设计简介

摘 要

本文的主要任务是注塑模具结构设计,内容包括塑料模具的工作原理及应用,塑件分析,模具的各零件设计以及总体设计。

大致的设计思路如下:通过所给塑件的具体分析,确定注塑机;根据所选的注塑机来确定型腔数量和布局;注塑模具的关键是分型面的设计,这关系到产品质量和模具的设计;浇注系统设计包括主流道设计、分流道设计、浇口设计和冷料穴设计;排溢系统设计保证填充效果;成型零件设计计算,保证产品质量和模具的加工制造;导向机构、定出机构、复位机构必须合理;冷却系统设计控制模具温度,影响塑件成型质量。

关键词:

Auto CAD,PROE, 塑料,注射模,注射机。

Injection mold design of watches bracket

The main task of this paper is the structural design of injection molds, including plastic mold of the working principle and application of analysis of plastic parts, mold design and the overall design of the parts.

Rough design ideas are as follows: through the plastic parts to the specific analysis of injection molding machine; according to the selected cavity injection molding machine to determine the number and layout; injection mold is the key to the design surface, it relates to product quality and mold design; gating system design including the design of the mainstream, separate design, gate design and the design of cold-feed points; row overflow filling system design to ensure results; molding part design terms, to ensure product quality and mold manufacturing; oriented institutions, for institutions, reset must be reasonable; cooling system designed to control mold temperature, affecting the quality of molding plastic parts.

Key Words:

Auto CAD,PROE, Plastic, Plastic injection mold, Plastic injection.

目 录

前 言 5本文的主要任务是注塑模具结构设计,内容包括塑料模具的工作原理及应用,塑件分析,模具的各零件设计以及总体设计。

大致的设计思路如下:通过所给塑件的具体分析,确定注塑机;根据所选的注塑机来确定型腔数量和布局;注塑模具的关键是分型面的设计,这关系到产品质量和模具的设计;浇注系统设计包括主流道设计、分流道设计、浇口设计和冷料穴设计;排溢系统设计保证填充效果;成型零件设计计算,保证产品质量和模具的加工制造;导向机构、定出机构、复位机构必须合理;冷却系统设计控制模具温度,影响塑件成型质量。

关键词:

Auto CAD,PROE, 塑料,注射模,注射机。

Injection mold design of watches bracket

The main task of this paper is the structural design of injection molds, including plastic mold of the working principle and application of analysis of plastic parts, mold design and the overall design of the parts.

Rough design ideas are as follows: through the plastic parts to the specific analysis of injection molding machine; according to the selected cavity injection molding machine to determine the number and layout; injection mold is the key to the design surface, it relates to product quality and mold design; gating system design including the design of the mainstream, separate design, gate design and the design of cold-feed points; row overflow filling system design to ensure results; molding part design terms, to ensure product quality and mold manufacturing; oriented institutions, for institutions, reset must be reasonable; cooling system designed to control mold temperature, affecting the quality of molding plastic parts.

Key Words:

Auto CAD,PROE, Plastic, Plastic injection mold, Plastic injection.

