设计简介

球形顶盖注塑模设计

摘要

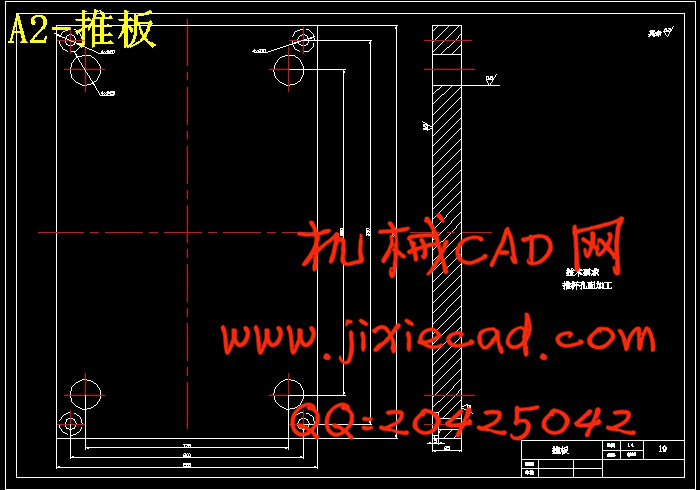

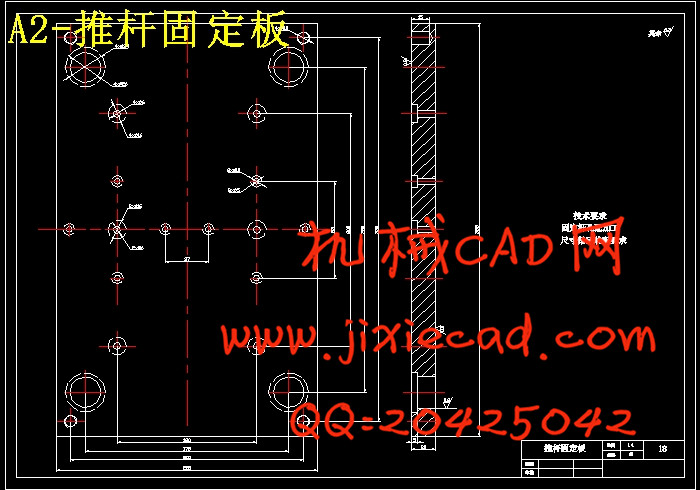

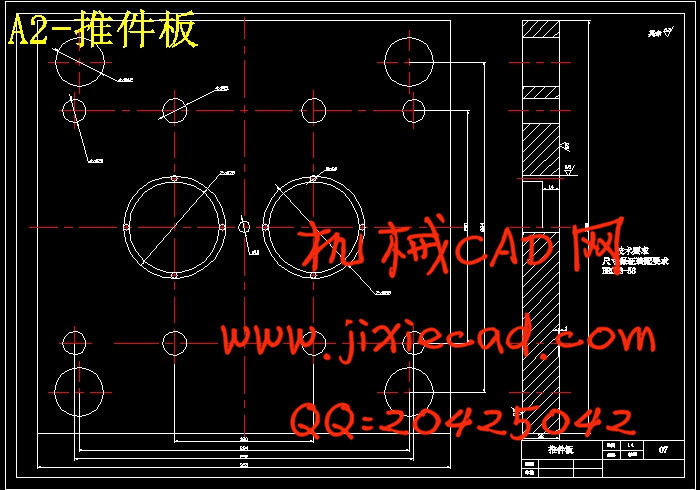

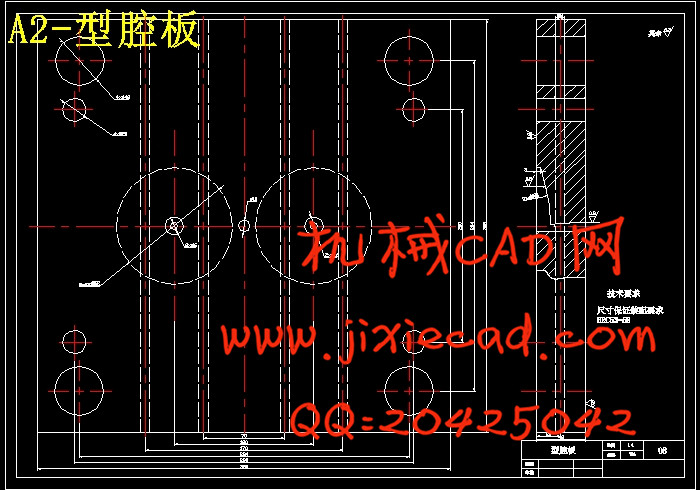

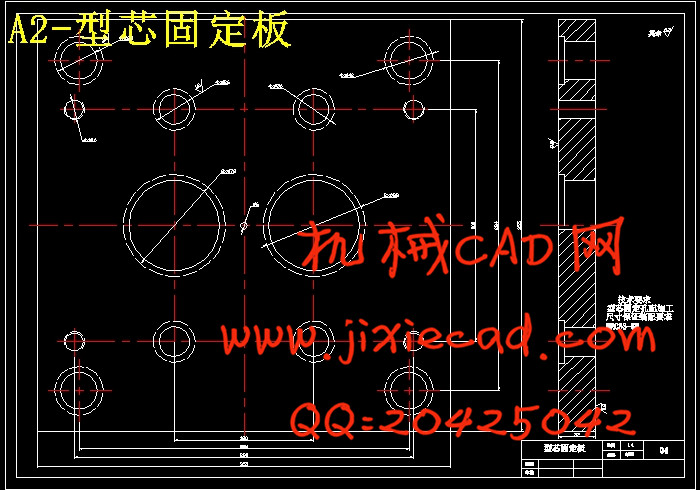

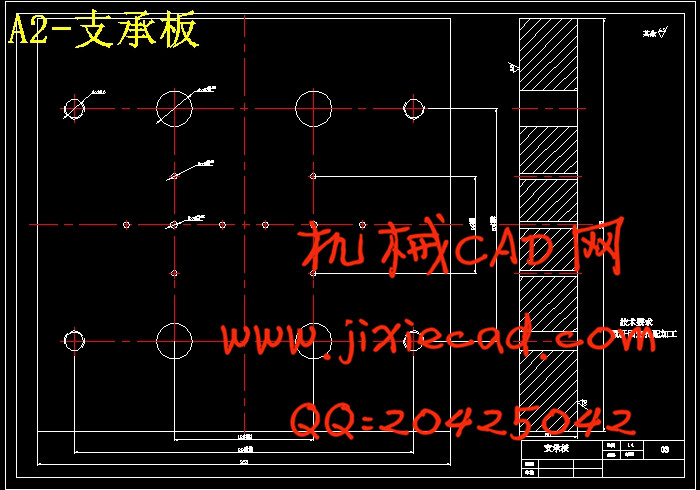

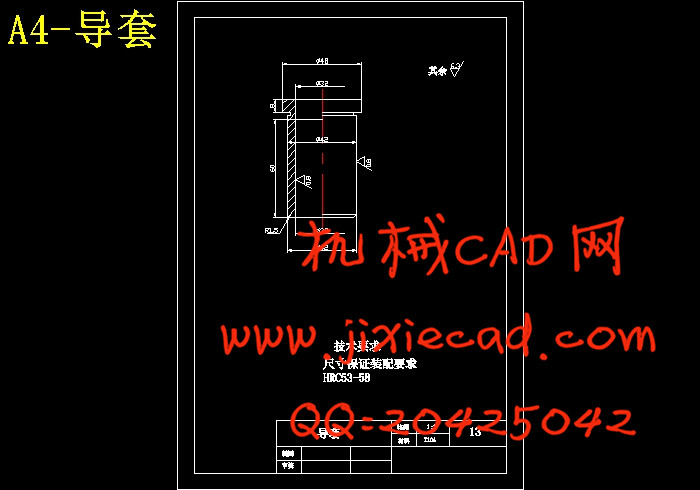

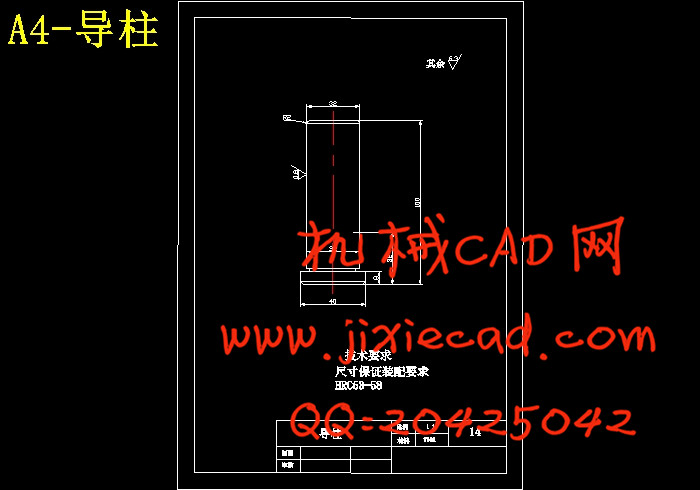

