设计简介

手表包装盒内芯塑料注射模具设计

摘 要

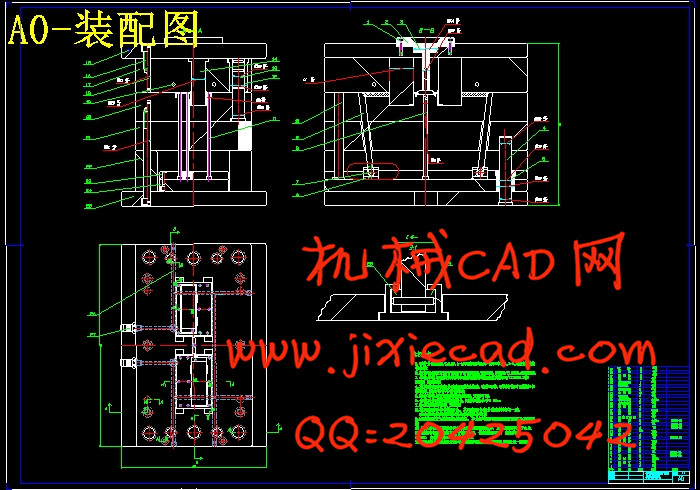

本论文介绍了手表包装盒内芯塑料注射模具的设计与制造方法。该注射模采用了1模2腔的结构。塑料模具的设计和制造水平反应了机械设计和加工水平,模具的设计已应用了当代先进的设计手段,如CAD、CAM、CAE的逐渐广泛使用,使模具的设计效率大大提高,快速成型技术的应用及现代加工技术的使用如高档加工中心、特种加工技术的使用使模具的制造精度越来越高,加工周期越来越短。各行各业对模具的要求量与日俱增,我国的模具行业蒸蒸日上,正需要大量的模具设计与制造技术的人才。

通过参观,查阅资料,计算,用PRO/E 、CAD等软件绘图进行塑料零件的注射模具设计,我熟悉并掌握了塑料零件注射设计全过程,能够根据不同的塑料材料的性能,塑料的结构特点,选择恰当的模具结构,并掌握了模具主要零件的强度计算及每一个零件的尺寸确定,掌握了材料的选择热处理要求及其制造工艺知识,通过该设计,检查了自己的外语翻译及理解能力,能熟练运用计算机进行设计和绘图。通过本次设计后,我能够完全独立完成中等难度以上塑料注射模具设计,并能在选材,结构设计等方面进行环保、经济技术分析。

简言之,本论文就是将人们常见的手表包装盒的内芯作为设计模型,将塑料注射模具的相关知识作为依据,阐述塑料注射模具的设计全过程。

关键词:塑料;注射模具;设计

The design of plastic injection mold about the core of

Watch box

Abstract

This paper describes the design of plastic injection mold and the methods of manufacturing about core box watches.The structure of one mold and two cavity was use in this injection mold .

Plastic mold design and manufacturing level reflects the level of mechanical design and processing,The contemporary-art instruments has been applied to the mold, such as CAD,CAM,CAE are use of the progressive with widespread, so that the efficiency of mold design are greatly improved, The application of the technologies about rapid prototyping and modern processing such as high-end machining centers and the technology of special processing enable the precision of manufacture to grow. processing cycles becoming shorter andshorter.The requirements of various industries on the amount of mold are growing with the success of China's mold industry, is in need of a large number of people about mold design and manufacturing skills.

Through visiting, accessing to information, computing, using drawing software such as PRO / E, CAD to do the design the injection mold about the plastic parts, I am familiar with and mastered the whole process of the design of the injection mold about plastic parts,I can depend on the performance of plastic materials,the characteristics of plastic structural, to select the appropriate mold structure, and be able to calculate the strength of the main parts and determine the size of each part , have the knowledge about the require of heat treatment in choice of materials and manufacturing processes, through the design, inspect the proficiency of the translation and understanding to foreign languag with own can design and graphics quickly in the use of computer. Through this design, I can be totally independent to finish the design of plastic injection mold which is more than the middle difficulty, I be able to protecte environment and analysis the technical of economic in material and structural design.