目 录

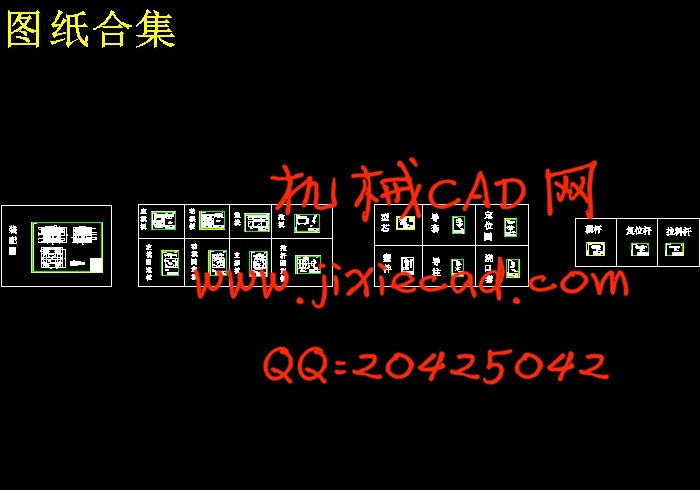

1 设计内容 6

2 设计目的 6

3.塑件成型的基本过程 7

4 塑件制品分析 8

5 型腔数量及排列方式 10

6 注射机的选用与校核 11

6.1注塑机的选择 11

6.2注射机的校核 11

6.2.1注射量的校核 11

6.2.2锁模力的校核 12

6.2.3 注射机安装模具部分的尺寸校核 12

7 分型面的确定 13

8 浇注系统设计 14

8.1浇注系统的基本概念 14

8.1.1浇注系统的组成 14

8.1.2浇注系统的作用 14

