设计简介

摘 要

本设计根据从事塑料注塑模设计与制造的工程技术综合性应用型人才的实际要求,符合大专模具设计专业的毕业生毕业设计需要所编写的,对初学注塑模设计者有一定的参考价值。

本设计共分六章,分别对设计题目的来源、设计意义、零件工艺性分析、工艺方案的确定、模具结构及成型设备的选择、工艺计算、模具结构设计及校核、加工工艺等几方面进行了阐述。

本设计在设计过程中得到了杨占尧、原红玲、于智宏等几位指导老师的大力支持和帮助,再此表示诚挚的感谢!由于编者水平有限,收集资料困难,定有许多不尽人意的地方,恳请读者不吝赐教,提出改进意见,以便使此设计进一步修正和完善。

关键词:塑料模 注塑成型 工艺

Abstract

This design according to be engaged in the plastics note the Plastics mold design synthesizes with the engineering technique of the manufacturing sex application the talented person's actual request in type, match the professional graduate student in design in university molding tool graduate design the demand the plait writes of, note to the beginner Plastics mold design have to consults certainly value.

This design is divided into six source for, distinguishing to designing topics and design the meaning, spare parts craft analysis, craft project to really settle totally, molding tool construction and model choice, craft calculation, molding tool construction design and school of the equipments and process craft etc. several aspects proceeded to expatiate.

This designed to get in design process the virtuous plum, yang zhan yao , yuan hong ling , yu zhi hong ...etc.a few leadings the teacher supports strongly with help, again this mean the sincere with gratitude!Because the editor level is limited, collect data the difficulty, settle many not exhausted the place of person's idea, plead the reader the not stingy advising, put forward to improve the opinion, in order to make this design further revised with perfect.

