设计简介

摘要

塑料成型的方法有很多,其中最主要的是注射成型的方法,他的优点是可以快速的大量的成型大量塑料制品,本设计主要是用三维软件先进性整体计,之后再用二维软件进行图形的绘制,主要可以使工作量大大减少,使得设计本身更加的方便。

在本设计里,三角衣架做为生活里的日常用品可以使用注射成型的方法,通过对模具的结构进行分析,设计出一套一模两腔的塑料注射模具,并且要合理的写出制造的流程,在这个设计里,三维软件Pro/E的使用贯穿整个设计的过程,第一步是利用软件对对三角衣架的整个模型进行建模设计,然后在分模,型芯的设计、浇注系统的设计。最后要利用外挂为(EMX4.1)成标准模架,在对其模具整个系统进行合理布置。

在模具设计里,有许多的尺寸要确定列如:壁厚,顶杆直径,流道尺寸,这些尺寸的大小都要根据进一步的查找相关的文献进行设计,而且在得出的数据中要进行大量的校对,对于一些尺寸的确定要对实际的环境进行考虑尺寸大小要基本满足设计的要求与此同时也要符合实际生活的要求,而且由于一些成本和加工难易度的原因也要对尺寸大小进行更进一步的计算,最终得出整个系统合理的尺寸大小。

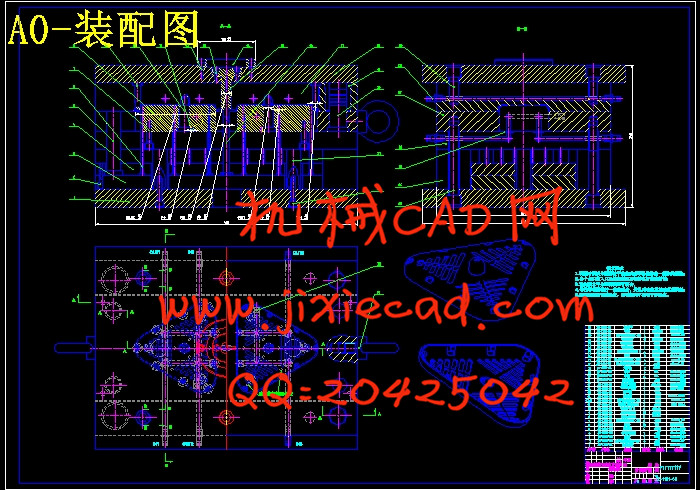

对于本设计来说,最终的绘制要用到CAD二维软件,前期我们主要是利用三维软件对模具的整体部分进行设计,并计算分析出它的尺寸,并且对其校对,但是考虑到CAD强大的制图能力以及很方便的功能,所以决定用CAD进行最终零件图和装配图的绘制,利用三维软件强大的建模能力,在建模完成后就将结果直接导入到CAD中这样很方便快捷,不仅体现了三维软Pro/E的强大之处,也结合了CAD的优点,这样的二者结合使的整个设计变得更加的方便和便捷。

经过本设计,对于模具的整体结构有了一定的了解以及对模具设计成型的过程有了一定的把握,对于零件的结构也有了一定的了解,也查找了大量相关的资料。本设计主要是利用了三维软件Pro/E进行设计,与此同时运用CAD进行绘制零件图和装配图,在设计里要进行大量的细节设计以及进行分析,了解了模具的结构以及模具的工作。模具各部分结构设计好后,利用创建好的模型生成Pro/E工程图并将其导入autoCAD中做出符合国标的装配图及部分零件图,跳过了直接绘制工程图中大量繁琐的工作,降低了设计工作量。该设计充分体现了Pro/E软件在模具设计的优越性。

关键词: 三角衣架塑件; 注射模; Pro/E; EMX4.1

Abstract

Plastic molding method has a lot of, is one of the main injection molding method, he has the advantage that can quickly a large number of molding plastic products in great quantities, this design mainly is to use advanced 3 d software overall design, and then using two-dimensional graphic drawing software, main can greatly reduce the workload, making itself more convenient.