8.1.3浇注系统设计时要考虑的问题 14

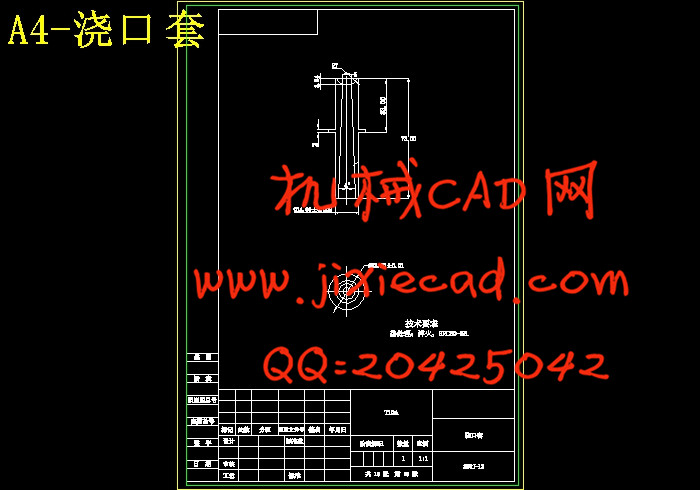

8.2主流道设计 14

8.3 分流道设计 15

8.4浇口的设计 17

8.5 冷料穴的设计 17

9排溢系统的设计

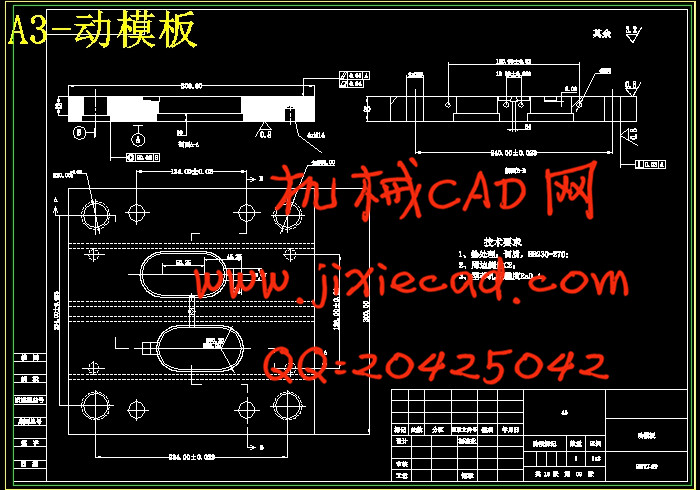

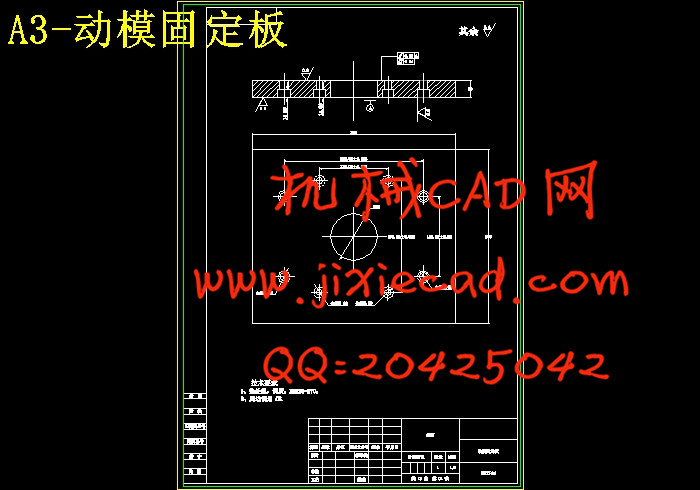

10 成形零件的设计 19

10.1 成形零件应具备的性能 19

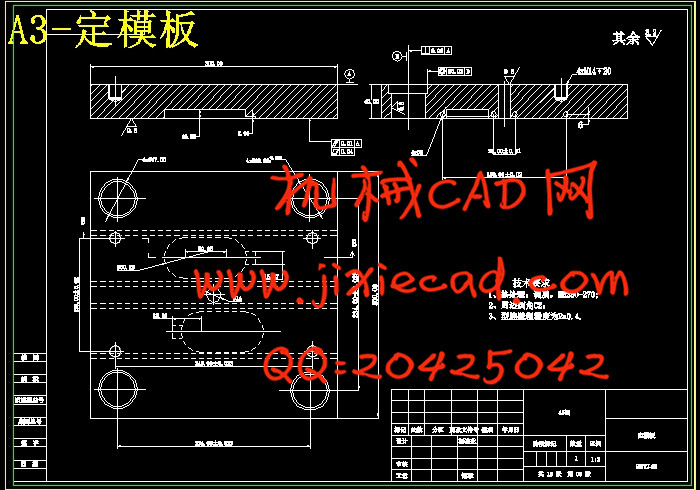

