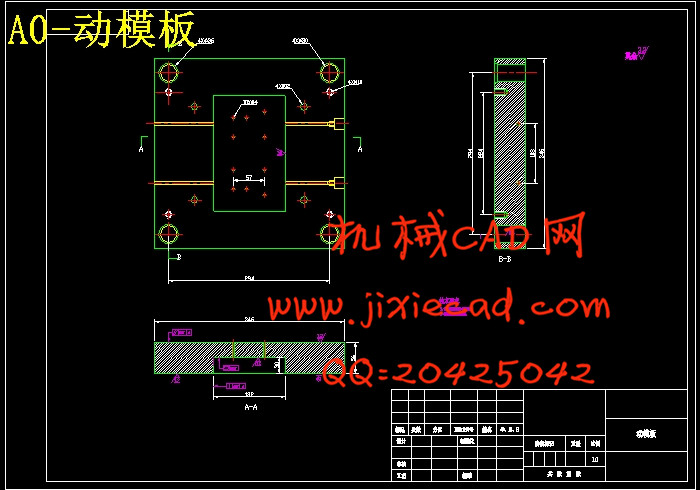

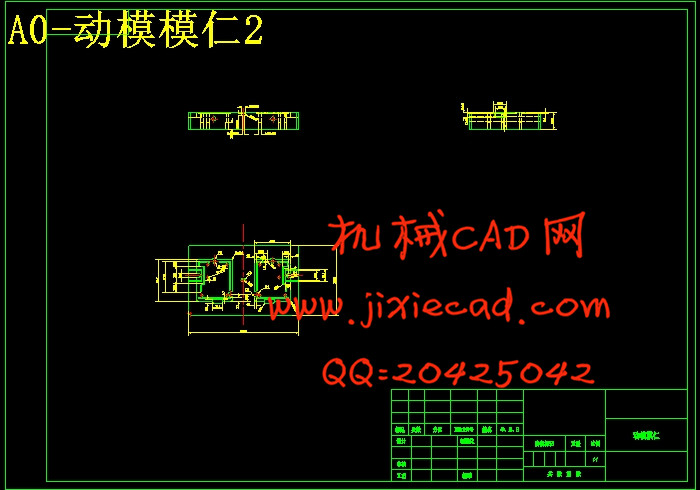

4.2 动模板的尺寸的设计计算 22

4.3 具材料例表 23

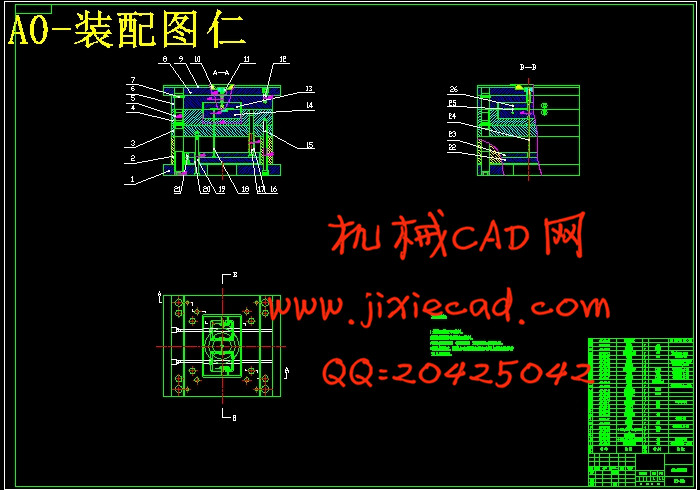

5 模具装配 24

5.1 塑料模具装配的技术要求 24

5.2 塑料模具装配过程 25

5.2.1 装配动模部分 25

5.2.2 装配定模部分 25

6 经济性分析 26

结 论 27

参 考 文 献 28

致 谢 29