In short, the core of watch box what people often look was as a design model in this paper and the knowledge related- plastic injection mold was as the basis to describe the design process of the plastic injection mold .

Key words: plastics; injection mold; design

目 录

主要符号表

1 绪 论 1

1.1模具工业简介 1

1.2 我国模具工业的现状 1

1.3我国模具工业的发展趋势 2

1.4课题研究的背景、主要内容、基本要求 3

1.4.1 课题背景 3

1.4.2 主要内容 3

1.4.3基本要求 3

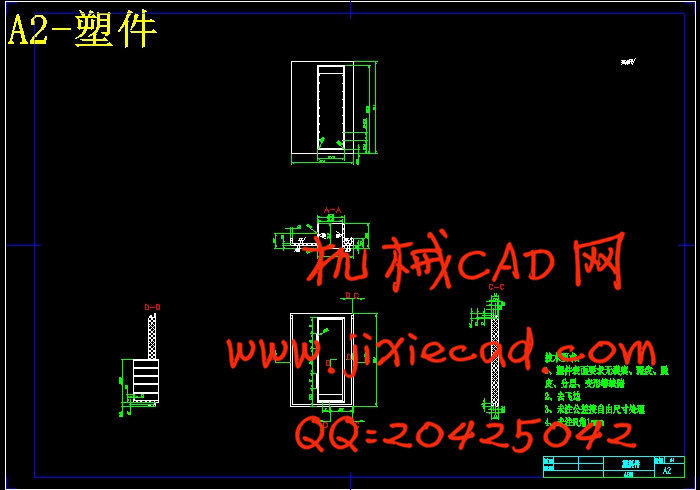

2注塑件的设计 4

2.1 功能设计 4

2.2塑件的工艺分析 4

2.2.1 分析塑件使用材料的种类及工艺特征 4

2.2.2分析塑件的结构工艺性 6

3初步确定型腔数目 7

4注塑机的选择 8

4.1注塑机简介 8

4.2 注塑机基本参数 8

4.3选择注塑机 9

4.3.1 塑件体积的计算 9

4.3.2计算塑件的质量: 10

4.3.2按注射机的最大注射量确定型腔数目 10

4.3.3计算浇注系统的体积,其初步设定方案如下 11

4.3.4查表确定型号 12

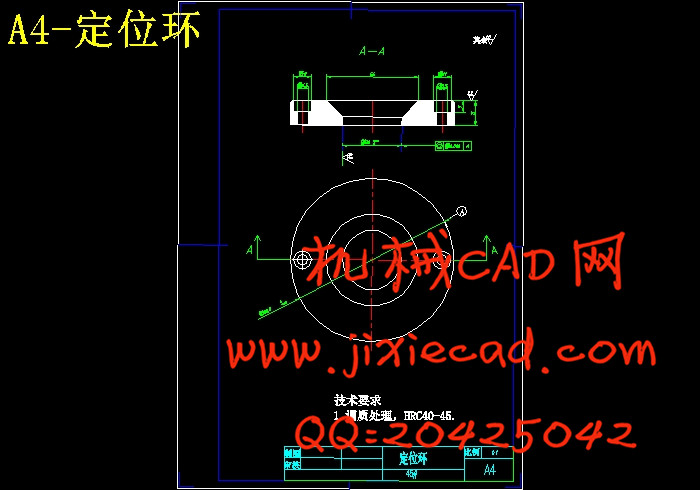

5分型面的确定 13

5.1分型面的形式 13