In this design, the triangle hanger as life everyday objects can be used in the injection molding method, through the analysis of the structure of the mould, design a set of one module and two cavities of plastic injection mould, and should be written out in reasonable manufacturing process, in this design, the use of 3 d software Pro/E throughout the entire design process, the first step is to use the software for the whole model of triangle hangers modeling design, and then in the die, the design of the core, the design of gating system. Finally, use the plugin for (EMX4.1) generate standard mould frame, reasonable layout in the mold of the whole system.

In die design, there are many dimensions to determine the column, such as: wall thickness, plunger diameter and flow channel size, the size is according to the size of the further search the related literature to carry on the design, and in the data to a large number of proofreading, for the determination of some size to the actual environment, considering the size to meet the requirements of design basic at the same time also want to accord with the requirement of practical life, and because of some of the costs and processing difficulty level also want to further calculation of the size, the final size of the whole system is reasonable.

For this design, the final draw will use 2 d CAD software, we mainly use 3 d software to design an integral part of the mould, and the calculation and analysis of its size, and the proofreading, but given the CAD powerful mapping ability and very convenient, so I decided to use the final detail drawing and assembly drawing CAD drawing, use 3 d software modeling capabilities, strong in modeling is completed will result directly imported into the CAD of it's so convenient and quick, not only embodies the powerful 3 d software Pro/E, and combines the advantages of CAD, such combination to make the whole design becomes more easy and convenient.

Through this design, for the overall structure of the mould had certain understanding and the mold design molding process with a degree of certainty, for the structure of the parts have a certain understanding, also to find a large number of relevant materials. This design mainly is to use the 3 d design software Pro/E, at the same time using CAD drawing parts drawing and assembly drawing, in the design to a large number of detail design and analysis, understand the structure of the mould and die work. Mold structure design, the parts used to create a good model to generate the Pro/E engineering drawing and import it into autoCAD to comply with the national standard of the assembly drawing and parts diagram, skip the directly map project in a large amount of tedious work, reduce the workload of design. The design fully embodies the advantages of Pro/E software in the mold design.

Key words: Triangular plastic hanger; Injection mold; Pro/E; EMX4.1

目 录

塑料成型的方法有很多,其中最主要的是注射成型的方法,他的优点是可以快速的大量的成型大量塑料制品,本设计主要是用三维软件先进性整体计,之后再用二维软件进行图形的绘制,主要可以使工作量大大减少,使得设计本身更加的方便。

在本设计里,三角衣架做为生活里的日常用品可以使用注射成型的方法,通过对模具的结构进行分析,设计出一套一模两腔的塑料注射模具,并且要合理的写出制造的流程,在这个设计里,三维软件Pro/E的使用贯穿整个设计的过程,第一步是利用软件对对三角衣架的整个模型进行建模设计,然后在分模,型芯的设计、浇注系统的设计。最后要利用外挂为(EMX4.1)成标准模架,在对其模具整个系统进行合理布置。

在模具设计里,有许多的尺寸要确定列如:壁厚,顶杆直径,流道尺寸,这些尺寸的大小都要根据进一步的查找相关的文献进行设计,而且在得出的数据中要进行大量的校对,对于一些尺寸的确定要对实际的环境进行考虑尺寸大小要基本满足设计的要求与此同时也要符合实际生活的要求,而且由于一些成本和加工难易度的原因也要对尺寸大小进行更进一步的计算,最终得出整个系统合理的尺寸大小。

对于本设计来说,最终的绘制要用到CAD二维软件,前期我们主要是利用三维软件对模具的整体部分进行设计,并计算分析出它的尺寸,并且对其校对,但是考虑到CAD强大的制图能力以及很方便的功能,所以决定用CAD进行最终零件图和装配图的绘制,利用三维软件强大的建模能力,在建模完成后就将结果直接导入到CAD中这样很方便快捷,不仅体现了三维软Pro/E的强大之处,也结合了CAD的优点,这样的二者结合使的整个设计变得更加的方便和便捷。