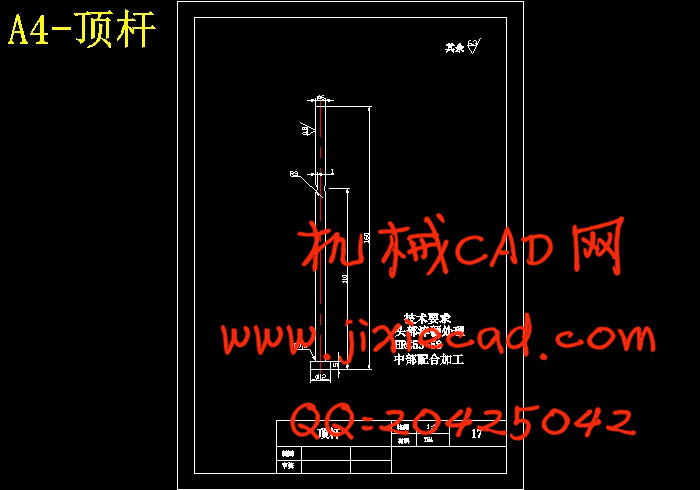

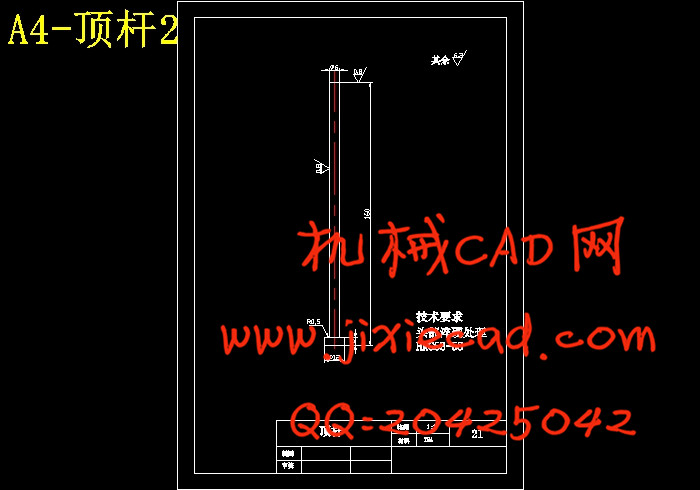

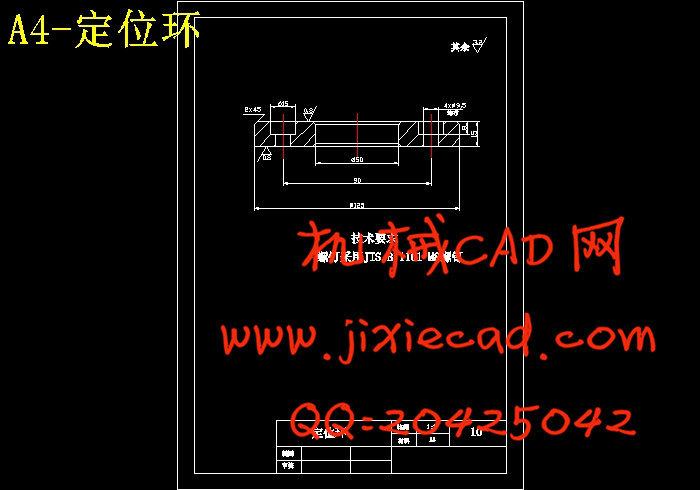

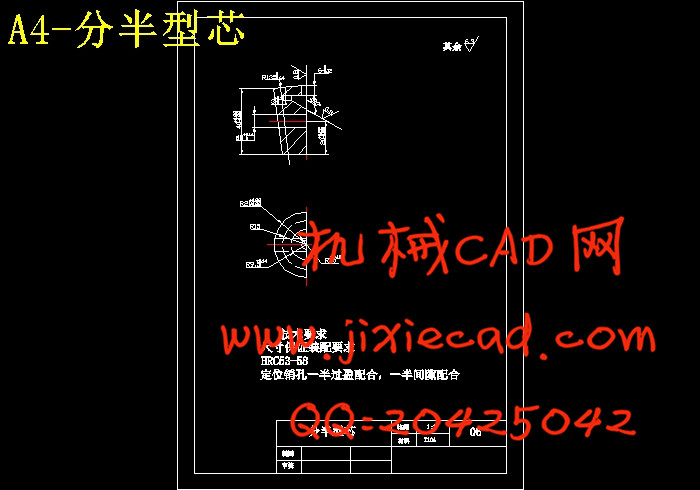

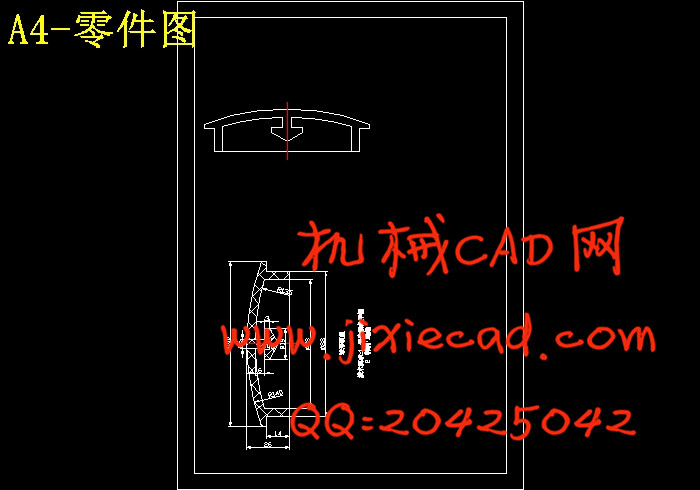

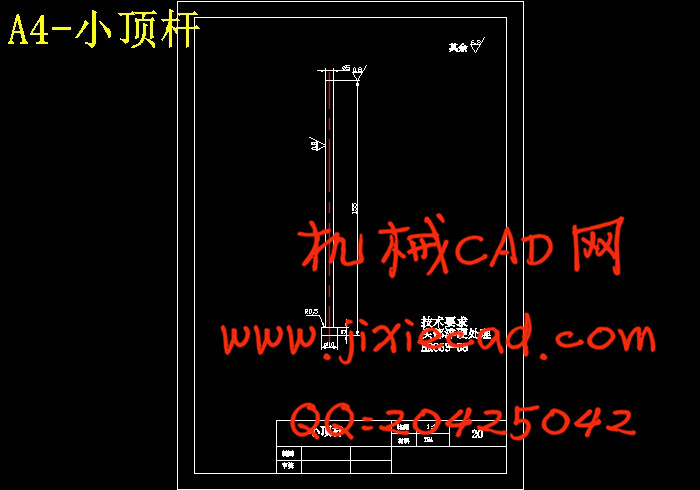

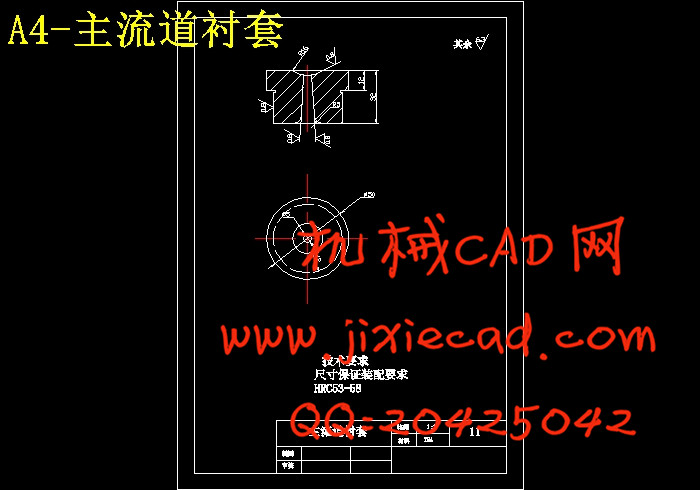

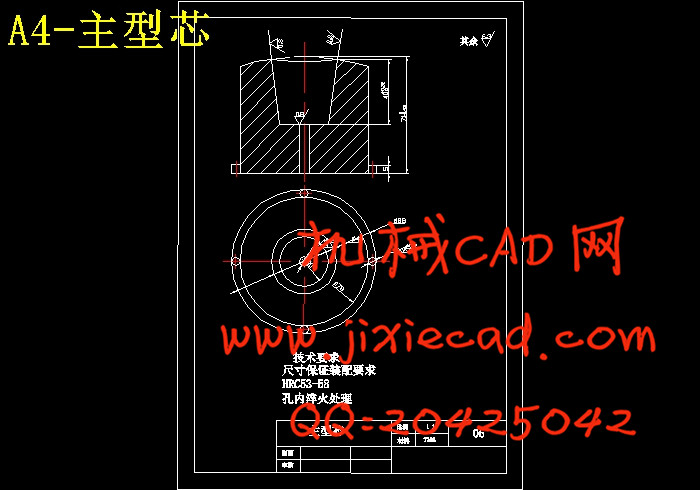

对塑件的工艺性进行分析,该模具适合采用一模两件结构。由于塑件原料为尼龙1010,流动性好,故适合点浇口凝料自动脱落结构,但需增加一个分型面。塑件内部结构复杂,不能直接脱模,故对于塑件不能直接脱模的中间部分,采用分半型芯结构,模外手动脱模。由于成型后塑件对型腔的粘着力和对型芯的包紧力较大,一次脱模可能造成塑件断裂损伤,故采用顶杆推件板二级脱模机构。

关键词:分半型芯 点浇口 二级脱模

The top probably producing plastic articles by injection moulding, the model designs sphere

Structure carrying out analysis on to moulding piece of manufacturability , being a mould's turn to be fit to adopt one two pieces of models. Be a nylon since moulding piece of raw material 1010, flowability is good , structure, but necessaries increases by a mark of type face therefore being suitable to a running gate curdle to expect that the automation comes off. Mould piece of inner structure complicated , can not demould directly , adopt half mark of core structure , model right-hand side to move drawing of patterns therefore to moulding piece of unable deciduate direct centre part. The force is firmly bigger since the molding queen moulds piece of the adhesion force to type cavity and the parcel to the core , a drawing of patterns may bring about moulding piece of tearing loss, therefore adopt top material to push piece of board two stage drawing of patterns organization.

