设计简介

摘 要

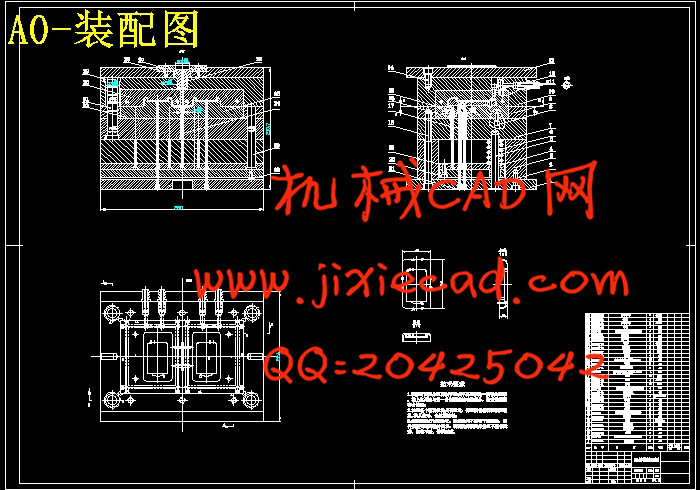

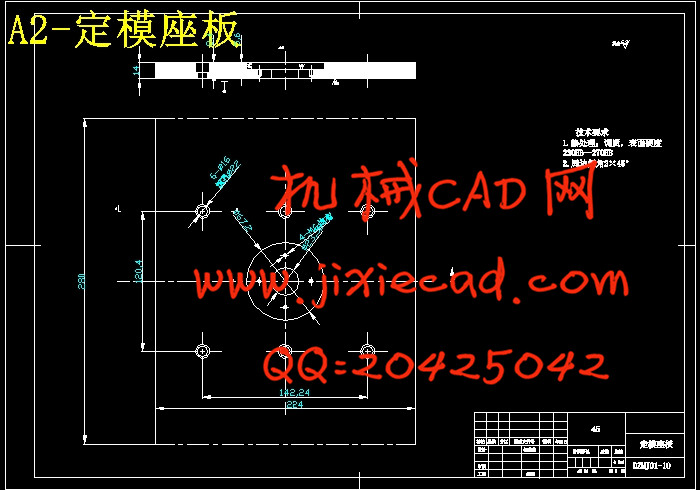

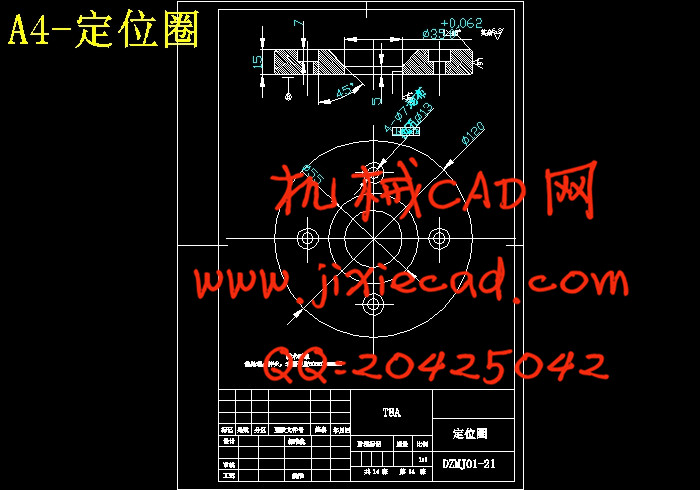

通过对手机充电器的设计分析,是应用电子计算机对系统的结构、功能和行为以及参与系统控制的人的思维过程和行为进行动态性进行模仿。在整个模具的设计过程中,涉及到了塑件的结构设计、注塑机和模架的选择及注塑机的一些重要的工艺参数和校核,并详细叙述了模具设计中的分型面设计、浇注系统设计、成型零件设计、顶出机构设计和冷却系统设计,最后还对成型零件制订加工工艺方案,从而得出数量指标,为决策者提供有关这一过程或者系统定分定量分析,作为一个理论依据。在模具的设计过程中,采用了Pro/E、Auto CAD等软件,采用这些软件进行设计分析,优化了设计参数和缩短了设计时间,提高了设计效率。下面便是我通过pro/E对手机充电器外壳进行结构设计、参数设计及三维建模。

关键词:手机充电器,模具,注塑机,三维

Abstract

Through the mobile phone charger design analysis, is the application of computer on the system structure, function and behavior as well as in the control system of the process of people's thinking and behavior are dynamic imitation.In the whole process of mold design, relates to the plastic parts of the structure design, injection molding machine and the choice of mold and injection molding machine of some important parameters and check, and a detailed description of the design of the mold parting surface design, the design of gating system, molding part design, ejection system design and cooling system design finally, also forming part of developing process, so that the number of indexes, for decision makers with this process or system quantitative analysis, as a theoretical basis.

In the mold design process, using Pro / E, Auto CAD and other software, the software design and analysis, to optimize the design parameters and shorten the design time, improve the efficiency of design.Below is I through Pro / E on mobile phone charger shell structural design, parameter design and modeling.

Key Words: the mobile phone charger, mold design , Injection molding machine,3D

In the mold design process, using Pro / E, Auto CAD and other software, the software design and analysis, to optimize the design parameters and shorten the design time, improve the efficiency of design.Below is I through Pro / E on mobile phone charger shell structural design, parameter design and modeling.

Key Words: the mobile phone charger, mold design , Injection molding machine,3D

目 录

摘 要 IAbstract II

目 录 III

第1章 前 言 1

1.1模具行业及其产品发展方向 1

1.2 选题意义 2

1.3 设计任务 2

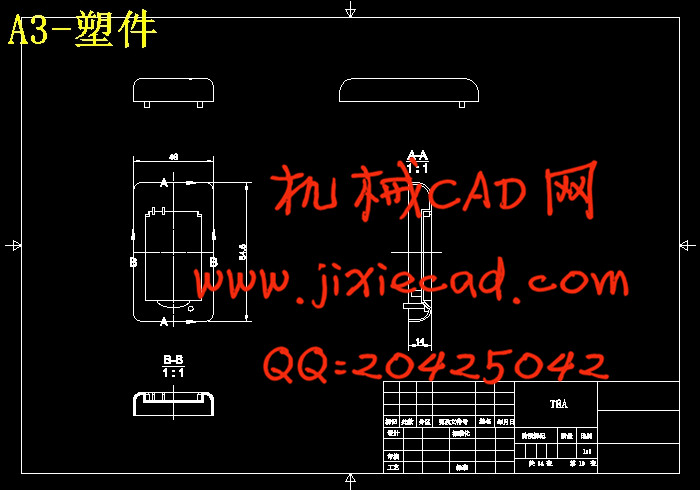

第2章 塑件的设计分析 3

2.1塑件模型建立 3

2.1.1模拟3D图 3

2.2塑件参数设计 3

2.2.1材料的选择 3

2.2.3ABS树脂材料的展望 4

2.2.4ABS树脂的特点 5

2.3 塑件收缩率 5

2.4塑件的壁厚 6

2.5塑件的拔模斜度 6

第3章 注塑成型的准备 8

3.1注塑成型工艺简介 8

3.2 注塑成型工艺条件 10

3.3注塑机的选择 12

3.3.1 注塑机简介 12

3.3.2 注塑机基本参数 12

3.3.3选择注塑机 13

3.4 注射机的校核 14

3.4.1 最大注塑量的校核 14

3.4.2 锁模力的校核 15

3.4.3 塑化能力的校核 15

3.4.4 喷嘴尺寸校核 15

第4章 模具设计 17

总 结 43

致谢 44

参考文献 45