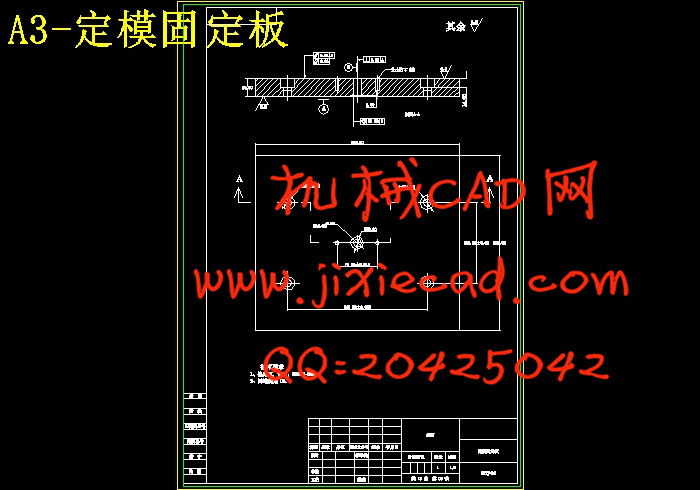

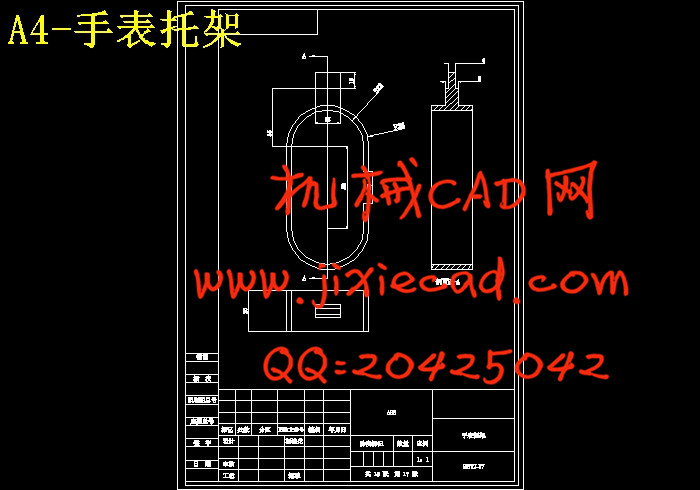

10.2型芯和型腔的结构形式设计 19

10.2.1型腔结构设计 19

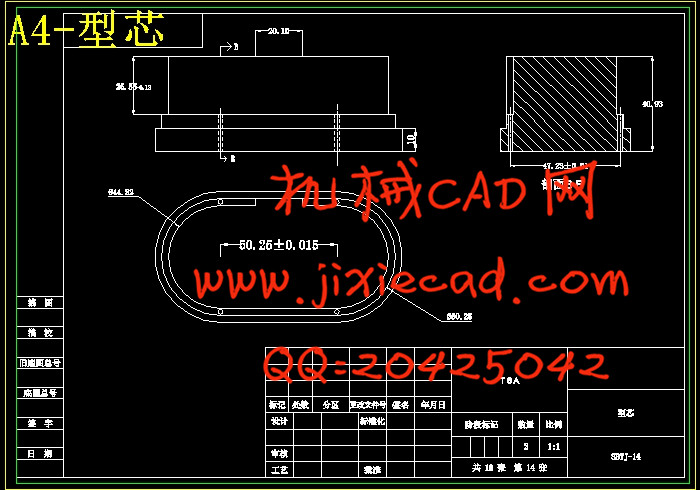

10.2.2型芯结构设计 19

10.3成形零件的工作尺寸设计 19

10.4型腔侧壁和底板厚度的计算 21

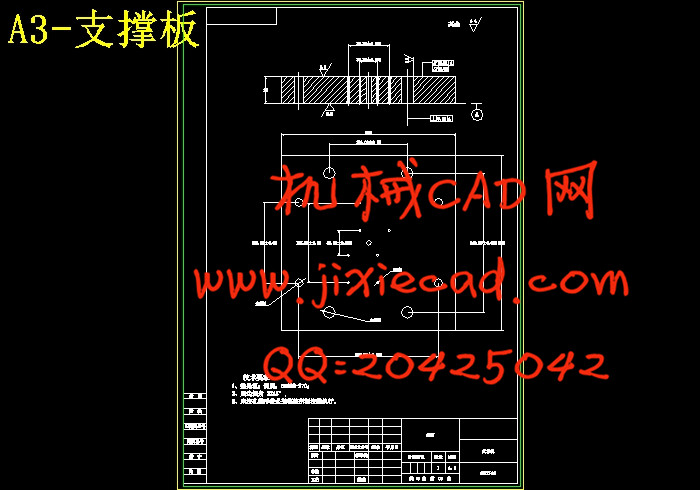

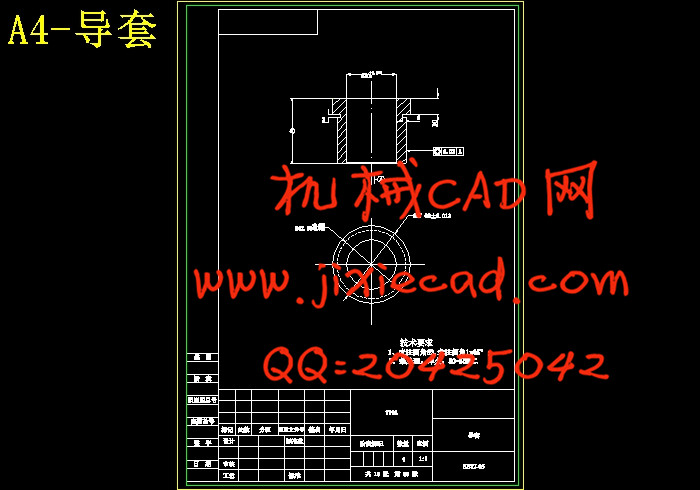