Keywords: Be allotted half cores Count a running gate The two stage is deciduate

前言……………………………………………………………6-7

一 模塑工艺规程的编制…………………………………………8-10

二 注塑模的结构设计……………………………………………10-17

三 顶盖注塑模具的有关计算……………………………………18

四 模具加热和冷却系统的设计…………………………………18-19

五 模具闭合高度的确定…………………………………………19-20

六 注塑机有关参数的校核………………………………………20

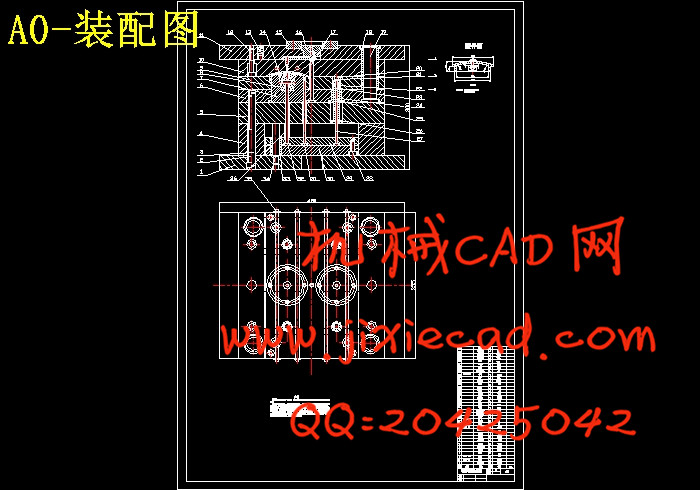

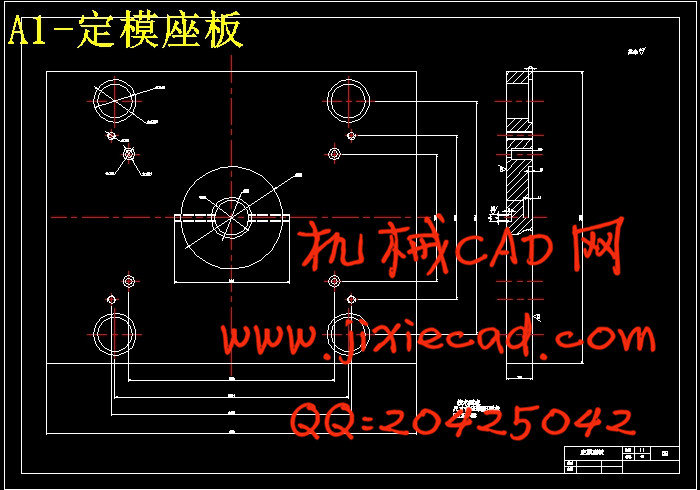

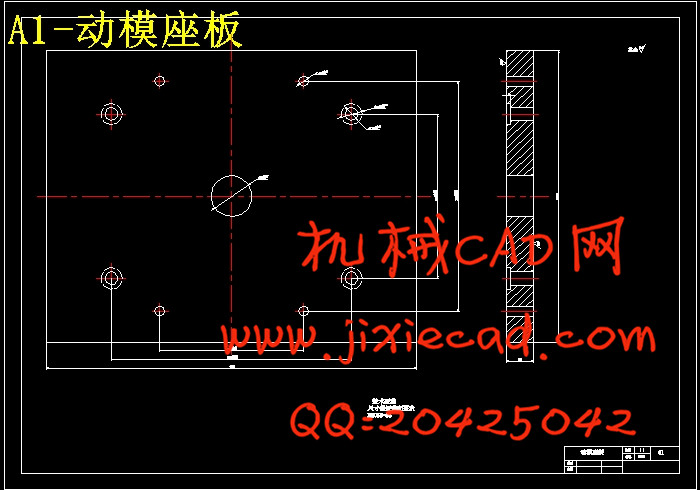

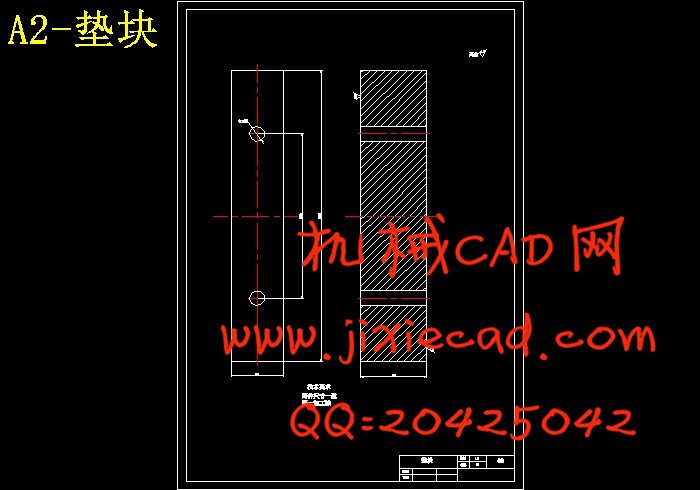

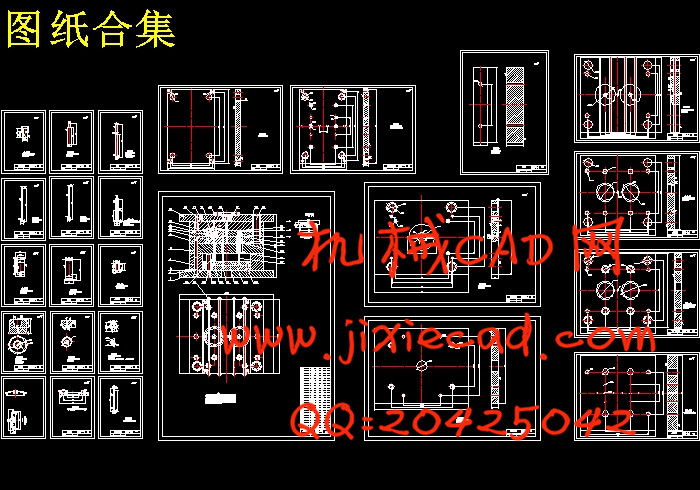

七 绘制模具总装配图和非标准零件工作图……………………21

八 模具主要零件加工工艺规程的编制…………………………22-23

九 结束语…………………………………………………………23

致谢……………………………………………………………24

参考文献………………………………………………………25

摘要

对塑件的工艺性进行分析,该模具适合采用一模两件结构。由于塑件原料为尼龙1010,流动性好,故适合点浇口凝料自动脱落结构,但需增加一个分型面。塑件内部结构复杂,不能直接脱模,故对于塑件不能直接脱模的中间部分,采用分半型芯结构,模外手动脱模。由于成型后塑件对型腔的粘着力和对型芯的包紧力较大,一次脱模可能造成塑件断裂损伤,故采用顶杆推件板二级脱模机构。

关键词:分半型芯 点浇口 二级脱模

The top probably producing plastic articles by injection moulding, the model designs sphere

Structure carrying out analysis on to moulding piece of manufacturability , being a mould's turn to be fit to adopt one two pieces of models. Be a nylon since moulding piece of raw material 1010, flowability is good , structure, but necessaries increases by a mark of type face therefore being suitable to a running gate curdle to expect that the automation comes off. Mould piece of inner structure complicated , can not demould directly , adopt half mark of core structure , model right-hand side to move drawing of patterns therefore to moulding piece of unable deciduate direct centre part. The force is firmly bigger since the molding queen moulds piece of the adhesion force to type cavity and the parcel to the core , a drawing of patterns may bring about moulding piece of tearing loss, therefore adopt top material to push piece of board two stage drawing of patterns organization.