经过本设计,对于模具的整体结构有了一定的了解以及对模具设计成型的过程有了一定的把握,对于零件的结构也有了一定的了解,也查找了大量相关的资料。本设计主要是利用了三维软件Pro/E进行设计,与此同时运用CAD进行绘制零件图和装配图,在设计里要进行大量的细节设计以及进行分析,了解了模具的结构以及模具的工作。模具各部分结构设计好后,利用创建好的模型生成Pro/E工程图并将其导入autoCAD中做出符合国标的装配图及部分零件图,跳过了直接绘制工程图中大量繁琐的工作,降低了设计工作量。该设计充分体现了Pro/E软件在模具设计的优越性。

关键词: 三角衣架塑件; 注射模; Pro/E; EMX4.1

Abstract

Plastic molding method has a lot of, is one of the main injection molding method, he has the advantage that can quickly a large number of molding plastic products in great quantities, this design mainly is to use advanced 3 d software overall design, and then using two-dimensional graphic drawing software, main can greatly reduce the workload, making itself more convenient.

In this design, the triangle hanger as life everyday objects can be used in the injection molding method, through the analysis of the structure of the mould, design a set of one module and two cavities of plastic injection mould, and should be written out in reasonable manufacturing process, in this design, the use of 3 d software Pro/E throughout the entire design process, the first step is to use the software for the whole model of triangle hangers modeling design, and then in the die, the design of the core, the design of gating system. Finally, use the plugin for (EMX4.1) generate standard mould frame, reasonable layout in the mold of the whole system.

In die design, there are many dimensions to determine the column, such as: wall thickness, plunger diameter and flow channel size, the size is according to the size of the further search the related literature to carry on the design, and in the data to a large number of proofreading, for the determination of some size to the actual environment, considering the size to meet the requirements of design basic at the same time also want to accord with the requirement of practical life, and because of some of the costs and processing difficulty level also want to further calculation of the size, the final size of the whole system is reasonable.

For this design, the final draw will use 2 d CAD software, we mainly use 3 d software to design an integral part of the mould, and the calculation and analysis of its size, and the proofreading, but given the CAD powerful mapping ability and very convenient, so I decided to use the final detail drawing and assembly drawing CAD drawing, use 3 d software modeling capabilities, strong in modeling is completed will result directly imported into the CAD of it's so convenient and quick, not only embodies the powerful 3 d software Pro/E, and combines the advantages of CAD, such combination to make the whole design becomes more easy and convenient.

Through this design, for the overall structure of the mould had certain understanding and the mold design molding process with a degree of certainty, for the structure of the parts have a certain understanding, also to find a large number of relevant materials. This design mainly is to use the 3 d design software Pro/E, at the same time using CAD drawing parts drawing and assembly drawing, in the design to a large number of detail design and analysis, understand the structure of the mould and die work. Mold structure design, the parts used to create a good model to generate the Pro/E engineering drawing and import it into autoCAD to comply with the national standard of the assembly drawing and parts diagram, skip the directly map project in a large amount of tedious work, reduce the workload of design. The design fully embodies the advantages of Pro/E software in the mold design.