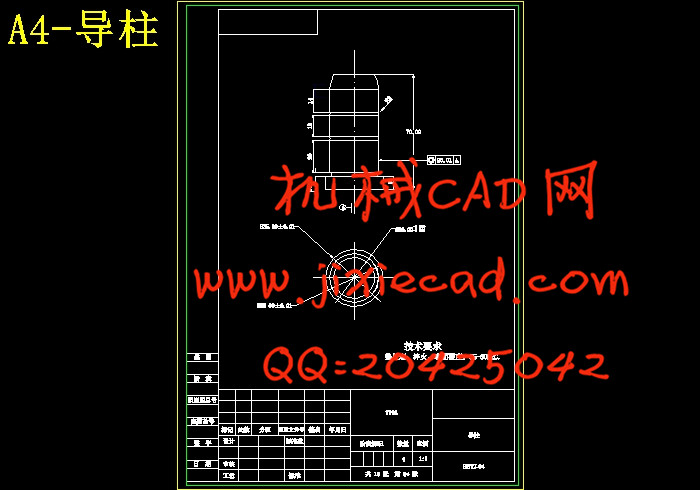

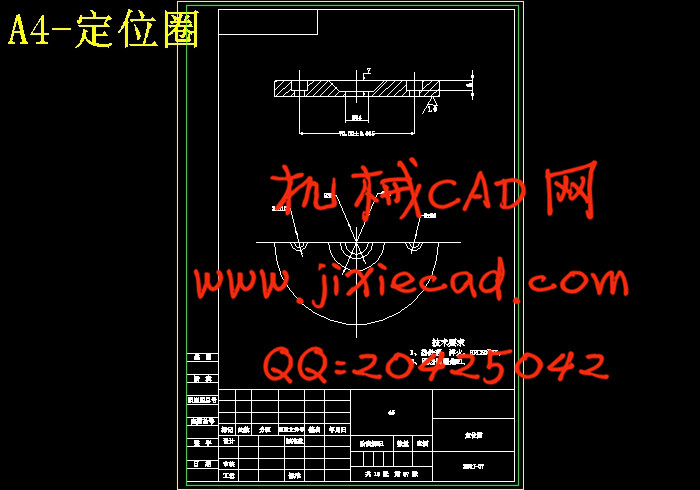

11 导向机构设计 23

11.1 导向机构的作用 23

11.2 结构设计 23

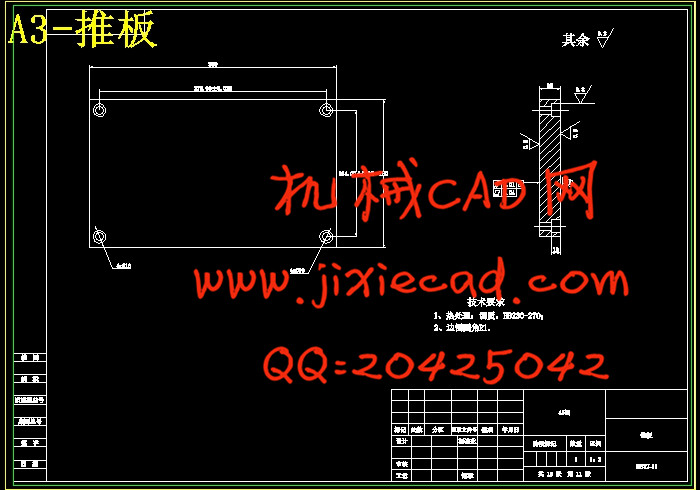

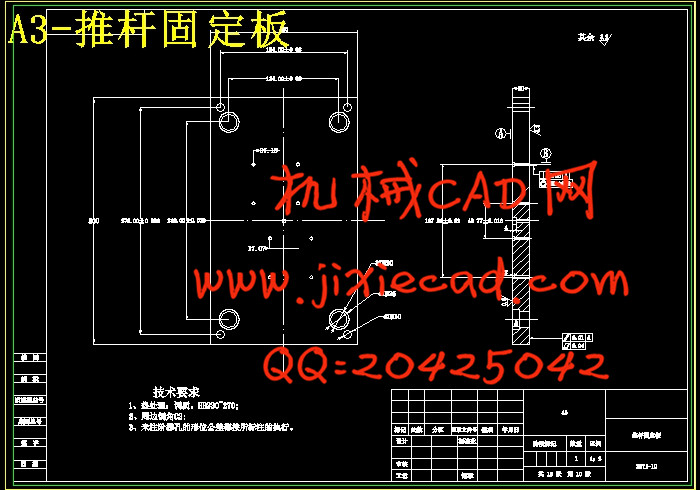

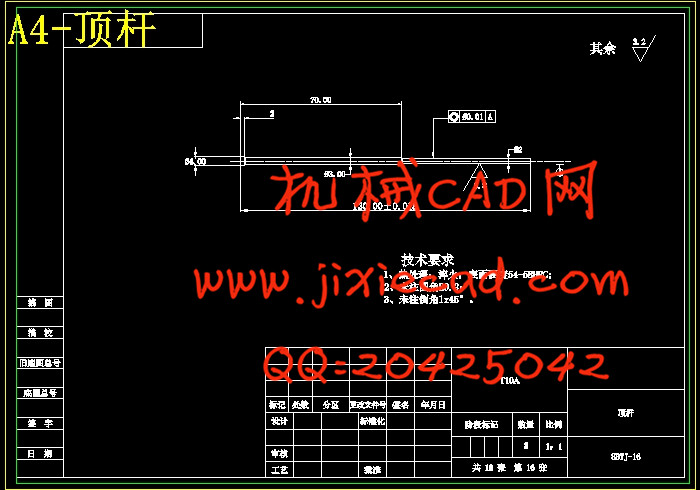

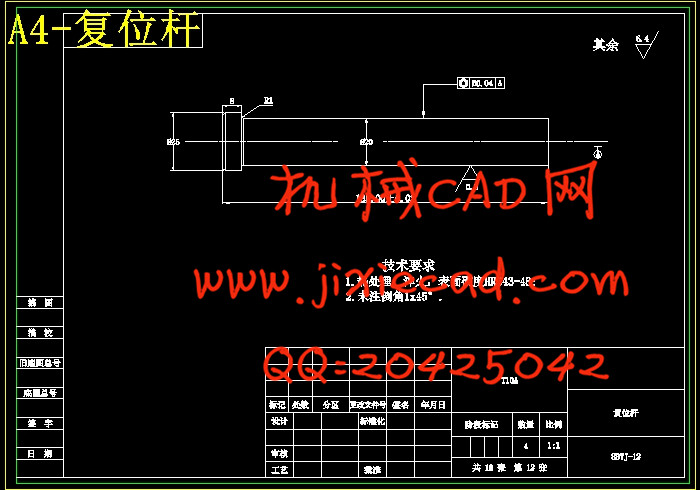