Key: Plastic mold Injection Molding Technology

绪 论 --------------------------------------------------------- ------1

第一章 任务书来源及设计意义 --------------------------------4

1.1 设计任务 -------------------------------------------------4

1.2 设计目的及意义------------------------------------ -----4

第二章 零件的工艺性分析 --------------------------------- -----5

2.1 塑件的原材料分析 -------------------------------- -----5

2.2 塑件的结构和尺寸精度及表面质量分析 -----------6

2.3 计算塑件的体积和质量 --------------------------------7

2.4塑件注塑工艺参数的确定 -------------------------------7

第三章 工艺方案的确定 --------------------------------------- -8

3.1 分型面的选择 ---------------------------------------- ---8

3.2 确定型腔的排列方式 ----------------------------------8

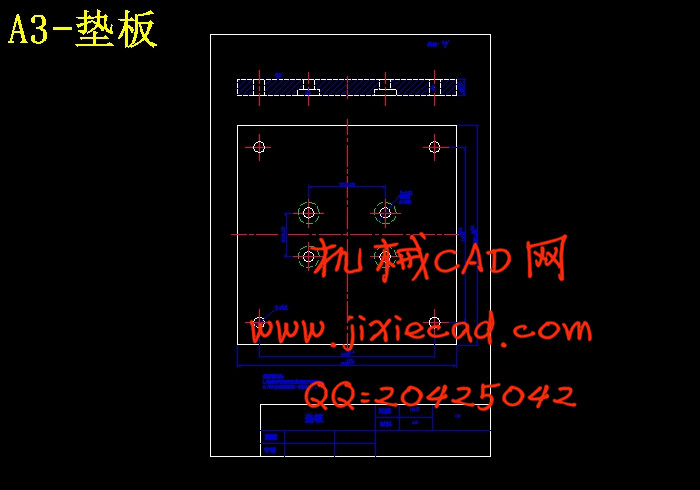

3.3 模架的选取 ----------------------------------------------9

3.4 浇注系统的设计 ----------------------------------------9

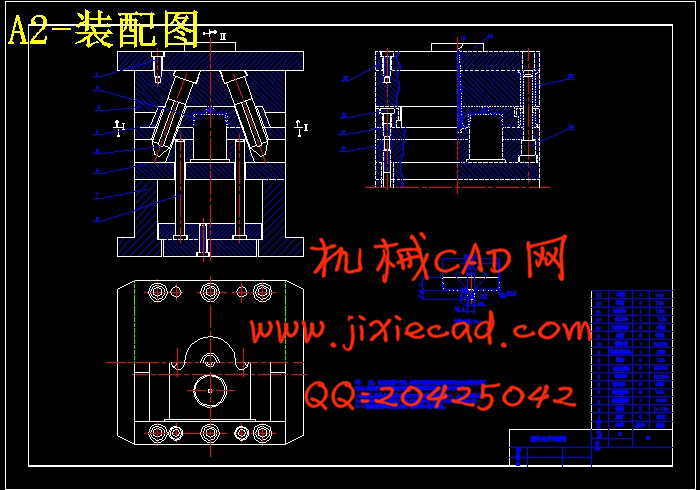

3.5 抽芯机构的设计 ---------------------------------------11

3.6 成型零件的结构设计 -------------------------------- 12

第四章 工艺计算 -------------------------------------------------13

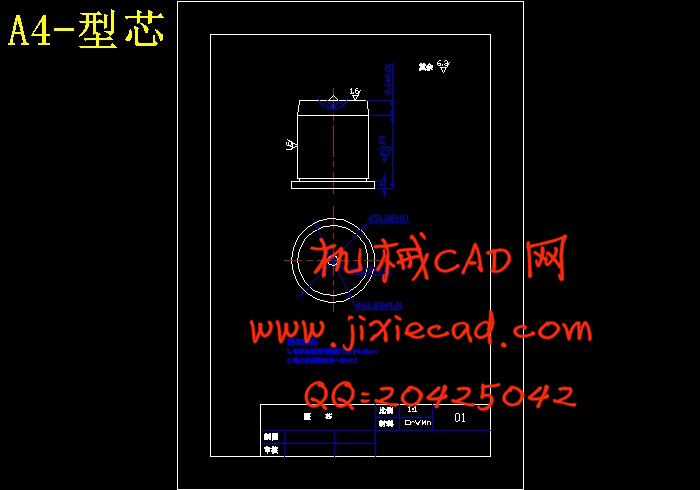

4.1 型腔和型芯工作尺寸计算 ---------------------------13

4.2 模具加热与冷却系统的计算 ------------------------15

第五章 模具闭合高度的确定、注塑机参数校核 ----------16

5.1 模具闭合高度的确定 ---------------------------------16

5.2 注塑机参数校核 -----------------------------------------16

第六章 编写主要零件加工工艺规程 -------------------------18

6.1 型芯加工工艺 -------------------------------------------18

6.2 型腔加工工艺 -------------------------------------------19

设计总结 ----------------------------------------------------------21

致 谢 ----------------------------------------------------------22

参考文献 ----------------------------------------------------------23

本设计根据从事塑料注塑模设计与制造的工程技术综合性应用型人才的实际要求,符合大专模具设计专业的毕业生毕业设计需要所编写的,对初学注塑模设计者有一定的参考价值。

本设计共分六章,分别对设计题目的来源、设计意义、零件工艺性分析、工艺方案的确定、模具结构及成型设备的选择、工艺计算、模具结构设计及校核、加工工艺等几方面进行了阐述。

本设计在设计过程中得到了杨占尧、原红玲、于智宏等几位指导老师的大力支持和帮助,再此表示诚挚的感谢!由于编者水平有限,收集资料困难,定有许多不尽人意的地方,恳请读者不吝赐教,提出改进意见,以便使此设计进一步修正和完善。

关键词:塑料模 注塑成型 工艺

Abstract

This design according to be engaged in the plastics note the Plastics mold design synthesizes with the engineering technique of the manufacturing sex application the talented person's actual request in type, match the professional graduate student in design in university molding tool graduate design the demand the plait writes of, note to the beginner Plastics mold design have to consults certainly value.

This design is divided into six source for, distinguishing to designing topics and design the meaning, spare parts craft analysis, craft project to really settle totally, molding tool construction and model choice, craft calculation, molding tool construction design and school of the equipments and process craft etc. several aspects proceeded to expatiate.

This designed to get in design process the virtuous plum, yang zhan yao , yuan hong ling , yu zhi hong ...etc.a few leadings the teacher supports strongly with help, again this mean the sincere with gratitude!Because the editor level is limited, collect data the difficulty, settle many not exhausted the place of person's idea, plead the reader the not stingy advising, put forward to improve the opinion, in order to make this design further revised with perfect.

Key: Plastic mold Injection Molding Technology

绪 论 --------------------------------------------------------- ------1

第一章 任务书来源及设计意义 --------------------------------4

1.1 设计任务 -------------------------------------------------4

1.2 设计目的及意义------------------------------------ -----4

第二章 零件的工艺性分析 --------------------------------- -----5

2.1 塑件的原材料分析 -------------------------------- -----5

2.2 塑件的结构和尺寸精度及表面质量分析 -----------6

2.3 计算塑件的体积和质量 --------------------------------7

2.4塑件注塑工艺参数的确定 -------------------------------7

第三章 工艺方案的确定 --------------------------------------- -8

3.1 分型面的选择 ---------------------------------------- ---8

3.2 确定型腔的排列方式 ----------------------------------8

3.3 模架的选取 ----------------------------------------------9

3.4 浇注系统的设计 ----------------------------------------9

3.5 抽芯机构的设计 ---------------------------------------11

3.6 成型零件的结构设计 -------------------------------- 12

第四章 工艺计算 -------------------------------------------------13

4.1 型腔和型芯工作尺寸计算 ---------------------------13

4.2 模具加热与冷却系统的计算 ------------------------15

第五章 模具闭合高度的确定、注塑机参数校核 ----------16

5.1 模具闭合高度的确定 ---------------------------------16

5.2 注塑机参数校核 -----------------------------------------16

第六章 编写主要零件加工工艺规程 -------------------------18

6.1 型芯加工工艺 -------------------------------------------18

6.2 型腔加工工艺 -------------------------------------------19

设计总结 ----------------------------------------------------------21

致 谢 ----------------------------------------------------------22

参考文献 ----------------------------------------------------------23