Key words: Triangular plastic hanger; Injection mold; Pro/E; EMX4.1

目 录

第一章绪论 1

1.1 设计的目的和意义 1

第二章塑件成型工艺分析 2

2.1 塑件的使用要求 2

2.2 塑件的材料分析 2

2.3 塑件的尺寸精度、塑件表面质量、塑件的结构工艺性分析 2

2.3.1 塑件的尺寸精度分析 3

2.3.2 塑件的表面质量分析 3

2.3.3 塑件的结构工艺性分析 3

第三章选择成型的设备和编写模塑工艺的参数 5

3.1 该衣架的重量和体积 5

3.2 对于零件型腔数量确定 5

3.3 浇注系统凝料的估算 6

3.4 注射机的选用及其技术参数 6

3.5 成型工艺参数 7

第四章模具结构方案的确定 9

4.1 分型面位置确定 9

4.2 型腔数量的最后确定及型腔的排列形式 9

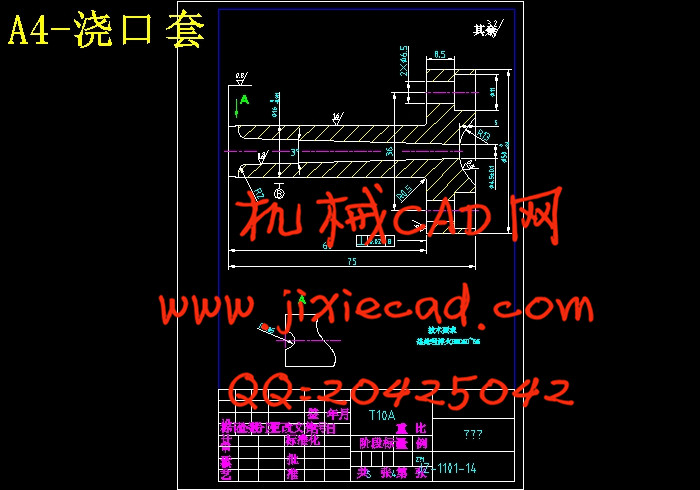

4.3 浇注系统的设计与计算 10

4.3.1 主流道设计 10

4.3.2 分流道的设计 11

4.3.3 浇口的设计 13

4.4 成型零件结构的确定 14

4.4.1 凹模的结构设计 14

4.4.2 凸模(型芯)的结构设计 15

4.5 排气与引气系统结构的确定 16

4.6 冷料穴与拉料杆的设计 16

4.7 侧凹部分的处理 17

4.8模具结构形式的确定 17

第五章主要零部件的设计计算 18

5.1 成型零件工作尺寸计算 18

5.2 成型零件尺寸及动模垫板厚度的计算 20

5.2.1 凹模侧壁厚度计算 20

5.2.2 凹模底部厚度计算 21

5.2.3 动模垫板厚度计算 21

5.3 标准模架的选择 22

5.3.1 模架的确定 22

5.3.2 各模板尺寸的确定 22

5.3.3 导柱长度确定 23

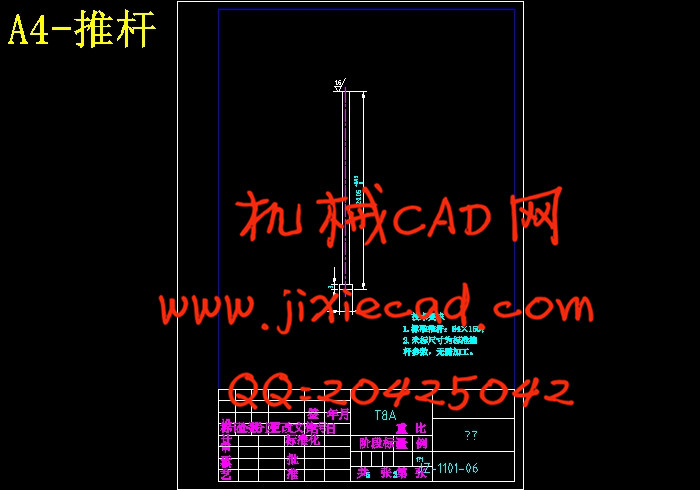

5.4 脱模机构的设计与计算 23

5.4.1 推出方式的确定 23

1.1 设计的目的和意义 1

第二章塑件成型工艺分析 2

2.1 塑件的使用要求 2

2.2 塑件的材料分析 2

2.3 塑件的尺寸精度、塑件表面质量、塑件的结构工艺性分析 2

2.3.1 塑件的尺寸精度分析 3

2.3.2 塑件的表面质量分析 3

2.3.3 塑件的结构工艺性分析 3

第三章选择成型的设备和编写模塑工艺的参数 5

3.1 该衣架的重量和体积 5

3.2 对于零件型腔数量确定 5

3.3 浇注系统凝料的估算 6

3.4 注射机的选用及其技术参数 6

3.5 成型工艺参数 7

第四章模具结构方案的确定 9

4.1 分型面位置确定 9

4.2 型腔数量的最后确定及型腔的排列形式 9