12 脱模机构与复位机构设计 24

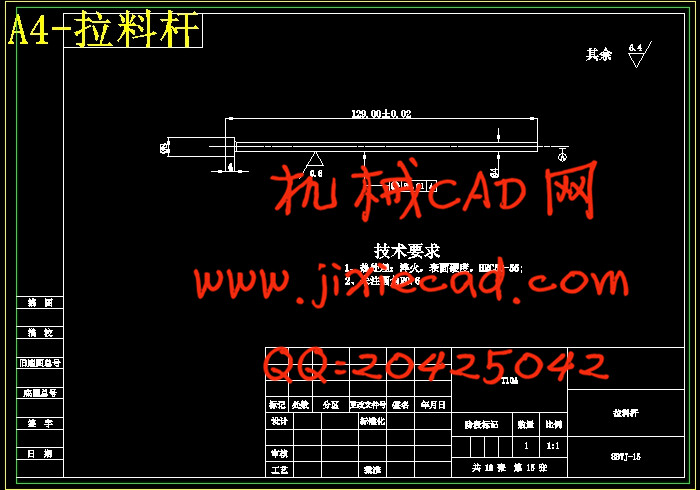

12.1.脱模机构 24

12.2 脱模机构设计原则 24

12.3 脱模机构的结构设计 25

12.4 顶料机构的设计 25

12.5复位机构设计 25

13 冷却系统的设计 26

13.1 冷却水孔的设计原则 26

13.2 冷却系统的计算 26

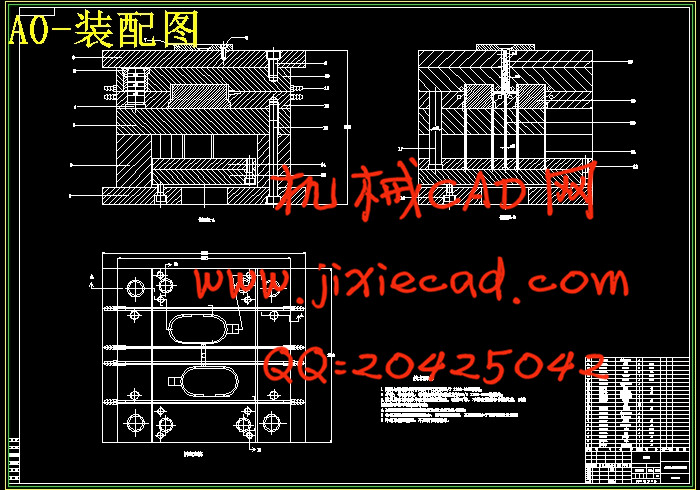

14 模具的整体设计 28

结 束 语 29

致 谢 31

参考文献 32