设计简介

摘要:本世纪的科学技术正处于日新月异的变革之中,通过与计算机技术的紧密结合,人工智能技术、并行工程、面向装配、参数化特征建模以及关联设计等一系列与模具工业相关的技术发展之快、学科领域交叉之广前所未见,随着模具工业的快速发展,近几年来世界各国的软件开发商投入了巨大的人力和物力,针对各类模具的特点,将通用的CAD/CAM系统改造为模具行业专用的系统,取得了较大成效。

本设计是CAD/CAM技术在曲面加工中的应用。包括两大部分:一是摩托车塑料挡板模具的设计;二是模具型面的造型与数控仿真加工。在Mastercam 9.0环境下利用CAD功能进行摩托车塑料挡板模具的实体造型,利用CAM功能进行模具刀具路径的编制、模拟加工,并通过后处理生成数控加工程序。

期望通过此课题的研究,能够提高自己对CAD/CAM技术在模具制造业中应用的重要性的认识。并对注塑成型工艺及模具设计方面有了进一步的理解和提高。

关键词: 注塑模 数控加工仿真 CAD/CAM技术

Abstract: The science and technology has been changing in a fast pace. With the tight combination of computing technology, those technologies such as AI, Parallel project, face to assembling, The parameter turns the characteristic to set up the mold and associate designing which are relevant with modeling industry are growing incredibly fast. With the rapid growth of modeling industry, worldwide software companies invest huge capital and human resource to modify general CAD/CAM system into modeling industry specified system regarding the feature of all kinds of moulds.

This project is the use of CAD/CAM technology in the curved face process area. It includes two parts: First part is the design of the motorcycle plastics block’s injection mould. Second part is mould sculpt design and numerical emulation machining. We use Mastercam 9.0’s CAD function to design the he motorcycle plastics block’s injection mould and use the CAM function to program the cutter path, simulate the process and generate numerical modeling program.

I hope to enhance the acknowledgement of the importance of the use of CAD/CAM technologies in modeling industry and have a further understanding of injecting mold craft and model design during the course of this research.

Keyword: injecting mould Numerical control simulation machining

CAD/CAM technology

目 录

1 前言……………………………………………………………………………(1)

1.1 CAD / CAM /CAE 技术的概念………………………………………………(1)

1.2 注塑模 CAD / CAM / CAE 技术的应用现状………………………………(1)

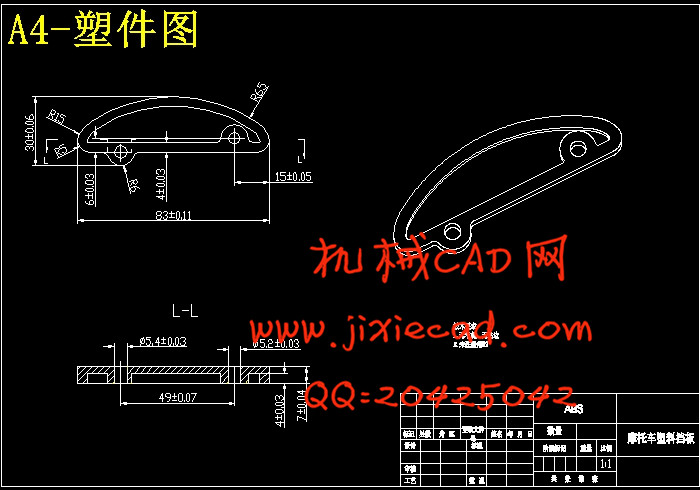

2 摩托车塑料挡板塑件的分析与注塑成型原理……………………(3)

2.1 塑料的性能、分类和摩托车挡板的分析……………………………………(3)

2.2 注塑成形原理与过程…………………………………………………………(4)

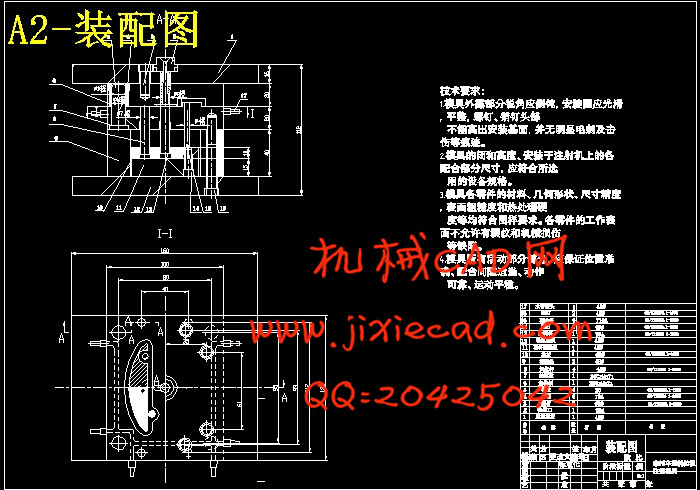

3 摩托车挡板注塑模的设计……………………………………………… (10)

3.1 塑件成型的工艺性能分析……………………………………………………(10)

3.2 注塑机的选择…………………………………………………………………(11)

3.3 塑件成型方案的确定…………………………………………………………(11)