Keywords: Be allotted half cores Count a running gate The two stage is deciduate

前言……………………………………………………………6-7

一 模塑工艺规程的编制…………………………………………8-10

二 注塑模的结构设计……………………………………………10-17

三 顶盖注塑模具的有关计算……………………………………18

四 模具加热和冷却系统的设计…………………………………18-19

五 模具闭合高度的确定…………………………………………19-20

六 注塑机有关参数的校核………………………………………20

七 绘制模具总装配图和非标准零件工作图……………………21

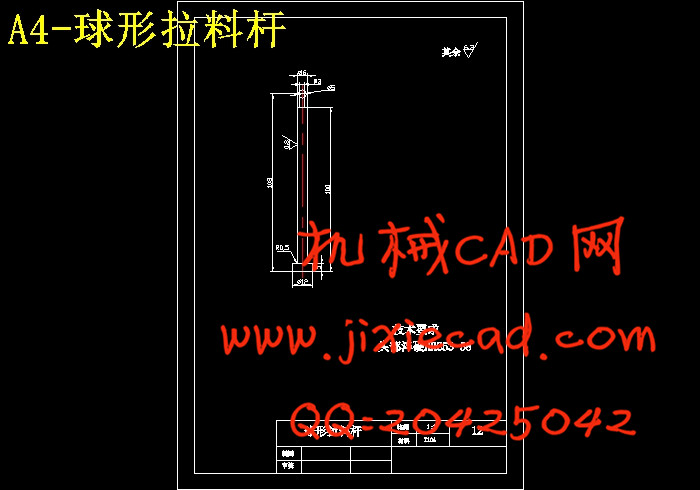

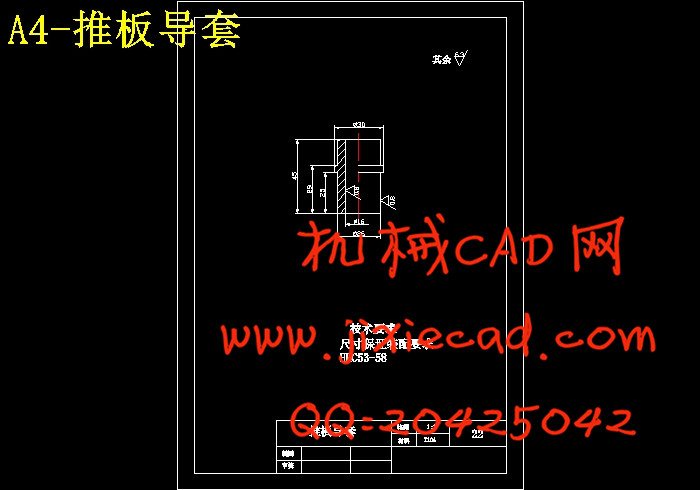

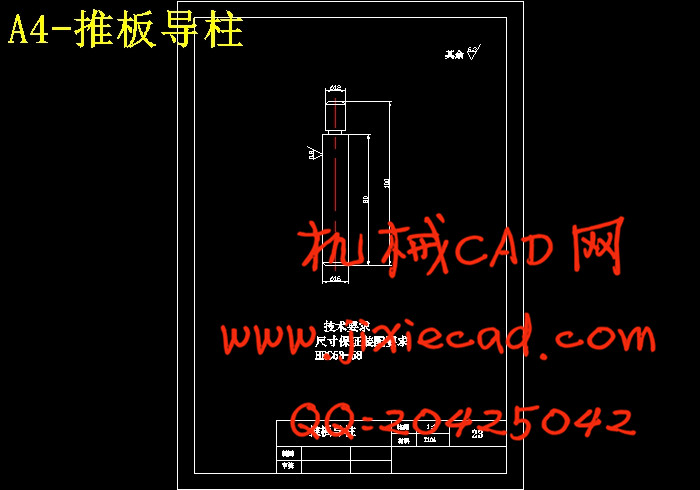

八 模具主要零件加工工艺规程的编制…………………………22-23

九 结束语…………………………………………………………23

致谢……………………………………………………………24

参考文献………………………………………………………25