5.2分型面的设计原则 13

6 浇注系统的设计 15

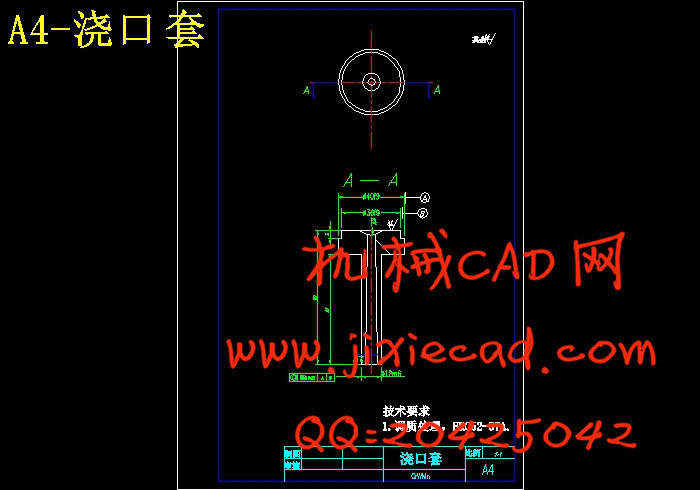

6.1主流道的设计 15

6.2 分流道的设计 16

6.3浇口设计 17

6.4冷料穴的设计 18

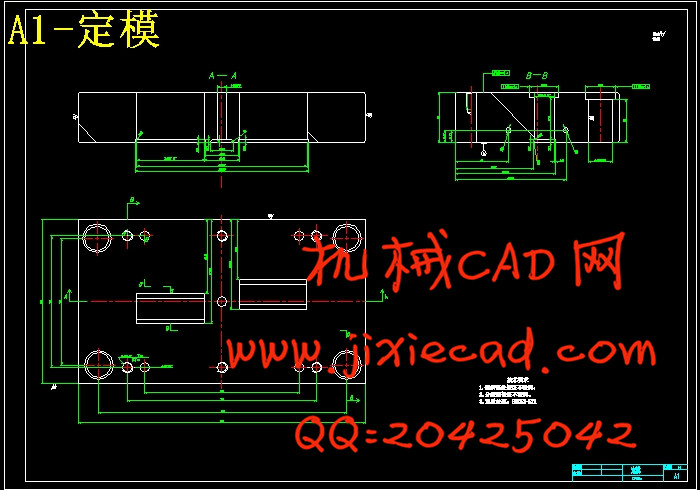

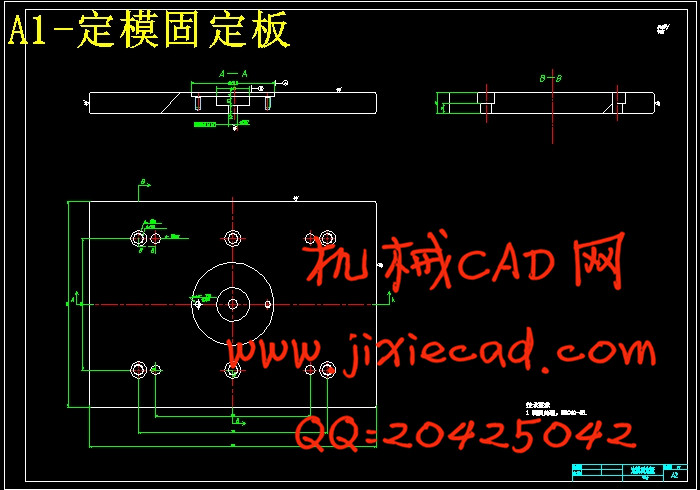

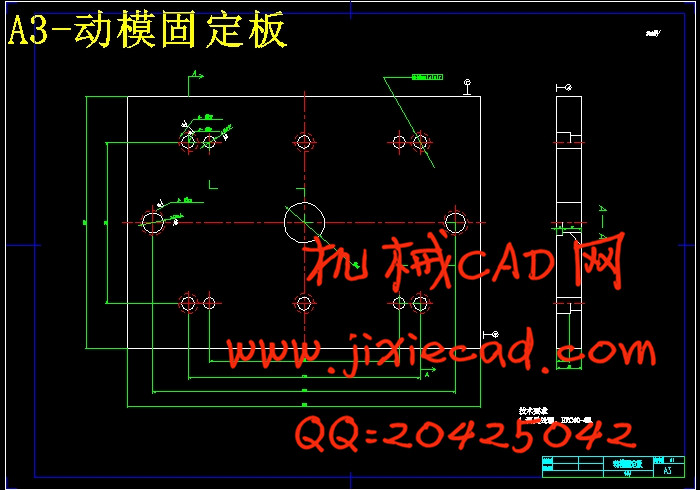

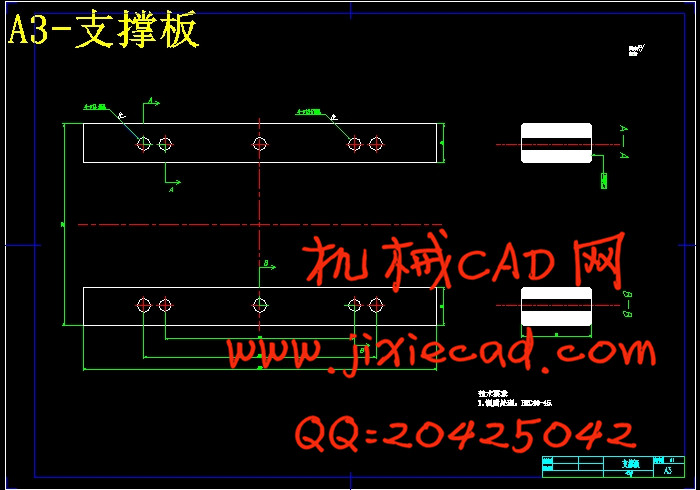

7 确定主要零件结构尺寸选模架 19

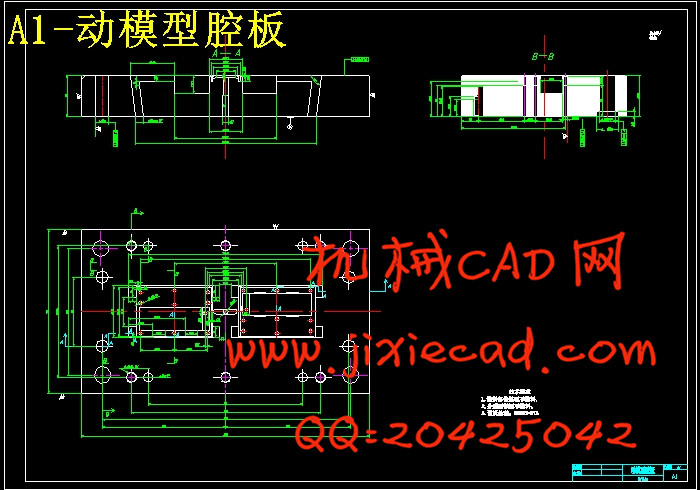

7.1型腔、型芯工作尺寸计算 19