3.3.1分型面位置的选择………………………………………………………… (11)

3.3.2设计冷却系统的原则……………………………………………………… (12)

3.3.3推出形式、复位形式的确定……………………………………………… (13)

3.3.4 浇口形式、位置的设计与确定……………………………………………(14)

3.4 其它机构……………………………………………………………………… (15)

3.4.1合模导向机构……………………………………………………………… (15)

3.4.2 支承零件的设计……………………………………………………………(15)

3.4.3 排气和冷却机构……………………………………………………………(16)

3.5 模具设计的计算……………………………………………………………… (16)

3.5.1影响成形零件尺寸的因素………………………………………………… (16)

3.5.2成形零件工作尺寸的计算………………………………………………… (16)3.5.3整体式矩形型腔侧壁和底板厚度的计算………………………………… (23)

3.6机构设计……………………………………………………………………… (23)

3.6.1合模导向机构的设计……………………………………………………… (23)

3.6.2确定脱模结构形式………………………………………………………… (24)

3.7确定温度调节系统…………………………………………………………… (24)

3.7.1单位时间内塑件在凝固时所放出的热量………………………………… (25)

3.7.2模具冷却时所需冷却介质的体积流量…………………………………… (25)

3.8 模具尺寸确定………………………………………………………………… (25)

3.8.1型腔壁厚以及定模板尺寸的确定………………………………………… (25)

3.8.2确定模架规格……………………………………………………………… (25)

3.9成型设备的校核计算………………………………………………………… (29)

3.9.1锁模力的校核……………………………………………………………… (29)

3.9.2喷嘴的校核………………………………………………………………… (30)

3.9.3模具轮廓尺寸与注射机装模空间关系…………………………………… (30)

3.9.4注射机参数的校核………………………………………………………… (30)

3.9.5注射机安装模具部分的尺寸校核………………………………………… (31)

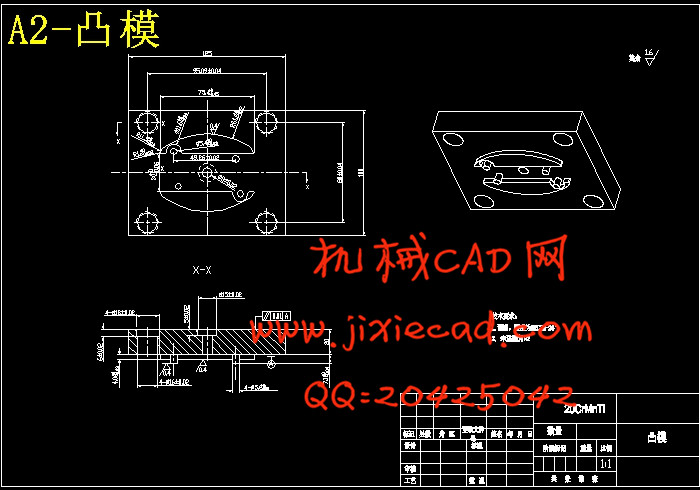

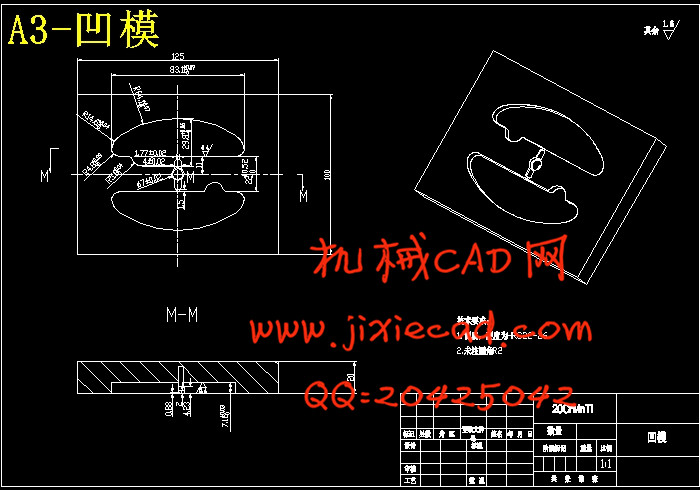

4 模具外壳、型腔和型芯的三维造型与数控仿真加工……………(31)

4.1 MasterCAM9.0软件的简介……………………………………………………(31)

4.2摩托车塑料挡板注塑模的三维曲面造型…………………………………… (32)

4.3摩托车挡板型芯模的三维曲面造型与数控仿真加工……………………… (45)

4.3.1 摩托车挡板型芯模的三维曲面造型……………………………………… (45)

4.3.2摩托车挡板型芯模的数控仿真加工…………………………………………(46)

4.4摩托车挡板型腔模的三维曲面造型与数控仿真加工……………………… (58)

4.4.1 摩托车挡板型腔模的三维曲面造型……………………………………… (58)

4.4.2 摩托车挡板型腔模的数控仿真加工……………………………………… (58)

5 结论………………………………………………………………………………(66)

参考文献…………………………………………………………………………… (67)

致 谢…………………………………………………………………………… (68)