4.3 浇注系统的设计与计算 10

4.3.1 主流道设计 10

4.3.2 分流道的设计 11

4.3.3 浇口的设计 13

4.4 成型零件结构的确定 14

4.4.1 凹模的结构设计 14

4.4.2 凸模(型芯)的结构设计 15

4.5 排气与引气系统结构的确定 16

4.6 冷料穴与拉料杆的设计 16

4.7 侧凹部分的处理 17

4.8模具结构形式的确定 17

第五章主要零部件的设计计算 18

5.1 成型零件工作尺寸计算 18

5.2 成型零件尺寸及动模垫板厚度的计算 20

5.2.1 凹模侧壁厚度计算 20

5.2.2 凹模底部厚度计算 21

5.2.3 动模垫板厚度计算 21

5.3 标准模架的选择 22

5.3.1 模架的确定 22

5.3.2 各模板尺寸的确定 22

5.3.3 导柱长度确定 23

5.4 脱模机构的设计与计算 23

5.4.1 推出方式的确定 23

5.4.2 脱模力的计算 24

5.4.3 推杆尺寸确定及校核 25

5.5 模具冷却系统的计算 27

5.5.1 冷却介质 27

5.5.2 冷却系统计算 27

5.5.3 水路的布置形式 28

第六章注射机有关参数的校核 30

6.1 注射量的校核 30

6.2 注射压力的校核 30

6.3 合模力校核 30

6.4安装部分相关尺寸的校核 31

6.5 开模行程的校核 31

第七章模具的建模过程 32

7.1 三角衣架模型创建 32

7.2 衣架的分模步骤 33

7.3标准模架的导入 36

第八章成型零件的加工工艺设计 38

8.1 动模大型芯加工工艺 38

8.2中部型芯加工工艺 39

8.3 整体式凹模加工工艺 39

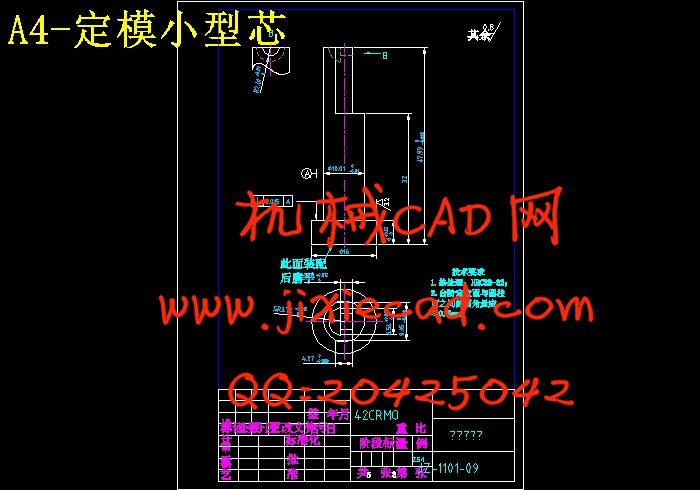

8.4定模小型芯加工工序 40

第九章绘制模具装配图及相关零件图 41

第十章结束语 425.4.3 推杆尺寸确定及校核 25

5.5 模具冷却系统的计算 27

5.5.1 冷却介质 27

5.5.2 冷却系统计算 27

5.5.3 水路的布置形式 28

第六章注射机有关参数的校核 30

6.1 注射量的校核 30

6.2 注射压力的校核 30

6.3 合模力校核 30

6.4安装部分相关尺寸的校核 31

6.5 开模行程的校核 31

第七章模具的建模过程 32

7.1 三角衣架模型创建 32

7.2 衣架的分模步骤 33

7.3标准模架的导入 36

第八章成型零件的加工工艺设计 38

8.1 动模大型芯加工工艺 38

8.2中部型芯加工工艺 39

8.3 整体式凹模加工工艺 39

8.4定模小型芯加工工序 40

第九章绘制模具装配图及相关零件图 41

参 考 文 献 43

致谢 44