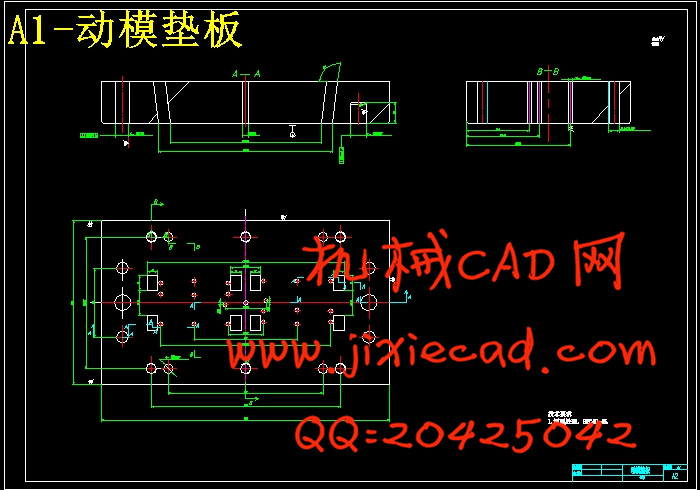

7.2模架的选择 19

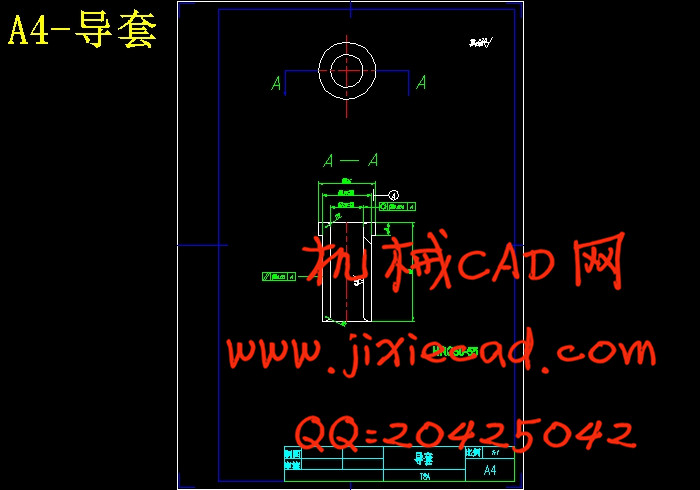

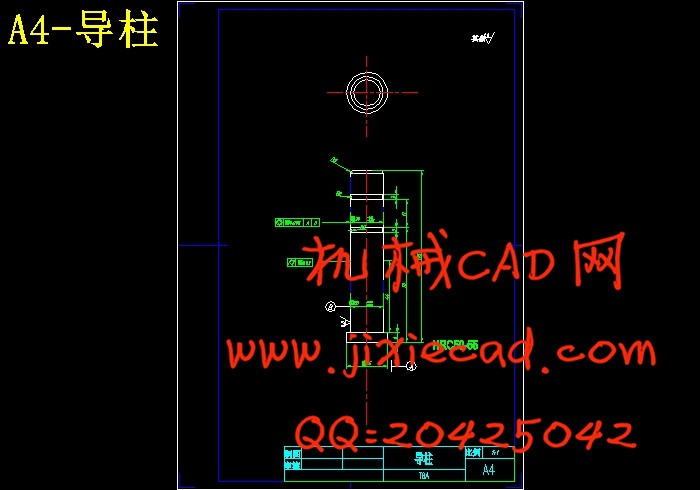

8导向结构的设计 21

8.1导柱结构的设计 21

8.2导套结构的设计 21

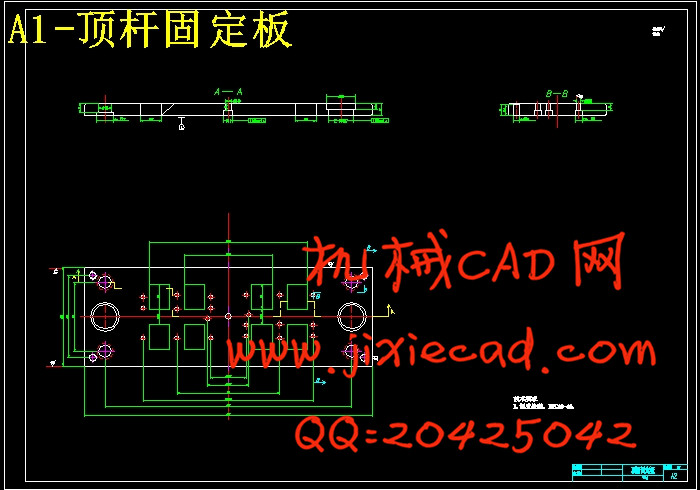

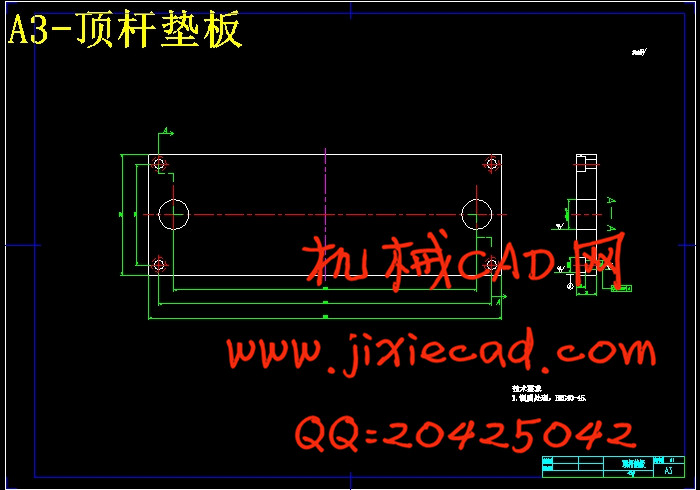

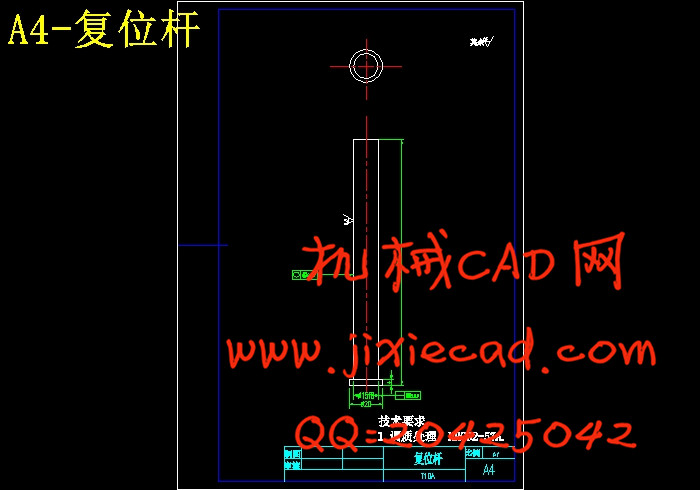

8.3推出机构的设计 21

8.3.1推件力的计算 22

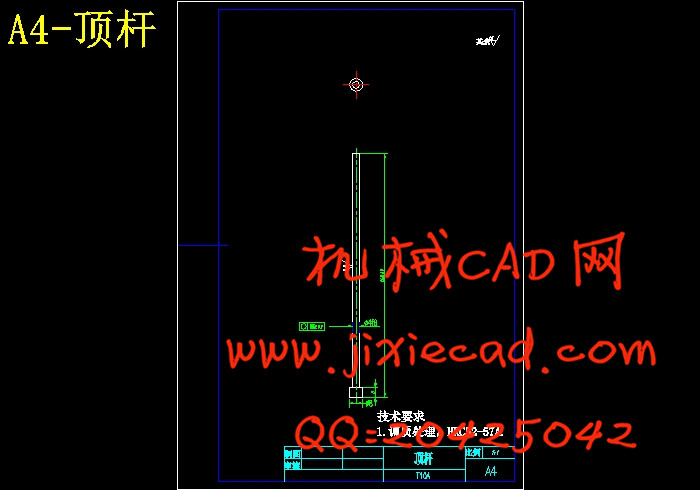

8.3.2 推杆的设计 22

9 抽芯机构设计 23

9.1 抽芯距的确定 23

9.2 斜顶杆双滚轮抽芯机构的设计 23

10 冷却系统的设计 24

10.1 冷却水回路布置的基本原则: 24

10.2确定冷却水道直径 24

11模具排气槽的设计 26

12校核 27

12.1注射机有关工艺参数的校核 27

12.2模具厚度H与注射机闭和高度 27

13 模具工作过程 28

13.1成型前的准备 28

13.1.1原料的检验和预处理 28

13.1.2料筒的清洗 28

13.1.3嵌件的预热 28

13.1.4脱模剂的选用 28

13.2注射过程 28

13.3脱模过程 29

13.4制品的后处理 29

13.4.1退火处理 29

13.4.2调湿处理 29

14结论 30

参 考 文 献 32

致 谢 33