本设计是CAD/CAM技术在曲面加工中的应用。包括两大部分:一是摩托车塑料挡板模具的设计;二是模具型面的造型与数控仿真加工。在Mastercam 9.0环境下利用CAD功能进行摩托车塑料挡板模具的实体造型,利用CAM功能进行模具刀具路径的编制、模拟加工,并通过后处理生成数控加工程序。

期望通过此课题的研究,能够提高自己对CAD/CAM技术在模具制造业中应用的重要性的认识。并对注塑成型工艺及模具设计方面有了进一步的理解和提高。

关键词: 注塑模 数控加工仿真 CAD/CAM技术

Abstract: The science and technology has been changing in a fast pace. With the tight combination of computing technology, those technologies such as AI, Parallel project, face to assembling, The parameter turns the characteristic to set up the mold and associate designing which are relevant with modeling industry are growing incredibly fast. With the rapid growth of modeling industry, worldwide software companies invest huge capital and human resource to modify general CAD/CAM system into modeling industry specified system regarding the feature of all kinds of moulds.

This project is the use of CAD/CAM technology in the curved face process area. It includes two parts: First part is the design of the motorcycle plastics block’s injection mould. Second part is mould sculpt design and numerical emulation machining. We use Mastercam 9.0’s CAD function to design the he motorcycle plastics block’s injection mould and use the CAM function to program the cutter path, simulate the process and generate numerical modeling program.

I hope to enhance the acknowledgement of the importance of the use of CAD/CAM technologies in modeling industry and have a further understanding of injecting mold craft and model design during the course of this research.

Keyword: injecting mould Numerical control simulation machining

CAD/CAM technology

目 录

1 前言……………………………………………………………………………(1)

1.1 CAD / CAM /CAE 技术的概念………………………………………………(1)

1.2 注塑模 CAD / CAM / CAE 技术的应用现状………………………………(1)

2 摩托车塑料挡板塑件的分析与注塑成型原理……………………(3)

2.1 塑料的性能、分类和摩托车挡板的分析……………………………………(3)

2.2 注塑成形原理与过程…………………………………………………………(4)

3 摩托车挡板注塑模的设计……………………………………………… (10)

3.1 塑件成型的工艺性能分析……………………………………………………(10)

3.2 注塑机的选择…………………………………………………………………(11)

3.3 塑件成型方案的确定…………………………………………………………(11)

3.3.1分型面位置的选择………………………………………………………… (11)

3.3.2设计冷却系统的原则……………………………………………………… (12)

3.3.3推出形式、复位形式的确定……………………………………………… (13)

3.3.4 浇口形式、位置的设计与确定……………………………………………(14)

3.4 其它机构……………………………………………………………………… (15)

3.4.1合模导向机构……………………………………………………………… (15)

3.4.2 支承零件的设计……………………………………………………………(15)

3.4.3 排气和冷却机构……………………………………………………………(16)

3.5 模具设计的计算……………………………………………………………… (16)

3.5.1影响成形零件尺寸的因素………………………………………………… (16)

3.5.2成形零件工作尺寸的计算………………………………………………… (16)3.5.3整体式矩形型腔侧壁和底板厚度的计算………………………………… (23)

3.6机构设计……………………………………………………………………… (23)

3.6.1合模导向机构的设计……………………………………………………… (23)

3.6.2确定脱模结构形式………………………………………………………… (24)

3.7确定温度调节系统…………………………………………………………… (24)

3.7.1单位时间内塑件在凝固时所放出的热量………………………………… (25)

3.7.2模具冷却时所需冷却介质的体积流量…………………………………… (25)

3.8 模具尺寸确定………………………………………………………………… (25)

3.8.1型腔壁厚以及定模板尺寸的确定………………………………………… (25)

3.8.2确定模架规格……………………………………………………………… (25)

3.9成型设备的校核计算………………………………………………………… (29)

3.9.1锁模力的校核……………………………………………………………… (29)

3.9.2喷嘴的校核………………………………………………………………… (30)

3.9.3模具轮廓尺寸与注射机装模空间关系…………………………………… (30)

3.9.4注射机参数的校核………………………………………………………… (30)

3.9.5注射机安装模具部分的尺寸校核………………………………………… (31)

4 模具外壳、型腔和型芯的三维造型与数控仿真加工……………(31)

4.1 MasterCAM9.0软件的简介……………………………………………………(31)

4.2摩托车塑料挡板注塑模的三维曲面造型…………………………………… (32)

4.3摩托车挡板型芯模的三维曲面造型与数控仿真加工……………………… (45)

4.3.1 摩托车挡板型芯模的三维曲面造型……………………………………… (45)

4.3.2摩托车挡板型芯模的数控仿真加工…………………………………………(46)

4.4摩托车挡板型腔模的三维曲面造型与数控仿真加工……………………… (58)

4.4.1 摩托车挡板型腔模的三维曲面造型……………………………………… (58)

4.4.2 摩托车挡板型腔模的数控仿真加工……………………………………… (58)

5 结论………………………………………………………………………………(66)

参考文献…………………………………………………………………………… (67)

致 谢…………………………………………………………………………… (68)